How to restore damaged

If the metal button has stopped performing its function and is constantly coming undone, a regular hammer can help. To do this, the convex part of the fastener is placed on a hard surface and blows are carefully applied, slightly flattening the “bump”. After each blow, you must try to fasten it. Once the fixation is secure, the goal is achieved.

The plastic fastener can be repaired using an iron, tracing paper or foil. To do this, cover the convex part with foil or tracing paper and melt it a little. After the plastic hardens, try to fasten it. You can correct the melted edges of the button using a nail file.

Varieties

Clothes buttons differ in the material they are made of:

- metal;

- plastic.

According to the method of fastening they can be:

- installation - secured using special tools;

- sewn - to attach them you need a thread and a needle.

Depending on their form, purpose and application, they are divided into:

- simple;

- s-shaped;

- shirts;

- magnetic;

- clasp;

- holsters;

- straps;

- tablet

O-shaped

The most common type of buttons is o-shaped. They are called simple, ring or flight, because the fastener first appeared on jackets and overalls of pilots. The design is not complicated and consists of two metal parts that fit tightly into one another. The upper component has a spring fastening.

Simple buttons are used both on different types of everyday clothing and on specialized textiles.

S-shaped

This type is of the spring type. One of the parts resembles the letter “S”, which is why they are called s-shaped. Depending on the size they are divided into several types:

- uniform - the size of the top ranges from 27 to 40 mm;

- article - half the size of the uniform;

- anorak - compact size;

- mini anorak - the upper part is less than 8 mm.

The shape of the top is varied - from flat and round to diamond-shaped, square, drop-shaped. They are fixed by sewing or fastening. The large spring allows it to withstand heavy loads.

Shirt

Shirt-type buttons differ from regular ones in the way they are fastened - not with a single pin, but thanks to 6-8 spikes. The design allows fastening fasteners on fabrics of light density. They are suitable for children's clothes, knitwear and knitted clothes, light summer jackets.

The devices are convenient to use, but quite expensive to manufacture. During installation, the material is pierced with spikes located on the ring. Their diameter varies from 9.5 mm to 40 mm. The largest ones are used on jackets.

Magnetic

Self-fastening magnetic fasteners are most often used in household products - bags, outerwear, wallets. They are convenient to use, but they are expensive to produce. The connection strength thanks to the magnet is high, and it is very easy to unfasten even with one hand. The magnetic button device includes four parts - two bases and the same number of mounting flanges. The magnet allows you to automatically select the position and close. The larger the fastener size, the greater the connection force.

Koburnaya

This type has another name - tablet. They have been produced since the times of the USSR, when they were necessary for fastening military haberdashery. The lower part of the structure is very similar to the part of the s-shaped device. The top of the lock is hollow inside, petal-shaped. Its size is 12 mm. When the button is fastened, it expands and contracts. Most often, the fasteners are nickel-plated, but they can have two more color variations - black and brown.

Options for attaching to clothing

In principle, buttons of any type and material perform one function. But to secure fasteners on things, two fastening options are used.

Sew-on method

Suitable for installation of two-piece fastener. They are sewn by hand in such a way that the seams are invisible from the front side of the items. Moreover, the top element of the button is installed first, and then the bottom one. Both metal and plastic products are used to decorate clothing:

- plastic components do not guarantee strong fixation and therefore are most often used as an auxiliary element. As a rule, they are very popular when decorating children's clothing. Also attached to the corners of the collars of men's shirts, to the straps under the fastener;

- metal sew-on buttons are used as fasteners for outerwear. For a fashionable wardrobe design, you can cover the buttons with fabric. If you choose textiles of the appropriate shade, then metal fasteners will be invisible on things.

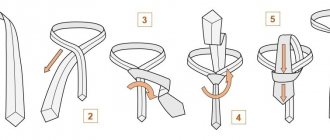

Installation of punch buttons

Widely used for sewing sportswear, outerwear, and denim products. The button set consists of two upper and two lower parts

During installation, it is important not to confuse: the “lid” of the fastener is located on the front side of the upper fabric of the item, and the “leg” is located on the back. And accordingly place the remaining two elements of the button on the bottom field of clothing

Before installing the fasteners, special holes are first made in the fabric. We must try to ensure that the diameters of the hole in the material and the leg of the button match or the hole is slightly smaller. The parts are secured with a special tool, which can be purchased separately or in a set with fasteners. The equipment is equipped with a special press matrix and special attachments - punches (of different diameters). At home, when installing buttons, craftsmen use an ordinary hammer, a Phillips screwdriver or dowel, a wooden block, pliers, or a knitting needle.