Cleaning the USR valve (needed for recirculation) is an important operation to extend the life of the car, ensure high-quality circulation of exhaust gases and avoid a decrease in traction quality. To avoid having to turn off the valve mechanically, experienced craftsmen recommend cleaning the automotive EGR valve at least once a year. Otherwise, the car may simply stop at a traffic light and never move. To determine the moment when it is necessary to remove the device and remove accumulated soot, you need to take a close look at the quality of the vehicle.

A little information

From an environmental perspective, such a system plays a positive role, minimizing the production of harmful substances. But often his activities bring a lot of difficulties to motorists. The problem is that this device, along with the intake manifold and working sensors, can become covered with carbon deposits during operation, and this leads to deterioration in engine performance. In this regard, car owners often give preference not to repair and cleaning, but to shutting down the system.

The EGR valve is located directly on the machine's engine. Its location may vary depending on the model, however, it is necessary to start from the location of the intake manifold. On its side there is a pipe outlet. The unit can also be located on the intake manifold, on top of the throttle valve block or in the suction tract.

How to clean the egr valve

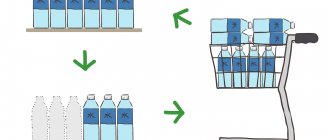

First it is removed from the car. Before dismantling, you need to purchase new valve gaskets. The old ones are pressed in and air is leaking through them. The EGR valve is located in front of the intake manifold. Sometimes it is between the intake and exhaust manifolds, the connection goes through the tubes.

Cleaning the USR does not require the use of special means. Regular WD40 will do. Carburetor cleaner is also suitable. This cleaning option will bring more noticeable results. You need to pour the cleaning agent onto the contaminated parts and leave for a few minutes to soak the dirt. Then clean it using available means, let the valve dry, and put it back in place. We must not forget that new gaskets will need to be installed.

If you experience symptoms of a clogged USR valve, we recommend that you contact a specialist as soon as possible, which will allow you to quickly eliminate problems with uneven engine operation. The staff will be happy to help you. To do this, simply fill out the form below.

What is an EGR valve?

The EGR valve sends a small amount of exhaust gases into the intake manifold. They are then combined with oxygen and fuel, and then sent into the engine cylinders along with the fuel mixture.

The volume of gas is calculated by a specially developed program, which is embedded in the ECU. Data on the computer monitor comes from sensors, and then the program makes a decision. These are mainly sensors for coolant temperature, absolute pressure, throttle position, air flow meter, as well as an air temperature sensor on the intake manifold, etc. But the system cannot operate continuously.

The very first valves were pneumomechanical: they were controlled by the vacuum of the intake manifold. After some time, they began to be made electro-pneumatic, and then completely electronic.

If the car has an electronic USR system, this means that it is controlled by an ECU. This system can have 2 types of digital valves: 2 or 3 holes. Their opening and closing is carried out thanks to working solenoids. A two-hole valve has three levels of recirculation, and a three-hole valve has seven levels, respectively.

The best type of such a unit is the one whose opening level is achieved thanks to a stepper motor, which guarantees gradual adjustment of the gas flow. Today, individual systems are equipped with their own gas cooling regulator. They make it possible to significantly reduce the level of waste nitrogen oxide.

Error P0171

One of the most popular errors when the Check Engine indicator is activated on the dashboard of Chevrolet Cobalt and Ravon R4 . If we look at the decoding, we can see it as the reason for the appearance of a lean mixture. Without going into details, this term means the excess of air by a certain amount of gasoline in the fuel mixture. There are plenty of reasons for “sucking” excess air, but on our Uzbek-made cars you can immediately narrow your search to checking the functionality of the adsorber valve .

Causes and consequences of failure

Most often they encounter such a malfunction as depressurization of the device. This leads to uncontrolled air leaks into the manifold. If the car is equipped with an engine with an air flow meter, then this situation can lead to a lean fuel mixture. If there is an air flow pressure sensor, it becomes over-enriched, which leads to increased pressure on the intake manifold. If the engine is equipped with both types of sensors, then at idle speed it will receive an excessively enriched fuel mass, and in other modes, on the contrary, it will be lean.

The second most common problem is the problem of device contamination. It should be noted that any, even the most minor, malfunction of the motor carries the risk of contamination.

The cause of the malfunction may be one of the following situations:

- Excessive passage of exhaust gases through the valve.

- Small amount of exhaust gases passing through it.

- Valve body depressurization.

A number of signals may indicate a problem with the EGR valve, the main ones being:

- Jerky movements of the car.

- Frequent engine stops.

- Misfires.

- Unstable engine operation at idle.

- A decrease in the degree of vacuum in the manifold, due to which the engine operates on an enriched fuel mixture.

Often, if there is a significant malfunction of the exhaust gas recirculation valve, the system lets you know about it with a check light.

Throttle valve

Another element of the car that is susceptible to very rapid contamination by soot, oil or dust is the throttle valve. The process of contamination of the throttle assembly is affected by the condition of the engine, the freshness of the air filter, and the operation of the recirculation system. Indeed, in most cases, exhaust gases are directed back into the cylinders through the throttle valve. Usually, contamination of the unit accumulates for quite a long time - at least 100,000 km, but if the EGR does not work correctly, the process of contamination of the throttle valve is greatly accelerated.

Symptoms of critical contamination of the throttle assembly are not very indicative: tripping, slow response to the gas pedal, errors in air supply, increased fuel consumption.

However, there is good news. The throttle body is fairly easy to open to clean. For this, there are special auto chemicals that wash away carbon deposits and oil deposits in a few minutes: for example, Throttle Cleaner from LAVR.

Checking EGR operation

During the inspection, you need to inspect the condition of the tubes, electrical wires, and other components. If there is a pneumatic valve, a vacuum pump should be used to operate it. For a comprehensive check, it is necessary to use special equipment that makes it possible to calculate the error code. To carry out such diagnostics, you should know the technical parameters of the device to identify discrepancies in the declared and received data.

Inspection sequence:

- Disconnect the vacuum hoses.

- Blow out the device so that no air passes through it.

- Disconnect the connector from the solenoid valve.

- Supply power from the battery to the device using wires.

If the check confirms that the device is not suitable for further use, then you will need to purchase a new one and install it. Often you just need to turn off this unit.

Jamming the device

If malfunctions begin to occur while the system or valve is operating, then shutting down the valve will be the right solution.

It should be noted that performing chip tuning will not be enough. In other words, the process of turning off the device will not help solve all problems, but will only eliminate the system check, and therefore the program will no longer generate an error. In the meantime, the USR continues to operate, so it should be excluded mechanically from engine operation. In some cases, plugs may be included in the package. They are usually a wide steel plate about 3 mm thick, made in the form of an opening in the device. If such a plug was not provided initially, then you can make it yourself from metal of suitable thickness.

Then you need to unscrew the valve, and in certain models, the intake manifold, clean the valves, then find the gasket installed at the place where the device is mounted, and in its place install a ready-made plug, made with your own hands or purchased at a car store.

At the time of assembly, the existing gasket and the new plug must be aligned. It is necessary to fasten all parts with bolts very carefully, because industrially produced plugs are quite fragile. After installing the plug, the temperature in the cylinders may increase, which can lead to the formation of cylinder head cracks.

Then you need to turn off the vacuum hoses and place plugs in them. At the very end, you should carry out chip tuning, in other words, make changes to the ECU firmware so that the system does not generate an error.

Cleaning the device

Often, in order to improve the operation of the EGR valve and the system, it is enough to clean the device. Owners of car brands such as Opel, Chevrolet Lacetti, Nissan, Peugeot often deal with this. To clean the EGR valve, you need to know some nuances. When cleaning the pneumatic valve from carbon deposits, you need to clean the seat and stem.

When cleaning a system with a control solenoid valve, the vacuum system protection filter is usually cleaned. It is necessary to use special tools designed for this purpose.

First of all, you need to remove the terminals and connector from the battery, then you need to unscrew the bolts holding the device with a key and remove it. The internal parts of the device should be soaked in carburetor cleaner. The collector channel is washed using a tube and a special cleaner. This process lasts from 5 to 10 minutes. You can do about five such approaches, depending on how dirty it is.

During the time that the manifold was being washed, the valve, soaked in the wash, had already become wet. Now you can start disassembling it, after unscrewing the bolts. Using lapping paste, it is necessary to grind the device. After completing this procedure, you need to carefully wash everything, dry all the parts and reassemble them.

After this, a leak test should be carried out, for which kerosene is poured into one of the compartments. If within five minutes it does not flow into another compartment, then the valve can be considered sealed. If this does happen, then the assembly process will have to be repeated again, only this time in reverse.

Selecting diesel egr cleaning products

Car owners complain that cleaning is of no use. But high-quality cleaning of components and assemblies is possible provided that the vehicle owner uses products specially produced for these purposes to perform operations. Do not forget: when cleaning the EGR system, do not use devices that scratch the surface of the parts. You don't even need to use a soft toothbrush. Only aerosol liquids are applied to the treated surfaces of the device.

The most effective:

- foam-forming carburetor cleaners;

- foaming agent in the form of a spray;

- USR, turbine, intake tract cleaner;

- carburetor flushing.

Carbon deposits are removed from the walls with a foam cleaner. The procedure is repeated up to 6 times. The number of repetitions depends on the thickness of the carbon layer. It is possible to keep the system operating stably by waiting for the moment when the dirt is removed from the action of the chemicals.

Carburetor flush is used as a means of soaking valve parts if they are significantly dirty. After soaking and pre-cleaning, you can use a spray. The product will help remove any remaining dirt.

How to change the device

Quite often, if the valve malfunctions, it has to be replaced with a new one. Before changing this unit, you should carry out some procedures related to the ECU, for example, deleting information so that the program “skips” the new valve and does not show an error. To do this, you must resort to the following procedures:

- Checking the vacuum hoses of the recirculation system.

- Checking the functioning of the EGR sensor and the system as a whole.

- Replacing the USR sensor.

- Determining the patency of the gas recirculation line.

- Cleaning the valve stem from carbon deposits.

- Removing ECU fault codes and testing the functioning of the new device.

Replacing this device can be considered using the example of the Volkswagen Passat B6 model. The sequence of work in it will be as follows:

- Disconnecting the valve disc position sensor connector.

- Loosen the clamps and remove the cooling hoses from the fittings of the device.

- Unscrewing both screws to inlet and exhaust gases directly to the valve.

- The device is attached to the engine using a bracket, a power bolt and two M8 screws. Therefore, they should be unscrewed, the old unit should be removed, replacing it with a new one and screwing the screws back.

- Finally, you need to connect the device to the ECU and be sure to adapt it using certain software.

Qualified specialists from a service station will charge about 4,000-5,000 rubles for it. The EGR valve itself will cost 1500 - 2000 rubles. and more. Knowing how to flush the USR valve with your own hands, you can save a lot on this procedure.