Not a single pair of shoes, even the highest quality ones, will last forever, but proper care and timely repairs will help extend their life. And if your favorite boots or shoes are “begging for porridge,” it’s time to look for good glue for them. In this review, we will look at reliable and proven compositions that are used even by professional shoemakers.

Desmokol - the best glue for leather shoes

Synthetic polyurethane-based adhesive can be used for more than just shoe repair. It is also suitable for rubber and plastic. However, its application has its own tricks: after application, the glue must be allowed to dry completely, and then heated to +80 ° C. At this temperature, Desmokol is “activated” and firmly connects the parts to be glued.

Recommendations: 13 Best Work Shoes

15 best sports sneakers

16 best shoe models

Pros:

- Dries quickly - it usually takes only 10-15 minutes;

- The adhesive layer remains elastic after hardening;

- It adheres well to the porous sole, since it is able to expand and flow into small pores;

- Suitable for repairing shoes with textile uppers (sneakers, slip-ons, ballet flats);

- A variety of release forms - from small tubes to 20-kilogram cans intended for professional use;

- Inexpensive - a 40-gram tube of 40 can be bought for only 25-30 rubles.

Minuses:

- Flammable;

- Requires careful application - if the glue gets on the upper part of the shoe, it can no longer be cleaned.

How to make it yourself

Many people wonder how to properly glue shoes if there is no desire to use professional methods and compositions due to lack of experience. In this case, it is recommended to use improvised means prepared independently. Casein glue has good moisture resistance. To make it, you need to put skim milk in a warm place, when it oxidizes, separate the curdled milk from the whey. The casein will remain on the blotting paper used for this. The resulting substance must be boiled in water to get rid of any remaining fat. Next, grind the mass to a powder state. To make glue, it is recommended to take 10 parts casein, 4 parts water, 1 part borax, and mix everything.

You can also prepare another, lighter composition. To do this, you need to finely crumble a piece of rubber, fill it with gasoline and let it sit for three days. Then carefully drain the solution and wait until the mixture turns into a thick mass. The composition is suitable for working with rubber products.

NOVBYTHIM “Uran” – for shoes with polyurethane soles

This glue is considered an analogue of professional Desmokol and is best suited for repairing shoes with polyurethane soles.

Like other PU adhesives, it needs thermal activation, otherwise the gluing will not be as durable. However, the cold method in this case also turns out to be quite effective.

Pros:

- Suitable for repairing demi-season shoes, as it does not get wet under the influence of water;

- High elasticity of the adhesive layer prevents the shoes from deforming;

- There are two gluing methods available - hot and cold;

- A huge selection of packaging - from 50 ml tubes to 200 liter barrels;

- Long shelf life (2 years).

Minuses:

- Fire hazardous and toxic.

What is it used for?

Fastening the upper part to the sole involves connecting parts from different materials that have their own characteristics. There are several basic repair methods. One of the most commonly used is the use of glue. It provides a tight fit with no gaps. The composition of the substance must be resistant to moisture, temperature changes, and mechanical stress. If the shoes come unglued, then the same remedy is used when repairing them.

In addition, glue plays a supporting role when used together with threads, nails, and staples. The tool can be used as an additional tool, accompanying, for example, firmware. In this case, it is worth using domestically produced rubber glue. It securely fixes the various layers, which makes it possible to get neat shoes without protruding parts. This is especially important for hard-to-reach places like the toe. An option is possible when the sole is fastened using a different method, and the heel is glued.

KENDA Farben SAR 30E – suitable for minor repairs

Nairite glue from an Italian manufacturer allows you to glue the rubber sole to almost any upper - regardless of the material. But it does best with minor repairs.

Another area of application for Nairit is the manufacture of custom-made shoes: for covering heels, gluing insoles, placing blanks on lasts and other assembly work.

Pros:

- Does not allow water to pass through;

- Does not harden or crack in the cold, always maintaining good elasticity;

- You can do without thermal activation, but it is precisely this that provides the strongest adhesion;

- It evaporates more slowly compared to nairites from other manufacturers, which gives time to correct flaws;

- If something goes wrong, the frozen composition can be reheated and re-glued.

Cons:q

- “Not friendly” with PU soles;

- It takes a long time to dry.

Selection by purpose

You should start choosing an adhesive by defining the task, that is, you need to decide on the purpose. Depending on where the shoes need to be glued, the product is selected for its intended purpose:

- Basics. Used if you need to glue the sole at home or attach a heel. Select products that provide high adhesion strength.

- Related. Used for additional gluing of parts fastened in another way (for example, after stitching with threads). The main requirement of such a connection is elasticity.

- Additional . Used for gluing decorative parts. Can form rigid joints; increased bond strength is not required.

MOMENT “Marathon” - affordable glue for home use

This popular glue is universal. In this case, the manufacturer means that with the help of “Marathon” you can repair shoes with any combination of materials – even with a wooden (cork) sole.

After drying, the composition retains some elasticity, which is important for connecting flexible parts of shoes. It is sold in small tubes of 30 or 125 ml.

Pros:

- Waterproof;

- Has a wide temperature range – from -40 to +110 °C;

- Does not lose its properties when refrigerated during storage;

- Residues of fresh glue can be easily removed from the top of the shoe;

- A tube with a long spout is convenient when you need to pour glue into a narrow gap;

- The cap does not stick tightly to the tube;

- Shelf life is 2 years versus 1-1.5 for professional adhesives.

Minuses:

- Requires adherence to technology (cleaning, degreasing), otherwise the torn part of the shoe will have to be glued again and again.

Reliable manufacturers

You should not skimp on glue; the quality of the repair depends on it. It is recommended to purchase it from reliable manufacturers:

- "Contact". Domestic manufacturer, produces adhesives for leather and rubber shoes. The products are good sealants. The glue of the same name does not have great frost resistance, so it is not advisable to use it for winter applications.

- "EVA." This is a manufacturer from Taiwan. Manufactures products that are waterproof, elastic, strong, and durable. Mainly intended for winter shoes, but not for rubber boots.

- "Henkel". “Moment” is the most famous trademark of this concern in Russia. Shoe glue of the same name is elastic, frost-resistant, and water-resistant. There are many varieties. Moment glue is sold in packages of various sizes.

- Kenda. Manufacturer from Italy. It produces adhesives that are successfully used on any surface. The product is resistant to temperature changes and moisture resistant.

- "Desmokol." An Italian company that has gained popularity due to the high quality and reliability of its products. The compositions it produces combine various materials and can seal any crack in the sole or upper part of a shoe. Can be used as a sealant.

All compositions are flammable, so precautions should be taken during operation and storage. It is very important to use a mask and protective gloves during the repair process. To avoid inhaling harmful fumes, it is necessary to ensure good ventilation of the room. At this moment it is better to send the children for a walk.

Kenda

Desmokol

Contact

Henkel

EVA

BOCHEM Bonikol MG – rubber adhesive for textiles, leather and auxiliary works

This adhesive is not intended for attaching soles and other loaded elements of shoes. But he is quite capable of restoring decor, braid and welts.

It can also cope with the restoration of leather models (again, if we are not talking about the sole). In addition, Bonikol has a rubber base - ideal for repairing rubber shoes.

Pros:

- Non-toxic, no suffocating odor;

- After drying, it forms a flexible layer that is not disturbed when wearing shoes;

- It is not sensitive to ordinary solvents, although it is not advisable to keep repaired shoes in water for a long time;

- Suitable for sealing welts and seams.

Minuses:

- Sold only in large jars of 700 grams.

Properties

The requirements for shoe glue are very strict. If you need to glue a decorative element (bow, buckle, etc.) or attach insoles, you can use regular shoe glue. If the sole falls off or a crack appears on it, then enhanced professional compounds are needed.

They must have the following properties:

- grip reliability;

- water resistance;

- resistance to low and high temperatures;

- elasticity of the formed seam.

In addition, the glue should not destroy the material from which the shoes are made. Most adhesives are universal, however, there are varieties that cannot be used for polymer soles.

In addition, you need to take into account how long you plan to wear the shoes after repair. If you need to repair your shoes so you can wear them for a few days until you buy a new pair, you can buy an inexpensive product. To perform quality repairs, professional tools are required.

Faux leather

The positive characteristics of artificial canvas are significant. Modern leatherette is very difficult to distinguish from genuine leather in appearance. In addition, faux leather can be more durable and breathable. It is much cheaper, although it is less resistant to humidity and temperature differences. The principles of repair are the same for the types. The main thing is to choose high-quality glue for artificial leather.

Glue selection

To determine which glue to use for leather, you need to familiarize yourself with the selection criteria. The main attention should be paid to the following parameters:

- is there an unpleasant odor and how quickly does it disappear;

- the ability of the glue to color the surface, especially of a light shade;

- whether lumps form when applying a layer;

- adhesive qualities of the adhesive;

- temperature range at which the composition retains its characteristics.

For gluing leatherette, it is good to use the following compounds:

- Kenda Farben. Provides an elastic, strong seam. Requires preliminary stretching of the skin before application.

- Moment. High-quality fastens leatherette to leatherette in 10 hours. The smell disappears after 24 hours. Advantages: low cost and ease of use.

- Composition 88. Used for gluing leatherette with other materials. It has a strong odor that does not disappear within 2-3 weeks.

You can use foreign brands of glue that have higher temperature and quality characteristics (GTA Botern, Mah, Patex). Their cost significantly exceeds domestic ones.

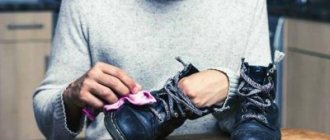

How to glue

The restoration process is similar to gluing natural leather. But, when working with leatherette, you need to remember a few nuances. There are useful recommendations on how to glue artificial leather:

- Before starting work, stretch the material a little and treat it with soapy water.

- After drying, it is recommended to degrease the surface with alcohol rather than acetone.

- Liquid leather can only be used on high quality material.

Gluing artificial leather is best done with minor damage.

The strength and neatness of the seam will depend on the quality of preparation of the leather surface, wear of the material and the characteristics of the selected glue. Severe damage takes a long time to recover; a new item can be glued together in a few minutes.