Error 3E that appears when using a Samsung washing machine indicates an incorrect determination of the rotor speed of the electric motor ✔. The control controller receives an erroneous feedback signal, which leads to the interruption of the washing process?. The owner can independently check the operation of the SMA units and eliminate any faults found.

Motor problems

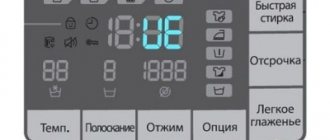

In a Samsung washing machine, error 3E is displayed on the LCD display. On equipment manufactured after 2013, codes like 8Ex or 8Cx (where x denotes an Arabic numeral) may appear on the screen, which indicate similar problems. In older modifications that are not equipped with a display, the code is transmitted by constantly turning on the LEDs of the standard wash modes at 40°C and Bio 60°C, while the orange indicators are flashing.

The equipment may display an error code after adding water, but when trying to start, error code 3E is displayed. This symptom may indicate a short circuit or broken turns of the motor winding. The owner needs to manually drain the drum or try to drain the water using a standard pump (by forcibly turning on the drain mode). For manual removal, a pipe with a filter element located in the lower part of the housing is used. The liquid is poured in portions into a flat tray or removed with hygroscopic material.

At home, the user can remove the motor, which is located under the drum. The motor is secured with bolts and nuts; if you have a test device, you can check the condition of the insulators. Breakdown of the windings to the housing is not allowed; you can also disassemble the motor and find damaged turns.

The motor must be repaired (rewinded) in a specialized service; if restoration is impossible, then you will need to purchase a new unit (supplied assembled by Samsung as a spare part).

If a malfunction appears during the washing process, then it is necessary to check the condition of the brushes. When graphite elements are worn or damaged, sparking of the collector occurs, which leads to a decrease in engine power. When installing new brushes, it is recommended to inspect the commutator; if mechanical damage is detected, it is necessary to transfer the engine to a repair shop.

Malfunctions of the Samsung washing machine: codes, types of breakdowns, repair methods

Household appliances, even the highest quality ones, can break down during use. The main malfunctions of a Samsung washing machine are mainly related to instability of the electrical network, low-quality water in city water supply systems, and improper operation.

The manufacturer has taken care of the possibility of eliminating minor breakdowns at home. All models with electronic displays inform the owner in the event of malfunctions with a characteristic sound signal and error code.

Knowledge of basic codes allows you to simplify the task and speed up the process of repairing equipment.

In most cases, knowing this information allows you to completely eliminate the problem and prevent more serious situations from occurring.

When you turn it on, you should pay attention to the turn-on sound; after it, a set of certain symbols is displayed on the display for several seconds. Deciphering them will determine the cause of the breakdown with high accuracy. An exception is a malfunction in the microcircuit, which can produce false signals, the validity of which is not difficult to determine.

In cases where different codes appear on the unit’s screen, you should carry out a full diagnosis of it by holding down the power, rinse and temperature sensor buttons at the same time until all indicator lights on the device turn on. After this, you should follow the commands that appear on the LCD display.

Blockage in the tube or air chamber of the pressure switch

The sensor needs to be cleaned. To do this, you need to remove the pressure switch from the machine, disconnect the air tube from the fitting and check both the sensor and the chamber. The design of the pressure switch practically eliminates clogging, but the tube sometimes gets clogged. Rinse it with running water.

The cause of such clogging may simply be dust.

Open circuit in the water level sensor circuit

Check the connecting wires; external signs of this damage will be poor insulation and a broken wire. If connection is possible, solder and insulate; if this is not possible, replace the entire cable.

The reason for this malfunction is machine vibration. To avoid this and other damage associated with vibration, it is necessary to install the machine correctly, perhaps use silicone pads under the legs, follow the loading standards of the machine and make sure that the laundry does not bunch up.

The pressure switch (water level sensor) is faulty

Before checking the sensor itself, pay attention to how the air tube is attached to it. If the connection is loose and loose, there may be an air leak and the pressure generated is insufficient for normal operation of the device.

To check the pressure switch, attach a small tube of a suitable diameter to its fitting and blow lightly. You should hear clicks. If they are not there, the sensor is faulty.

The final stage of testing the device is a multimeter. When measuring the resistance at the relay contacts when it is activated, the value should change.

Setting up and repairing a pressure switch is a job that requires qualifications and experience. Usually they just buy a new one.

In order to buy a sensor, you need to know the brand and model of the washing machine, since pressure switches for all machines are made completely different.

The electronic controller (control board) is faulty

In order to test the control board, it must be removed from the machine. External signs of a malfunction may include burnt board elements, soot, and the smell of scorched insulation. The cause of the breakdown is the failure of any element: resistors, transformer, relay and others. Repairing the control board is also quite complicated. Often it is simply replaced with a new one.

Fill valve broken

To test the fill valve, it must be disconnected and removed from the machine. If there are cracks or deformation on it, the valve needs to be replaced; it cannot be repaired. If the valve appears to be intact, then perhaps it just needs to be cleaned, and for this to be completely disassembled. The cause of the blockage may be scale. When disassembling, you also need to carefully inspect all parts for damage.

If you follow all the recommendations in the instructions for use, your washing machine will serve for many years without breakdowns. Modern washing machines are complex mechanisms; if you are not confident in your qualifications, then it is better to entrust repairs to professionals.

Error interpretation

Codes 3E, 3E1, 3E2, 3E3, 3E4, 3C, 3C1, 3C2, 3C3, 3C4, EA on a Samsung washing machine mean an error in the tachometer (Hall sensor) of the motor. The control module receives an incorrect or too weak signal from the sensor, or the tacho is simply “silent”. Therefore, the “control brain” stops the engine. And the Samsung machine tells you about the problem with code 3 E, EA, 3C, etc.

Note! In the new generation SMA, in case of such a problem, a group of codes 8E / 8E1 / 8C / 8C1 is displayed, which indicate an error in the VRT+ vibration sensor. This is a new, improved tachometer that can control both engine speed and three-dimensional drum vibrations.

Most often, the EA / 3 E / 8E error on a Samsung washing machine indicates significant failures in motor control.

But sometimes you can eliminate the cause of the code without calling a technician.

Error 3E, 3C, EA, 8E - in what cases can you fix it yourself?

- The drum is overloaded with laundry. The maximum load of the machine during washing is not indicated by chance. If you put more than the norm, then the engine “does not pull” such weight and refuses to rotate the drum. Because of which the machine gives an error. To deal with it, take out some of the laundry and start the wash again. If the error disappears, then the code “popped up” due to overload.

- Random control failure. There is a lot of electronic stuff in the washing machine, and sometimes it gets weird. The error may come on for no reason. Especially if it “draws” when you turn on the wash. A “fictitious” malfunction and a message about it can be “removed” by disconnecting the AVR from the network using the “Start/Stop” button. To be safe, you can completely turn off the power to the equipment and remove the plug from the socket. After a couple of minutes, turn it back on and start the wash again. If the cause was a failure, the error will not appear.

If the drum unloading and “restart” do not work, and error 3E, etc. appears again on the Samsung washing machine, which means the equipment needs professional help.

What should I do to fix the error?

Initially, turn off the SMA and unplug it from the power outlet. Further:

- Review the amount of laundry loaded, remove excess items or add missing items.

- If the drum is jammed, you will have to remove the foreign object that caused it. It is necessary to dismantle the front wall of the MCA, then remove the main heating element, and remove the “interference” through its mounting hole.

- Check the condition of the tachometer with a multimeter. If it fails, it will need to be replaced with a new part. The back wall of the machine is removed, the drive belt is dismantled so that it does not interfere with further repairs. Next, the engine wiring is removed, then the engine itself. After this, the tachometer is changed.

- To replace the electric brushes, unscrew the mounting screws from the sides of the housing. Next, the graphite spring-loaded rods themselves are removed. It is important to remember that if only one brush has pronounced defects, the pair is still replaced.

- Clean the inner magnetic ring thoroughly.

- Replace the stretched drive belt.

- Sometimes it is enough just to turn off the machine for 5-10 minutes and then turn it on again.

Some solutions to the problem are quite easy to implement, you can do them yourself. But a number of problems require professional intervention, so that through ignorance or inability not to aggravate the situation and cause even greater harm to the SMA.

Tachogenerator malfunction

A common reason for the appearance of error 3E in Samsung washing machines is the sensor that determines the number of revolutions of the electric motor rotor (tachometer, or Hall sensor). Electronic components fail or the sensitive element on the motor shaft (magnetic ring) becomes dirty. In this case, the machine can wash clothes; when you try to turn on the spin cycle, the motor stops and a code is displayed on the screen. The equipment cannot operate without a sensor, which limits the speed of rotation of the parts and prevents the machine from being destroyed by vibrations.

If excessive or insufficient spinning of the drum occurs, the cause of the defect is a weakened attachment of the ring to the rotor shaft. To restore functionality, you need to disconnect the equipment from the water supply and drain lines, and then get to the engine. The magnetic ring is secured with a screw; when the tension is loosened, the element slips. It is recommended to clean the outer surface of dirt and oxides that impair the reading of information by the sensor.

Problems with the sensor can arise due to oxidized or broken wires connecting the sensor to the electronic components of the machine. The cables are checked with a test device in dial mode or with a test light. It is recommended to connect the tester and then move the wire by hand (the defect may be floating and appear when the machine is running). Damaged sections of cables must be replaced, but it is recommended to install a new harness. Contacts are cleaned of traces of oxidation, damaged elements must be re-soldered.

If the error code appears again, then a service check of the electronics is required. The device checks the circuit going from the sensing element to the control controller. The cause of the defect may be a burnt-out diode (the defect is not visually detectable). The problem may arise due to an incorrectly operating electric heater (TEH), which is recommended to be inspected and checked with a tester. The combination of a burnt-out diode and a damaged heating element was noted in Samsung Eco Bubble washing machines.

What is this, what does it mean?

The appearance of “3E” on the display indicates a malfunction associated with the tachometer. This is a device that controls engine speed.

Other names for this small device are tachogenerator and Hall sensor. It is used to measure engine rotation speed. 3E can also signal problems with the engine itself that interfere with its rotation.

Depending on the year of manufacture of the machine, the encoding on the display may look like a different combination of letters and numbers: 3E2, 3E1, 3C2, 3C1, 3C, 3E4, 3E3, EA, 3C4, 3C3.

For machines that do not have a light screen, malfunctions can be indicated by the blinking of all washing mode lamps. The topmost and second from bottom temperature indicator lights should light up at the same time.

An error related to the operation of the tachometer is quite rare when compared with the frequency of other failures.

Drum load exceeded

Power drive failure may occur due to excessive weight of laundry loaded into the drum. For example, Diamond series machines are designed for 6 kg of items; when placing an additional 500-700 g, the equipment turns off. The manufacturer has installed overload protection, since the drum with increased mass breaks the bearing supports. In addition, the body and electronics of the machine may be damaged due to increased vibration levels. With slight overloads, the motor windings may overheat, which causes the bimetallic fuse to trip.

The owner needs to turn off the equipment, remove the water through the emergency drain, and then remove some of the laundry from the drum cavity. If the error does not appear when the wash cycle is restarted, then the cause of the malfunction was overload. If the warning light comes on, the drivetrain and electronics need to be checked.

How to fix error 3E

First. What you need to do when an error occurs is to unload the machine and try to start it with less laundry. Unfortunately, if the message repeats regularly, it is not recommended to repair the washing machine yourself and eliminate the cause of the WE error. We recommend contacting a technician, especially if your device is still under warranty. Depending on the cause of the breakdown, the technician will offer you the following options for solving the problem:

- cleaning the tank and engine from dirt and foreign objects;

- cleaning and restoration of contacts, power cords and sockets;

- replacement of the tachogenerator;

- disassembling and checking the engine, eliminating assembly errors;

- repair of the electronic module must be carried out exclusively by a professional, preferably a warranty center;

- replacing the drive belt.

Be careful and trust the repair of your equipment exclusively to a professional, since the repair of such parts of the washing machine by third-party specialists makes the product non-warranty.

Loose drive belt

A belt drive is used to transmit torque from the electric motor rotor to the drum. To increase operating efficiency, a poly-V-belt is used, which has an increased service life. There is no automatic drive tension, so when the material naturally ages, the belt begins to slip. As a result, code 3E or 8E is displayed on the screen (depending on the year of manufacture of the equipment), the problem appears at the beginning of the washing process or when the drum accelerates during the spin procedure.

To access the belt drive you must:

- Turn off the electrical power and then disconnect the connection hoses.

- Unscrew the screws holding the back cover to the machine body.

- Inspect the belt; there are no scuffs or cracks on the treadmill. It is also possible that the elastic element may delaminate or the pulleys may be damaged. Faulty parts need to be replaced, and then the machine must be checked.

To dismantle the pulleys, a screw puller for rolling bearings is used. The small pulley on the rotor is removed after several warm-up cycles, since a special solution is applied to the joint line to fix the parts. Do not install a new belt on damaged pulleys because the sharp metal edges will destroy the treadmill. It should be remembered that some Samsung machines use a direct drive motor and the belt is eliminated from the kinematic chain.

Repair

Once the reason for the error code has been determined, it must be corrected. If a specific part is faulty, it needs to be repaired or replaced. It is not recommended to carry out work if you do not have the necessary knowledge and skills. Otherwise, you can aggravate the problem and also get damaged during operation. You can’t do without a set of special tools.

If you are going to do the replacement yourself, make sure that the new element is suitable for your specific washing machine model. While working, you must follow safety precautions.

Let's look at options for correcting error 3E.

- If the problem is caused by a foreign object, it must be removed. It is necessary not only to carefully remove the item, but also to check the integrity of the “filling” of the washing machine. Make sure that the object does not damage parts needed for the job. As a rule, the source of the malfunction is small change (it gets into the drum of a stylish car from clothing pockets), buttons and other metal elements. If you hear unnecessary noise when the equipment is operating, be sure to take the necessary measures.

- If the power contacts are damaged, they should be repaired as quickly as possible. In most cases, simple cleaning is sufficient. And also check the wiring in the apartment and sockets.

- When the problem is with the tachogenerator, the only way to fix it is to replace it. This item cannot be repaired.

- When code 3E appears, unload the drum. Perhaps it is overloaded. From now on, observe the maximum permissible load.

- If a new household appliance malfunctions, it should be repaired by a service center. As a rule, the warranty on washing machines is provided for a period of one to two years. If the warranty period has passed, you can reassemble the motor, check each of its components and reassemble it. Remember that such work should only be carried out by a specialist.

- If the drive belt is damaged (cracks appear on it or it has lost its shape), it must be replaced with a new one. Many users recommend tightening the old strap to save money, but professional engineers recommend abandoning this idea.

- By re-winding the rotor or stator of the washing machine, they solve the problem of improper operation of the electric motor of the appliance if the problem lies in the winding. As in most cases, it is better to entrust the solution to this problem to a professional who will do everything correctly. The most common cause of winding damage is equipment overload. Often the brushes that transmit electric current become faulty. This element wears out as the equipment operates.

Control module problems

If the equipment turns off when washing starts, the cause of the defect may be the control unit located in the upper part of the housing. The controller contains electronic components that can move away from the contact paths or fail due to vibration or moisture. Service center employees note poor soldering of electronics and poor quality of printed circuit boards, from which the metal substrate peels off.

The unit is checked under the service conditions. The user cannot find microcracks in the elements or determine an incorrectly functioning diode or transistor. To remove damaged parts and install new parts, special soldering equipment is required. A controller with fatal damage must be replaced.

General recommendations for use

Despite the fact that modern manufacturers use innovative techniques to protect and improve the performance of equipment, you should listen to certain recommendations from experts.

- Any household appliance is not friendly with excessively high humidity. If you are going to install a washing machine in the basement, where there is constant dampness, it is better to choose another room.

- Modern household chemical stores offer a wide range of products designed specifically for automatic washing machines. Use only suitable washing powders and gels.

- The appearance of new sounds during operation of the equipment may indicate the presence of malfunctions. In this case, carry out diagnostics as soon as possible or use the services of a specialist.

- Buy household appliances from trusted and reliable stores that offer customers certified products. When purchasing large household appliances, you are required to provide a warranty, which is confirmed by the relevant document.

Problems with draining water: E2, 5C or 5E

Of course, in order not to ask questions about what to do if software errors occur, you should adhere to operating standards. A malfunction is not always our fault, especially when it comes to drainage. If you see code E2 on the screen, this means that the unit cannot drain water.

This problem occurs for the following reasons::

- The drain hose is clogged with a foreign object or is pinched.

- The pump is broken.

- External blockage in the sewer.

- Electrical conductivity is impaired.

Imbalance error codes: E4, UE or UB

As a rule, an imbalance in a washing machine can be caused in several ways, which in the future will incorrectly affect the entire operation as a whole. This usually happens due to improper installation; it is not level, on a slippery or curved surface.

The cause of the resulting imbalance may be your items that were not sorted correctly, which after washing have bunched up into one lump that is too heavy for the machine to handle. Due to the imbalance, the machine may stop spinning things and you will most likely see the code “E4”, “UE” or “UB” on the display.

In what cases can you fix it yourself?

- You poured in a lot of powder or mistakenly added hand washing powder . This is the simplest reason for the error. Too much foam prevents the sensor from detecting the water level. You need to wait until the drain is complete, remove the laundry and start the rinse program. This will clear the machine of powder and foam. Reload the laundry and start the wash.

- Water from the sewer enters the machine (incorrect connection). Connecting the drain to the sewer must be carried out according to the instructions for the machine. It happens that you connect the drain to the sink siphon in the bathroom or kitchen, it becomes clogged and the water in it rises, then it ends up in the drain hose, and then into the washing machine tank. With this connection, it is necessary to constantly monitor the cleanliness of the siphons. Carefully inspect the drain connection location and check it with the instructions.

- A failure has occurred in the control module . Turn off the machine, unplug it for a few minutes - this will reset all programs. Then plug in and start washing.

See also -

Samsung washing machine displays error SUD (5UD) or SD (5D) - what does it mean?