- Shock absorbers or dampers

Washing clothes nowadays is not difficult. All the once manual work has been taken over by equipment that washes, rinses and spins clothes, and all this quickly and almost silently. Nevertheless, many users are familiar with the situation when the washing machine vibrates strongly during the spin cycle.

Strong vibration may be a sign of a serious problem with your washing machine.

This fact causes irritation among household members, but we should also not forget that in some cases it indicates the presence of serious malfunctions in the device. Sometimes user inaction can lead to serious damage to expensive equipment beyond repair. In this article, we will help you figure out why the washing machine jumps during the spin cycle, and we will tell you how to eliminate this inconvenience.

Visual inspection

First of all, it is necessary to do an external inspection of the machine and its location. The unit must be installed on a hard, level surface. It is unacceptable to install the machine on carpet or any other soft surfaces. If it is not possible to install the machine on a surface with the specified parameters, you need to make a special tray.

The machine must stand absolutely level, this can be easily achieved with the help of adjustable legs - set them level. You should also pay attention to the legs themselves. They usually have a rubber lining that is designed to soften vibrations. If the gasket is damaged, it should be replaced.

If everything is in order outwardly, then it’s worth looking “under the hood.” There are many reasons for excessive vibrations, let’s consider the possible options.

What do experts advise when your washing machine jumps?

- Use the included noise-insulating rubber or silicone pads for the legs;

- When installing, lay an additional soundproofing layer behind the wall of the machine;

- Built-in models require additional space to prevent the headset from loosening;

- Load the equipment so that it is 1/3 free;

- Remove shipping bolts before installation and connection;

- Use a magnet or vacuum cleaner to remove small objects;

- Sort items by size and fabric type before storing;

- It is better to entrust the replacement of the engine, bearings, and springs to a specialist.

Watch a video about what to do if the washing machine jumps during the spin cycle

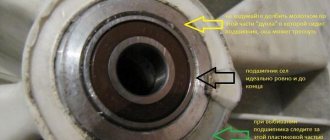

Damper failure

Dampers or shock absorbers are designed to smooth out vibrations that occur during washing. Their condition is easy to check. To do this, you need to open the loading hatch door and try to pull the tank towards you, and then release it. If it falls into place, the shock absorbers are ok. If this is the reason, then the tank begins to oscillate unnaturally.

Most often damaged are the linings that extend from the tank and flow around its tubes. The linings are strongly pressed to these elements using special U-shaped rods. The rods themselves are attached to the washer tank.

To replace broken linings, you need to unscrew the bolts that secure the damper to the body of the main unit. Then remove the defective covers and put new ones in their place. To install, you will need to unclench the shoulders of the metal rods, place the lining and bring them together again.

The replacement process is complicated by the fact that manufacturers do not produce individual parts for shock absorbers of washing machines, so choosing a suitable lining is problematic. It is most advisable to replace the shock absorbers with new ones; moreover, their price is low.

Causes of SMA vibration

If a new washing machine that was recently installed vibrates and jumps, the reason may be:

- In transport bolts. These are protective bolts that are installed to secure the tank. This way it is protected from damage during transport. If the bolts are not removed in time, the main parts begin to wear out, the machine makes noise and wobbles when spinning. The bolts are located on the rear panel; you can remove them yourself.

Save the shipping bolts. They can be reinstalled when moving.

- If the washer shakes and moves during washing, the cause may be due to improper installation. When equipment is installed on a wooden floor, it sags over time. Check that the machine does not wobble when turned off. If so, it's an installation issue.

- Why does the washer jump, twitch and skip across the floor? Improper use leads to imbalance. An overloaded drum will vibrate strongly during the spin cycle. And if you put large items, they may bunch up on one side of the drum. Modern cars have protection against imbalance. But it is better to stop the wash, drain the water and distribute the laundry evenly.

- It happens that a small object gets into the space between the tank and the drum. You can detect it by turning the drum by hand. Try to remove the item by bending the cuff of the hatch. If this was not possible, you need to remove the heating element and remove the object through its hole.

Which models vibrate most often?

Manufacturers are constantly improving the design of washing machines, trying to reduce noise levels. The drum rotates at high speed during spinning, so natural vibrations are simply inevitable. The ones that jump the most are:

- Narrow built-in washing machines. Due to the narrow body, the supporting part is reduced, therefore, if the machine is poorly secured or built-in, it will move along the bathroom floor.

- SMAs with metal tanks also make a lot of noise during operation.

When purchasing, pay attention to the methods of mounting the washing machine, as well as the materials of its construction.

Loosening the counterweights

Counterweights are attached directly to the tank of the machine at the top and bottom. There are two types of counterweights used in washing machines:

- Plastic;

- Concrete.

Problems most often arise with concrete counterweights because they crumble over time. Also, due to constant vibration, the fastening bolts may become loose. The counterweights can be accessed by removing the top and front covers of the machine. If the problem is in the bolts, then you just need to tighten them. If the counterweight bursts, then it must be replaced with a similar one. Increased vibration is the main reason for rapid wear of washing machine parts.

What does this mean?

First of all, I asked how long their washing machine “jumps.” It turned out that from the date of purchase, that is, three years. When asked why they didn’t solve the problem, my neighbor raised his eyebrows in surprise - isn’t the washing machine supposed to vibrate? Of course, it’s supposed to, but not in such a way as to jump all the way to the corridor.

Having examined the unit, I realized that these “jumps” were not in vain.

- I discovered a loose drum - coupled with the “shaking”, their device suffered from frequent leaks.

- Broken corners at the bottom of the body - it turns out that the washing machine vibrates so much that it even tipped over a couple of times during the spin process.

- Loose springs that strengthen the tank. One of them fell out when I turned the machine over.

In addition, I sincerely did not understand how one could tolerate the washing machine making so much noise and not even seek advice from a professional. I am generally outraged when technology is treated so negligently. But my first task was to provide assistance, and not to lecture. Therefore, I patiently explained that high vibration during spinning is dangerous for the washing machine, and below I described for you the reasons why it may occur. To help avoid costly repairs in the future.

Uneven distribution of laundry

The reason for strong vibration may be trivial and lie in the uneven distribution of laundry in the drum. When wet clothes roll up into one large ball, they have considerable weight. The rotation of such a lump can also cause vibration and bouncing of the machine. The solution to the problem is very simple - stop the washing process and lay out each item separately.

Strong vibrations can lead to damage to the drum and tub of the washing machine; if such symptoms are detected, you should immediately contact our specialists.

This video will help you understand the possible causes of vibration more clearly:

External reasons why the washing machine vibrates or shakes

Unremoved shipping bolts cause the washing machine to vibrate

If the new washing machine was not installed by a specialist, he may not have removed the shipping bolts.

Shipping bolts firmly fix the tank inside the case so that the tank does not swing during transportation of the washing machine. If these bolts are not removed and the wash is turned on, then the springs and shock absorbers that dampen the vibration of the tank during operation will not work. Therefore, the washing machine will vibrate, shake, or even jump.

Improper installation of the washing machine may cause the washing machine to shake

The washing machine must be positioned strictly horizontally. The surface under the washing machine must be strong and hard. The legs of the washing machine must be firmly fixed to the machine body. The machine must stand firmly on all 4 legs and must not move.

If any of these conditions are not met, then the washing machine will vibrate when the drum rotates rapidly (when spinning clothes).

The check should begin with these possible causes.

Try moving the switched off washing machine with your hands. She shouldn't move. If it moves, then check the legs of the washing machine and the surface on which it stands. Perhaps there is an uneven surface. Or one of the legs is not adjusted in height. Or one of the legs broke off. Or there is a fragile surface under the machine that “walks” under the weight of the washing machine.

After this, check whether the machine is installed horizontally or on an incline. This is best done using a regular building level. Place a level on the top cover of the washing machine and see what it shows. Important note: you need to check the level in two directions, across the width of the machine and across the depth. The fact is that the deviation from the horizontal can be not only in two directions, but also in one of them. For example, the width of the car is horizontal, but at the same time it is tilted forward or backward.

Adjusting the height of the washing machine legs:

By adjusting the height of the legs, you can compensate for uneven floors and set the horizontal level. However, do not twist the legs too much! The more the leg is twisted, the higher the likelihood that the fastening of this leg will break off over time. If the gap under any leg is too large, then place something solid under it, such as a wooden strip or a metal plate.

Vibration due to improper loading of laundry into the washing machine

The washing machine may vibrate and even shake if the laundry in the tub is not loaded correctly. The following errors lead to vibration:

- The tank is completely filled with laundry . In this case, there is no space inside the drum that can be used to move things and thus it is impossible to distribute things evenly on the inner surface of the drum. As a result, a strong imbalance occurs, which causes the washing machine to vibrate.

- Things are placed in the tank in a lump . They are confused with each other. During the washing process, the machine cannot separate them from each other and distribute them evenly over the inner surface of the drum. As a result, a strong imbalance occurs, which causes the washing machine to vibrate.

Correct loading of the washing machine with laundry

Items must be placed in the drum one at a time. Stacking them one on top of the other. In this case, you need to leave free space in the drum - about a quarter of the height.

When to worry - additional signs

A malfunction should be suspected only when play in the washing machine drum is accompanied by the following additional symptoms, one or more:

- The washing machine makes a lot of noise, especially during the spin cycle.

- During the spin cycle, the drum knocks on the SMA body or on the glass of the hatch

- The machine jumps or vibrates strongly during the spin cycle

- The belt regularly falls off the pulley

- The drum rubs against the hatch cuff

- The machine seems to wash and spin normally, but it makes noise or creaks when the drum rotates

- Traces of an oily dark liquid are visible under the washing machine

- SM leaks from below, if you remove the back wall, rusty traces of leaks are visible on the tank

- The washing machine stains the laundry with black oil or rust stains

- The washing machine drum flew off and fell to the bottom of the tank

- The drum is jammed and rotates heavily with a metallic grinding noise.

- SMA chews on things

- The washing machine breaks plugs or smokes

- SM drum warped

Attention! A loose drum in combination with any of the listed symptoms indicates a serious malfunction. Even if the machine fully performs all cycles of the program, we do not recommend its operation. This will lead to more serious malfunctions, including the equipment being written off as scrap.

Call the master

If you cannot find the reason for the vibration of the LG washing machine during the spin cycle on your own, you need to call a technician from a household appliance repair company. The easiest way to find such a company is on the Internet.

You should pay attention to whether there are positive reviews about the company’s work , how long it has been on the market. This thoughtful approach will help you avoid falling for scammers.

The cost of repair work in different companies can vary significantly. The amount of payment depends not only on the region, but also on the pricing policy of the company itself, the complexity and labor intensity of the repair work.

On average in the capital, the price will start from the following amounts:

- replacement of bearings - about 4,500 rubles;

- replacement of shock absorbers - about 3,000 rubles;

- replacement of an electric motor – from 2600 rubles, etc.

The cost of spare parts is paid separately by the client.