Having a good understanding of the classes, you can ideally choose the flooring for the conditions of a particular room (premises) and save a lot of money.

Classification of linoleums according to the indicator “abrasion”

Abrasion is the resistance of the front protective layer of linoleum to abrasion (resistance to abrasive effects on the surface). This parameter is checked using a special test on high-precision equipment.

Linoleum is subjected to abrasive action (dosed) under standard conditions. The entire procedure is regulated by the EN660-1 standard. After testing, one of four markings is applied to the material.

“T” is a group of durable and reliable coatings that practically do not wear out. This type of coating is used in the production of industrial linoleum. The price is very high, so they are rarely used. During testing, changes in layer thickness amounted to 0.08 mm.

“P” is a group of low-abrasion coatings. Used for the production of linoleum, which is subject to large dynamic and static loads. It can be used in industry if heavy equipment will not move on the surface of such a coating. During testing, changes in layer thickness amounted to 0.15 mm.

“M” is linoleum with a moderately abraded coating. A more appropriate phrase here is “ideal value for money.” This option is ideal for both offices and home. During testing, changes in layer thickness amounted to 0.3 mm.

“F” - This group of highly abraded linoleums. They should be used in places with little traffic. Ideal for bedroom, hall. Lowest price for material. During testing, changes in layer thickness amounted to 0.6 mm.

Legend

The wear resistance class, as well as a number of additional characteristics of linoleum, can be found on the back of the canvas in the form of icons or pictures.

The meaning of the pictures is:

- the coating has antistatic properties;

- This linoleum has a low susceptibility to fire;

- the surface of the material has an anti-slip effect;

- linoleum is not afraid of mechanical damage, including from the claws of pets;

- the coating is additionally protected by a polyurethane layer;

- linoleum lends itself well to wet cleaning using any type of household detergent.

It is worth noting that for families in which small children are growing up, linoleum with antibacterial protection is preferable, which will be especially important if there are pets in the house.

Classification of linoleums by wear resistance

Wear resistance is the ability of the linoleum surface to resist constant mechanical loads.

Attention!!! The concepts of abrasion and wear resistance are not the same. Because “T” class linoleum will not be inferior in strength to “M” class linoleum if it has a thick protective layer.

To understand wear resistance classes, you should refer to the unified European classification EN 685, which was adopted in December 1995. This classification includes all types of flooring (parquet, laminate, ceramic tiles). This is very convenient because it allows you to compare different finishing materials according to two parameters: load intensity and type of room.

This means that each material model is assigned a two-digit number. The first number is responsible for the type of room, and the second is responsible for the wear resistance of the front layer. The manufacturer first carries out all the required tests, and only after that a class is assigned to the linoleum.

Now we will consider each parameter separately and in more detail.

Wear resistance or the level of load that a surface can withstand:

- Low load level.

- Average load.

- High or intense workload.

- Extreme or very high load.

Room type or application class

The number “2” denotes household linoleum . This category includes all floor coverings that have a picture of a house on the packaging.

The advantages of this category include:

- Lowest cost.

- The material is pleasant to the touch, pleasant to walk barefoot.

- Good thermal insulation.

- High selection of textures and patterns.

- Environmentally friendly material, confirmed by hygienic certificates.

The thickness of the protective layer of household linoleum lies in the range of 0.1-0.35 mm, with a total product thickness of 1.5-5 mm. As for the service life, it is about 5 years.

Class 21 - soft linoleum, it is advisable to install it in places with little traffic - bedrooms, closets and closets.

Class 22 - linoleum, which can be exposed to average dynamic and static loads. They are widely used in children's rooms, halls and bedrooms.

Class 23 is the most common and popular product from this group. Placed in places with high dynamic load, such as corridors, halls.

You should pay attention to the products of the following manufacturers: Utex, Sinteros and Tarkett. The average price for 1 square meter is 200-300 rubles.

The number "3" denotes commercial linoleum . But sometimes it is also called “Office”. The packaging of this product shows an office building. The service life of these linoleums is about 15 years.

The advantages of this category include:

- The variety of textures, colors and patterns is less than that of household ones, but there is quite a large selection.

- Increased wear resistance.

- Dense structure.

The thickness of the protective layer of commercial linoleum is in the range of 0.3-0.6 mm. As the name suggests, it is widely used in offices, public places, and, more recently, in residential buildings.

Class 31 - used in bosses' offices, where there is little traffic, hotel rooms, in the kitchen and in corridors.

Class 32 – used for flooring in shops, reception areas, kindergartens. Where there is an average dynamic and static load on the surface. It is in great demand among ordinary people, since for reasonable money you get high-quality linoleum.

Class 33 - high-strength linoleum is ideal for offices with high traffic. The manufacturer provides a guarantee for the material for 10-15 years.

Class 34 is the most reliable and durable linoleum of this class. Used in critical places such as hypermarkets, airports, train stations.

The cost of one square meter of production is approximately 300-400 rubles.

The number “4” denotes industrial linoleum . The packaging of this group of materials shows the plant. It should be said right away that this type of coating is used only in industry, rarely for commercial purposes. Due to increased requirements for the material, the choice of colors is limited. Service life is at least 10 years. The thickness of the protective layer starts from 0.6 mm. The main disadvantage is the very high cost.

Class 41 - this type of linoleum is used in production for floors mainly for sedentary work. For example, a workshop, quality control department (technical control department), repair areas, and so on.

Class 42 - can be used in almost any industrial premises where special equipment is not used.

Class 43 is the most durable and reliable type of linoleum. Used in rooms with heavy traffic of people and special equipment.

Due to its high cost, it is rare on sale. Approximate cost per 1 sq.m. is about 1000-1500 rubles.

Homogeneous and heterogeneous

In fact, these two terms can be replaced by the words single-layer and multi-layer. In a homogeneous pattern, the pattern passes through the entire canvas, so if the surface is damaged, it can be sanded and defects removed. Such products have fewer image options than multilayer ones.

Heterogeneous linoleum consists of different layers, the image is applied only on the top - if damaged, the entire coating will need to be replaced.

Read more about laying linoleum in a separate article on our website.

Specialized classification of linoleums

On the reverse side of linoleum, in addition to the above classifications, the following classes must also be present: smoke generation, flammability, flammability and flame distribution.

The safety of people directly depends on these parameters. All approvals can be viewed here - GOST 30402.

Flammability is indicated by the letter “G” and shows what danger the material poses during combustion. There are 4 groups.

“G1” is a group of slightly flammable materials. Almost all linoleums belong to this group. At a temperature of 135 degrees Celsius, the first off-gases appear, and the material changes mass by at least 65%. And the main thing is that the material itself does not burn.

“G2” is a group of slightly flammable materials. Rubber and cellulose linoleums are suitable here. The characteristics are similar, but the material supports combustion, but not more than 30 seconds.

“G3” and “G4” - there are no linoleums in these groups. But it is not recommended to buy this product. These classes burn easily and support this process.

Flammability is indicated by the letter “B”. Here, the larger the number behind the letter “B”, the worse the material.

Smoke production is indicated by the letter “D”; the lower the number, the better. There are only three number options.

The flame distribution is designated by the letters “RP”, and then by analogy, the lower the number, the better.

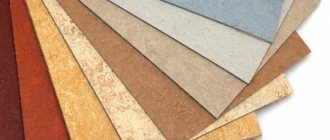

Variety of flooring designs

One of the advantages of linoleum is the variety of its design. There are plain options, with patterns and designs. There are also types that imitate various materials, such as wood, marble, parquet boards, etc. This allows you to choose the right canvas for any room and interior.

Linoleum for the home has an optimal cost and a wide range of colors.

It is also worth remembering that light shades can visually expand the space and add more light. Dark colors “eat up” space. Therefore, they should be used in spacious rooms.

Natural

The material, made exclusively from natural ingredients, eliminates the risk of allergic reactions and is absolutely environmentally friendly. It is made on the basis of linen or jute fabric. The composition includes 30% linseed oil and up to 30% non-biological binders. In the production of such oilcloth products the following are used:

- wax;

- wood powder;

- linseed oil;

- dyes;

- sap.

This type of coating has a long service life and will last for almost 30 years. The natural fabric does not fade in the sun and has antibacterial properties and is installed in medical institutions. It is presented on the market in the form of rolls or tiles, which are used for arranging floors with complex patterns. Designers and lovers of eco-interiors love to use it in country house projects. It is easy to install, does not slip and can be restored. Not used at sub-zero temperatures and for rooms with high humidity, such as a toilet, bathroom.

Width

Manufacturers produce the same decor in different widths. In nature, there are rollers from 1.5 m to 5 m wide. But, naturally, the narrowest and widest options are less common. The most popular width is 3 m; widths of 4 m and 2.5 m are also popular. Almost any decor can be found in this width.

At the buyer's request, a piece of the required length is cut from the rollers of the required width. For example, for a kitchen measuring 2 by 4, you can cut four meters from a two-meter linoleum or two meters from a four-meter covering. The specific choice depends on the pattern: if these are dies, then it is recommended to lay the coating in a pattern along the incidence of the light rays. If the design is abstract, then most likely there will be no difference - in most stores all widths cost the same.

For domestic premises, they try to “cut” the linoleum in this way in order to lay it over the entire area without joints. In large commercial premises this is an almost impossible task, so hot welding is used for joining. You can also join linoleum in your favorite kitchen - for household purposes, the cold welding method will be sufficient: linoleum is glued together with a special compound, which is sold in tubes with a thin nozzle, which are called “cold welding”. It is desirable, of course, that the seams do not run through the center of the room - this does not affect performance, but from an aesthetic point of view it is better to remove them closer to the walls.

Not all linoleum is sold cut; in some cases it is possible to bring only rollers. To select a coating for cutting, you can also use the filter.

Relin

Previously, it was made from recycled car tires by heating to 140 degrees with the addition of sulfur. The current Relin contains no rubber dust or tire residue, which makes it much cleaner and safer to use. This rubber material is produced from rubber, both synthetic and natural. This anti-slip fabric is quite reliable and will save you from fire or short circuit.

It is produced in the form of rolls of various colors or composite slabs. The thickness of linoleum in the form of tiles is 6–10 mm and has a rigid structure, sometimes reinforced. It also has low sound conductivity, copes well with any vibrations, and therefore is widely used for covering floors in industrial premises, football grounds, and power plants. It is installed in both residential and commercial buildings. This is an easy to install material that can be laid out without additional help or special knowledge.

Nitrocellulose or colloxelin

It is produced on the basis of nitrocellulose, which provides such excellent properties as gloss, high elasticity, and moisture resistance. It is a baseless, single-layer coating with high moisture resistance and elasticity. Since this type has high flammability rates, it is not used in educational institutions, children's institutions, residential buildings, outdoors and at temperatures above +40 °C and below -10 °C. Colloxyline flooring can only be found in office premises.

The above characteristics of linoleum are enough to select a safe material suitable for the expected load in a particular room. Pay attention to the labeling when purchasing.

What to consider when purchasing

- During the cold season, avoid buying linoleum in markets and retail outlets without heating.

- Be sure to ask the seller for certificates of conformity and fire safety.

- Pay attention to the smell: for high-quality linoleum it should be mild or completely absent.

- Roll out the roll and make sure that there are no waves, bumps or other flaws on the coating. The multilayer fabric should not delaminate.

- When purchasing linoleum for several rooms, if possible, take everything from a specific roll. The color of paintings even from the same batch may differ.

- Do not fold the cut linoleum in half to avoid kinks. Roll it up with the front side inward, preferably wound on a special paper tube.

- Consider the considerable weight (1.5–3 kg/m²) and dimensions of the roll when transporting. Linoleum may not fit into a regular elevator and may not fit into narrow openings.

Fire safety class

Another class inherent in linoleum is the fire safety class.

. This is a complex indicator that determines the resistance of a material to fire according to several criteria. The most resistant coatings have class KM0 (“ka em zero”). Linoleum with class KM2 is suitable for use in commercial premises. For home use, KM5 coating is sufficient. Indeed, such linoleum received lower ratings in all respects compared to KM2, but it does not have the task of holding out until hundreds of people safely leave the building. Therefore, if you choose linoleum for an apartment or private house, you don’t have to rely on the fire safety class. But if you are doing repairs in a school, office, or medical facility, choose only from the KM2 options (on our website, for example, you can use the filter of the same name).

| Criteria for evaluation | Fire hazard class of building materials depending on groups | |||||

| KM0 | KM1 | KM2 | KM3 | KM4 | KM5 | |

| Flammability | NG | G1 | G1 | G2 | G2 | G4 |

| Flammability | — | IN 1 | IN 1 | AT 2 | AT 2 | AT 3 |

| Smoke formation | — | D1 | D3+ | D3 | D3 | D3 |

| Toxicity of combustion products | — | T1 | T2 | T2 | T3 | T4 |

| Flame spread over surface | — | RP1 | RP1 | RP1 | RP2 | RP4 |

Thickness

The thickness of linoleum varies from 1.8 mm to 6.5 mm. It is quite logical that thin linoleums are cheaper and belong to a lower wear resistance class (except for calender linoleum, which will be discussed below), while the thickest ones - sports coatings - are comparable in cost per square to parquet boards. Among household coatings, 3 mm linoleum is the most reliable. An even more durable option is reinforced household linoleum.

or

semi-commercial

.

They also gradually increase in thickness and protective layer. The choice of linoleum thickness is a purely individual matter and depends on the circumstances. If you are making temporary repairs, then you can get by with cheap linoleum

. If you want to solve the problem with the floor for a long time, look at options with a good wear resistance class. An important criterion is the drawing. Sometimes you have to sacrifice thickness (or pay a little more money) because of a design you like.