In order to answer the questions as comprehensively as possible: how to polish plexiglass at home, how to polish plexiglass and how to polish plexiglass with your own hands , it is necessary to consider in detail what plexiglass essentially is and what its properties are. Plexiglas (acrylic plastic) is not inferior to classical glass in its performance, and in some nuances it surpasses it. Its use in many industries allows it to be purchased in almost any shape. Acrylic glass (block plexiglass) is used in ophthalmic interventions, advertising, trade, scientific, technical and household spheres.

Plexiglas does not refract the image, has high strength and heat resistance. So the softening temperature is 95-105 degrees. And the permissible temperature of use is 80 degrees. However, despite the good resistance to damage, with prolonged and active use, it becomes necessary to polish the plexiglass from scratches. Many consumers sooner or later wonder whether plexiglass can be polished. Below we will look in detail at how to polish plexiglass from scratches and how to polish plexiglass with your own hands. We also suggest that you read the article: how to cut plexiglass at home.

When polishing plexiglass from scratches with your own hands at home, you need to consider that:

- The impact of aggressive techniques is not acceptable;

- Many chemicals can reduce the aesthetics of appearance and performance characteristics of the material.

Processing plexiglass involves the use of available techniques and means that are not complicated or expensive.

Polish for plexiglass. How to polish plexiglass using a regular hair dryer

In fact, plexiglass is a popular material in production and at home. It has a lot of positive characteristics. These include transparency, thermoplasticity and strength. But with prolonged use, it may become necessary to polish it. This process can be carried out at home, spending a minimum of time and effort.

Distinctive features of plexiglass

Among the key features of the material are softness and lightness. They are achieved due to the fact that plexiglass is made from acrylic paste using chemical reactions. Externally, it is practically no different from ordinary glass.

Important! The material also has the following names: carbon glass, acrylic paste or plexiglass.

Organic glass can be easily transformed, can be processed and has high throughput rates. But it is worth considering that some chemicals can lead to the decomposition of the material.

When is polishing needed?

The need for polishing may arise in two cases: after long use or processing. Cutting often leaves tools with rough edges, chips and small cracks. In order not to harm the appearance of the panel, you need to perform polishing work. Then you will be able to avoid the problem of tarnishing and distortion of the glass surface.

Advice! You can stick a colored film on the product. This will add aesthetic appearance and strength to it.

Instructions for self-polishing

A mandatory component for polishing synthetic glass is paste. Moreover, this is not necessarily a polishing agent. Dental or chalk will do just fine. You will also need a towel or soft cloth and a hairdryer. Next you need to take the following steps:

- Selecting a polishing product;

- Applying the composition to a towel or fabric;

- Rub the product into the coating using circular movements until the desired plexiglass state is formed;

- Blow drying;

- Wash off the composition with water;

- Re-drying.

Tips and tricks

Even when performing polishing procedures yourself, it is important to take precautions and safety measures. The following points require special attention:

- Spray agents should only be applied while protecting the respiratory tract using a respirator or medical mask;

- The room where work will be carried out must be constantly ventilated to avoid high concentrations of harmful components in the air;

- When using an electric tool, you must first check its serviceability;

- When operating with a grinding machine and sandpaper, you need to wear goggles over your eyes to prevent small fragments and dust from getting into your eyes;

- It is necessary to work with gloves made of durable materials, as harmful substances can get on the skin of your hands.

By following these simple rules, you will be able to quickly and efficiently polish plexiglass, restoring its transparency, shine and attractive appearance. You will need available tools and some free time to repair products.

What methods of polishing plexiglass do you know? Share with us!

Required Tools

Before cleaning, it is recommended to prepare the necessary tools . Ideally, they should be grouped close to the work area so that they are easy to reach. Here is a list of tools needed to properly clean plexiglass:

- Sponge or soft cloth;

- From warm water ;

- Suede so as not to scratch the surface;

- Spray ;

- Rotating brush or scraper for large areas.

Available commercially, much of this material is relatively affordable.

Chemical polishing of plexiglass. Polishing plexiglass yourself

If we talk about polishing plexiglass, then we are talking not only about the polishing process itself, but also about preparatory work, or rather, preliminary preparation for polishing. If polishing conditions allow, then the part to be polished should be dismantled, thus making polishing much more convenient. After this, remove dirt from the surface of the product and dry it.

Now, using fine-grain sandpaper, you need to process the surface of the part, special attention should be paid to places where there are irregularities or chips. It is best to give preference to waterproof sandpaper and carry out this procedure using the “wet” method. Next, polishing the plexiglass is done using a piece of flannel, or felt will do. The cut of material should first be lubricated with polishing paste; their choice is quite wide. And with such a simple device you need to rub (polish) a part made of plexiglass. To complete the polishing process, it is necessary to use the same material, but without polishing paste; the material is lubricated with oil; olive, machine or any other oil will do.

The polishing process is labor-intensive and takes quite a lot of time, but in the end you will get a beautiful and neat product. You should not use highly abrasive elements and aggressive chemicals for polishing plexiglass; polishing plexiglass can only be carried out using low-abrasive cleaning elements.

You can also speed up the polishing process by using a polishing wheel, which is attached to the shaft of a conventional emery sharpener. The main thing is to ensure that the product does not overheat, because in this case small bubbles will appear on its surface, which will be quite difficult to deal with.

Related services

- Choose …

View

Cutting polycarbonate and acrylic pipes

100 ₽ – 650 ₽

- Choose …

View

Cutting plexiglass rods

150 ₽ – 280 ₽

- Choose …

View

Polishing polycarbonate and acrylic pipes

210 ₽ – 1500 ₽

- Choose …

View

Polishing acrylic rods

240 ₽ – 600 ₽

Polishing plexiglass with dichloroethane. How to restore the transparency of plexiglass

If you have plexiglass with scratches or abrasions, then you will certainly have a question, how to restore the transparency of plexiglass? The main and most common method is to polish the surface of plexiglass using GOI paste, or using any other polishing paste.

But this method is suitable if there are only abrasions or small, not deep scratches on the surface of the plexiglass. What to do if the product has deep scratches? We’ll figure out exactly how to deal with deep scratches that have spoiled the original transparency of plexiglass.

So, if you are going to restore the transparency of plexiglass, the surface of which has deep scratches, they can be removed using regular transparent nail polish. It is necessary to apply varnish well in the place of the scratch, the main thing is that no air bubbles form in the thickness of the varnish, and let the varnish dry. You should not speed up the drying process, otherwise air bubbles will certainly form in its thickness, which is completely unnecessary.

Now that the varnish has dried, start polishing the surface of the material. For polishing, use sandpaper, take one medium No. 3, and polish with it the entire surface that has lost its former transparency, the surface will begin to become even more cloudy, then take and treat the surface with sandpaper No. 0, thereby you will get rid of small scratches on the surface of the plexiglass . Now start polishing the surface of the material that needs to be restored to transparency. Using felt cloth and GOI paste, after some time the plexiglass will become transparent and will look like new.

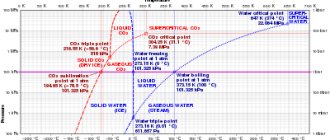

There is another way to restore the transparency of plexiglass with deep or multiple scratches. The surface of the plexiglass simply needs to be treated with pure dichloroethane. Since dichloroethane is capable of dissolving plexiglass, when it gets into cracks and scratches, it will melt it and, as it were, seal all the flaws from the inside. After this, when the plexiglass is dry, perform the polishing process as described above.

Do not forget that dichloroethane is a highly toxic substance, and work should be carried out exclusively in fresh air or in a well-ventilated area. Use pure dichloroethane, as it evaporates more quickly and will not melt the plexiglass much; if you use dichloroethane, which has plexiglass sawdust added, it can damage the surface of the material, dissolving it greatly.

What is it for?

Plexiglas is considered a strong and reliable material. However, over time, small scratches, chips and cuts appear on it. This happens due to mechanical stress on the product during its use. To return plexiglass to its attractive appearance, it is necessary to polish it.

Please note that the procedure itself is not complicated. But at the same time, this is a meticulous and lengthy task that requires patience and endurance. In addition, strong, aggressive substances should not be used to process plexiglass. As reviews show, after using such products, the material may become dull and cloudy.

How to polish plexiglass on a phone. Is it possible to remove scratches from a phone screen?

There is nothing you can do about deep scratches on your smartphone at home; in such cases, there is only one way out: go to a service center. But if the scratches are small, you can actually get rid of the problem yourself. There are several different removal methods using professional or improvised means. But the most important thing is to have patience, do everything carefully and not turn off your brain so as not to spoil the thing.

It is important to understand that this is a scratch, not a crack. And the scratches are not removed (this is just a turn of phrase), but polished. The edges of the scratch simply grind off and the surface becomes smooth, or rather slightly concave. In this case, the scratch ceases to be noticeable, since only the reflective edges are visible to the human eye.

Small scratches can be polished by yourself

Before you start, consider a few important points:

- If you have the opportunity to choose polishing products, give preference to specialized products. Read the instructions carefully and follow them exactly.

- You need to understand what material the screen is made of. This is necessary in order to practice on similar material with the tool you have in order to avoid possible troubles.

- It will be much easier to remove scuff marks on glass screens than on plastic ones.

- If you cannot determine what material the screen of your phone or smartphone is made of, try to find all the necessary information on the Internet.

- None of the methods for removing scratches guarantees the desired result. It will largely depend on how damaged the screen is and how deep and numerous the scratches are on it.

Attention! A hard abrasive may not only fail to remove scratches, but may even add them if the sanding is intense.

If edge processing and chamfering is required

...Then it’s better to contact the online store Zuker.by. Thanks to this service, you can create a smooth and even edge, which will help not only create an even more attractive look for the product, but also avoid various cuts and damage.

For processing edges, a modular edge router Festool MFK 700 EQ-Plus is used, which allows you to cut materials with an accuracy of 0.1 mm.

Edge rounding radii can be as follows:

- R2 (radius 2 mm);

- R4 (radius 4 mm);

- 45⁰ (45 degrees).

More details about the service can be found in the material “Edging Processing of Polymer Materials”.

How to remove cloudiness from plexiglass. How to restore the transparency of plexiglass?

During the operation of plexiglass products, it is practically impossible to avoid any damage. These may be scratches left by accident, or perhaps upon contact with some kind of solvent, cloudiness may appear on the surface of the product. When plexiglass becomes cloudy, the product loses its original transparency, which significantly worsens the appearance of the product. If you are asking the question - How to restore the transparency of plexiglass?, then there are even several answers.

The first and most common way is to use GOI paste and felt, apply the paste to a piece of material and begin polishing the surface of the plexiglass in a circular motion until the required shine and transparency appears. If you have the opportunity, it is better to remove the cloudy part from the product, this will greatly facilitate the process.

If plexiglass has lost its transparency due to scratches and chips on its surface, sandpaper will help you out, it must be moisture-resistant, since work to remove damage will need to be done by periodically wetting the plexiglass with water. After all minor damage has been removed from the plexiglass, you must again use GOI paste with felt, in this combination they will help you restore transparency to the plexiglass. Another option is to make your own polishing wheel. To do this, you will need to cut out a large number of circles from soft fabric, it can be felt, flannel or flannel, choose for yourself.

Afterwards, these circles need to be sewn together so that they do not fall apart, but stick together, you will also need two circles cut from metal or plastic, these circles should be 7 centimeters in diameter less than fabric circles, they will serve as clamps. Once the polishing wheel is assembled, place it on the sharpening machine axle. Use GOI paste together with the circle. Please note that polishing should be done gradually, do not do it at high speeds, as this will damage or deform the material.

Depending on the reason why the plexiglass product has lost its former transparency, choose the appropriate method by which you can restore its transparency. This process is of course quite labor-intensive and will require patience from you, but it is worth it.

Option 2

In this case you will need:

- paste GOI;

- soft fabric, or felt, felt, cotton pads, sold in cosmetic departments.

First, the paste is applied to plexiglass and polished using one of the above materials. Then it is processed with fine sandpaper dipped in water. Plexiglas is also sprayed with water; its surface should not remain dry during operation.

At the final stage, the glass is wiped with a soft cloth and again treated with GOI paste using felt. This option is recommended for polishing old plexiglass.

How to clean plexiglass. How to clean plexiglass?

If you pay attention to the interior of your apartment, you will find that there are many parts and products that are made of plexiglass. Yes, precisely because of its properties and excellent characteristics, this material is quite actively used by designers and other specialists in the design of premises. Therefore, the question is quite rational: how and with what to clean plexiglass?

Cleaning plexiglass is quite simple. In order to keep products made from this material clean, you just need to wipe their surface with warm water, to which you can add a mild detergent.

How to clean plexiglass? Use a soft sponge for cleaning; if you use hard material, scratches and small cracks may appear on the surface of the product, which will ruin its appearance. If there are regular stains or any dirt on the surface of the plexiglass product, try removing them with a regular cotton swab.

To clean plexiglass, use only natural materials; synthetic ones can damage the surface of the plexiglass and it will become dull. After the plexiglass has been washed, it should not be left to dry on its own; wipe it with a natural cloth so that streaks do not form in the end. It is also recommended to use natural fabrics in order not to charge the material with static electricity, as a result of which dust and debris will be attracted to the surface, which will also spoil its appearance.

Under no circumstances use harsh abrasive detergents to clean plexiglass and plexiglass products, as this can damage the surface of the material, which will be quite difficult or almost impossible to correct. Plexiglas does not tolerate any solvents, so do not try to clean plexiglass with any solvent, otherwise you will ruin the plexiglass product.

If you need to clean plexiglass from greasy stains that have formed on its surface, try treating it with alcohol or kerosene, being careful not to damage the product.

In order to give the plexiglass product its former transparency, after cleaning it using one of the above methods, start polishing it. To polish plexiglass you will need GOI paste, or use any other suitable paste for polishing plexiglass. Apply a small amount of polishing paste to the natural fabric and begin polishing the plexiglass in a circular motion.

As a result of polishing, small cracks and scratches will disappear from the surface of the plexiglass, abrasions will disappear, and the plexiglass will again become transparent like new.

Using GOI paste, sandpaper and felt (with detailed video)

Plexiglas polishing paste is most often used for this type of work. Even professional restoration specialists use this method. To achieve maximum results, you need to use a certain algorithm:

- The first step is to limit the work surface using masking tape. If it is possible to separate the acrylic part, then it is better to do just that.

- Sand the surface with sandpaper (grain 2000), periodically moisten it with cold water. The result of this stage should be a uniform matte surface. Don't rush into work, do everything measuredly.

- Polishing plexiglass with your own hands, although it does not require much effort, is a rather lengthy process. At the third stage, you need to dry the acrylic element, take felt and apply GOI paste. Then get to work. It is recommended to divide the surface into small sections and rub them until they have a glossy shine.

Plexiglas polishing technology. Plexiglas, how to polish it from scratches?

It is difficult to imagine an area of human activity in which products or product elements made from organic glass would not be used. Plexiglas has a number of advantages compared to silicate glass.

It is much lighter, more flexible and durable. However, this modern material has a significant drawback. Despite the high strength of plexiglass, its surface is susceptible to mechanical damage. For example, exposure to dust and sand scratches display cases, and prolonged use of a mobile phone with an unprotected screen leads to clouding caused by microscopic scratches.

How to polish plexiglass from scratches? In fact, this is not a complex surface polishing operation. The essence of this process is to remove or modify the thin surface layer damaged by scratches. Depending on the degree of damage and depth of scratches, as well as the shape of the surface and access to it, there are different polishing methods.

The classic technology for polishing plexiglass at home is as follows. Using fine-grained sandpaper, for example, 2000, carefully sand the surface. It is better to carry out the operation under water or periodically wet the surface with a spray bottle. After obtaining a uniform, stain-free matte surface, wipe it dry and begin the actual polishing. As an option, you can use felt with GOI paste applied to it. The surface is polished slowly until the required quality is obtained.

Instead of GOI paste, you can use other polishing compounds. Car polish and Japanese Compound paste have proven themselves well.

If the surface area is significant, then it is better to mechanize the procedure. You can use polishing machines or make your own polishing wheel. Care should be taken that the rotation speed is not high. Otherwise, the surface may melt due to heat.

If the requirements for surface quality are not very high, then scratches can be made invisible by melting the surface layer or dissolving it. If you spray the surface of the plexiglass with dichloroethane, the scratches will disappear after drying due to the dissolution of the surface layer. The scratches will “float”.

In production environments and service centers, special equipment is used to polish plexiglass, but the principles remain similar.

Recommendations

The following recommendations should be followed:

- any work with plexiglass should be carried out with minimal pressure so as not to break the product;

- before starting work, the glass should be washed with water and dried without using heating devices; It would be ideal to be able to detach the organic glass from other surfaces, but if this is not possible, then seal them with tape;

- When processing with sandpaper, it is recommended to periodically moisten the glass surface with plain water;

- when felt is missing, it can be replaced with a regular felt insole;

- a polishing wheel will make the polishing job much easier, and grinding machines are also an excellent choice; but when using the technique, you should remember that the rotation speed should not be at maximum - this will help avoid damage to the glass surface;

- after using car cosmetics, the glass can be wiped with vegetable oil;

- Do not forget about the protection of the master - use safety glasses when polishing and grinding;

- when using chemicals, it will be necessary to ventilate the room well; if even mild dizziness occurs, you should immediately stop working and go out into fresh air;

- the use of fire must be very careful;

- a respirator will help protect your respiratory organs from dust, but if you don’t have one, you can try replacing it with a medical mask or scarf;

- gloves will help protect the skin of your hands from dust and other small powders that can get on the skin and cause allergies;

- When grinding glass with deep scratches, you should start with coarse-grain paper, and as the top layer wears off, replace it with a finer one; after this, the surface will become matte, but if the difference is visible, then the less transparent areas of the glass should be additionally sanded until the same result is obtained;

- the grinding process should periodically be replaced by the process of cleaning the resulting dust;

- GOI paste should not contain ammonia, since it can make the glass dull;

- when polishing using technology, you need to know that thermoplastics require up to 1.5 thousand revolutions per minute, and thermosetting compounds - up to 2 thousand; thermoplastic glass compositions should be treated with softer polishing components compared to thermosetting ones;

- It is better to treat corrugated organic glass with chemical steam, since grinding and further polishing will not bring results;

- Steam polishing is not suitable for transparent glass, unless the goal is to make it matte;

- using GOI paste with aluminum in its composition will give color to transparent glass, and chromium oxide will penetrate into the damaged surface and most likely will remain there; it will be very difficult to remove it;

- chemical matting or sanding with fine-grained paper is suitable for obtaining a matte surface.

It is always possible to polish the glass at a car service; for some, it will even be much easier to simply replace it. But this method will require more extensive financial costs. In the case of your favorite things, it will be inappropriate to talk about replacement, so choose a method that is more convenient for you and restore your dear things yourself. The proposed methods of influence will help you achieve good results.

You can get acquainted with the technology of polishing plexiglass in the following video.