It is impossible to describe the disappointment of a housewife whose favorite Samsung, Bosch, Ariston or any other washing machine suddenly stopped washing properly. The device, which until some point was performing its job properly, suddenly begins to spin the drum without water or to collect it until it flows out of all the technological holes. However, there is no need to panic prematurely. Perhaps the pressure switch on the washing machine has stopped performing its functions correctly. This unit, with certain skills in working with a screwdriver, can be checked, repaired or replaced by yourself.

Purpose and design

During washing, clean water is drawn in, contaminated water is drained, and rinsing occurs.

Each stage requires a fluid level set by the manufacturer. Regulates processes by sending a signal to the control controller circuit, pressure switch. It is often called a “water switch”, “pressure sensor”. The purpose of this part is to determine the amount of liquid in the tank. While executing the program, the sensor “gives a command” to open or close the water supply and pumping valves.

Manufacturers design the device depending on their ideas about what a sensor should be like for a particular model. Often a pressure switch looks like a plastic part with electrical wires connected to its contacts. Additionally, a rubber compression tube is connected to the relay, the other end is connected to the washing machine tank.

Sensor design

The design of the pressure switch is round, with adjusting screws and flat-shaped contacts located on the outside. Moreover, the function of the screws is to set and regulate the switching on and off of the pumping device at a given water level. There is a separate pair for the water level mode, namely:

- To fully load the drum.

- If the unit is only half loaded.

- Delicate wash mode.

4.Eco mode.

One screw is supposed to turn on when the set level is reached, and the second works to turn off.

The range of offered machines differs in the number of modes, that is, the sensor is adjusted for a specific model. To purchase a replacement element, you must tell the seller the name of the model, since an analogue from other equipment will not work.

The heads of the screws themselves are painted, this allows them to be unscrewed and installed unmistakably, and the color itself acts as a seal for the assembly. If the coating is damaged, then we can say that the warranty will not automatically apply.

The cylinder is structurally provided with a chamber for air, connected together with a tube, which in turn is lowered into the tank. When water is collected, the pressure indicator increases and a notification is transmitted from the built-in membrane to the signal contacts.

The terminals are in one row and located along the entire plane of the sensor, after which a terminal block with wiring is installed on them, directed to the immediate program. From the end, a tube of different sizes is lowered into the tank.

What is a level sensor

We figured out why a pressure switch is needed. Now let's see what it looks like and where it is located. A pressure switch, a water level sensor for a washing machine, is a small round plastic part to which electrical wires are connected. A tube is also connected to the device, which connects the sensor to a high-pressure container.

Inside the sensor there is a thin membrane made of elastic material that can bend under the influence of air pressure. The membrane is located next to the switches, each of which has a different setting. It has a rigid pad with a plastic tip.

Where is the pressure switch located in the washing machine? Many people naively believe that the level switch should be located directly in the tank of the machine, working on the principle of a float. But this is far from true. The sensor sends signals about air pressure, not water, and is therefore located outside the tank, in the upper part of the body, where its contact with water is excluded. In some models of washing machines with plastic tanks, the sensor may be located under the tank.

Location of the sensor in the washing machine on its side panel

Why is a pressure switch needed and what is its role?

What a pressure switch is and why it is installed in a washing machine is already clear, but what does it look like? This device has a small round shape made of plastic. A pair of wires and a special tube are connected directly to it. For the sensor to function, indicating the volume of water filled, it will be connected to a tank where a very high pressure reading is noted.

As soon as the pump starts pumping water, the pressure will gradually begin to increase using the tube. It will fully correspond to the amount of liquid collected. As soon as there is enough water in the tank, to stop its supply, the installed relay first closes and after that a certain contact opens. Thus, the main processor of the washing machine, which controls its operation, receives the necessary signal that the tank has accumulated enough water necessary to start the cycle and washing can begin.

Part appearance

Principle of operation

When any malfunctions occur, checking the pressure switch of the washing machine is a prerequisite. It will allow you to determine what exactly broke or caused the part to malfunction.

Instrument location

The following may indicate that there are certain problems with the sensor:

- The washing process starts at a critically low liquid level, or without water at all. Most often, machines have certain programs that are activated when a mode is selected. In the event of a failure, the automatic machine can start the temperature sensor of the washing machine and the heating element when the required degree for washing has not yet been reached. Ultimately, this may cause the heater to burn out, which should not perform such a function.

- There is a lot of water entering the drum or the amount may be slightly insufficient. In some situations, water can be collected without stopping, which can cause serious damage to the equipment itself.

- At the end of the next cycle, dirty water is not removed from the tank. Sometimes, at the end of the spin program, the loading hatch may become blocked. It is worth noting that problems with spinning are not in all situations caused by a breakdown or malfunction of the pressure switch.

- The washing machine does not rinse washed clothes.

Such an insignificant small detail is responsible for such important tasks in the washing process. Therefore, you need to inspect it from time to time and at the same time it would not be superfluous to check the temperature sensor built into the washing machine.

The figure below shows a generalized diagram of the internal structure of a water pressure sensor. As the washing machine is filled with water, excess pressure is created in the air chamber of the tank, which acts on the membrane through a rubber tube through the inlet fitting. The elastic membrane, when deformed, moves the rod that closes the groups of sensor contacts. Depending on the programmed program, water flows or is pumped out of the washing machine.

We suggest you read How to care for suspended ceilings

The adjusting screws set the relay activation levels.

Pressure switches have one, two or three groups of contacts - their number depends on the washing program. Some models are configured for different operating modes, depending on the weight of the loaded laundry.

Frequent causes of pressure switch failure:

- mechanical destruction of the membrane - under the influence of air it stops deforming, remaining in one position;

- burnt contacts or their thermal deformation - when the rod moves, the signal does not reach the washing machine controller;

- loss of elasticity or breakage of the spring inside the sensor.

Let's look at how the pressure switch of a washing machine works. To operate, the sensor uses air pressure that is generated in a high-pressure tank. When the tank is filled with water, a certain amount of air is retained in this container. The more water the tank is filled with, the more important the air pressure in the tank becomes. Since the container communicates with the level switch through a tube, pressure acts on the sensor membrane.

Operating principle of the pressure switch

When a certain water level in the tank is reached (depending on the washing mode), one of the switches is activated. The water level sensor in the automatic washing machine gives a command to shut off the water supply valves. After this command, the flow of water into the tank stops and the machine starts washing. If the wash cycle is changed, the pressure sensor may command water to be added to the tank and then shut off the water supply again.

Preventing pressure switch failure

It is not necessary to allow the water level sensor to fail and require repair. You can extend the service life of the pressure switch by following the rules for proper use of the washing machine and promptly cleaning it from deposits and accumulated dirt. It is washing waste that is one of the main reasons for the failure of the liquid level sensor. It is also recommended not to allow the washing machine to idle or when the tank is empty. Such a process disables not only the pressure switch, but also many other household appliance systems. An equally important point is the temperature of the water that is collected for washing. It is not recommended to serve liquid at temperatures exceeding 45 degrees Celsius.

What malfunctions may occur in the operation of the part?

The faulty state of the relay is determined by characteristic external signs and disturbances in the operating mode:

- a lot or, conversely, little water is collected in the tank compared to previous (successful) washes;

- after finishing the wash, liquid remains in the machine;

- water is continuously drawn into the washing tub.

- The machine does not enter rinse mode.

- Washed laundry is wet at the end of the spin program.

- The wash starts without first filling the tank with water.

What characteristic signs can be used to determine that the water level switch of a washing machine is faulty? This can be assumed quite accurately in the following situations:

- The washing unit takes up very little water, or the amount is too large. It is possible that the washing machine will continuously draw water until it is unplugged;

- after the end of the wash, a certain amount of water remains in the tank of the machine;

- The laundry rinsing function does not work;

- the laundry remains wet after the spinning procedure is completed;

- The heating element turns on when there is no water in the tank. That is, the machine turns on the washing mode without waiting for the tank to start filling.

Symptoms of a problem

Sometimes it is quite difficult to determine the malfunction of a product, especially for people who do not understand technology. It is recommended that you familiarize yourself with the common signs that indicate a faulty pressure switch.

Stops drawing water into the tank

People who have their own washing machine often experience that liquid stops filling into the tank. There are several reasons for this problem:

- Problems with the valve responsible for supplying water. Liquid enters the system under tap pressure. The supply is opened using a special built-in valve, which begins to operate after a signal from the control module. If it is faulty, the liquid will not begin to flow.

- Control module failure. Due to a malfunction of this part, the valve does not receive a signal, and it does not begin to draw water.

- Blocker failure. He is responsible for blocking the hatch door. If the lock is faulty, the machine will not start working.

However, the most common cause is considered to be a faulty pressure switch. If this product does not work, the machine will not be able to evaluate and will not begin to fill the tank.

Repeated cycles of water supply and drainage

Modern washing machines are equipped with an automatic liquid collection system. Not only valves, but also level switches are responsible for the flow of water. All these parts function using special commands coming from the control unit.

The control unit perceives this as a failure to comply with the command, and therefore it re-sends the signal to supply water. This results in the supply and drain cycles being repeated many times. Due to repetition of cycles, the washing time can increase significantly.

Reduced rinse and wash quality

Sometimes, after using a washing machine for a long time, the quality of rinsing and washing clothes gradually deteriorates. Many people attribute this to the use of inappropriate powders. However, there are other reasons why things begin to wash worse.

A common reason for poor washing quality is a faulty level switch. Due to the breakdown of this part, the washer cannot determine how much water is in the tank, and because of this, it often does not fill completely. This leads to the fact that the collected liquid is not enough to properly wash and rinse the washed items.

Water remains after finishing washing

There are times when, after completing work, some water remains inside the drum. This can happen because the pressure switch has failed and stopped functioning normally. If it does not work correctly, the control unit of the device will not receive a signal about the need to clean the tank. This will lead to the pumps not starting to work to pump out excess water.

However, there are other reasons for this problem:

- Pump filter clogged. Obstruction of liquid from the tank sometimes occurs due to a clogged filter. It will have to be cleaned for the drain to start working.

- There is a blockage inside the pipe. During the draining process, the waste liquid passes through the pipe. Experts advise cleaning it once a month to prevent it from becoming clogged.

Examination

An independent check will help identify only obvious damage to the part. Only an experienced technician can adjust the sensor without special measuring equipment.

Check the following aspects yourself.

- Safety of body parts. There should be no obvious mechanical damage on the sensor. Violation of the integrity of the device body is unacceptable; this interferes with proper operation.

- Clean contacts. Contaminated ones are cleaned, and if the sensor is severely burned, the sensor is replaced (the cause of the burning is a malfunction inside the relay).

- Membrane integrity. To check, attach a piece of hose of a suitable diameter to the inlet fitting. By blowing into the tube, listen for clicks caused by the closing or opening of the contacts inside the sensor.

We suggest you read: How to properly clean a coat at home? How to clean leather, cashmere, wool and drape coats?

Washing consumption

Any washing machine spends a lot of water on washing, and it is not always possible to save money, which leads to financial waste. What determines the consumption of an automatic washing machine? First of all, it depends on the model of the washing machine. Modern automatic cars are equipped with “smart” modes programmed to save money. Therefore, the purchase of a machine should be accompanied by the following knowledge:

- Tank size. A large tank in the machine is the first sign of high water consumption for washing and rinsing.

- Washing mode. Washing machines have many modes: some of them consume a minimum, while others, on the contrary, spend many liters at a time.

- Frequency of SM use. Some housewives do laundry 1-2 times a week. At the same time, they diligently collect laundry in the basket, sort it by color and load the tank as much as possible. So the average consumption will be minimal. But other washing machine owners prefer to wash a small amount of clothes every day. This leads to high water consumption.

- Health status. Those who care about their health are afraid of causing allergic reactions that may occur due to the fact that all the powder has not been washed out of the fabric. Therefore, users select a mode and then set it to an extra rinse. This instantly increases the amount of water wasted.

Important! Have you noticed that when you select the economical mode, water consumption increases? There may be a problem with the washing machine.

The SMA is equipped with a passport in which the manufacturer must indicate the average consumption rate. When studying dozens of SMs, it was calculated that water consumption per cycle is a minimum of 38 liters, a maximum of 80 liters. Let’s calculate on our own how much water a washing machine consumes. The figure today is approximately 59 liters.

Important! If your SMA consumes more, it could be due to serious damage. Take a closer look. If you find a malfunction, contact an experienced technician.

What malfunctions may occur in the operation of the part?

This type of sensor is considered quite reliable, since its operation is based on the mechanical movement of the membrane under the influence of air pressure. However, the possibility of its failure cannot be ruled out. If this happens, the consequences can be very serious, including burnout of the heating element. And this will already entail significant financial expenses.

Are there ways to check the pressure switch in a washing machine? An ordinary person can do this, even without going to a repair shop.

1. Turn off the power to the washing machine by unplugging it from the socket. Carry out further actions only after completing this step.

2. You need to get to the level sensor itself. Since the relay is located in the upper part of the machine body, you need to completely remove its top cover. To do this, unscrew the bolts holding the cover to the body. The cover slides and is removed.

3. Having found the sensor, you should unscrew the bolts holding it, and then remove the sensor itself.

4. The tube and all wires are disconnected from the sensor body. The tube is secured with a clamp that can be unscrewed. If the electrical wires are held on a chip, then to disconnect them it is enough to simply pull this chip out of the socket.

5. The tube is checked for blockages. If there is a blockage, the tube is washed until it is removed.

6. A visual inspection of the sensor is carried out. If any broken elements are found, the sensor must be replaced. The cleanliness of the contacts is also checked.

7. The pressure switch of the washing machine is checked. To do this, you need to take a piece of tube whose diameter corresponds to the diameter of the removed hose. You can also use the removed hose if it is not dirty inside. One end of the tube needs to be connected to the sensor, and blow into the other end. Moreover, you should not blow hard to avoid damaging the membrane.

The cost of the pressure sensor is low, so if you suspect it is faulty, it is recommended to purchase a replacement and install it on the machine.

Operating principle and choice of relay for a washing machine

The pressure switch is made in the form of a round tablet. It is located under the top cover of the washing machine. A tube extends from the body of the part into the tank. The more water the machine takes in, the higher the pressure in the tube rises. As a result, one of the contacts closes and the module sends a signal to turn off the intake valve.

You can select the correct sensor based on the serial number or model of the SMA. The series numbers are indicated on the pressure switch itself, so it’s easier for you to dismantle it and go to the store. There, show the part to the consultant, and he will suggest a suitable replacement.

Signs of a pressure sensor failure are failures in the water filling and draining system:

- The liquid is collected until an overflow or leak occurs.

- The waste liquid does not leave the tank.

- The wash cycle runs normally, but does not go into rinse.

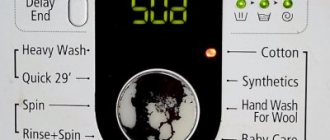

- The display shows a fault code.

- The cycle begins even though the water has not reached a certain level.

All these “quirks” are associated with incorrect operation of the pressure switch. To carry out additional diagnostics and replacement, the element must be dismantled.

How to replace a relay?

All you need is a screwdriver and a short tube. Unplug the machine by unplugging the plug from the socket. Close the water inlet valve. Unscrew the screws securing the top cover. Slide the panel back and remove it from the body.

You will see a pressure sensor on the side wall. How to remove the part:

- In some SM models, the pressure switch is bolted. In others - on latches. In the first case, unscrew the fixing screw. In the second, turn the part clockwise to release the latches.

- Disconnect the wiring connectors.

Disconnect the hose. Check it for blockages. Often it becomes clogged with debris that comes from the main line. Therefore, the relay may give incorrect readings.

Before replacing the level sensor, perform diagnostics. Connect a hose of the same diameter in place of the pressure tube. Blow lightly into it. When the contacts close, clicks should be heard. If you don't hear anything, it means the contacts are not working and the part is broken.

Another way to check for serviceability is with a multimeter. Set its toggle switch to resistance measurement mode. Connect the probes to the relay contacts. Blow into the tube and watch the readings on the screen. If nothing has changed, the sensor is faulty.

Prepare a new pressure switch. Reinstall it and secure the mounting bolts. Connect the wires. Put the hose in place and secure it with a clamp.

Without replacing the lid, run the wash cycle on a short cycle. Does water flow in and out normally? This means that the SM repair was carried out correctly.

During operation, it is recommended to clean the inlet hose and filter from debris and rust. Install cleaning filters to prevent small debris from the water supply from clogging tubes, hoses and other equipment parts. The video shows the stages of work:

https://youtube.com/watch?v=T4WqANQOZ9s

Bad 1

Interesting

Super

Replacing the water level sensor in an automatic machine

You can determine the feasibility of replacement by comparing the average prices of pressure switches and the cost of washing machines.

| Manufacturer | Pressostat price, rub. |

| Ariston, Indesit (Arcadia) | 350 – 750 |

| Electrolux, Zanussi | 800-1200 |

| Samsung – DC97-00731A | 1500-2400 |

| Bosch | 1400-2800 |

| LG | 650-900 |

| Candy | 1200-3000 |

If all signs indicate a malfunction of the device, try to replace it with your own hands.

Replacement procedure

Replacing the relay yourself can be done by someone who has experience working with screwdrivers and pliers.

Procedure

- Purchase a new sensor. Its type must exactly match the model of the washing machine.

- If the wires are single-core, the installation locations are marked with a marker so as not to be confused when connecting a new pressure switch.

- The old relay is dismantled.

- A compression tube is attached to the new sensor and secured with a clamp. Be careful when connecting - the plastic fitting can easily be damaged by excessive force.

AdviceWhen replacing a relay, install a new clamp. Old fasteners may be damaged during removal and may not provide a reliable connection.

- Attach the pressure switch to the body of the machine.

- Connect the electrical wiring.

- Check the reliability of the fastenings.

- Install the washing machine cover.

- Connect to the power supply and carry out a test wash.

If all manipulations were carried out efficiently, the device provided by the washing machine manufacturer was installed, and the problem was a malfunction of the sensor, the repair can be considered complete.

Incorrect installation causes malfunctions in the operating modes of the washing machine.

- An excess of water in the tank leads to poor-quality washing, incorrect choice of operating mode, and breakdown of the electric motor.

- Turning on the washing mode when there is no water in the tank will certainly cause the heating element (tubular electric heater) to burn out - an expensive part.

- Incorrect detection of the water level by the sensor disrupts the washing program.

Replacing a faulty relay with your own hands will help you save on repairs. Objectively evaluate your skills and feel free to start repairing if you think you can handle it.

If, after checking, you find that the pressure switch does not work, then it should be replaced immediately. This item is inexpensive, so anyone can purchase it. You can buy the spare parts needed for repairs online or in a specialized store. To select the correct device, tell your dealer what make and model of sensor you need to replace.

Replacement must be timely

You don't need any technical skills to replace it. You just need to put a hose on the sensor, attach the necessary contacts back and screw it with bolts to the place where the broken part was previously located. Next, start the washing machine to check its normal operation.

The replacement process is very simple

If the process of checking and replacing the sensor seems too complicated for you and even the diagram does not help you, then you should contact a specialist. They will quickly check the pressure switch and replace it.

In order not to disrupt the operation of the water level sensor in the drum and the entire system as a whole, carefully monitor the operation of the washing machine and treat the washing device itself with care.

How to check the pressure switch for problems?

Sometimes an unpleasant situation arises when the pressure switch starts to “glitch”. In this case, the entire system will not function correctly - the machine will stop executing the given commands, and malfunctions will begin.

The reason for the improper operation of the washing machine can only be determined by disassembling it and inspecting all important parts, including the sensor and pressure switch. Disassembling the machine takes time, so the first thing you should do is find out where exactly the pressure switch is located in your washing machine model.

A small detail can cause serious problems

- First of all, you need to carefully remove the top panel of the washer. To do this, just unscrew the bolts and move the panel slightly in the direction opposite to you. In most modern washing machines, the pressure switch is located in the upper part near the side wall.

- Experienced mechanics say that it will be enough to carefully disconnect the water level sensor. In most cases, it is fixed with a couple of screws that can be unscrewed in just a few minutes.

- Next, you need to carefully disconnect the connected contacts and tube from the pressure switch. It is worth noting that the hose is secured using special clamps. In this situation there are two options. Or disassemble them, which will be quite long and problematic. Or you can simply cut them out and install new ones.

After the pressure switch is dismantled, inspect it from all sides, paying attention to all, even minor, damage. There should be absolutely no damage or even minor formations on the body. It is also worth checking the tube and the condition of the wiring insulation material. If necessary, you need to clear all possible blockages and remove damage. We advise you to pay attention to the contacts of the water level sensor. They must be thoroughly cleaned.

Contact Locations

Now you can check the pressure switch itself directly. To do this, you need to use a hose, the length of which will be approximately ten centimeters. The diameter of the hose must be exactly the same as that previously removed. Connect the tube to the inlet fitting of the water level sensor and blow into it as hard as you can. The sensor should create clicks at this moment. Their number will vary depending on how hard you blow into the hose.

If during this procedure the pressure switch makes absolutely no sounds, then this can only mean one thing. It doesn't work and the part needs to be replaced.

In order to be sure that the water level sensor is not suitable for further use, you need to use a multimeter. Using this device, resistance values are measured. If, when air is blown into the hose, the resistance level does not increase at all, then it is worth purchasing and installing a new pressure switch.

Timely checking of the sensor is the key to normal operation of the washing machine.

This device, even considering its size, plays a very important role in the operation of the entire washing machine. If the sensor stops functioning, then you will not be able to start even the simplest washing mode. In some cases, problems of this kind can provoke more serious problems with equipment.

Replacing a water level sensor is a hassle, but the process itself is not very complicated. It is worth carefully monitoring the condition of the washing machine and then such a breakdown will be corrected on time, and none of the important spare parts will be damaged.

How to replace a faulty water level sensor

Since repairing the pressure switch of a washing machine is possible in very rare cases, it is better to replace this element immediately by purchasing a sensor of the required type. When purchasing a sensor, you must tell the seller exactly the make and model of your washing machine so as not to buy a different type of sensor. It would be even better to purchase a relay with markings that correspond to the number indicated on the body of your sensor.

One of the water level sensor models

Installing a new pressure sensor is carried out in the following order:

- the tube that was removed from the old sensor is put on the same place on the new sensor;

- electrical wires are connected to the sensor;

- The pressure switch of the washing machine is bolted to the old place;

- The top cover of the washing machine is installed in its place and secured with bolts;

- the machine is connected to the electrical network;

- laundry is loaded into the machine;

- The required washing mode is set, after which the machine starts working. During the first wash after the repair, it is recommended to monitor the operation of the pressure switch. If there are no comments on its operation, then the repair is considered successful.

How to set the pressure switch correctly?

In order for the pressure switch to accurately control the amount of liquid drawn, it is necessary to set some settings and set the optimal pressure level. Due to this, he will be able to signal at the right time that the water supply has stopped and start the selected washing mode. As a rule, the sensor for the washing machine is configured directly by the manufacturer, setting certain basic standards for its model. The owner very rarely encounters such a problem, which must be resolved as soon as possible. If this does happen, first of all you will need to learn how to check the pressure switch installed directly in your washing machine.

Layout of the sensor and screw for adjustment

Sometimes you can meet owners of washing machines who mess up the established standard settings, which affect the operation of the pressure switch. Any factors can cause problems. It is enough to at least slightly change the position in which the special screw connected to the machine body is located. If you turn it in one direction or another, this will contribute to an increase or decrease in the pressure level and to a failure of water level control, which will lead to incorrect readings on the sensor.

Do not try to change the settings yourself

What determines the amount of water consumed by a machine?

3-4 adults spend an average of 2-3 washes per week to keep themselves clean. And if there are small children, then the water flows out in hundreds of liters. Therefore, experienced users pay attention to this characteristic when choosing household appliances.

Passport information may not be entirely correct. After all, such calculations were carried out in laboratory conditions.

In everyday life, the consumption of liquid, which becomes more expensive every day, is influenced by various factors:

The simplest method to help calculate consumption is to measure time. The shorter the program, the lower the consumption. “Quick wash” is considered the most economical.

Article on the topic: Do you need pressure for a washing machine?