We've all experienced a situation where a crack has formed on our favorite pair of shoes. The question arises, how to glue the sole of a shoe at home. To do this, you will need to select some materials, study the procedure and completely follow the instructions.

When walking, it is the sole that suffers the most, so it wears out faster. Over time, cracks and holes form on the sole of the shoe, which are difficult to eliminate. You may need your everyday boots tomorrow, so you need to know how to seal your shoes at home. First of all, you will need to choose glue.

Ideally, it is better to contact a specialist if the sole of your shoes is cracked. They will be able to quickly fix everything in the shortest possible time. In order for the work to turn out beautiful and of high quality, it is necessary to choose the right adhesive depending on the characteristics.

What should I use to glue the sole?

If you do not want to ruin your shoes, it is recommended to select a special adhesive. Usually the packaging contains a corresponding mark. You can choose one of the following options:

- "Moment Marathon". The substance is intended specifically to repair broken soles. It is characterized by high resistance to humidity and other adverse weather conditions. Can be used in hot or severe frost. For some types of manufacturing materials, use is not recommended. This list is on the packaging, so please read it carefully before purchasing. Quite easy to use. You can wear the boots within 24 hours after gluing them.

- "Desmokol." Used for shoe repair. Helps against burst soles. More suitable for synthetic materials and suede. Sold only in specialized stores. Used in practice by professional workers.

- "Shoemaker" or "Nairit". The composition uses natural materials that provide high adhesive properties. Makes it possible to easily glue a broken shoe sole. Can be used for gluing the inside of boots, as well as small cracks. It is recommended to leave the work for several days to dry completely. Otherwise, rapid re-breakage is possible.

- Epoxy resin. Is a powerful adhesive. It has a high density, which is suitable for boots that are actively used every day in aggressive conditions. It will take several days for the damp surface to dry completely. After this, the shoes can be worn at your usual pace.

- Bonikol or Kenda Farben. Industrial imported products that are used in professional crafts. Suitable for problem areas, gluing heels, soles, socks, insoles. One of the best options for how to seal shoe soles at home.

Caution must be exercised when using the materials listed. Keep products away from open flames as they are explosive. It is also advisable to keep children away from the composition due to its high toxicity.

Types of glue that are often used to repair shoe soles

It is immediately necessary to dispel the myth that most people believe: professionals never use superglue or PVA when they see a cracked sole in front of them.

Often, craftsmen resort to introducing one of these mixtures:

- A transparent polyurethane-based solution called Desmokol.

- Special glue “Moment”, designed for repairing boots that have a hole in the sole.

- Epoxy resin is an excellent void filler.

- The fixing composition called “Shoemaker” is no less popular and contains rubber.

- When looking for a universal model, you should pay attention to Bonikol; this product is used in factories and workshops.

You can choose a manufacturer and model at your personal discretion, depending on the volume of repairs and financial capabilities; the range of products will pleasantly surprise you.

| Name | Description |

| Moment Marathon | Advantages:

|

| Nairit | The seam is flexible, resistant to water and heat, durable. The main advantage is the absence of harmful compounds in the composition.Repair methods:

|

| Eva | Suitable for any shoe repair.Advantages of the composition:

|

| Kenda Farben | Requirements for work:

|

| Contact | High quality product, significant savings |

| UHU "Schuh & Leder" | Distinctive features of the glue:

|

Which adhesive is not recommended to be used?

The substances listed in the previous section are the best options for gluing shoes yourself. There is also a group of products that are not recommended to be used if cracks have formed on the sole of your shoes. Do not buy these products:

- Super glue. A fairly hard material that roughly fixes and deforms the sole. Repairing the sole with such material is not recommended, as you will completely ruin the shoe.

- Ceiling tile adhesive. Can handle rubber and leather. This will leave traces that will be difficult to remove with improvised means.

- PVA. It is not stable. It is not recommended to seal a crack in your shoes, as it will immediately fall apart.

Materials and tools to fix shoe problems

The list of accessories and components for repair can be changed depending on the chosen method for implementation, but most often on the table of a professional shoemaker you can see such things as:

- A sharp knife with a thick and thin blade.

- A roll of sandpaper.

- Liquid for degreasing surfaces.

- Glue.

- Heat source, veins or paraffin candle.

- Marker for marking.

- Rubber scraps of different thicknesses.

- Tweezers.

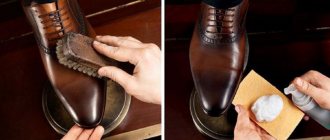

- Brush.

- Heavy objects or vices.

The place where manipulations are carried out should also be taken seriously; it is prepared in advance by placing several lighting fixtures.

Since the work is sometimes very delicate, when viewing the surface it is important to notice all the nuances, and the room must be constantly ventilated and dry so that the material does not become saturated with moisture.

How to glue the sole at home using improvised means?

After choosing the glue, you can try one of the ways to repair the sole of your shoe if it has burst. To do this, you need to carefully follow the instructions and follow the technology. Otherwise, you will not be able to achieve the result. Follow the algorithm:

- Clean your winter shoes from dirt and dry everything thoroughly so that no wet marks remain.

- Inspect the work surface for integrity. If the leather on the sole is cracked in several places, it is recommended to completely tear it off and glue it back. Also consider the surface texture. This is very important as the procedure will be different for different types.

- Clean the surface from any remaining old adhesive. Treat with alcohol to degrease the surface.

- Take something to seal the sole with. Apply to surface according to package directions. The adhesive layer should not exceed a few millimeters.

- Wait a few minutes for the surface to set. Press the sole down so that there are no untreated areas.

- Now leave the shoes under high pressure. To prevent it from deforming, place pieces of newspaper inside. You can use clothespins to secure the seam. Do this carefully so as not to damage the leather on your boots.

This is a cold technology for gluing winter shoes. The hot methodology is as follows - you need to heat the adhesive and carefully press the surface of the shoe. After this, you can wear your favorite pair of shoes after a few days.

Method 2

For work you will need the following materials:

- shoe knife;

- sandpaper;

- acetone or gasoline;

- a piece of inner tube from a bicycle;

- rubber glue.

What should be done:

- As in the first case, the burst sole needs to be cleaned and degreased. Use a shoemaker's knife to remove part of the sole: cut 5 mm along each edge of the crack. Keep the cutting depth to approximately 1 mm.

- The next step is to measure the depth of the fracture at the base. Add 15 mm to the resulting value - this will be the width of the strip that needs to be cut out of the chamber.

- Clean the cut strip, degrease it thoroughly, and apply rubber glue to it. Cover one side completely with glue, and leave a 5 mm edge of the dry surface on the other.

- Take the damaged shoe and bend it so as to expose the crack as much as possible. Holding it in this position and not closing it for 10 minutes, apply glue to the damaged area.

- Bend the prepared strip from the chamber in half and insert it into the crack. Now the sole can be straightened. With pressure, press the edges of the strip protruding from the crack onto the surface of the sole. Place your shoes under something heavy for a day.

How to glue the sole of sneakers?

Sports shoes are subject to a lot of pressure. While running or walking, the sole of a shoe can easily burst or a sock can come off. Therefore, it is necessary to know the sole repair procedure.

What to do with holes?

On sports shoes, the sole is very soft and sensitive, so it can easily break in half. If there is a large hole, you will need to fill it with glue. To ensure surface integrity, it is recommended to use special construction tape. It allows you to maintain the original shape of the product.

For gluing it is best to use a specialized sealant. It allows for the highest gluing density, which extends the service life of the product. Moreover, the cost of such compositions is much more expensive than conventional glue.

What to do with cracked socks?

Socks are the part of sneakers that deteriorate the fastest, as they are subject to a lot of pressure. If you urgently need a working method on how to seal the soles of sneakers, you first need to treat the working surface. Use alcohol to get rid of fat. Apply the patch, glue it and leave the shoes until all the glue has dried.

What to do with voids in shoes?

In winter, problems with shoes often arise due to unfavorable weather conditions. Let's try to figure out how to restore it. Winter boots most often have a porous surface, so you will need to fill the voids or completely replace the insole. Remove fats from the surface with alcohol and treat with glue.

The nuances of repairing shoes with voids

The unique honeycombs can wear off over time, and it is this exposure that often leads to significant damage, moisture on the feet and dust. Before applying a patch or filling the space with pieces of polyurethane, as well as pieces of rubber, the surface must be trimmed with a knife.

Such manipulations will protect the foot from excessive load, as well as bevel to one of the problem sides, and the repaired model, although it will become a little lower, will look more presentable.

Before using one of the solvents, you need to find out the composition of the sole; ignoring such measures, the master, without knowing it, is capable of causing irreparable harm to the product; foam versions are easily burned through with potent reagents.

How to properly care for rubber boots

If you choose the right glue and carry out the procedure carefully, you will be satisfied with the repair. And in order for your boots to last longer, you need to organize proper care for rubber shoes and repaired products. After use, thoroughly clean and wash your boots in running water.

We offer a few simple rules for the care and use of rubber shoes:

- Wipe the outside of the rubber surface with a clean cloth. For very dirty shoes, first rinse in water and then wipe dry;

- Colored boots are cleaned with Vaseline. It will retain color and shine, and the boots will not burst or become cracked;

- Be sure to use shoe insoles, preferably warm ones. Wash insoles every two to three months;

- Do not wear rubber boots in hot sunny weather, as the rubber deteriorates and fades;

- Periodically lubricate the surface of the products with oil varnish with rubber glue or glycerin. This will keep the boots shiny;

- Before long-term storage, be sure to lubricate your shoes with glycerin. Then wrap the items in newspaper or paper and place them in a cool, dry place;

- You can remove dark spots and streaks from rubber using a regular school eraser. It should be soft and clean;

- If your foot does not fit into the narrow top of the boot, lower the elastic stocking inside and put on the shoes. Then the leg will fit in without any problems, and the stocking can then be easily pulled out.

To keep your shoes shiny and attractive in appearance longer, lubricate the surface with oil varnish and rubber glue or wipe with a damp cloth containing glycerin. By the way, glycerin is an excellent product for caring for leather items. It will help smooth out a genuine leather jacket and give the product a presentable appearance. Read more about how to care for a leather jacket here.

VULCANIZATION (DIRECT INJECTION METHOD)

DIP (vulcanization or “direct injection”) technology for attaching the sole to the upper of the shoe, which does not use any glue or stitching method.

The FLUIDFORM™ DIP method uses thermoplastic polyurethane. This material is weather-resistant and holds its shape well; it is also characterized by high flexural and tensile strength; The method of attaching the upper of the shoe to the sole is one of the advantages of ECCO shoes; it has been used in production since 1980. The sole is fastened in a special machine (Desma). The top of the shoe on the last (see picture) is fixed over a specially prepared hollow form into which liquid polyurethane is fed under pressure.

https://www.youtube.com/watch?v=upload

In the production of two-layer soles, the outer sole is placed at the bottom of a hollow mold, liquid polyurethane filling the remaining space, and simultaneously soldered to both the upper and the outer sole, creating a single structure. When producing soles using the vulcanization method, the strongest connection between the shoe upper and the sole is formed.

Sneaker heel repair

If the tread is thoroughly worn out, it is carefully torn off from the surface of the sole, cutting it precisely in those places where it is impossible to tear it off. You can moisten these areas with solvent so that the protector comes off.

Transfer the outline of your sole onto cardboard, draw in the erased edges, and then cut out the pattern. You can make a new protector from any rubber mat that can be found in any hardware stores.

Important! During gluing, thoroughly clean the surfaces to be joined, but otherwise, the gluing technology itself is the same.

What to do if there is a hole in the heel of your shoe?

In order to remove the hole in the heel of the sole you will need tape, epoxy glue, hardener:

- wash the shoes, remove any debris that has gotten into the crack in the heel, dry the shoe;

- mix epoxy glue with hardener;

- pour the mixture into the hole and seal it with tape;

- put the shoes in their normal condition and leave them for a day;

- After 24 hours, remove the tape and smooth the surface of the heel with sandpaper.

For this method it is better to use masking tape.

Recovery methods

There are several ways to seal a sole if there is a crack in the bend. Each method involves preliminary work. To effectively eliminate defects in shoes, it is recommended to clean the base from dirt, wash it with a degreaser and dry it thoroughly with a hairdryer. Further, the technological process depends on the type of model and the complexity of its deformation.

Installing a patch

The method of repairing a burst sole using a patch is not as simple as it might seem at first glance. However, using it you can achieve the best results. The work begins by carefully separating the top of the shoe from the sole using a screwdriver. Such an event will simplify further actions and also contribute to high-quality fixation of the glue.

It is recommended to glue a cracked shoe in this order:

- the shoe material is disconnected from the granite by 1 cm;

- prepare a patch - its length should correspond to the size of the hole;

- the internal through void of the shoe and the flap of the patch are coated with glue;

- half of the patch is inserted between the material and the granite;

- to quickly fasten parts together, dry the joint with a hairdryer;

- Using acetone, clean the inside of the sole;

- then it and the second part of the patch are coated with glue.

The shoes are left in this position for 12 hours. After this time, the parts of the product with glue are dried with a hairdryer. Next, with careful but quick movements, glue the second part of the patch and the inner surface of the sole. At the end of the work, the insole is connected to the base of the shoe using rapid. This option is rational to use if the soles of summer and demi-season shoes are cracked.

Gluing the area with special glue

This restoration method is used for smooth soles made of polyurethane or elastic rubber. Restoring the operational characteristics of products depends on certain knowledge and skill in carrying out work. In addition to gluing the cracks, they will also have to be sewn up with nylon threads.

The repair procedure consists of the following steps:

- a layer of quickly hardening glue is applied to the crack in the sole;

- with strong pressure, glue the edges of the hole;

- draw a zigzag along the contour of the crack with a pencil;

- Slots are made along the line of the drawing with a shoemaker's knife;

- Using an awl and a hook, the sole is sewn together using small stitches along the cut holes;

- The edges of the nylon thread are first scorched with fire and then attached to the welt.

This repair option allows you to wear shoes immediately after their restoration. However, it is worth considering that the bonded surface will partially allow moisture to pass through.

Partial replacement of the damaged area

If the sole of a model without a heel is cracked, it can be patched by partially replacing the damaged area. To do this, a number of actions are carried out:

- a small amount of glue is poured into the cavity of the crack;

- for maximum bonding, the deformed edges of the sole are compressed together;

- the section requiring repair is degreased with the selected product;

- The crack site is first sanded with zero sandpaper, and then with troika;

- shoes are placed on the outsole material, the outline is outlined with a pencil;

- use a knife to cut out a blank for a partial replacement of the sole;

- the outsole material in the places where the glue is cut and applied is treated with sandpaper;

- the outer part of the sole with the outsole is lubricated with an adhesive;

- the glue is dried with a hairdryer and reapplied to the repair parts;

- a heel is applied to the sole;

- The products are placed under a load until the glue dries completely.

Regardless of whether the sole of the second product of the pair bursts or not, similar measures are taken with it. Otherwise, the shoes will have different heights, which will cause inconvenience when wearing them.

Express sole repair

This sole repair option involves patching cracks with rubber or nylon without subsequent stitching. Therefore, it is relevant for waterproof boots, boots and winter shoes. Partial replacement of the damaged area of the sole using rubber is carried out in the following way:

- The edges of the cracks are treated with sanding paper.

- The holes are degreased with a special product.

- A piece of rubber is cut out of a bicycle inner tube. Its size should be twice the depth of the slot.

- The rubber strip is first treated with sandpaper and then degreased.

- The sole of the shoe is bent so that the crack widens as much as possible.

- The sections of the resulting hole and the strip of rubber are lubricated with glue.

- The rubber piece is inserted into the groove of the crack.

After the procedures are completed, the boot is placed under pressure for 24 hours. After this, it is used for its intended purpose.

The stages of repairs for partial replacement of a section of the sole of winter shoes will be slightly different:

- A heated soldering iron is applied to the edges of the crack. At high temperatures, the rubber will begin to melt and fill the recess of the sole.

- A piece of nylon thread is placed into the molten damage.

- When using a soldering iron, the nylon begins to melt.

The repair operation is continued until the synthetic polyamide fiber reaches the edges of the base of the winter shoes.

Method 4

Thick, broken soles on winter shoes can be repaired as follows:

- Clean and dry your shoes thoroughly. Clean and degrease the crack itself.

- Apply a layer of Desmokol glue to the inside of the fracture and leave the product for 10 minutes.

- Coat the crack again, since usually the material from which the sole is made is porous and easily absorbs various substances. Wait 10 minutes, during which time a glossy film will form on the surface.

- Warm up the glue using a hair dryer and press firmly on the sides to be glued.

Note: when using Desmokol glue, the quality of gluing depends on the pressure on the surface.

How to seal the soles of autumn or winter shoes?

As a handy tool for repairing the soles of sneakers, the following is suitable:

- glue, for example, “Moment”;

- epoxy sealant “Crazy Hands”;

- product with polyurethane “Desmokol”.

Each of them comes with instructions that you need to follow during operation.

Important! You must also take into account that these products are somewhat toxic. If any of them gets on the mucous membranes, they must be immediately washed off with a stream of ordinary running water.

Sequence of work:

- Since winter or autumn shoes often have soles with a honeycomb structure, first you will have to deal with the honeycombs. You must remove the rubber that covers them to such an area that will allow you to remove absolutely all accumulated dirt from the holes. It happens that access to the honeycombs occurs from the side of the insole, which will have to be completely removed when cleaning the holes.

- Fill the honeycombs with small scraps of micropores, and then fill them with silicone sealant, thoroughly sealing them.

- You will need to wait for the sealant to dry and harden before you begin to seal the cracked sole.

- Next, cut out a piece of rubber or micropores that can fit into the hole in size if it is large, or press out small holes with a mixture of sealant and micropore sawdust.

- According to the size of the shoe, cut the sole from a thin piece of rubber and glue it using the already prepared adhesive over the entire area of your shoe.

- Place your shoes or boots under the press.

Important! The time required for the glue to dry completely is indicated in the instructions for it.