Features and characteristics of fibertech

Fybertek is a structured polyester fiber with hollow beads inside. Outwardly, it resembles holofiber, but significantly surpasses it in characteristics: it withstands low temperatures better and does not cake even with daily wear.

Composition: what is it made from?

The sealant fiber consists of thin polyester threads rolled into balls with a layer of air between them. The threads are treated with silicone to increase their strength.

What properties does insulation have?

Manufacturers have taken into account all the gaps of similar synthetic fibers, so fibertek has the following properties:

- Ease. Despite double stitching and siliconization, the fiber is lightweight and suitable for filling jackets, down jackets and overalls that fit on the body like a “second skin.”

- Form stability. The threads are strong enough not to roll or cake when bent, dried and stored, and they take the shape of a person’s figure without turning outerwear into an oversized sheepskin coat. In addition, the material quickly restores its shape after washing, exceeding synthetic winterizer by 10-20%.

- Moisture resistance. It repels moisture and does not deteriorate under its influence, thanks to which it also dries quickly after washing.

- High thermal insulation. In terms of thermal insulation properties, this material is twice as good as such natural materials as wool felt and alpaca wool. Cotton wool is inferior to fibertek in thermal conductivity by 35%. This means that clothes made from this material do not require any additional insulation or lining.

- Immunity to odors. Such a pleasant property as odor resistance contributes to the long service life of the material, because there is no need to wash it often.

- Wear resistance. Double stitching makes the material invulnerable to attempts at physical impact and tearing, making it also one of the most durable artificial fillers known today.

- Air permeability. This means that the material is well ventilated, evaporating moisture, but does not release cold. The filler does not contain fusible materials and is fire resistant.

- Hypoallergenic. Suitable for wearing by pregnant women and children, as well as for filling children's blankets, sofas, ottomans. The material is highly environmentally friendly, thanks to treatment with compounds that do not contain toxic substances.

- One-piece. It is made by thermal bonding, without the use of chemical glue, in layers up to 5 cm thick and 150-240 cm wide, which are stitched together. There is no need to hem these layers completely under the outer layer of clothing - only under the shoulder, side seams and hemming seams.

- Competitive price. The products have a relatively low cost compared to down jackets and jackets made of wool blend fabric.

It is manufactured exclusively according to GOST criteria and good material meets the following values:

- air permeability – 68.6 dm3/m2s;

- thermal conductivity – 0.031 W/mK;

- moisture resistance – 39.

Temperature conditions: what weather and temperature, up to how many degrees

The artificial filler based on polyester fibers stitched with spabond is frost-resistant: it effectively retains heat at temperatures down to -30°C.

Advantages and disadvantages of filler

A multi-purpose material due to its high heat-insulating properties and wear resistance: it does not bend, does not bunch up, it is convenient to move in clothes with such a filler, it does not visually weigh down the silhouette. It has variations in design, for example, with laminated fabric, based on the customer’s purposes of use. Read about the elasticated bedspread and bed cover here.

It is difficult to name disadvantages for a fabric that provides maximum protection from adverse external weather conditions, but there is still one - the material is electrified, which affects drying and operation.

Production: how to get it

Fibertek is woven in factories in such a way that there is an air gap between the filler balls, sufficient to retain heat, but the material is not too loose or not dense enough.

The level of thermal insulation of the filler determines how much the clothing is able to retain the heat generated by the human body.

It has a high resistance to heat loss - 25.8 kg/sq.m. This is achieved through additional stitching of the fibers with spabond - propylene, which duplicates the layers of insulation, but does not compact its structure. Excessive compaction of synthetic fibers is fraught with low levels of heat conductivity - the material will become too rigid.

Insulation materials used in winter outerwear for children

When choosing children's winter clothing, the main factor influencing the choice in favor of one option or another is the type of insulation used.

There are a large number of types of synthetic insulation, which have their pros and cons. In the production of children's clothing, padding polyester, isosoft and holofiber are most often used. Less commonly used are Thinsulate, Shelter, Fybertek, and Sherstepon. Any high-quality insulation provides protection even from severe frosts.

The hygienic and operational differences between synthetic insulation materials are leveled out due to the fact that a knitted turtleneck, woolen sweater, etc. is worn under outerwear.

Insulation effectively protects from bad weather only in combination with the materials used in the production of clothing, namely the outer fabric, windproof membrane and lining. Even if the insulation is of very high quality and warm, but weak windproof fabric is used, the jacket will not warm the child in cold windy weather.

Sintepon

Sintepon is a voluminous, light, elastic and soft material. Made from synthetic fibers. Previously, synthetic winterizer was the most popular insulation material. The main advantage of synthetic winterizer is its low cost. Today, this material is inferior to modern insulation materials in terms of thermal insulation, hygienic and performance characteristics. Synthetic winterizer is not a trademark; it is produced by different companies, and therefore the quality of synthetic winterizer depends on the integrity of the manufacturer.

The disadvantage of synthetic winterizer is low wear resistance. After washing, it “falls off” and becomes compacted, which reduces the thermal insulation properties of the products. Teenage outerwear based on high-quality synthetic padding can withstand from –10 to –15º C.

Hollow fiber

Holofiber fibers, used to insulate children's clothing from the BestKidsClub store, are twisted into springs that form a soft, light and very warm material. Holofiber is safe for health, so it is allowed to be used even in clothes for newborns.

Advantages of holofiber:

- hypoallergenic;

- wear resistance;

- environmental Safety;

- high resistance to deformation;

- does not absorb moisture and odors;

- does not roll down;

- has antistatic properties;

- prevents the spread of dust mites, bacteria, fungi;

- This insulation is recommended for use in all climate zones.

Fibertek

It is a non-woven fabric made of mechanically intertwined hollow, siliconized, highly crimped fibers. Fibertek is durable and easy to care for. Thermal resistance is similar to holofiber.

Isosoft

Isosoft fibers have a spherical shape. It is resistant to deformation, retains heat well and allows air to pass through. The material is hypoallergenic, wear-resistant, elastic, soft, so it is very suitable for insulating children's clothing.

Thinsulate

Thinsulate is a synthetic substitute for natural down. The material has a fine-fiber structure with high heat-insulating properties, low density and weight. It does not fall off or become deformed when washed. Clothing based on this insulation is quite expensive.

Valtherm

Synthetic insulation containing cotton. The structure of the fabric is cellular. Mainly used in the production of women's, children's and sportswear.

Sherstepon

The properties are similar to padding polyester, but the composition includes sheep wool, which increases the heat resistance and environmental friendliness of the material.

Thermofil

It is an improved analogue of padding polyester. Has good heat-insulating properties. Thermophile is lightweight, durable, resistant to compression, does not absorb moisture and does not wrinkle.

Scope of application: what to sew

The convenience of using workwear made from fibertech is due to two main factors: the ability to work outdoors without interference at low temperatures and the absence of a greenhouse effect due to breathability. Read about Turkish bamboo towels here.

Uniforms with such filling are sewn for traffic police officers, rescuers of the Ministry of Emergency Situations, and they are also used to create ammunition for lovers of active winter recreation: ski suits, overalls, kits for expeditions and extreme hikes, since they do not hinder movement. Sleeping bags and bedding are also made from it. But for workwear for medical professions, satori fabric is used.

Firefighters, rescuers and metallurgists are sewn overalls from Fibertek with treatment with fire-resistant compounds that increase the resistance of the lining to fire, even if the outer fabric has melted.

Representatives of professions that involve direct contact with electricity, wiring and instruments need protective clothing with antistatic properties. Fibertek, treated with silver-based compounds, will be an excellent replacement for classic batting and other heavy fillers, which make work uniforms uncomfortable for oil workers, gas sector workers, gas stations, etc. This material will tell you about a blanket for a bed in a sea-green bedroom.

Fibertek is used to sew soft parts of children's furniture - lining the sides of strollers, cribs and playpens.

Compound

The fabric is made from thin polyester fibers that are hollow inside. These fibers are treated with silicone, intertwined with each other and form a bulk layer of non-woven material. Thanks to silicone treatment, the fibers move freely, so the insulation retains its shape, resists caking well and does not bunch up.

Material sheets are manufactured that vary in thickness (from 15 mm to 50 mm), width (from 1.5 m to 2.4 m) and density (from 120 g/m2 to 400 g/m2). To obtain a more durable and stable material, the surface of Fibertek is reinforced with spunbond (polypropylene) and quilted using special equipment during manufacturing.

The material has an ideal ratio of fabric fibers and air quantity. Air has the best thermal insulating properties, which is why insulation materials are made from fibers that can retain air around them. But also if there is a large increase in air volume, then the thermal insulation properties decrease. And if you make the insulation more dense and do not increase the volume, then the heat-insulating functions will also deteriorate due to the fact that the thermal conductivity of the material fibers will begin to increase, and it is many times greater than air.

Fibertek has an ideal ratio of fibers and air per unit volume, due to which the thermal conductivity of the fabric is at the level of 0.031 W/m, which is only 19% different from air, and this is the best indicator among insulation materials.

Recommendations for product care

Another advantage of fibertek and shelter insulation is that it does not require any special conditions of operation, washing and storage. If for some reason the manufacturer has not indicated how to care for a product with this filler, you can follow the standard instructions for other synthetic materials - holofiber, padding polyester, etc. Read about an orthopedic sleeping pillow in this article.

How to wash in a washing machine

How to wash the product:

- The material can be washed by hand and machine in the “Delicate” mode.

- The water temperature should not exceed 40°C.

- It is preferable to use conditioning gels rather than powders and oxygen bleaches.

- It is prohibited to use bleaches and stain removers containing chlorine on fibertek.

- Spin must be set at no more than 500 rpm.

To straighten it, just shake off the clothes a couple of times and hang them on hangers to dry away from direct sunlight and heating devices.

It is not recommended to take jackets and down jackets made of fiberglass to the dry cleaner - aggressive chemical solutions can irreversibly damage the material.

Simple operating rules

To tidy up our products, they can be washed by hand or in a washing machine on a delicate cycle up to +40 degrees without spinning and drying. It is not recommended to use chlorine-containing substances as detergents. Also, you should not go to a dry cleaner - there may be an unpredictable reaction of the materials to the products used there. By following these simple recommendations, you will maintain the original appearance of your winter equipment for a long time.

The jacket dries very quickly, so you don’t have to worry about missed workouts and walks.

Fibertek or down: which is better?

The increasingly widespread use of fiberglass in clothing makes it reasonable to question the need to use natural down, which also has a high heat capacity. Read about tulle mesh and its use in the interior at this link.

The answer is unequivocal - fibertek is more comfortable and multifunctional to wear. It does not cause allergies, unlike bird down, and, like any synthetics, it keeps its shape much better.

The price-quality ratio, maintenance and operation characteristics are also on the side of this innovative seal.

Material properties

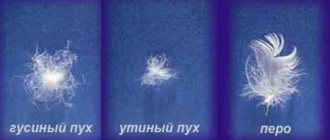

Comparison of the thermal insulating properties of Fibertek, Holofiber, Sintepon.

Thermal insulating properties are reflected by the “thermal resistance” indicator, measured in kg/m2. Measurements in accordance with GOST 20489-75 showed that the total thermal resistance of padding polyester is 20 kg/sq.m., Holofiber 24 kg/sq.m., Fibertek 25.8 kg/sq.m. This allows us to conclude that Fibertek is better than any material of the same thickness and density. In accordance with GOST 29335-92, this insulation can be recommended for the production of clothing used in a special climate zone.

Thermal conductivity

Thermal conductivity was measured at 20 °C, in units of W/m°K. For the best air heat insulator this figure is 0.0259, for Fibertek 0.031, for cotton wool 0.042, for wool felt 0.052. This indicator, the lower, the better.

Fibertek's indicators differ by only 19% from those of air, which is considered an excellent result. The thermal conductivity of the material becomes even better in cold weather.

Breathability

Air permeability is measured in dm3/m2s. According to research, according to GOST 12088-77, this indicator for Faybertek after several washes is 68.6 dm3/m2s. While synthetic winterizer after several washes has an air permeability of 21.1 dm3/m2s.

Moisture-holding properties

Tests have shown that the moisture capacity of Faybertek is 39.3, that of Holofiber is 57.7, and that of Sintepon is 61.8. These data show that Fibertek has a moisture capacity that is 30% less than other materials and at the same time has a high drying rate.

Elastic properties

Elastic properties reflect the restoration of the original shape by the material after deformation. Indicators of padding polyester 81%, Holofiber 89%, Fibertek 100%. It turns out that Fibertek has 30-40% less creasing, and shape recovery after load is 10-20% higher than other insulation materials. Fibertek restores its shape by 100%, and other insulation materials up to 90%.

According to the research results of SGSU.S. TestingCompanyInc. It was found that after three washes, products made from the Fybertek material almost do not change their dimensions, the deformation is no more than 3%.

Safety and environmental friendliness

The material is non-toxic and does not cause allergies, due to the fact that no glue or various polymer compounds are used in production. Also, the fabric fibers, which are the basis of the material, are very resistant to decomposition of polymer chains and the appearance of allergens and toxic monomers due to this. Faybertek has a radiation safety certificate dated May 16, 2005, No. 83/2005.

The environmental safety of the material is confirmed by the received certificates of hygienic compliance; no synthetic materials are used in its production, unlike the same padding polyester, which contains up to 20% emulsions and latexes.

The fibers are treated with an antibacterial agent based on natural raw materials, which protects the material from mites, bacteria and other organisms. After washing, this treatment remains and continues to protect the item.

An electrostatic charge is generated on the surface of the fabric as a result of friction. This electrification can lead to a lot of contamination and accelerates destruction, which also causes the release of toxins. Therefore, silver-based antistatic substances can be introduced into various types of Fibertek material. This measure increases the conductivity of electricity and removes charges. Sometimes metal-polymer fibers are added to the material, which also removes static electricity.

conclusions

- Fybertek is an innovative filler consisting of polyester synthetic fibers with a layer of air between them.

- This material is inferior in thermal resistance to many well-known synthetic insulation materials, such as synthetic fluff, holofiber, holofan and thermofiber due to the double stitching of the fibers with spabond.

- It is resistant to fire, does not absorb moisture and odors, restores its shape well in the wet and after washing, and is also resistant to tearing, which affects its service life.

- The products are lightweight and protect from frost down to -30°C.

- Clothes and workwear cannot be taken to dry cleaning.

- The material is hypoallergenic and does not contain toxic components.

Preparation method

The production technology requires the use of only clean, proven, non-toxic raw materials. In comparison with the main competitors (“Fiber”, “Discend”, “Tony Sailor”, “Ogner”, “Sport Alen”) that produce insulation materials, Stayer products received an advantage at the creation stage, when the developers refused to use them as part of the future fabrics of low-melting fibers. It is their presence in the composition that leads to creasing, clumping into separate lumps and deterioration after washing, especially when using water with a temperature above 30 degrees. But, as housewives well know, in this mode it is almost impossible to put clothes in order after active winter walks. With modern insulation this has become possible.