The toilet is rocking - how to strengthen it + Video. Some of the plumbing fixtures, due to their long service life, begin to work worse than before. One of the most common troubles associated with the toilet is its unstable fixation, which makes using the device extremely inconvenient (there is a chance of falling). How to strengthen a toilet if it is wobbly? This can be done with your own hands, especially if you have at least basic skills in handling various tools.

Let's look at all possible ways to solve the problem.

Why does the toilet start to wobble?

How to strengthen a toilet if it wobbles? Before you figure out what to do if the toilet is crooked, you need to determine why this happens. There are several reasons:

- Uneven floor.

- Poor quality plumbing installation.

- The base of the toilet is uneven.

Let's look at possible defects in more detail:

- The second option provides for two types of flooring: concrete or wood. Often, it is on wooden floors that the fastening screws become loose, and the tightness of the fit inside the wood is lost over time.

- It is not uncommon for cracks to appear in the boards directly at the attachment points. This is perhaps the most common cause of loose toilets.

- If during the construction of a concrete floor some technologies were violated, then this is guaranteed to entail a violation of the fixation of plumbing.

- Differences in floor level and unevenness also lead to similar problems. Therefore, you should clearly know how to install a toilet on uneven tiles or other types of covering.

- As for old apartments, the weakest point in them is the mortgage board embedded in concrete. Over time, under the influence of moisture, its properties weaken, and the fixing bolts can no longer hold the device.

- The reasons for unreliable fastening are also related to the fasteners themselves. But here the main factor of failure is the poor quality of installation work. If you do not observe the ratio of holes and recesses, then problems will certainly arise soon. Therefore, the marking of fastening points should be taken as seriously as possible.

This is interesting: What should be the minimum depth of the sewerage foundation of the SNIP pipeline: Review

How to solve the problem with loose plumbing yourself?

How to install a toilet on a tiled, wooden and concrete floor? “Dancing” toilets are quite common. Such little things, as a rule, drive apartment owners crazy, making adjustments to everyday life. They make us nervous, irritate us, and some even drive us into hysterics. Therefore, such problems must be resolved promptly. Below we will look at how to solve such issues in cases with wood, concrete and tile floors.

Wooden floor

Your toilet is wobbly - what should you do if it's on a wooden floor? The answer to this question is very simple! It is enough to move it slightly and re-screw the screws, but in a different place. This process is greatly facilitated by a corrugated drain pipe.

Concrete floor

Fixing such problems when it comes to a concrete foundation is much more difficult. But anyone can cope with this. Thus, concrete floors with embedded boards are often found in buildings dating back to the existence of the USSR. To resume fastening, you need to perform a few simple manipulations:

- Clean your plumbing fixtures thoroughly.

- Turn off the cold water supply to the device.

- Remove the tank.

- Remove the sewer drain connecting pipe.

- Unscrew the fasteners.

Once the concrete is dry, follow these steps:

- Install the toilet, mark the points for its attachment.

- Make holes in the concrete using a hammer drill.

- Secure the device.

- Reinstall the cistern.

- Connect the water.

- Replace the sewer drain.

By doing this simple work, you will get rid of the problem. Pay maximum attention to the accuracy of marking the holes for placing dowels.

Ceramic tiles (video)

Situations when the toilet on the tiles wobble are no less common. We will find out what to do in this case further. The fact is that the device cannot be fixed reliably if serious mistakes were made at the stage of laying the tiles. Solving such a problem radically is perhaps the most difficult, because removing tiles is a rather labor-intensive process:

- Experts strongly recommend starting with the simplest option - using plastic pads, the thickness of which can vary. They will help eliminate the backlash.

- If this option turns out to be ineffective, you will have to re-lay the tiles and install the toilet.

Assembly and installation of the tank

Next we proceed to assembling the tank. For the tank we have a gasket that is inserted here:

Everything needs to be additionally sealed with sealant on both sides to reduce the possibility of leaks.

Here we insert the drain mechanism:

The drainage mechanism, as a rule, is already assembled. You just need to insert it.

Place the tank and tighten the plastic nut:

Now you need to attach this tank to the toilet.

For this, the kit also has its own fasteners, but you need to make no mistake - first there are plastic nuts, then a rubber cone-shaped seal, and before that you need to put this thick rubber seal under the tank:

Also be sure to apply sealant on both sides. After the seal is level, we place the tank on it.

The tank looks like this:

We set everything up evenly, carefully, check the holes and the fasteners that we assembled, and insert them.

Next from the bottom - again, make no mistake - first there is a rubber seal, then a plastic nut and finally a regular nut with which we tighten it all.

Technical nuances of plumbing installation

Before looking at repair examples, let's start with the basics. A correctly installed and secured new toilet is a guarantee of reliable operation for many years. There are several ways to attach a sink to the floor. And they all depend on the floor covering. The screw method is mainly used. But you can use self-tapping screws.

If drilling is not done carefully, the tile may crack.

If the floors are concrete, you will have to drill holes for the dowels. You will need a hammer drill with concrete attachments. In the case where ceramic tiles are laid on top of a cement coating, a hole in it is first drilled using a drill. And only then do they switch to a hammer drill.

When drilling a hole in a tile, use only a special nozzle. The rotation speed of the electric drill should be the lowest, the force on the device should be minimal.

Step-by-step screw fastening process

Using the set of screws that comes with the toilet, there is the following algorithm for installing and then securing the sink:

- The toilet base is installed on the floor in the right place.

- Through the holes for fasteners, places for recesses for dowels are marked.

- The sink is put aside and grooves are drilled in the marked places to a depth of 70 mm or according to the size of the plastic plug for the screw that will be used.

- If there is a tile on the floor, then an electric drill with a special drill is used to go through it. Only then can you use a concrete drill.

- Plastic dowels are driven into the holes.

- Then the corrugation is placed on the toilet and the mounting holes are aligned with the installed plastic plugs.

- Place plastic or rubber washers under the screws and tighten the anchors until they stop.

- Using a spatula, seal the gaps between the floor and the toilet sole (if any). You can use cement mortar or sealant.

The toilet can be used immediately after completion of the work.

Find out the causes of poor toilet flushing.

How to fix a toilet with side holes

There are sinks in which the mounting holes are not located vertically, but at an angle. This is designed to improve the overall appearance. The delivery set includes special fastenings at an angle of 90 degrees. This does not make the installation any more complicated and proceeds like the previous one.

Installing a toilet on an adhesive base

You can not use the factory fastening, but fix the sink using adhesive (without bolts). But then you need to check that the surface of the floor and the sole of the toilet bowl has no defects, that is, it is smooth.

After installing the toilet, additionally coat all joints with sealant

The process of attaching with glue comes down to:

- designation of the exact installation location;

- surface preparation (cleaning and degreasing);

- applying adhesive composition to the sole and floor;

- installation of the sink in a given place, according to the intended boundaries;

- removing excess glue.

After the work is completed, the structure must be allowed to stand for at least a day. This will allow the adhesive to completely harden.

Helpful information! Review of toilet cleaners.

Installation using taffeta

Taffeta is a lining made of durable wood that the toilet is attached to. The lining itself is used for installing plumbing fixtures on a wooden floor. Its thickness should be 25–30 mm. Having given the taffeta the desired shape (along the sole), the wood is treated with drying oil. This is necessary to protect the part from moisture.

The taffeta is firmly nailed to the floor in the intended place. Then the toilet is installed on it and secured through the holes with self-tapping screws.

To prevent the board from being conspicuous, cover it with tiles

There is a way to attach a sink using taffeta to a concrete floor. In this case, it is necessary to prepare a recess in the floor. The depth of the recess should allow the taffeta to be buried in it flush with the floor surface.

The gasket is first pierced through with nails in a checkerboard pattern. They will serve as reinforcement.

The excavation is filled with liquid cement mortar. Taffeta with nails is sunk into the solution and leveled with the floor. Excess cement mixture is removed. You must allow at least 12 hours of time before installing the sink on the taffeta.

If the work is done by a professional, then you won’t have to strengthen the toilet later. But you should consider the situation when the toilet wobbles not from the moment of installation, but after long-term use.

Methods of fixing the toilet and their features

There are three main options for attaching a toilet to the floor:

- strengthening using anchors embedded in the screed, or using dowels;

- installing the toilet on a wooden base pre-installed in the screed using screws;

- fixed with epoxy resin.

What is the best way to fasten during a major floor renovation?

If the toilet is being replaced during a major overhaul, then it is better to use the option with anchor fastening or with a prepared wooden base. In this option, at the stage of forming the screed, anchors are placed on the floor strictly in accordance with the placement of the toilet bowl and mounting holes. As a result, they should protrude above the surface by about 5-6 cm. It is better to cut off the excess later than to face the problem when there is not enough anchor to secure the nut on it.

The wooden board (taffeta) is selected according to the size of the toilet base. Nails are driven into it in a checkerboard pattern over the entire surface so that they protrude from the other side. After this, the board is turned over and installed in the future location of the toilet. Concrete is poured into the screed along with taffeta along its upper edge. After this, you can install the toilet in place and secure it with screws.

Mounting a toilet on a tile

When securing the toilet under the nuts for anchors and on the dowels, it is imperative to wear rubber gaskets, which will protect the toilet from cracking when tightened and prevent the formation of rusty streaks on the ceramics. It is best to use nickel-plated bolts and anchors so that after their service life has expired, they will still be easy to unscrew.

You can completely dispense with the use of screws, dowels and anchors. To do this, just take epoxy resin and properly prepare the surface of the floor and the base of the toilet. This option is best suited if the barrel is installed on a wall, because it makes up half the weight of the entire structure. First of all, you should go over the surface of the floor with an abrasive stone or sandpaper so that the epoxy resin will stick to the surface normally. After this, a layer of a few millimeters of glue is applied to the floor and toilet. Having installed everything in its place, you should wait until the glue dries completely.

Suspended solutions

It is gaining more and more popularity. The wall-hung toilet is installed on the wall without fastenings or contacts with the floor. In order to secure it, it is necessary to build a metal frame that is attached directly to the load-bearing wall, and the toilet itself to it in the event that the tank and pipes are supposed to be hidden behind a plasterboard wall. In some cases, a wall-mounted toilet with an open cistern can be attached directly to the wall, but then you will need to move the sewer pipe into the thickness of the wall. The fastening itself is done using anchors mounted into the wall or frame.

What do you need to have for installation work?

Before fixing the toilet to the floor, you need to make sure you have all the tools. In addition to plumbing equipment, to work you need to have:

- corrugation;

- drill;

- screwdriver;

- pencil;

- silicone sealant;

- putty knife;

- traffic jams;

- wrench;

- water hose;

- core;

- winding for thread;

- drill bit with pobedite tip;

- glass drill.

Read: how to clean suede shoes so that they maintain their impeccable appearance longer.

What to do if the toilet becomes loose during use

When a toilet wobbles on a tile or wooden floor, you need to carefully inspect the structure to find the cause of the play.

There are three reasons why a sink sways:

- Uneven floors.

- Defects on the sole.

- Poor quality installation.

Wooden floors can sag over time. Cracks that appear in them will cause backlash. But as for unevenness on the concrete floor or tiles, this already refers to poor quality work when installing the sink. This also applies to sole defects.

If you do not use rubber washers to secure the bolts, the sink will crack and the reliability of the fasteners will be compromised.

Surfaces must be prepared. Floors and tiles are leveled until refacing work is carried out. The toilet seat is worn down.

Poor installation can occur if you use an unreliable fastener. Anchors that are too short will cause the structure to become loose over time.

There are several ways to “fix” a structure.

Healthy! Tablets for the toilet cistern.

On a wooden floor

It is necessary to unscrew the fasteners and move the sink slightly to the side. This will be enough for the screws to hit the undamaged board. New fasteners are carried out according to all rules.

Never try to tighten loose screws. This will damage the integrity of the sink body.

On the concrete floor

If a backing board has been used on a concrete surface and it has become unusable, experts advise removing it. It is necessary to dismantle the equipment by first turning off the water supply and removing the drain tank.

The damaged board is removed from the floor and the hole is concreted. The surface is carefully leveled. The time required for the solution to harden is maintained. Then carry out the work described in the paragraph on fastening with screws.

Find out how to eliminate sewer smell.

On a ceramic floor

When play occurs on a tiled floor, this indicates that the tiles are not laid evenly. Experts advise using various gaskets. The best material is made of plastic, varying in thickness. The correct size is found experimentally.

To avoid re-tiles, concrete the area under the toilet

But if the method does not work, then you will have to reposition all the tiles in the room.

Silicone sealant can help secure the toilet so it doesn't wobble. It is applied to the location of the bowl and left for a day. The plumbing is then reattached.

This is interesting: What can you use to make a septic tank for your dacha with your own hands? Selection criteria - Instructions

Some problems

Sometimes, after a couple of years of service, the toilet loses its original appearance. Traces of rust appear on it. This happens due to low-quality components of the tank. It is almost impossible to eliminate an old phenomenon of this type, especially if the unit is made of sanitary ware. When purchasing toilets, you must carefully monitor the quality of all components.

Water may damage the unit. The quality of water, as a rule, does not meet the standards to which units of Western brands are developed.

Sometimes the plastic elements in the tank design do not hold up. They can bend due to temperature changes or mechanical stress. If the tank fails prematurely, this indicates that the quality of the kit was not very high to begin with.

Problems with water flow often indicate that the float valve is not installed correctly. You need to adjust it, and the water consumption will be reduced.

In order for the toilet to retain its original appearance for many years, it is necessary to constantly keep it clean. You can use a number of products to care for it. For example, to avoid having to constantly wash and clean the inner surface, various gels and tablets are used today.

Baking soda and vinegar are indispensable tools for cleaning your toilet. If red stripes begin to appear on the surface of the unit, they can be eliminated with a solution of vinegar in hot water. Baking soda will gently and carefully clean the surface of dirt.

For severe contamination, use special solutions. They usually contain hydrochloric acid. There are different types of contaminants, so the range of cleaning products is also very wide. When purchasing, you need to clarify whether a specific composition is suitable for the product. They differ not only in the nature of the impact, but are also produced for toilets made of certain materials.

During a major overhaul or due to a plumbing failure, it is most often necessary to replace the toilet. In order for everything to go smoothly, you should take into account a number of features of this process and correctly approach the choice of a new toilet. To carry out all the work, you can seek help from the plumbers of your housing office or from private craftsmen who will perform all the necessary operations. However, installing a toilet yourself will save a lot of money, and understanding the whole process will help you choose the best option and installation method.

A complete toilet replacement is part of a major overhaul and includes the following items:

- – choose a new toilet according to the mounting method and flushing method;

- – dismantle the old toilet;

- – repair the room (replacement of cladding, screed, sewer pipes, etc.);

- – installation and connection of a new toilet.

It is very important to select and purchase a new toilet in advance. This takes into account a number of features and nuances.

How to attach with sealant - instructions

Materials:

- Transparent sanitary silicone sealant, it is sold at any hardware or construction store. If you do not have a special gun, buy this sealant in a regular tube. Applying it from a tube is not so convenient, but it will not affect the result in any way;

- Gun for glue and sealant 330 ml. (not necessary);

- Scraper for removing excess sealant. If it is not there, you can adapt cardboard for these purposes by cutting out a convenient piece;

- 2-3 household disposable towels, can be replaced with napkins or rags;

- Approximately 100 grams of vodka or alcohol;

Wipe or mop the floor around the toilet to ensure there is no dirt or debris.

Take a disposable towel, wet it generously with vodka or alcohol and wipe the joint between the toilet and the floor well

Take the sealant and carefully pour it into the gap between the toilet and the floor around the entire perimeter.

sealant mounting

The most important thing is that the sealant fills the entire gap. If it doesn’t turn out very neatly, don’t worry, excess sealant can be removed with a disposable towel until it dries

Remove excess sealant using a special scraper (or any available tool). Wipe the sealant off the floor with a disposable towel if it is spilled or smeared during application.

It’s okay if it doesn’t turn out quite smooth, the sealant will smooth out the unevenness as it dries.

Do not use it for 2-3 hours to allow the sealant to dry thoroughly. This is what the final result looks like. The toilet is now securely fixed and will never wobble again.

Video: What to do if the toilet wobbles and dances?

Method No2. How to fix a toilet with glue

This method is almost as popular as the previous one. For fixation in this case, use a special construction adhesive (you can buy it in a specialized store) or a mixture prepared with your own hands from epoxy resin. In addition, toilets are often secured with simple silicone sealant.

How to fix a toilet with glue

- Reliability. A device fixed with glue/sealant will definitely not wobble.

- No dirt, dust. Therefore, there will be no need to clean up after the work is completed.

- Easy to install. To work, you do not need to have any serious knowledge or experience. You just need to know how to work with a glue gun.

- Safety. By attaching a toilet with glue, you do not risk damaging its bowl.

Do not forget that this method also requires some patience - it will take 12-24 hours for the glue to dry completely (which means you cannot use the toilet during this time).

Epoxy is the best adhesive for toilet bowls

To secure the plumbing fixture, prepare everything you need, namely:

- roulette;

- silicone-based sealant or glue;

- square;

- ammonia;

- marker;

- sandpaper;

- spatula (you will need a narrow one);

- a spray bottle filled with soap solution;

- a rag.

Installing a toilet: a – preparing the installation site; b – preparation of the base; c – coating the bottom of the toilet with glue; d – installation of a toilet; d – installation of the tank; e – sealing of the socket; g – connecting the tank to the water supply network; h – adjusting the water level in the tank; and - a fully installed toilet

After preparing everything you need, follow the step-by-step guide below.

Step 1. The toilet is tried on - placed on a pre-placed cardboard so as not to damage the floor covering. The convenience of the device is checked, how best to connect it to the sewer/water supply.

The toilet is being tried on

Step 2. The product is centered, for which you can take a tape measure or a corner. The distance to the walls on the right and left is indicated.

The distance is indicated on the left. The distance is indicated on the right. The toilet is centered.

Step 3. The cardboard is removed from under the toilet. The device is aligned with the walls of the room, for which you will need, as in the point above, a tape measure or a corner.

The product is re-leveled

Step 4. The part of the bowl that will be in contact with the floor is outlined with a marker.

The contour of the support is outlined

Step 5. The edge of the support is cleaned with sandpaper or a knife. It should turn out perfectly smooth - this way the adhesion to the glue will be maximum.

The edge of the support is cleaned

Step 6. Where the toilet will be installed, the tiles are treated with ammonia to degrease. Then wipe dry with a microfiber cloth.

The tiles are degreased

Step 7. Sealant or glue is applied to the edge of the support

It is important to correctly calculate the amount of adhesive, because if there is too much of it, you can stain the tiles, and if not enough, then the attachment of the toilet to the floor will be fragile

Glue is applied to the edge of the supportThe adhesive composition is applied

Step 8. After treatment with glue, the toilet is brought into the toilet and carefully placed in the place that was marked at the beginning of the process. It is better to do this with an assistant, so as not to stain the tiles with glue and not to install the product crookedly.

Installing a toiletIt is advisable to do everything with an assistant

Step 9. The floor around the support is sprayed with soapy water. This will ensure that any excess sealant that needs to be trimmed away will not stick to the tile.

The floor around the support is sprayed with soapy water

Step 10. A spatula is moistened in a soapy solution and used to remove any remaining adhesive.

Residues of glue are removed with a spatula. Residues of glue or sealant must be removed immediately after attaching the toilet to the floor in order to prevent the composition from drying out and staining the tiles.

Step 11. After some time - on average, 12-24 hours - the glue or other composition used to fix the toilet will dry. The product must not be used or moved during this time.

Step 12. Now, after the glue has completely dried, work can continue. It is connected to the sewer network, a tank is installed and connected to the water supply, a seat with a lid is installed, etc.

The toilet is wobbly: instructions for fixing it

1. Wipe or mop the floor around the toilet to ensure there is no dirt or debris.

2. Take a disposable towel, wet it generously with vodka or alcohol and wipe the joint between the toilet and the floor well:

3. Take the sealant and carefully pour it into the gap between the toilet and the floor around the entire perimeter. The most important thing is that the sealant fills the entire gap. If it doesn’t turn out very neatly, don’t worry, excess sealant can be removed with a disposable towel until it dries:

4. Remove excess sealant using a special scraper (or any available tool):

Wipe the sealant off the floor with a disposable towel if it is spilled or smeared during application.

5. It should look something like this:

It’s okay if it doesn’t turn out quite smooth, the sealant will smooth out the unevenness as it dries.

6. Do not use the toilet for 2-3 hours to allow the sealant to dry thoroughly. This is what the final result looks like:

The toilet is now securely fixed and will never wobble again.

Good luck to you!

Every time you share this article on social media, the author becomes a little happier! Please click on one of the buttons above!

Root Causes of a Swinging Toilet

There are only three reasons that over time lead to deterioration of stability and unexpected dances of the toilet bowl:

- Irregularities of surfaces when comparing them. (floor, toilet base)

- Loosening of toilet fasteners. (negligent installation).

- Time factor.

Uneven floors and areas under the base of the toilet are typical when plumbing fixtures are installed on a concrete floor, or on a floor covered with linoleum. A difference in height even on such a small plane will lead over time to weakening of the fixing elements. In modern apartments and houses, this reason is offset by the fact that the floor in the toilet is often tiled. Proper installation of which creates a perfectly flat surface.

Loosening of anchor bolts in cases where short fixing bolts are used, loosening of the floor-mounted part of the bolt, or “tearing out” even minimally (a few millimeters) will lead to play in the fasteners.

The last, in fact, the most important reason will be the time factor. A toilet securely fixed to the floor is subject to multidirectional displacement forces. Forward, backward, lateral loads. When a person sits down or gets up from it, he tries to reach something without getting up from the toilet. Even the strongest fastening will weaken over time, the toilet will wobble and “dance”.

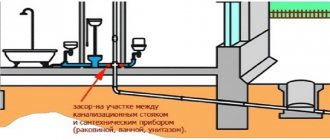

If the repair of a wobbly toilet is delayed, the decrease in the reliability of its fastening will increase over time. It is fraught with damage in the form of:

- ceramic cracks;

- leaks in the area where the flush water is supplied;

- leak at the connection with the sewer pipe;

Effective ways to install and secure plumbing fixtures to the floor

Problems with toilets being unstable are quite common. On the one hand, this is a trifle, but if it is not corrected in time, it can cause a complete breakdown of the plumbing. If you don’t want to be left without the main item in your home at some point, you shouldn’t put off renovations. Correction or reinstallation of toilet equipment is necessary based on the characteristics of the floor covering.

Tools and materials

Depending on the method of installing the toilet, you need to prepare a certain set of tools and materials. If the compact is planted on ceramic tiles using sealant or glue, then the following items will be needed:

- sealant or glue and a gun for them;

- scraper for removing excess material;

- unnecessary but clean rags or paper towels;

- alcohol.

If the toilet “sits” in a different way, then you need to prepare:

- hammer drill with drill;

- tile drill;

- drill;

- mounting screws, which are usually included with a new toilet, but you can buy them separately;

- sealing fluoroplastic tape (FUM);

- adjustable wrench;

- Screwdriver Set;

- rubber hammer;

- cement mixture;

- marker;

- roulette.

When planting a toilet involves replacing communications, you must also have on hand:

- flexible hose for cold water supply.

- ball valve;

- corrugation for connecting the toilet outlet to the outlet pipe;

Having everything you need, coping with the task will not be difficult.

Mounting on a wooden floor

When the toilet began to rock on the wooden floor, it would be more rational not to install it in the same place, but to move it a little to the side. First, place the device in the chosen place. Through the holes in its base, marks are made for the holes on the floor. They are drilled, the equipment is installed and securely secured with screws.

Mounting the toilet on a wooden floor

On a wooden floor, do not tighten the fasteners too much, because... this may cause the device to crack. In this case, it is better to make the connection to the sewer flexible.

Securing the toilet to a concrete floor

Concrete floors with embedded wood planks are relics of the past, but such rarities are still found in some apartments. Reinstalling the toilet in such cases is difficult, but it is possible even on your own. To resume fastening, you need to perform several steps.

- Shut off the water supply to the tank.

- Remove the tank.

- Disconnect the supply pipe from the sewer drain.

- Unscrew the fasteners.

After the toilet is dismantled, you need to remove the old covering, and in its place install new boards and fill it with concrete. You can simply clear and concrete the entire space, leveling it. When the solution has hardened, begin installing the toilet. To do this, place it in the desired area and mark the attachment points. Holes are made with a hammer drill, the device is placed and secured with bolts. The drain tank is connected and communications are connected.

Installation on ceramic tiles

If the toilet swings on the tiles, then you can solve the problem without removing the floor covering. The step-by-step planting method is as follows.

- The toilet is placed in the right place and the outline of its base is drawn on the floor.

- Inside the outlined outline, notches are made on the tile using a chisel.

- Prepare a cement mortar as thick as sour cream. Usually cement and sand are mixed in equal quantities, but the second component can be taken to a minimum.

- The tile and the cutout area are moistened with water. The same is done with the base of the toilet.

- Cement mortar is applied to the cutout, on which the equipment is then placed.

This installation has its advantages - the absence of complex devices. The disadvantage is that you can use the installed toilet only after a day.

Do-it-yourself high-quality repair of a swinging toilet

There are several options for eliminating a wobbling toilet:

- Emergency, short-term.

- Complete renovation work.

Emergency measures should be resorted to only when a toilet leak is first detected. Temporary placement of fixing wedges formed between the floor and the base of the toilet. Plastic, wooden.

It is strictly forbidden to overtighten the mounting bolts. Since earthenware is very fragile.

This will allow you to eliminate the instability for a short time, and plan for a period of complete repair work. Which step by step looks like this:

Before starting work, you should clear out the toilet room as much as possible, or the space around the toilet in the case of a bathroom combined with a bathroom. Don’t forget to turn off the water supply to the flush tank and be sure to drain the water from it.

We loosen the fastenings of the toilet to the floor. If they are clearly loose, it will be necessary to completely unscrew them, deepen the screw-in point, and then replace the dowel anchor with a longer one, or strengthen the existing plastic plugs in the floor by replacing them or filling them with glue.

Before the next step you will need substitution wedges. The material of manufacture is not of fundamental importance. They should be at least 10 centimeters long, up to one and a half to two centimeters thick, and up to 0.5-1 cm high in their widest part. It will be convenient to make wedges from a block of a suitable size. You will need four pieces in total.

Carefully lifting one edge of the toilet, we place a pre-prepared wedge under its base. We carry out the procedure from four opposite sides of the base.

We carefully place the wedges under the toilet so as not to damage it

Important! Before lifting the toilet, make sure that the sewer drain (often made of corrugated material) and the tap water supply pipe allow this to be done. In other words, there are no additional hard points for fixing the toilet to the floor or wall.

If the work is done correctly, a gap of up to 10 mm should form between the toilet and the floor. And at the same time, the toilet stands stably on the substitution wedges.

This is followed by a thorough cleaning of the area under the sole area of the toilet base. We clean from sand, dirt, and remnants of previously fixed glue.

Cleaning the area under the toilet

If a clear defect is visible - unevenness of the floor, then complete dismantling of the toilet will be necessary to level the floor area under the base using sand-cement compounds. After completing the work, be sure to give the applied solution time to dry completely.

Using a silicone adhesive sealant, we apply a filling layer under the base of the toilet using a construction gun.

We glue with tape the places that do not need to be dirty and coat everything with glue-sealant

Comfortable! To avoid unnecessary contamination of the floor with adhesive. Around the contour of the base of the toilet, retreating 0.5 cm, use construction paper tape to outline the contours. It is advisable to use adhesive tape at least 2-3 centimeters wide.

We carry out subsequent work as carefully and quickly as possible. Having the opportunity to remove excess glue before it is completely cured.

Carefully pull out the wedges sequentially. By tightening the fixing bolts, we ensure that the sealant is sealed under the toilet so that an adhesive layer of up to 2-3 mm is formed between the floor surface and the base of the toilet. thick.

Remove excess squeezed out glue with an elastic rubber spatula. Carefully wipe the ceramic base if it becomes dirty.

Do not rush to remove the tape pasted around the base. Allow the adhesive to set.

Important! Subsequent use of the toilet is limited by the time it takes for the adhesive-sealant to completely dry, depending on the type used and the time specified in the instructions. It is preferable to use silicone adhesive-sealant due to its: high adhesion, ease of use, elastic properties, reliability, moisture-heat resistance. If you use the toilet earlier, it will wobble and “dance” again.

After final drying, you should slightly tighten the bolts securing the toilet to the floor. In this case, we check the horizontalness of the installation using a building level. The tightening force of the fastener must be commensurate with the reliability of the fixation. We remember that ceramics are very fragile and cracks may form.

Before turning on the water supply, you must ensure the integrity of the drainage joint and the tightness of the sealing rubber. If necessary, we treat the joints with a sealing compound.

If a toilet is installed in a bathroom for the first time, the procedure for fixing it to the floor will be similar. This installation option guarantees long-lasting, strong, reliable fixation of the toilet to the floor.

It is worth mentioning once again about compliance with safety regulations when carrying out construction and repair work. Be sure to shut off the tap water supply to the toilet. Drain the water from it. When using power tools, if necessary, follow the rules for safe handling.

As you can see, the volume of work carried out is not large, limited only by the drying time of the adhesive mixtures and the availability of construction equipment. But the value is high. A firmly installed toilet will save the nerves of the residents of the house and will avoid possible flooding.

Installing a toilet on tiles using cement mortar

Installing a toilet on tile using this method is not the best option. It is suitable for cases when the toilet is installed in place of a dismantled one or when installation tools are not available.

To attach a toilet to a tiled floor without drilling using cement mortar, you need the following tools:

- cement mortar or cement-based tile adhesive;

- marker or pencil;

- hammer;

- spatula (narrow and medium);

- chisel.

Before you begin, you need to roughly check the joints of all installation elements by installing the device in the intended location and connecting all the necessary plumbing elements. Then you need to outline the base with a marker or pencil. Using a chisel, it is necessary to apply notches at the marks.

The next step is to prepare the cement mortar; the cement mortar is diluted 2:1. The cement mixture contains large admixtures of sand, which can affect hardening. It is best to use a ready-made mixture of tile adhesive, as it is much more reliable and dries faster. Calculate the preparation of the solution for 4 kilograms.

Once the mixture is prepared, it should be carefully applied to the notched area. Before gluing the toilet to the tile using the resulting composition, you need to moisten the surface a little. The base of the device’s leg must also be moistened and installed in the place allocated for it.

On the front and back sides, plastic plates must be placed under the base, the thickness of which should be 5 mm and the width 50 mm

The base of the device’s legs must also be moistened and installed in the place allocated for it. On the front and back sides, plastic plates must be placed under the base, the thickness of which should be 5 mm and the width 50 mm.

Remove excess solution using a spatula. After drying, it is necessary to remove the pads and concrete the holes from them with the same solution. Do not use plumbing fixtures for 5 days.

If in the future you want to dismantle it, this will happen by splitting its base. This means that it can no longer be reinstalled.

Safety precautions

In conclusion, some advice from the experts. They will help those who decide to eliminate all defects on their own. Following these recommendations will help you avoid accidents that could result in serious injury.

Experts advise:

- During any plumbing work, turn off the water supply to the apartment. This will save you from flooding in the event of an emergency.

- Use special clothing. Hands must be protected from cuts by wearing work gloves. There are always bacteria in the sewer system, which, if they enter the bloodstream, can cause serious infection. It is better to work in uncomfortable gloves than to lie in the hospital for a long time.

- When working with a hammer drill, use safety glasses, or best of all, a plastic shield that covers the entire face.

- Smoking and using open fire is prohibited. Sewer vapors are very volatile. Ignition can occur at any time.

- It is recommended to plug the drain hole with a rag. This will help avoid poisoning from inhaling its vapors.

Larisa, June 3, 2022.

- My piece of paradise. How to create a landscape design on your personal plot with your own hands?

- How color changes the mood of your home, experts say

Features of plumbing installation

Plumbing fixtures, and in particular the toilet, are installed based on the installation instructions that are included with purchase. During construction or major renovations, such work is carried out by professional plumbers, but in the future, after moving in, most residents want to make their own adjustments to the arrangement of the sanitary unit, so they replace the original toilet with a new one that they bought themselves.

In order to carry out such work efficiently, it is imperative to know what methods there are for securing the device to the floor covering, as well as how to use them correctly. All features of the installation of a plumbing fixture will be directly related to the configuration of the plumbing fixtures. As a rule, in a household sanitary unit they use only compact models that are installed on the floor, and the mounting of such devices varies.

Why does the toilet become loose?

Before fixing the device to the surface of the floor covering, it is imperative to determine the reason why the plumbing is loose.

There are usually several reasons, but they can be combined into the three most basic and popular:

Uneven floor covering.- The plumbing is installed, but with errors.

- There are irregularities and defects on the bottom surface of the bowl.

The flooring in the sanitary area usually has a concrete base, but there are also options with wood finishing. Due to the loss of tightness of the fastening screw during operation, the fixed toilet on the wooden floor begins to loosen, and sometimes cracks appear in the areas where everything is attached with screws. This is what most often results in loss of stability.

Also, sometimes the surface of the concrete screed is poured, but with some violations, which can lead to deformation and a difference in floor level in height. This causes the toilet to start “walking”. In special cases, the cause of unreliable fastening may be failure to follow the technology for installing a plumbing fixture.

Installation with adhesive composition

The use of glue ensures maximum convenience and ease of installation. Using adhesive solutions, work can only be done on smooth surfaces, so it is better to mount the toilet to the floor on tiles. This requirement is due to the fact that connection to an uneven surface will not provide reliable adhesion of the plumbing fixture due to the thin adhesive layer.

Epoxy-based adhesive is used for installation. There are two options for preparing the solution:

- purchase of ready-made mixture;

- preparing the mixture yourself.

Factory-made epoxy compounds are diluted with water strictly according to the instructions on the packaging. Failure to comply with the manufacturer's recommendations will lead to a violation of the characteristics of the solution. To save money, the toilet is attached to a hand-made solution. To do this you will need to prepare the necessary components:

- epoxy resin ED-6 (take 100 parts);

- cement (take 200 parts);

- solvent or plasticizer (take 20 parts);

- hardener (take 35 parts).

A modifier is introduced into the resin heated to 50-65ᵒC, after which a hardener is added. The last component of the mixture is cement and the composition is thoroughly mixed. Heating the epoxy resin is done in a water bath.

The toilet bowl is fastened to the floor only using a proven adhesive mixture that meets the requirements. The lifespan of the solution (the time during which the mixture is used) is 1-1.5 hours.

There are hidden fastenings (no glue)

To secure the toilet to the tiled floor, work is carried out in the following order:

Cleaning the floor from dust and other contaminants

You also need to clean the plumbing fixture from dirt, paying especially careful attention to the base. The tiles are cleaned to increase adhesion (adhesion to the surface). To ensure reliable fixation, the tiled surface is made rough. Surface degreasing

For this step, use a solvent or acetone. Preparation of adhesive solution. After completing the preparations, you need to secure the toilet. To do this, the adhesive composition is applied to the base of the plumbing fixture, and the fixture is installed in the design position, aligned with the pipes. The adhesive layer is assumed to be 5 mm.

It will take 12 hours for the adhesive solution to harden. During this time, you cannot connect plumbing or touch the device. If possible, wait longer, after which you can connect the device and use it.

- you need to quickly install the fasteners for the toilet (there is no time to wait for the solution to harden);

- fixing the toilet with minimal effort;

- the base for the plumbing fixture is level, without slopes or differences.

If the last condition is not met, flushing problems will arise during the operation of the plumbing fixture.

This method provides reliable fixation for lightweight models of plumbing fixtures. To distribute the load, the toilet is installed on the tile using a gasket. The gasket for the device is made independently:

- find a piece of old linoleum or rubber;

- You need to place a toilet on the material and trace the outline of the base with a marker;

- The gasket is cut along the contour with a knife or special scissors.

Dowels or bolts for attaching the toilet to the floor are included in the kit sold along with the plumbing fixture. In addition to these fasteners, long metal dowels are used, and the quality of fastening does not suffer. Work order:

- Marking the installation site. The use of fasteners requires precise installation and marking. Before attaching the toilet to the floor, place the device in its installation location and trace the outline with a marker.

- The second stage of work is to lubricate the floor covering with sealant and attach the manufactured gasket.

- Preparing holes for fastening. They should be slightly wider than the diameter of the dowels. This will ensure ease of installation of the device.

- Fasteners are driven into the prepared holes.

- Next you need to correctly install the plumbing and screw it on. The fasteners are tightened carefully; if you tighten them too much, the ceramic from which the device is made will be damaged.

- Connecting the toilet to the sewer.

If there are several plumbing fixtures in a house or apartment, a toilet stand is required. It is needed to ensure a difference in height when water moves in the pipes. To do this, use a board 32-40 mm thick, from which a stand is cut out according to the shape of the base of the plumbing fixture. The part is placed on the floor under a rubber backing.

On some surfaces, a substrate is used for fastening

Reasons for a loose toilet

Before fixing the device to the flooring surface, it is important to determine the reason for the loosening of the plumbing fixtures. There are usually several of them, but they come down to three main ones:

- uneven floor coverings;

- plumbing installed with errors;

- defects and irregularities on the bottom surface of the bowl.

Bathroom floors are usually covered with a concrete base, but there are also wood options. Due to the loss of tightness of the fastening screws during operation, a toilet mounted on a wooden surface begins to wobble. Sometimes cracks form where the screws are attached to the boards. This is what most often causes loss of stability.

Sometimes the surface of the concrete screed is poured in violation. This leads to deformation and differences in floor height. This also makes the toilet “walk”. In some cases, the cause of unreliable fastening is non-compliance with the toilet installation technology.

Useful tips

Plumbing materials, despite their strength, are very fragile. Therefore, maximum force should not be used when securing with screws or bolts. To reduce pressure, softening pads must be placed under the screw heads.

Important!

When using glue, you need to thoroughly degrease the surface. If epoxy resin is used for fastening, the proportions of solvent and base substance are strictly observed. The surface is covered with adhesive evenly, without the formation of bubbles.

Instead of wood, you can use high-quality multi-layer plywood as “taffeta”. It is important to ensure high-quality waterproofing so that the lining does not collapse prematurely.

Securing the toilet to a concrete floor

It is much more difficult to fix the problem if the flooring has a concrete base. In old buildings from the USSR, the devices were installed on concrete floors with embedded boards. In this case, to improve fastening, perform the following steps:

- Shut off the water supply to the toilet.

- Dismantle the drain tank.

- Disconnect the sewer drain pipe.

- Remove the bolts securing the plumbing fixtures to the floor.

Important!

Further work is carried out carefully so as not to damage the fragile material of the old toilet.

To eliminate the damage, the old backing board is removed and new lumber of considerable thickness is laid in its place. You can simply clear this place and concrete it.

After the concrete has hardened, plumbing installation is carried out in the following order:

- Having placed the toilet in the desired area, mark the points where it will be attached.

- The plumbing fixtures are removed and holes are made in the marked area using a hammer drill.

- The device is secured with bolts.

- Reinstall the drain tank.

- The plumbing is connected to the sewer pipes using a corrugated line.

Fastening plumbing fixtures to a wooden floor

If the bathroom floor is made of wooden planks, the loose plumbing fixture is not fixed back in its original location. It is correct to move the device slightly to the side and screw it in a new place. In this case, it is recommended to drill holes for reliable fixation, the location of which coincides with the mounting holes and secure with screws.

There is no need to try to tighten loose screws in the same place if the floor is made of planks. This will lead to cracking of the device itself. To make installation easier, it is better to make the supply line to the sewerage system from the toilet flexible.

Installation on ceramic tiles

In modern apartments, the floor in the bathroom is usually made of tiles. Then the plumbing has a backlash when the tiles are not level and have differences. This type of defect is the most difficult to eliminate. After all, in order to get rid of the wobbling of the plumbing fixture, you must first eliminate the unevenness of the floor. It is impossible to do this without dismantling the tiles.

Therefore, to begin with, the problem is eliminated by placing a plastic gasket under the base of the plumbing fixture. Such devices are sold in hardware stores and are quite inexpensive. If this option does not bring the desired result and the instability continues, dismantle the tiles and lay the covering again.

Important!

Silicone sealant is sometimes used as a gasket. They coat the area of the tiled floor where the device should be located. When the material is completely dry, install it. This method helps to temporarily solve the problem of a wobbly device.

Preparatory work before installing the toilet

Find a comfortable toilet pipe length

The drain sink is installed when the work on tiling the walls and floors with ceramic tiles is completed.

If you install the plumbing first, and then start installing the ceramic floor covering, you will have to deal with rather complex cutting in the slabs to contour the base of the pedestal of the plumbing fixture.

This will cause a risk of damage to the cladding if the selection of cut tiles is unsuccessful.

When covering walls and floors with ceramic tiles, you need to achieve a convenient length for the protrusion of the water pipe from the wall.

The outlet of the water pipe must be such that a shut-off valve can be installed.

This is interesting: DIY STORM Drainage FROM AVAILABLE MATERIALS

How to attach a toilet to the floor

To do the job efficiently, the master will need the following tools:

- hammer drill for construction work with several drills of various sizes;

- a hand drill along with a set of drills of different diameters for ceramic tiles;

- sandpaper with different grain sizes;

- rubber spatulas of different sizes;

- mechanical hand press;

- screwdrivers, bench wrenches and other tools.

Additionally you will need the following materials:

- plastic dowels of different diameters;

- metal screws or screws;

- several spacers for screws;

- construction adhesive;

- cement and sand;

- rubber sheet 15 mm thick;

- boards 25 mm thick.

Standard toilet fastening involves drilling holes in the floor for dowels. Then make 4 holes. If the device is mounted with screws, then only 2 holes need to be made. Difficulties are caused by drilling openings when the floor is covered with ceramic tiles. Due to awkward movement or incorrect selection of tools, the tiles easily crack.

Important!

It is necessary to drill ceramics with a drill designed for this purpose, setting the rotation speed of the device to low. During operation, the pressure on the tool should be light.

When fixing the device to cement mortar, it is important to properly prepare the working mixture so that the connection is of high quality. To do this, take 1 part of M200 cement and add 2 parts of sand.

Securing the toilet with screws

To secure the toilet to the toilet floor in the standard way with screws, perform the following steps sequentially:

- The exact position of the sole is determined on the toilet floor.

- Marks are placed in the center of the holes.

- Using a special tile drill, make recesses the size of which corresponds to the thickness of the tile.

- Then they take a concrete drill and bring the excavations to a depth of 70 mm.

- Insert dowels into the resulting recesses.

- The toilet is placed in the required place so as to align the mounting holes of the plumbing with similar ones in the floor.

- Connect the device to the sewer with a corrugated pipe.

- Secure the plumbing fixtures to the floor with screws from the installation kit.

Having completed this work, you need to additionally ensure the tightness of the connection of the corrugated pipe with the sewer inlet and the toilet pipe. To do this, use any sealant. Then, if there is one, the gap between the toilet sole and the floor is cosmetically sealed.

Installation options overview

How to attach plumbing fixtures to a wooden floor

If the floor in the bathroom is made of wooden planks, then it is quite possible to repair a toilet that wobbles, but it is not reattached to the damaged area. It would be better if you move the device a little to the side and screw it in a new place. At the same time, we recommend that you drill holes for reliable fixation, the location of which will coincide with the holes for fastenings and secure them with screws. You should not try to tighten loose screws further in the old place, especially if the floor is made of planks. The problem is that this can lead to further cracking of the device. To make installation easier, it is better to make the supply line to the sewer system from the toilet flexible.

How to fix a toilet on a concrete floor

In fact, it is much more difficult to fix the problem if the floor covering has a base made of concrete. In old buildings, dating back to the times of the USSR, the devices were installed on a concrete floor, which has embedded boards.

In this case, in order to improve the fastening, you should perform the following steps:

- Shut off the water supply to the plumbing fixture (toilet).

- Remove the drain tank.

- Disconnect the sewer drain pipes.

- Remove the bolts that secure the plumbing fixtures to the floor.

Please note that the rest of the work should be done extremely carefully so that you do not inadvertently damage the fragile material of the old toilet.

To fix the damage, you should remove the old backing board, and in its place lay a layer of new lumber, which will be thicker than the previous one. You can also bore this area and concrete it.

After the concrete has hardened, install the plumbing in this order:

- Place the toilet in the required area, mark the points where it will be attached.

- Remove the plumbing fixture and make holes in the marked area using a hammer drill.

- Secure the toilet to the bolts.

- Reinstall the drain tank.

- Connect plumbing and sewer pipes using corrugated liner.

Now let's talk about the features of installing a toilet on a tiled floor.

Installation on ceramic tiles

In modern apartments located in new buildings, the floor in the sanitary unit is usually made of tiles. In this case, the device will have a backlash if the tiles were not laid out level and also have differences. Eliminating such a defect is the most difficult, since it will be necessary to get rid of the device’s wobble by eliminating uneven floors. It is almost impossible to do this without removing the tile covering.

For this reason, the problem is solved by placing plastic gaskets under the base of the plumbing fixture. Such devices are always on sale in hardware stores or on the market, and they cost pennies. If this option does not give the required result, and the instability remains, you will need to disassemble the tiles and lay out the coating again.

Please note that sometimes silicone sealant is also used as a gasket, which is used to coat the area of the floor covered with tiles and where the device should be placed. When the material is completely dry, install the toilet. This method will only help temporarily, but solve the problem with a wobbly toilet.

How to attach to the floor

If your toilet wobbles, how to fix it?

To perform high-quality work, the master will need to use the following tools:

- A hammer drill for construction work, which has several drills with different diameters.

- A hand drill and a set of drill bits of different diameters to make holes in ceramic tiles.

- Sandpaper with different grits.

- Spatulas made of rubber with different mixtures.

- Mechanical press (manual).

- Locksmith's keys, screwdrivers and other tools.

Additionally, you will need to collect the following materials:

- Metal screws or screws.

- Dowels (plastic) with different diameters.

- Construction adhesive composition.

- Several spacers for screws.

- Sand, cement.

- Boards that are 2.5 cm thick.

- Sheet of rubber with a thickness of 1.5 cm.

Standard toilet mounting will involve drilling holes in the floor to install dowels. In this case, you will need to make 4 holes at once. If the fastening device is oriented to the use of screws, then only 2 holes should be made. You may have difficulty drilling holes when the floor is covered with ceramic tiles. The fact is that even from one awkward movement or the wrong choice of tool, the tile can easily crack.

Important! Drilling ceramics should be done with special drills designed for this purpose, and the rotation speed of the device should be set to low. When working, the pressure on the tool should not be too strong.

When it is decided to attach the toilet to cement mortar, it will be necessary to properly prepare the working mixture to ensure a high-quality connection. To do this, take 1 measure of cement, grade no less than M200, and add 2 measures of sand.

Screw fixing

If the toilet is wobbly, how to strengthen it? To secure it to the floor using the standard method, follow the following steps in sequence:

- First, on the surface of the floor in the toilet, determine the exact position of the sole.

- Marks should be placed in the center of the hole.

- Using a special drill, make recesses in the tiles, the size of which will correspond to the thickness of the tile.

- Next, arm yourself with a concrete drill and bring the excavations to a depth of 7 cm.

- Place the dowels into the resulting recesses.

- The toilet should be placed in such a way that the mounting plumbing holes are aligned with those made on the floor surface.

- Connect the device to the sewer using a corrugated tube.

- Secure all plumbing fixtures to the floor using the screws provided in the installation kit.

When all the work is completed, you should additionally ensure the tightness of the connection between the corrugated pipe and the sewer inlet, as well as the toilet pipe. You can use absolutely any sealant for this. Next, cosmetically seal the gap between the floor and the toilet sole, if there is one.

Strengthening with adhesive composition

It is not at all necessary to place the toilet on the screws if for some reason it wobbles. There is another high-quality way to strengthen the connection - using a special adhesive composition.

Work should be performed in the following sequence:

- First, place the seat for the plumbing fixture.

- The toilet base must be cleaned, leveled and degreased.

- Apply adhesive composition to the prepared surface.

- Place the device on the floor, and it should be aligned with the boundaries marked in advance.

Please note that after installation of the toilet, due to its heavy weight, excess glue may begin to protrude on the edges of the floor. To remove any remaining adhesive, use a rubber spatula. You can remove traces of tile adhesive using a rag soaked in a soap solution. After this, the toilet can be left for a day so that the glue can completely dry.

Installation on taffeta

This method is suitable if you need to install a plumbing fixture on a wooden floor surface. Taffeta is a kind of padding made of durable wood that will be placed under the device. From a board 3 cm thick, you should cut out a fragment that matches the shape of the sole of the plumbing fixture. To protect against moisture, such a part should be coated with a composition such as drying oil.

To ensure that the taffeta is securely fastened to the floor, drive in several nails in a random order. They must protrude 2 cm beyond the edges of the part. After this, use cement to fill the recess that is prepared for the plumbing, and you can drown the wooden part in the liquid solution, nails down. If you do everything correctly, it will be flush with the floor.

After 12 hours, the cement will completely harden. Afterwards, you can install the device in the prepared place, and use screws for fixation, and place cut washers from a rubber sheet under their heads. They are able to protect the frame from splitting when tightening the screw. To make it easier to unscrew the screws, lubricate them with graphite before fixing the toilet.