Strong-hold double-sided tape has a wide range of uses. It can be used in the automotive industry, at home, during construction and repair work.

- Properties

- Advantages and disadvantages

- Purpose

- Kinds

- Paper based

- From fabric

- Acrylic

- Polypropylene based

- Made from foamed polyethylene

- Popular brands of strong-hold double-sided tapes

- Recommendations for correct use

- Application

- Removing residues

- The best strong-hold double-sided tape: which one to choose?

Transparent adhesive tape is most often used in vehicle maintenance, when you need to secure many small elements without using nails and bolts. This article is about double-sided tape with enhanced fixation. It covers:

- properties of such adhesive tapes;

- their types;

- popular brands;

- recommendations for selection;

- instructions for use.

Properties

The technical characteristics of double-sided adhesive tape depend on the purpose of its use. It is usually used:

- For attaching decorations to a car.

- In construction, repair.

- For needlework.

Double-sided tape will eliminate the need to use screws, screws and other fasteners. Due to this, craftsmen are able to simplify the process of assembling the product.

Advantages and disadvantages

Advantages of double-sided tape:

- tolerates both low and high temperatures, ultraviolet radiation;

- resistant to oils, alkaline and acidic environments;

- has thermal conductivity;

- absorbs noise and vibration from impacts;

- distributes the load evenly throughout the entire seam;

- interaction with most surfaces;

- convenient to use.

Double-sided paper-based tape

The disadvantages of adhesive tape with increased fixation include:

- High price.

- Just one attempt to apply to the desired coating.

In case of an error, it is impossible to eliminate the curvature of the sizing - you will have to tear off the section and replace it with a new one.

Choice

From the many types, it is important to choose the adhesive tape that will best meet your requirements. Then the work performed using it will be durable and reliable. To decide which tape to buy, use the following recommendations:

- Double-sided tape with acrylic adhesive immediately provides excellent adhesion. It is recommended to be used for fixing mirrors, hooks, hangers, and information signs in public places.

- For smooth, flat surfaces, double-sided tape with a film base is suitable.

- When choosing adhesive tape, check the maximum weight and load it can withstand.

- For angular, rough, uneven surfaces, a tape with a rubberized base is more suitable.

Purpose

Construction double-sided tape is used to carefully glue materials together. The tape is positioned by manufacturers as universal. With it you can achieve a strong and high-quality connection of coatings to each other.

Manufacturers make such products using technologies developed specifically for gluing specific materials. For example, strong double-sided tape for plastic glues:

- steel;

- tree;

- glass;

- polyethylene;

- iron;

- acrylic;

- polyvinyl chloride

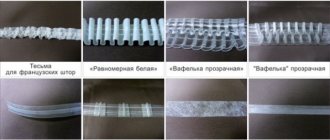

Kinds

Adhesive tapes are made depending on the nature of the planned work. They have different base materials.

Therefore, the properties and application completely depend on it. Let's consider their main classification.

Paper based

This is a tape coated with glue, on one side of which a paper coating is applied. Has medium intensity adhesive properties.

It is used to glue small objects with low mass. The cheapest type of double-sided tape.

From fabric

More durable, but not the most comfortable. The base is a fabric material that does not cope well with exposure to a humid environment. Upon contact with water, such a strip may fall off. Because of this, the quality of adhesion will suffer significantly.

It is characterized by strong fixation of glued objects in areas isolated from moisture. Can be used for sticking heavy products.

Acrylic

Double-sided automotive tape is used mainly in the field of auto tuning. The basis of this material is acrylic, which can provide fixation of the product.

The seams of this material are characterized by increased strength and reliability. The product can be used to repair the car body and its external elements. Acrylic is not afraid of water ingress and prolonged exposure to a humid environment. Therefore, it can be safely used for external repairs.

Polypropylene based

Helps to attach heavy elements to each other. They perform the finest work with glass and materials on which the appearance of extraneous adhesive traces is undesirable.

Manufacturers promise durable sizing that will not change under the influence of ultraviolet radiation, humidity and high temperatures. The seam is not afraid of temperature changes, so the material can be used in heat and frost.

Made from foamed polyethylene

Foamed polyethylene tape is the most rare. Few brands make it due to its narrow purpose.

Unibob double-sided adhesive tape is commonly found in hardware stores. The manufacturer positions it as a means for gluing glass and mirrors. The composition can withstand operation for a period of 3-5 years. This tape copes well with mechanical stress.

Popular brands of strong-hold double-sided tapes

The first place in the ratings of adhesive tapes is occupied by 3M double-sided tape. It is sold at a high price, which is compensated by good quality. Sold in hardware stores or household goods stores.

The composition is produced in roll format of different thicknesses and lengths. Manufacturers make them from: polypropylene, polyethylene, etc. Can be used mainly for tuning cars both in the interior and on the surface of the body.

Ultra-strong adhesive tape Flex Tape is also often found in online stores. It is sold at an increased price, starting from 950 rubles. For this money, the manufacturer promises durable bonding of different types of coatings.

How to remove double-sided tape?

The process of applying tape to a surface rarely takes the user a large amount of time, which cannot be said about the procedure for removing it. The rules for removing old tape depend on the material of the surface on which it is applied:

- First, you should try to remove the accessible part of the adhesive tape with your hands or scissors, and then try to remove traces of glue.

- It is easier to remove adhesive tape from paper or wallpaper if you heat it for a few seconds with a hair dryer or a regular hairdryer.

- Some types of tape can be removed by using masking tape that is applied over the top and then slowly peeled off.

- Fabric surfaces are cleaned with a cloth soaked in alcohol.

- Experienced housewives, advising how to remove double-sided tape from a plastic or varnished surface, recommend moistening it with sunflower oil and waiting 2-3 minutes. After this, the glue can be wiped off with a damp cloth.

- Another way to remove traces of tape from plastic is to use a regular office eraser.

- The painted wood is cleaned using a rubber attachment on a drill.

- A surface without paint can be treated with technical acetone or nail polish remover containing it.

Recommendations for correct use

In order for the material to adhere better and effectively perform all its tasks, you need to follow the instructions from the manufacturer. The method of using double-sided tape seems obvious.

However, you need to know a few nuances. Only correct application of the tape will allow it to last longer, firmly gluing products.

Application

To use double-sided tape, you need to work according to this plan:

- Providing temperature conditions. Manufacturers of double-sided adhesive tapes note that they need to be worked at a temperature of 20 to 40 degrees Celsius. Temperatures lower than 10 degrees are excluded.

- Pre-abrasive treatment. It will increase adhesion between surfaces. You need to work with fine-grained sandpaper. Then clean the surface with a solvent. You should not refuse abrasive processing because it will protect the metal surface from corrosion.

- Cleaning the work surface. Each of the connected parts must be cleaned with an alcohol solution. To do this, mix one part isopropyl alcohol and one part clean water at room temperature. Remaining solvent can be removed with a dry, clean cloth.

- Time for adhesion. For adhesion to become strong, you need to give it time. The minimum time required for this is about 6 hours, or 1.5 days. Moreover, the higher the temperature, the faster the materials set. Therefore, many craftsmen turn on heaters while working.

- Pressing on the surface. To improve adhesive properties, pressure is needed over the entire contact surface. The strip should be pressed with maximum force onto the surfaces to be glued. After connecting the parts, you need to briefly squeeze them together.

Removing residues

The easiest way to remove the adhesive tape is to stick a new layer on it. After a quick and sharp movement they come off together. In this case, there is a risk of damage to the paintwork, so you need to ensure that the separation angle is approximately 180 degrees.

If you don't have leftover tape in stock, you can simply heat up the excess to be removed. To do this, you can blow on them with a hairdryer on a hot setting. The remaining composition can then be wiped off with a lint-free cloth.

What is double-sided tape?

The familiar adhesive tape, which was quickly popularly dubbed scotch tape, was invented in America in the 1920s in a company that painted car bodies. It was intended to create a clear dividing line between two colors. The new product was quickly adopted by industrialists and office workers. It is not known for certain when double-sided adhesive tape appeared.

Double-sided tape is so called because both sides are covered with an adhesive composition based on rubber or silicone, which is hidden under a special removable protective strip until use. This product has many advantages:

- Ease of use. To connect parts, you just need to remove the protective layer and attach the tape to the desired parts.

- Reliability and durability. When used correctly, the parts are permanently connected to each other.

- Reasonable price.

- Resistant to ultraviolet radiation and moisture.

- Tightness of the connection.

- Economical consumption.

The best strong-hold double-sided tape: which one to choose?

How to choose double-sided tape? It's not difficult if you follow a few rules:

- We define the problem that the tape should solve. For example, inside a car you can use any option, even paper. On the outside, we recommend the best adhesive tape for this: polymer.

- The tape must be resistant to high temperatures and water. If the product does not cope with this, we recommend choosing a tape of a different brand.

- Storage conditions. When purchasing, read the manufacturer's instructions. The storage conditions for the composition are noted there. If the seller does not comply with them, there is a risk that the tape will not have sufficient adhesion and cannot be used effectively. It is worth studying advice on the Internet on driver forums.

Detailed review of reinforced adhesive tape in the video. Have you already chosen your favorite from its many brands? Share your experience with double-sided adhesive tape in the comments to the article.

How to peel off double-sided adhesive tape correctly so as not to damage the surface?

Sometimes it is necessary to remove the tape so that no marks are left on the surface. There are several ways to do this. A number of products may be required - gasoline, alcohol, oil, solvent. In some cases, a hair dryer and a rubber attachment for a drill will come in handy.

Sequencing

- Carefully pry off the tape using a knife or sharp blade. In some cases, already at this stage it is possible to remove the remaining tape. If this does not happen, use one of the methods described below.

- Buy a special disc designed for removing double-sided tape. It removes marks without unnecessary difficulty and effort, leaving no damage on the surface. If you often need to remove adhesive tape from products or packaging, such a purchase will quickly pay for itself - one disc lasts a long time.

- Moisten a rag with kerosene or white alcohol, apply and rub lightly. Carefully pick up the softened adhesive material and peel it off. Traces can also be removed with alcohol or kerosene. In some cases, to soften it, you have to rub it for quite a long time with a damp cloth. If you are removing marks from a paint surface, remember that white alcohol can darken it.

- Warm up with a hairdryer or rub until warm. Carefully lift the warm layer and gradually remove it from the surface. Next, you can remove all traces with a cloth soaked in alcohol.

- Use a special eraser. It is inserted into a screwdriver and all the tape is easily wiped off. Traces can also be removed with kerosene or alcohol.

- Vegetable oil can be used on some surfaces, but special care is required.

If it is important for you to preserve the surface and you do not know the chemical composition, and the above recommendations did not help, seek help from specialists. We will help you choose a removal method that will preserve the aesthetic and decorative properties of surfaces.

We are also ready to share with you other secrets of using the tape, tell and explain how to choose the best option in terms of cost and functionality. Call, write to us, we are always happy to communicate and have the opportunity to help you with your tasks and creative experiments.