Have you suddenly discovered that your washing machine is electrocuting? It is important to understand that this behavior of equipment is very dangerous for life and can bring a lot of trouble, even death. A washing machine is, first of all, an electrical appliance, therefore, when operating it, it is necessary to follow the electrical safety rules and in the event of the slightest defect, it is quite possible to eliminate such problems yourself with your own hands.

Grounding the washing machine

Possible causes of current leakage to the housing

A washing machine is a household appliance that uses electricity as the main driving force. It is used to power the logic board, indicate modes, rotate the drum and heat water, that is, there are plenty of places for its leakage. Let's look at the most likely possibilities:

- surge protector or power cord;

- control board;

- logic board and panel;

- heating element;

- engine.

Electricity is a dangerous neighbor. It can cause serious physical and mental harm. That is why, if you begin to feel that when you touch the body or drum there is an electric shock, move away from the device.

What not to do?

There are a number of steps that absolutely cannot be taken when identifying damage to the washing machine (when it receives an electric shock).

Let's look at the most popular:

- Grounding the machine to the battery/riser. This method does not solve the problem, but only aggravates it. Although the heating riser has contact with the ground, it may have high resistance in this place. As a result, the current will still flow through the person. In addition, not only you, but also the neighbors through whose apartments this riser goes, can suffer. There are a lot of such accidents in practice.

- Fork reversal. It is believed that if you change the direction of the phase supply (twist the plug 180 degrees), the washing machine will stop beating. But this is a false misconception. This action has no effect, because the machine receives alternating and not direct voltage.

- Using a rubber mat near household appliances. It is believed that in this way the resistance increases and the current will not flow through the person. But the path of passage can be not only hand - body - leg, but also hand - body - hand. The second option is possible if with one hand you touch the body of the machine that is piercing, and with the other you touch the battery or wall.

Surge protector and power cord

In order to less often look for answers to why the washing machine is electrocuted, it is necessary to follow the electrical safety rules even at the stages of installing the equipment. They consist in the banal grounding of the case with the third wire from the socket. If anyone doesn’t know, it is connected to the grounding bus and is designed to drain electricity from the case if it gets on it. Of course, if there is a grounding, you will not be able to determine that there is a leak, but it will still save and prevent discomfort and harm in the form of burns and other tissue defects.

Network filter

The main device that causes the washing machine to shock is the surge protector. This is a small plastic barrel with two pairs of contacts in the form of petals for chips. It is usually located with the petals facing upward, since the power cable comes to it from above. The problem is that there is a very small distance between the contacts, in which dirt accumulates. When it gets wet due to moisture evaporation, a short circuit or breakdown occurs in the housing.

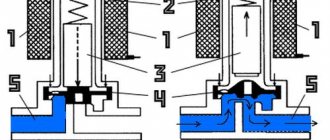

Connecting a surge protector

The walls of the machine are made of thin sheet steel and protected by only one or two layers of nitro enamel, so under certain conditions it will not be difficult for electricity to penetrate the body. The solution to the problem is to clean the contacts and the entire area from condensation. To do this you need to do the following:

- Unscrew the back wall of the washing machine to gain access to all mechanisms. It is secured with 6-7 screws, usually a Phillips screwdriver. Some of them will be covered in rust, so first apply a rust remover. For example, WD-40 is an effective liquid for this case.

- The filter is located on the left side closer to the lid. The place seems to be secluded, but condensation still accumulates there and becomes a serious problem.

- For better access, you can remove the top cover. It is secured with 2-3 screws at the front and 2-3 at the back.

- Any work should be started with the power turned off, so first remove the plug from the outlet. And carefully remove the chip with contacts.

- There you will probably notice oxide, which should be removed, and it is recommended to wash the contacts themselves with a special product, for example, Presto.

- Be sure to make sure that the contacts and the filter itself are dry and free of traces of moisture.

Surge filter in analysis

The peculiarity of this defect is that the body stops beating when the washing machine dries out from moisture, why? Please take this into account and ventilate the room regularly. Moisture will be intensively removed from the housing of the equipment and the room, eliminating the possibility of damage to the boards themselves and breakdown on the housing. Then neither the washing machine nor the water will shock.

Solution

Most causes can be eliminated by replacing devices. This applies to the network noise filter, heating element, control board, and power button. In other cases, you can get by with repairs or installation of additional devices.

Replace heating element

Replacing the heating element with a new one solves 90% of all problems. Detailed instructions for dismantling and installation are given just above.

Residual current device (RCD)

A residual current device (RCD) is designed to protect people and other electrical equipment in the house from voltage surges and accidental current leaks.

When choosing an RCD, they are guided by:

- Mains voltage. Regular networks have 220 V, special (three-phase) - 380 V.

- Current strength. Typically, a 30 mA RCD is sufficient for domestic needs.

- The class of the device itself. For washing machines, class “A” RCDs are used.

- Availability of additional levels of protection.

Self-installation of a residual current device is only possible if you have the appropriate knowledge and skills. If you are not confident in your abilities, it is better to entrust this task to a specialist. To understand the essence of the installation, watch two videos:

Installation of a differential machine

The differential circuit breaker performs the functions of a household circuit breaker, designed to protect the home network from overloads and short circuits, and a residual current device (RCD). This is the best solution for old apartments and private houses that do not have grounding. To install a differential machine, you will need the help of a qualified specialist.

Potential equalization system

Sometimes a potential equation system can be a solution. More often it is implemented in bathrooms where a washing machine is installed that is not connected to ground. The point is to equalize the potentials between electrical appliances and metal elements such as:

- heated towel rail;

- shower cabin;

- water pipes;

- metal ventilation ducts;

- sewer drain pipe.

All metal elements are connected by copper wire and reduced to a potential equation box (PEC). It is also better to entrust the installation of such a system to a specialist.

How to check grounding integrity

The integrity of the grounding is checked with a multimeter by measuring the voltage between the phase and the body of the machine. If voltage is detected, then there is no grounding or it is damaged. In this case, it is necessary to make grounding for the “washer”, or, if this is not possible, to create a potential control system with the obligatory inclusion of an RCD or differential circuit breaker.

Control and logic board

In some cases, the washing machine receives an electric shock due to a short circuit on the control board. The fact is that this is a rather complex device in design, in which there are many tracks. There must be a grounding loop, so trapped moisture may well become the shortest path for current to pass.

Control board

Eliminating the defect involves performing the following steps:

- Removing the back wall and top cover. The logic and control board is located at the top front. The power unit is on the side to the left or slightly higher, closer to the top cover.

- It is necessary to carry out preventive maintenance; to do this, remove the plastic protective casing and carefully inspect the blocks. Clean all suspicious areas and rinse with gasoline, but preferably with an alcohol-gasoline mixture.

- After thorough drying, install the blocks in place.

- Don't forget to check the chips with contacts, which could also be clogged. Especially those contacts that are located near grounding.

The power module burned out

Water is a very dangerous medium for electricity. When it hits a board with alternating current, it causes a short circuit in the circuits and a breakdown on the case while it is present in its path. On a board with constant current, it causes electrolysis with destruction of contacts.

It is important to know!

Pure water without impurities is a dielectric, but in our tap it is heavily contaminated with metal salts and minerals, which are good conductors of current.

heating element

If the washing machine drum is electrocuted, the heating element probably needs to be replaced. In fact, there are a lot of defects in this situation, and the equipment most likely requires comprehensive repairs. Still, situations are different, so to clarify the reasons it is necessary to disassemble and thoroughly analyze all components.

Checking the heating element

If the water in the washing machine is electrocuted, the problem is very serious and can cause injury. Therefore, immediately follow these steps:

- Remove the back wall of the washing machine to provide access to all devices.

- Disconnect equipment from the network to perform manipulations with electrical components.

- To check the heating element you will need a special device - a multimeter. With its help, you can check not only the integrity of the circuit, but also the breakdown of the housing. To do this, you first need to test the heating element for a break by connecting the measuring probes to the contacts. The device should show a resistance equal to zero or close to this value.

- To check the breakdown on the housing, you need to connect one of the probes to the housing, and the second to the contact. Resistance should tend to infinity at the limit of 20 MOhm or more.

- If there is resistance, this indicates a breakdown, but the test should be performed with water in the drum so that the circuit is closed. In this case, the test should be performed with one probe connected to the contact, and the second one lowered into the water.

Damaged heating element

Additional potential equalization system

The procedure for creating a DSU:

- You will need a PV-3 wire (cross section 4 mm²). They connect the washing machine body, ventilation, bathtub and water supply pipes.

- The wire must be taken out of the room to the electrical panel and connected to the ground terminal.

According to the rules, the wire must first be connected to the junction box - to connect to the apartment's fire control system. It is difficult to do such work yourself. If you already have a DUP system, then it’s easier - all you have to do is connect the washer body to the terminal block in the DUP box.

This solution is not sufficient. By connecting the housing to the DUP, you will only protect yourself from the danger of simultaneous touches - for example, there will be no shocks when touching the pipe and the machine. But it is still possible to form a chain - body - human body - floor. There are two ways to break this deadly circuit - by grounding it or installing a trip protection device (RCD).

Replacing the heating element

There is no resistance at all when dialing with a heating element connected to two contacts. In a normal state, it should tend to zero. If there is a leak, then the water in the washing machine generates an electric current, which can be very dangerous. In this case, it is necessary to remove the heating element.

Checking the resistance of the heating element

To do this you need to do the following:

- Disconnect contacts. They are attached with petal-type chips. Often one of them turns out to be highly oxidized, so it must be cleaned.

- To remove the heating element, you must unscrew the fixing screw. He is in the middle. After unscrewing the nut, you need to remove the heating element. The device sits tightly in place, so you will have to suffer a little. This should be done as carefully as possible so as not to damage the seal.

- When installing a new heating element in place, make sure that there are no particles on the contact surface of the cuff that could disrupt the seal.

- Carefully place the temperature sensor in place and connect the wires.

Problems with the heating element and factors of its damage

If the reason that the washing machine is electrocuted is due to a rotten heating element, then you need to know several very important nuances. The fact is that a breakdown cannot occur on its own. Therefore, you will need to look for some reasons. As a rule, these are runouts in bearings. The drum deviates strongly when rotating, which is why the heating element begins to catch.

The distance between the drum and the heater is very small, so it soon starts to catch on. As a result, the upper protective shell is cut off and the spiral is exposed. This is where breakdown occurs, current leakage into the water. The heater cannot be repaired, so the part must be replaced.

For information, the heating element is a heating coil enclosed in a special solid composition - an absorber. On the outside there is a protective copper alloy shell. It is also an insulator from a humid environment. The absorber is porous, so even if the spiral is not yet visible, the part is considered unusable.

The main reason for the destruction of the outer shell of the heating element is beating in the drum. Those, in turn, arise as a result of bearing wear, and, therefore, along with it, the oil seal, which prevents leaks, also fails. To prevent the problem from getting worse, it is recommended to replace the rotation parts in a timely manner. How to do this will be described in another article.

RCD connection

Experts recommend not limiting yourself to installing grounding, but connecting an RCD. The power of the device depends on the total power consumption of the line it serves. This device will protect the whole family from electric shock. When the RCD is turned on, the house is under control: as soon as problems arise with the wiring, the device turns off the electricity, preventing damage.

Can I get an electric shock if an RCD is connected? In addition to the power of the RCD, the consumer should be interested in the cutoff parameters. It depends on them how hard it will be hit before the cutoff is triggered. The lower the cutoff, the more protected the user is. For a bathroom, an RCD with a cutoff of 10 mA is suitable; for other sockets, 30 mA will be sufficient. The bathroom is humid, so the cutoff parameters are lower. Before installing the device, you will have to lay new wiring or install the RCD directly into the distribution board.

Important! Installing an RCD prevents electric shock, but does not eliminate the causes of the breakdown.

Engine

Another reason when a washing machine is electrocuted may be the motor. It is a device consisting of steel, aluminum and copper. The windings are insulated with varnish and placed in special insulating trays made of special cardboard or fiberglass.

The motor heats up during operation. In this case, the temperature can reach critical values and lead to melting of the varnish. As the insulation between turns deteriorates, the resistance changes downward, which leads to more current consumption and the release of additional heat. As a result, a breakdown often occurs on the motor housing, and then on the washing machine housing.

Checking the washing machine motor

Repair is carried out as follows:

- It is necessary to get to the inside of the washing machine, for which the back wall of the case is removed.

- The motor is located under the drum casing, at the bottom. The connector with contacts is on the side, on the left. It is necessary to remove it and at the same time clean it from possible contamination.

- Next, you need to check the motor using a multimeter. The technology consists of measuring the resistance of both windings and the housing. Accordingly, the readings of the device when testing the housing and between different windings should tend to infinity at the highest limit.

- If there is resistance, then it is necessary to remove the motor and wash and clean it, if necessary. If the resistance is not infinite, then the motor requires repair.

conclusions

If your washing machine is electrocuted and you don’t know what to do? The repair instructions will help you fix the problem. However, in more complex situations, it is still better not to try to eliminate the defect with your own hands. It is better to immediately contact specialists.

If you know how to hold a screwdriver in your hands and have a resistance tester on your household, then you are capable of more. In fact, most breakdowns can be repaired, but without knowledge of the technique and the availability of appropriate devices, this is difficult to do. Therefore, if complications arise, it is recommended to contact us for at least a consultation. The master will explain what needs to be done and how.

In difficult cases, you can immediately bring your equipment to us so that we can carry out professional repairs. We will provide a guarantee for our services. We undertake to advise on any issues.

Reliable SMEG washing machines

When choosing a new washing machine, we advise you to pay attention to household appliances from the famous Italian brand SMEG. Devices from this brand are made from high-quality components that are tested for performance. The company's engineers are constantly improving models and introducing many useful functions into them. Machines from SMEG are manufactured at modern enterprises that are equipped with advanced equipment, and innovative technologies are used when developing new models. Many washing machine repair technicians consider devices from SMEG to be among the most reliable on the market.

In addition to high reliability and build quality, SMEG washing machines have an elegant design and fit perfectly into both classic and modern interiors. In the catalog of our online store you can find stylish cars from various design collections created in collaboration with famous architects and designers.

You can choose vertical and frontal models that are suitable for bathrooms of various sizes. The catalog presents models that can be installed alone and appliances that can be built into furniture. The user can choose from machines with a load of 7 to 11 kg of dry laundry and a spin speed of up to 1400 rpm. Connoisseurs of combined devices can choose models equipped with a clothes drying function.