The question of how to remove a dowel from a concrete wall may arise both during the process of home renovation and at any time during your stay. When deciding to change the wall covering or redo something, rebuilding old dowels often becomes an obstacle to creating a beautiful, even surface.

When you may need to remove a dowel from a wall:

- In the process of preparing the surface before wallpapering.

- Before painting the walls, which involves creating a perfectly flat plane.

- When changing the location of certain items or furniture.

- When dismantling old windows, which are often supported by wooden dowels.

There are many ways and methods for removing dowels from concrete walls, but the situations are not always standard. Before removing the dowel, it is necessary to take into account the material of the element and study the features of its fastening.

So, if a rusty metal or plastic dowel breaks off or is deeply stuck in the monolith, the usual methods will not work and certain measures need to be taken.

How to remove a dowel from a wall: instructions for use, tips and recommendations from experts

During construction work, situations often arise where it is necessary to solve the problem of removing a dowel from a wall.

How to get it out? This fastening tool itself is not particularly difficult to remove, but the surfaces into which it is driven may be too hard or brittle to remove. The simplest task can become a real headache. All work carried out using power tools must be carried out wearing protective equipment. A detached dowel head can cause serious injury.

Tools

The list of tools required to pull out the dowel depends on the material from which it is made. During your work you may need:

- self-tapping screw or corkscrew,

- chisel, hammer,

- pliers,

- nail puller,

- knife or awl,

- soldering iron,

- "Bulgarian",

- punch or electric drill.

Such a small dowel and so many tools are needed to remove it from the wall! In fact, the above list applies to all types of dowels. Therefore, in the process of work, you will use exactly the tool that is necessary to pull out exactly those dowels that are firmly embedded in your walls or ceilings. Perhaps, let's move on to the process of removing the dowel itself.

What types of dowels are currently available?

The time has long passed when the most common means of fastening on vertical walls was a wooden chopper and a metal screw. Modern industry presents a huge variety of shapes, materials and manufacturing technologies for construction dowels. The most common now are:

- plastic with metal screws;

- rod, metal with impact fastening;

- metal, wedged in an aluminum liner.

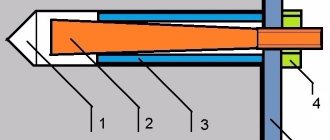

Dowel-nail fastening technology

Since many materials have high hardness, this does not allow direct fastening using a nail or self-tapping screw. Driving a fastener into a solid brick or concrete base using a nail gun may damage its structure or appearance. A more gentle way is to install the fastening using an intermediate elastic device called a dowel. It is a liner with a technological hole for screwing in or driving in a metal core in the form of a nail or screw.

How to remove a dowel from a concrete wall?

Hammering it in with a construction gun makes this fastening practically permanent. Since concrete bases are very hard, it will also be extremely difficult to swing the fasteners. How to remove a dowel-nail from a concrete wall? The most rational way is the following. It is necessary to cut off the head, and try to hammer the remains flush with the wall. You can also try to loosen it, but this risks destroying the top layer.

Since it is impossible to remove a dowel-nail from a wall lined with decorative materials without damaging them, it is better not to use such a fastening (in the form of a rod driven in by impact) in these cases. If it was hammered into an aluminum shell, then there is a chance of dismantling. To do this, you need to heat the fasteners using a gas burner and cool them with water. Aluminum will expand greatly when heated, and when cooled, it will return to its previous shape. This will relieve pressure in the mounting hole. Once cooled, it will easily come out of the wall.

Carpenter's pry bar

A steel rod of hexagonal or I-section, approximately 45 cm long, one end wide and flat with a wedge-shaped slot and a teardrop-shaped hole for pulling out nails. There is an angular variety, in which the second end is bent at a right angle and also has a wedge-shaped slot.

Read also: Who is a professional waiter?

In general, a more powerful mount model is used for dismantling parts with small gaps between them.

It is adapted for striking it with a large hammer, so it can be used as a chopping tool similar to a flat mount. Particularly useful when removing floor boards. There are many modifications of carpenter's pry bars, choose the one you need specifically.

How to remove an old dowel from a wall when it is broken?

In any job, defects happen. During installation, the screws may break, the notches on their heads may wear off, and the plastic of the bushing may crack. If the screw is not completely broken, then you can remove its remains using a little trick. To do this, take a reversible drill, clamp the remnants of the screw sticking out of the wall into the chuck instead of the drill, and turn on the reverse motion. If the fragment does not allow this to be done, then pliers with a large lever or pliers will be needed. These tools have a lot of pressure in the working part, which will allow you to grab the most difficult edge.

The same tool will help you remove the plastic part stuck in the wall. You need to carefully pry up the upper skirt of the liner and pull it, trying not to tear it. Since it can be difficult to remove a broken dowel from a tiled wall without damaging it, you can consider the option of partially dismantling it.

Partial dismantling of fasteners

If complete removal is not possible, only the protruding parts can be removed. It is also possible to use a soldering iron to melt the plastic of the sleeve and install a smaller dowel into the resulting hole. The protruding parts can be trimmed using a construction knife or cut off with a hacksaw blade from a hand saw for metal. To do this, the hacksaw blade is wrapped with rags at both ends (so that the central part is free). The resulting improvised handles will protect the worker’s hands. Then, taking the canvas in your hands and bending it slightly, cut off the dowel.

Removing old and rusted fasteners

How to remove a dowel from a wall if it has been in the damp environment of the bathroom for a long time and is covered with rust and hard layers of dirt? In this case, you will need WD-40 penetrating liquid or a solution of food grade acetic acid. First you need to pour a vinegar solution over the rusty fasteners to be dismantled. This will help dissolve the oxides and free the threads on the screw. If this does not help, then after rinsing the dowel with plenty of water and letting it dry, treat the fastening area with WD-40. Judging by the reviews, it easily penetrates cement building materials and softens them, and also facilitates the removal and rotation of the screw in the sleeve.

How to remove a dowel from a wall? Treatment with soap is also effective. It will help dissolve fatty deposits and penetrate into the pores of the wall. Also, being a good anti-friction agent, the composition will allow you to unscrew the fasteners.

Radical methods

To remove hard-to-remove dowels, you can use the following methods:

- drilling;

- dissolution with strong acids.

To drill, you will need a powerful drill that has protection against biting the drill. This is necessary to protect the worker’s hands, since residual fasteners can jam the tool and cause harm to it. To avoid worsening the damage, you need to act slowly. If you do not plan to reuse the hole, then only the very top parts of the dowel can be removed, and the remaining damage can be plastered or painted over.

How to remove a dowel from a wall when it cannot be removed and it is necessary to use this particular hole? You can use the most radical method. To do this, use a brush to apply a concentrated solution of sulfuric acid to the protruding parts of the dowel and leave for some time. Acid destroys the bonds of mortars, dissolves metal oxides, organic glue and paint. After such treatment, it is important to thoroughly rinse off any remaining acid, as it has a toxic effect. You need to work in personal protective equipment (a respirator) and in a well-ventilated area.

Precautionary measures

To remove an old dowel from a wall or replace one that is broken, you need to know not only the sequence of actions, but also have the necessary tools. It is important to understand the safety precautions for performing these actions. Depending on what kind of tool you have to deal with, you need to use protective devices. Using a screwdriver and a self-tapping screw, usually no problem situations arise, but in the process of removing the dowel, you should be concentrated and not distracted so as not to get hurt.

A hammer in skillful hands is an effective and safe tool, but accidents can happen to amateurs and beginners. Most often they hit their own fingers with a hammer, so it is important to keep them away from the hole with the dowel and not be distracted while working. The most dangerous tools include a soldering iron and a grinder. When using a soldering iron, there is a risk of injury to yourself if you accidentally touch your skin; in addition, it is a power tool, so it is important to follow safety precautions when working with it. When using an angle grinder, it is advisable to wear protective gloves and a mask that will protect your face from sparks and small parts that may fly apart during operation.

The procedure for removing the dowel is not a particularly difficult task, but even it must be handled correctly, minimizing any risks, which will allow you to quickly complete the job without risking your health.

Unusual methods of dismantling

To remove fasteners in difficult cases, you can use non-standard solutions.

How to remove a dowel from a wall if its metal fragment cannot be grasped with pliers? It can be electric welded to the bolt and unscrewed with a wrench. A non-removable dowel can be driven into a greater depth with a hammer drill and the old hole can be used again.

Remove with pliers

And finally, a tool designed specifically for removing nails - pliers. This is the most convenient device for solving such a problem.

The tool has wide and thin “jaws” that can easily be used to pick up the deepest nail. Even the torn head of a nail should not scare you, because pliers, like wire cutters, have pointed ends that can be used to firmly grab the body of the nail anywhere. So, by gradually grasping the metal rod in a new position each time, you can pull it out of the wall with light rocking movements, with virtually no effort.

Metal dowel

Please tell me the best and most expedient way to remove (pull out) the metal dowel from the concrete wall.

What dowel design? So, choose from the list and we’ll continue further » >

Yes, this is such an old dowel, maybe I’m calling it wrong? See photo (only his hat is there)

Antigluk wrote: Yes, this is such an old dowel, maybe I’m calling it incorrectly? See photo (only his hat is there)

Cut off the protruding part of the angle grinder (grinder). Other options are fraught with great destruction.

Alex___dr wrote: Cut off the protruding part of the angle grinder (grinder). Other options are fraught with great destruction.

Maybe tap the head and drill it out? And then there is no grinder.

it will not work to bend (as well as to drill out) - these dowels themselves are similar to the core in terms of strength. just blunt the core. take a large straight screwdriver, a crowbar, a chisel and a hammer and try to pry it out where there is a gap between the wall and the plate. when you loosen it to the point where you can catch the head with a crowbar, you simply tear it out like a nail puller. get ready for the fact that you will have to exert quite a lot of force and that a piece of the wall may fall out, up to 1 dm2 of luck.

I don’t think it will work to either punch or drill. It's solid. And in my opinion, red-hot. If you hit it, the pieces will fly off sharp and at high speed (I haven’t seen it myself, my acquaintances told the builders, maybe they’re lying). So it would be better to find an angle grinder (or a person with an angle grinder).

Everything is much simpler. Take a plumber's hammer - the heavier one - and strike it several times on the head of the dupel - like hammering it into a wall. Then you hook a nail puller under the metal plate and the dowel falls out. Just don't tell anyone that it's that simple. Let others suffer with grinders. Here you will have only one problem - the dowel holds very well in the metal, so pull it out along with the piece of iron. To avoid this, you need to knock several times at an angle to the head, as if to swing the dowel. In general, I myself did not expect how easily such things fall out with the right approach. If you just tear it up, then everything is useless. Good luck!

Of course, you can use the method proposed by Mikhalych:

Mikhalych wrote: Everything is much simpler. Take a plumber's hammer - the heavier one - and strike it several times on the head of the dupel - like hammering it into a wall. Then you hook a nail puller under the metal plate and the dowel falls out.

But keep in mind that the wall is yours, not Mikhalych’s, and in case of failure, it’s up to you, not him, to cover up the crater.

I ask the question because I have already encountered this. The hemorrhoids are still the same. The holders for the sink in the kitchen had to be torn off from the walls; they were also nailed with the same dowels. I used a chisel between the holder plate and the wall. One seemed to break off, the other was pulled out. So I’m asking, now I need to remove several of these from the bathroom, maybe someone knows an easier way?

Mikhalych wrote: Take a metalworker’s hammer, the heavier one, and strike it several times on the head of the double-bar, like hammering it into a wall. Then you hook a nail puller under the metal plate and the dowel falls out.

Explain why. Why does he suddenly fall out of there? Yes, and it won’t work with a big hammer (machinery hammer). You can see it in the photo. There is a pipe on top and the same pipe on the bottom. Access is limited! The grinder is also inconvenient.

If you try with a metal disc on a drill. Dangerous. Well, try it based on availability, and in general how it will be cut.

I don’t know why they fall out after that. I have a basement floor in my house. 5 windows, and two balcony blocks. All this was covered with iron and secured with such dowels. Not more than 3 weeks ago they came to me to install gratings instead of this task. So they also use a nail puller and a grinder. And there are a lot of windows, and also doors. In general, while they were fiddling with one dowel, I had already freed 2 windows. The guys' eyes widened! My base is made of concrete blocks. I don't know what kind of material you have. So, there are no funnels left, only the hole from the dowel. Why does it crash? Don't know. But it doesn’t fly out, you have to pull it out. And there’s no need to knock on it as hard as you can either! It’s easier for yourself: a heavy hammer - 2 hits, a light one - 4. Take any hammer. The dowel, apparently, is held in place only by friction, but we shake it a little and it falls out. If you pull it smoothly it won't come out. Try it - it's too simple to believe.

Plastic dowels

The most popular dowels today are plastic, nylon, or other soft, elastic material. They are available with different profiles, different depths of “spikes”; the best options have “whiskers” that fix the sleeve in the wall.

Such dowels can be easily removed with a strong corkscrew:

- Unscrew the self-tapping screw or screw that was mounted into the dowel.

- Turn the corkscrew clockwise, allowing the tip at the end to fit securely into the plastic dowel.

- Continuing to turn, pull towards yourself (sometimes you have to additionally swing the tool and dowel).

- The bushing will come out of the wall without collapsing it.

Plastic for aerated concrete

Conventional dowels are absolutely not suitable for this capricious and fragile material - you need those that have a larger contact area. This is usually achieved by "blades" that run in a spiral along the sleeve. You need to dismantle the Fischer type dowel for aerated concrete in the same way as a regular one: unscrew, pull and carefully loosen it.

Sequence of work

To remove the dowel from the surface, you need the following tools:

- screw or corkscrew;

- hammer, punch;

- pliers or pliers, nail puller;

- construction knife, chisel;

- soldering iron;

- Bulgarian.

Depending on the chosen method, you will only need those tools that will be involved in removing the item.

The wooden object is removed in parts. It must be broken into pieces using a hammer and chisel. Then take out the rest.

The plastic dowel is removed using a screw or a corkscrew. If that doesn’t work, you can make holes with a drill or cut off the cap and just leave it in the wall.

Metal rod. The part sticking out above the surface is cut off with a grinder. Or you need to tap milk on the protruding part from different sides. It will loosen and come out easily. The additional hole method is also applicable.

Metal

A metal dowel is also called an anchor or an anchor dowel. The difference is not so great: both fasteners have a sleeve/sleeve made of metal and having at least 3 “petals” that open and act as an anchor in the wall. The expanding element is either a regular screw or a special one, with a cast or removable cone - these are the most common options.

The main difference is that the dowel clings along its entire length, has spikes, whiskers, etc. along the entire length of the sleeve, while an anchor is usually called a smooth sleeve with an opening end.

How to remove the simplest expansion dowel:

- Knock out or unscrew a bolt or screw.

- Hook the edge with pliers, pliers or the like.

- Place the tool against the wall, or if the surface is fragile, such as tiles, against a stand (usually craftsmen take a hammer).

- Rocking, pull out.

Molly

Metal Molly dowels are compressed with a screw or special pliers so that the middle is flattened and unfolded in the form of petals. This allows you to distribute the load as much as possible and increase the strength of fasteners on hollow walls (for example, on hollow bricks, on false walls made of plasterboard), but it also makes dismantling impossible. When the screw is released and pushed, the “petals” do not straighten completely and tear in half.

Remove the dowel for the construction gun

If you look at fastenings from Soviet times, they almost certainly used dowels, reminiscent of a nail with a washer welded to them. They are still installed today, using a construction gun, but only in those places where they are not supposed to be dismantled. Neither doors, nor windows, nor radiators or plumbing fixtures should be equipped with these: today all these furnishings are considered replaceable.

Nevertheless. How to remove such a dowel? Three approaches are used:

- Hit the head 2-4 times with medium force (this will move the dowel out of place and it will lose its tenacity), then grab the head and, swinging, pull it out.

- Heat the fastener with a torch and let it cool (it will expand and push the concrete apart, then return to its previous dimensions) and pull it out.

- Use drill 6 as close to the dowel as possible, then squeeze a narrow tool (“crowbar” or the like) under the head and knock out the pin into the adjacent slot.

The best means

There are many ways to secure the mount. I advise craftsmen to wrap the dowel with a moistened plaster bandage or polyethylene, use wooden choppers, and fill a hole that is too wide with hot glue or liquid nails. Putty, epoxy resin, and repair cloth will securely hold the fasteners.

putty

Suitable if the funnel is large and the wall around it has cracks. It's better to take adhesive putty. After hardening, a dense plug is obtained. Moreover, it is easy to apply.

What should be done:

- Screw the screw into the dowel.

- Moisten the wall surface and holes with a spray bottle.

- Apply the prepared putty with a spatula if the hole is shallow.

- Remove excess.

- While the cork is still wet, place a screw in it.

To quickly fill deep holes, use a disposable syringe. The fastener can only be loaded after it has fully set.

Epoxy resin

Putty can be replaced with epoxy resin or glue. To make the mass plastic, add filler. What will suit:

- chopped fiberglass;

- fine sand;

- sawdust;

- ground cotton fiber;

- silverfish

The mixture should be viscous and elastic. Make small balls. Push them into the hole with the blunt end of a pencil or other suitable object.

Epoxy glue is best for metal dowels. It is degreased and inserted into the hole filled with mass. After this, the screw is screwed in. You can use the mount after 12 hours, when the glue has completely hardened.

Repair cloth

Designed specifically for cases where the funnel in the wall is too large for the dowel. Suitable for fastening in concrete, brick, aerated concrete. The round napkin is coated with a special compound. To make it work, wet it. Wrap the plastic mount and insert the entire structure into the funnel. After three minutes, screw in the screw.

How to remove an anchor

What is usually inserted into the anchor is not a screw or bolt, but a pin (the same bolt, only without a head) or a hook. A bolt is screwed into the frame anchors, at the lower end of which the expansion element is held using a thread.

In general, the anchor is pulled out using pliers:

- Remove the nut.

- Hit the pin with a hammer and push it deep into the hole.

- Grab the sleeve with pliers and remove.

- Unscrew the bolt.

- Use pliers or pliers to remove the anchor bushing.

- Insert the bolt into the vacated hole and turn clockwise to fit the wedge onto the bolt.

- Remove both elements.

If the bolt is rusty

If you cannot remove the bolt because it has oxidized, you should try to revive it. To do this, the parts are well moistened with a rust converter, kerosene or WD-40. Leave for the time indicated on the package or longer (up to half a day). During this time, the oxides should go away. After cleaning the bolt, you need to try to remove the nut or unscrew the bolt.

Important When unscrewing a rusty structure, you need to be extremely careful not to break the pin/screw.

If the bolt is broken or its spline is torn off

If you tighten a bolt, screw or screw too quickly or with the wrong screwdriver, it is easy to tear off its grooves. Less often, it happens that the head is torn off completely or partially - in particular, in an unsuccessful attempt to pull out the frame anchor without removing the conical “anchor”.

To unscrew a broken self-tapping screw or bolt, it is drilled out and a chopper (extractor: a wedge-shaped screw with a left-hand thread) fixed in a drill, screwdriver or pliers is driven into it. Then the entire structure is rotated counterclockwise.

Important: Never try to drill out dowels for a masonry gun. They are made of especially strong and hardened steel - if you break the drill, you risk being injured by splinters. Try knocking out such a dowel or heating it.

If the sleeve is installed incorrectly

The most common problem with anchor dowels is that they cannot be hooked onto the edge with pliers or even narrow-nose pliers. To avoid this, it is enough to install the anchor correctly: leaving at least 2 mm above the wall level. This length is enough to pick up the sleeve, but it is easily covered with plaster or any profile.

What to do if it is impossible to hook the sleeve:

- Screw the self-tapping screw between the sleeve and the stud and pull it out, if possible, grabbing the stud as well.

- Remove or push the pin/bolt, drive a self-tapping screw or other tool between the wall and the sleeve, tearing and bending the edge of the anchor. After this, pull the resulting corner of the metal.

- Drill out the top layer of the wall around the dowel to release the edge of the sleeve.

As a last resort, the anchor is cut with a circular saw and its parts are removed separately.

As a rule, metal dowels and anchors are installed where their dismantling is not required, but the load will be significant. In some cases, it makes sense not to pull out the sleeve, but to drive it deeper and cover it with cement or other mortar or a plastic / wooden block. In any case, there are no unsolvable problems: the dowel or anchor is almost always removed, it’s worth applying patience and effort.

Pulling algorithm

A protruding nail disrupts the aesthetic appearance, so it must be removed or hidden. When removing old fasteners from the wall, your wits and ability to use power tools will come in handy.

- The element that rises above the surface can be removed by rocking and unscrewing it. Loosen it with a hammer, hitting it on the protruding part from different sides. Then you should grab it with pliers or wire cutters and pull it out. It will not be possible to get it out if you pull it out of the hole using only translational force. If the fasteners are of significant size, it is advisable to use a nail puller, which will help remove them with less effort.

- Much more patience is required when it is necessary to remove a broken dowel if it is difficult or impossible to grasp or hook. The plastic case must be heated and melted with a hot soldering iron. This allows you to remove it from the wall using pliers or other similar tools.

- A metal tube, the diameter and length of which should be slightly larger than the fastener, often helps to get it out. It is driven in so that the bushing is inside. Then, at the same time, the nail should be pulled out.

- In the most hopeless situations, the dowel is removed with a hammer and drill. Using a drill of the required size, make several holes (recesses) directly around the socket. As a result, the strength of the nearby part of the wall decreases. The element can be easily removed with a suitable tool (pliers, wire cutters, etc.), then the surface is leveled with putty or plaster.

It is often necessary to remove the remaining plastic casing in the wall without a metal rod. Experts advise doing this:

select the appropriate self-tapping screw of the required size for the sleeve (about the types of screws for concrete), screw in three-quarters of the length, then loosen and remove; use a hand corkscrew to remove the dowel, carefully unscrewing it; if you can’t pull it out using the methods listed above, you should try cutting off the protruding parts with a knife, and hammer the rest into the wall; drill out the plastic bushing, selecting a tool of equal or larger diameter.

Before carrying out work, builders recommend assessing their feasibility. It is really necessary to think about pulling it out if you need to make a new hole nearby. For example, if you need to hang a new cornice in the same place, but the old fasteners do not fit.

The resulting depression, after you manage to remove the nail, will become large and will have to be sealed. To do this, you need to fill it with putty or plaster, apply a paint mesh, clean it, and level the surface with sandpaper after drying.

What to do if a dowel falls out of the wall?

The condition of the concrete does not always correspond to the required level, since low-quality mortar was used during construction. Interior partitions and window openings are made of material that, after decades, has become loose and free-flowing. In houses like this, nails fall out.

There are several ways to solve this problem:

- Drill a hole in the concrete, remove particles, fill it with liquid nails or epoxy glue. After thickening, install the dowel. Items can be hung after ensuring final curing.

- Screw a layer of electrical tape in the direction of the thread (ordinary cellophane will do), the resulting thickness should ensure a tight fit into the hole. Then drive the element into the plastic case, due to this it will expand, which will increase reliability.

- Wrap the dowel with a damp bandage (just wet it enough) until the required diameter is obtained and install it in the walls; you can immediately drive a nail. Use the fasteners for their intended purpose after the liquid has completely evaporated.

The main thing is to adhere to the rules that ensure reliability and durability during operation: make additional reinforcement, select an element with dimensions larger than usual.

| Articles |

Before finishing the walls, the surface must be carefully leveled, all protruding elements, nails, screws and dowels must be removed.

Getting the last element is very difficult, it is important to know the basic rules of how to do this. It will not be possible to pull out the dowel by hand; in any case, you will have to resort to using tools

How to get a dowel from concrete

Few people know how to properly remove an old dowel from a wall. The main thing is to try to choose a simple, reliable and economical method. Skills in installing and dismantling fasteners will help you achieve results; experience in using electric and hand tools will come in handy.

Several types are available specifically for concrete; they always use a nail as a rod. Reliable operation can be guaranteed if you are able to choose the right version based on the dimensions of the plane and the massiveness of the suspended structures, and perform high-quality installation.

Before starting work, you need to evaluate the quality and thickness of the surface. The presence of hidden electrical wiring and metal fittings is the basis for changing the location. Sometimes it is not easy to hammer in a dowel carefully without damaging the adjacent part of the wall.

The most commonly used options are:

You can insert the dowel using a drill with a hammer or hammer function, a concrete drill, or a hammer. Correctly perform the work in the following sequence:

- using a hammer drill, punch a hole with a diameter similar to the bushing and a depth exceeding the length of the fastener by 0.5 cm,

- clean the resulting recess from dirt and dust,

- fix the dowel body with a hammer until its edge aligns with the wall surface,

- hammer the nail into the body until it stops.

If you follow all the installation rules, it will be difficult to get it.

Pulling algorithm

A protruding nail disrupts the aesthetic appearance, so it must be removed or hidden. When removing old fasteners from the wall, your wits and ability to use power tools will come in handy.

- The element that rises above the surface can be removed by rocking and unscrewing it. Loosen it with a hammer, hitting it on the protruding part from different sides. Then you should grab it with pliers or wire cutters and pull it out. It will not be possible to get it out if you pull it out of the hole using only translational force. If the fasteners are of significant size, it is advisable to use a nail puller, which will help remove them with less effort.

- Much more patience is required when it is necessary to remove a broken dowel if it is difficult or impossible to grasp or hook. The plastic case must be heated and melted with a hot soldering iron. This allows you to remove it from the wall using pliers or other similar tools.

- A metal tube, the diameter and length of which should be slightly larger than the fastener, often helps to get it out. It is driven in so that the bushing is inside. Then, at the same time, the nail should be pulled out.

- In the most hopeless situations, the dowel is removed with a hammer and drill. Using a drill of the required size, make several holes (recesses) directly around the socket. As a result, the strength of the nearby part of the wall decreases. The element can be easily removed with a suitable tool (pliers, wire cutters, etc.), then the surface is leveled with putty or plaster.

It is often necessary to remove the remaining plastic casing in the wall without a metal rod. Experts advise doing this:

select the appropriate self-tapping screw of the required size for the sleeve (about the types of screws for concrete), screw in three-quarters of the length, then loosen and remove; use a hand corkscrew to remove the dowel, carefully unscrewing it; if you can’t pull it out using the methods listed above, you should try cutting off the protruding parts with a knife, and hammer the rest into the wall; drill out the plastic bushing, selecting a tool of equal or larger diameter.

Before carrying out work, builders recommend assessing their feasibility. It is really necessary to think about pulling it out if you need to make a new hole nearby. For example, if you need to hang a new cornice in the same place, but the old fasteners do not fit.

The resulting depression, after you manage to remove the nail, will become large and will have to be sealed. To do this, you need to fill it with putty or plaster, apply a paint mesh, clean it, and level the surface with sandpaper after drying.

What to do if a dowel falls out of the wall?

The condition of the concrete does not always correspond to the required level, since low-quality mortar was used during construction. Interior partitions and window openings are made of material that, after decades, has become loose and free-flowing. In houses like this, nails fall out.

There are several ways to solve this problem:

- Drill a hole in the concrete, remove particles, fill it with liquid nails or epoxy glue. After thickening, install the dowel. Items can be hung after ensuring final curing.

- Screw a layer of electrical tape in the direction of the thread (ordinary cellophane will do), the resulting thickness should ensure a tight fit into the hole. Then drive the element into the plastic case, due to this it will expand, which will increase reliability.

- Wrap the dowel with a damp bandage (just wet it enough) until the required diameter is obtained and install it in the walls; you can immediately drive a nail. Use the fasteners for their intended purpose after the liquid has completely evaporated.

The main thing is to adhere to the rules that ensure reliability and durability during operation: make additional reinforcement, select an element with dimensions larger than usual.

| Articles |

Quite often, when performing various types of repair work, you can stumble upon certain difficulties. It happens that a seemingly simple and understandable procedure causes a lot of problems. So, for example, not everyone can answer the question of how to pull a dowel out of a wall without preparation. The thing is that the design of this fastening element is precisely aimed at holding it firmly in the wall and preventing easy removal. However, there is a way out of the situation, and even more than one, which will be discussed further.