It is worth noting that a breakdown of the inlet valve and some other reasons also contribute to the constant intake of water. While the machine is washing, it repeatedly draws and drains water during one cycle, but this should not happen continuously throughout the wash. Here the reason lies either in its incorrect installation or in the presence of a malfunction. It is highly not recommended to operate such a machine - this can lead to more serious damage and flooding of neighbors.

First of all, you should check the connection to the sewer pipe. If the drain hose is located below the tank, the module recognizes this as a lack of water when filling, which is why it is topped up. The next filling occurs in the same way. This washing cycle is called “siphon effect”.

Checking the correct connection

It is worth understanding that the correct position of the drain hose is above the tank. From the floor to the connection with the siphon or sewer pipe, the distance should vary from 50 to 60 centimeters. This must be taken into account when connecting.

However, it is not possible to check this in all cases due to its inaccessibility. A cabinet or “screen” on the bathroom may interfere.

In this case, you should perform the following algorithm of actions:

- Start the program (you can quickly wash).

- Wait until the tank is filled with water.

- Enable drain mode.

- As soon as the water begins to decrease, press pause, and if at this moment the water remains at the same level, then the machine is connected correctly.

- If there is a characteristic sound indicating a drain, or visualization of a decrease in the water level, it is recommended to postpone the wash and seek help from a specialist.

Testing the washing machine for correct hose connection

If you can't easily reach the connection between the drain and the drain hose on your car, there is a simple test you can do to help you figure out if the problem is actually a faulty connection.

- Set your machine to the simple wash cycle, but do not put laundry in the drum.

- Turn on the machine and watch when the water fills the drum and it stops spinning.

- At this point, you should pause and see if the water level in the drum drops immediately. If this happens and there is not enough water, the machine drains the water by gravity. The hose is not connected correctly.

What to do next? Still get to the place where the hose connects to the sewer pipe and move it to the required height. If you cannot do this yourself or these actions were not enough and they did not help, contact a specialist.

Why does the washing machine fill with water and immediately drain it?

If a malfunction in the water supply is detected immediately after installation, then the connection of the machine to the sewer system is incorrect. Other reasons include:

- Damage to the electronic control module.

- Malfunction of the electronic control unit.

- Washer tank leaking.

- Inlet valve is faulty.

- Problem with the water level sensor, pressure switch.

- Blockage in the drainage system or sewer system.

Malfunction of the inlet (filler, inlet) valve

The inlet valve supplies water to the tank. The failed part does not shut off the water, the tank is filled completely, and the machine immediately drains without washing. If the valve has a weak membrane, water will leak out even when closed. You will be able to see the leak under the car.

Hoping that the problem will go away on its own is futile. You need to immediately call a technician to your home. Often, an experienced technician will replace the valve.

Malfunction of the pressure switch - water level sensor

The pressure switch is the most important element of an automatic washing machine; it determines the amount of water in the tank and sends a command to the fill valve to supply water. The fullness of the tank is determined by the pressure of the water column. The sensor's filling tube becomes clogged with small debris and scale and stops working correctly, providing deliberately false information about how much liquid is in the drum. The blockage is most often created in the hoses and valves of the sensor. If the water level sensor breaks down, the part produces incorrect data and therefore constantly pours water. It is not so easy to independently check the performance of a part. Professional assistance is required in diagnosing, repairing or replacing a spare part.

Our service center has formed its own warehouse of necessary spare parts. Therefore, we are always ready to make urgent repairs to your home assistant. We use only proven original spare parts from official manufacturers. That is why we provide a guarantee on the work of the master and components.

Washing machine tank leaking

Have you noticed that your washing machine tank is leaking water? Let's figure out the problem. First of all, there may be a crack in the tank. This happens if, before washing, users forget to empty their pockets and metal parts: coins, tokens could get into the small space between the drum and the tank of the machine. Service technicians recommend immediate replacement of the tank. Although many limit themselves to using moisture-resistant glue, the machine allows water to pass through again.

Another reason for a leak: the gasket between the two halves of the washing machine tank has dried out and leaked. It is necessary to replace the element, it is better to call a specialist, since the machine will have to be completely disassembled. If the machine has a solid tank, this cannot happen.

Incorrect connection of the washing machine

When connected correctly, the drain hose is located above the tank: it is attached to the siphon or directly to the sewer pipe, to a height of 60 cm from the floor. Have you recently connected the machine, but is it constantly filling with water? We check at what height the drain is located.

It happens that it is not possible to examine the connection location because of the wall or screen. Then you can do a simple test. When draining the water during the rinse process, press pause. If the water continues to decrease, then the problem is with the installation of the machine. Don't put off calling a technician until later. The machine may malfunction.

Damage to the control unit (electronic module)

The reason why the washing machine does not hold water is a malfunction of the electronic control unit, which is responsible for the operation of many components of the machine, including the pressure switch, pump, heating element and other elements. If the firmware has failed, then it is possible to launch the fill and drain functions simultaneously. An electronic display that displays an error code helps to recognize a breakdown. A malfunction of the electronic module is one of the most common breakdowns of washing machines of the Candy, LG, and Ardo brands. This is the most essential part of the machine; you should approach the repair responsibly and call a professional technician. After all, the cost of a new control unit is quite high, but a specialist can restore the original control unit.

Damage to the inlet (fill) valve

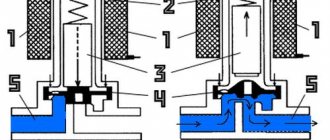

When diagnostics show that the pressure switch and associated parts are working properly, the cause of the uncontrolled drainage of water may lie in a malfunction of the inlet valve. Due to prolonged use, the valve's membrane may weaken, which leads to liquid leakage even when it is closed. Also, the valve may fail and not shut off the water at all. In this case, a situation similar to an incorrectly connected machine is repeated - the water from the tank is constantly decreasing, as a result of which the pressure switch gives constant signals about the need to fill the tank and the circle is closed.

Another sign of incorrect operation of the inlet valve is the situation when, even when turned off, the machine continues to draw water.

To eliminate the malfunction, the inlet valve must be replaced. Most front-loading washing machines have the inlet valve located at the rear of the unit near the top lid. You can access the part by removing the top cover. For machines with a vertical loading type, the valve should be looked for in the basement area - in the lower part of the rear wall. By separating the side wall you can gain access to the valve.

To replace this part, turn off the water and disconnect the inlet hose from the washing machine. The next step is to separate the wires leading to the valve and the hoses from its fittings. If possible, you can replace the disposable clamps installed there with worm clamps. After this, you need to unscrew the fastening screws with which the valve is fixed to the body of the washing machine. Some machine models provide for fastening the valve using a latch. You can remove the valve by retracting the latch tab and turning the valve body to the desired position. After this, the part can be removed without any hindrance. Install the new part in the reverse order.

First aid in case of lack of water supply

- Check that the tap through which the water is supplied is open.

- If it was open, then you need to close it. Then disconnect the water supply hose (it is located at the back of the machine) and lower it into a plastic container. Water will pour out of it.

- Check to see if the hose is kinked and straighten the kinks along its entire length.

- Unscrew the hose from the washing machine.

- A valve system appears before us, into which a mesh filter is inserted. The filter has a special indentation, so we take pliers and, grasping this indentation, pull out (do not unscrew) the filter mesh.

- The mesh can be cleaned with a needle under water pressure and inserted into the valve using pliers.

Unstable pressure in the water supply

Constantly changing water pressure can also cause problems with the washing machine, causing it to drain. The permissible pressure level is 1-4 bar. Values below or above these indicators indicate bursts and other problems with the water supply.

If the problem is of a general nature and has also arisen among neighbors, then it is advisable to contact service agencies. On a local scale, this may indicate flaws in the plumbing wiring or its defects. Namely:

- deposition of salts inside the pipe, which reduce its diameter and, accordingly, throughput;

- clogging of the water filter;

- presence of cracks.

The optimal solution in these situations is to replace the plumbing.

If holes have formed in plastic pipes, they can be filled with sealant or repaired using cold welding. Don’t forget to prevent the problem by regularly cleaning the filter.

Why is it better to contact a specialist?

The main disadvantage of constantly draining and collecting water is the complete washing out of the powder and other products. In this case, the machine does not remove dirt. In addition, during such work, the tubular electric heater experiences extreme load, since it is constantly trying to heat the water that has just been poured into the tank. The result is a corresponding error displayed on the screen, breakdown of the heating element and expensive repairs.

Of course, the correct connection diagram is contained in the instructions for the machine. Anyone can figure it out, but the correct connection will need to be checked without fail.

Independent work will not give a positive result in all cases. Often, lack of experience leads to even more serious malfunctions. The craftsmen have both experience and special equipment. In a short period of time, they connect the machine by moving the hose to the correct position or installing an anti-siphon valve. It is installed in exceptional cases, since it requires periodic cleaning.

What to do if your new washing machine does not work properly?

If you installed a new washing machine or you moved the old one to another place and, therefore, connected it in a new way, then it is likely that the cause of the problem is the incorrect connection of the water drain hose.

The instructions for your washing machine indicate exactly how to connect the hose, check this information again. Often, for almost all models (for example, Indesit), it should be fixed above the drum level. This is about 50 cm from the floor. This must be done so that the water from the drum does not constantly drain by gravity.

And if this happens, then the sensors transmit information that there is not enough water, and the machine fills it up again.

Possible violations of operating rules

Sometimes the reason for washing without spinning can be caused by simple inattention.

Wrong washing program selected

In this situation, the spin cycle does not work in the appliance. But rushing to wring out wet things with your hands is not an option. It is better to read the instructions more carefully. Not every washing program requires a spin cycle. Sometimes the laundry is spun at low drum speeds, or the wash cycle ends with a rinse. Then the water drains from the car, but the things inside remain wet. If, after opening the hatch door, the presence of water in the tank is detected, you need to check how the program options are set. Perhaps spinning is not intended initially. For example, if a gentle mode is selected for items made from delicate types of fabrics, and so on. The problem is not such, since everything will be fixed by resetting the regulator to the desired function.

But it also happens that the spin cycle is simply accidentally turned off by one of the household members. To spin out the washed items in this case, you just need to reset the regulator to the “Spin” option and start the process using the “Start” button. The number of revolutions on the regulator is not set - also one of the banal reasons for the spin failure. At the zero mark, the machine does not provide for spinning the laundry. The water will simply drain out and the cycle will end.

Uneven distribution of laundry

This is what upsets the balance of the washing machine. Models with a display report a balancing problem with the information code UE or E4. In other devices, the washing process simply stops at the spin stage, and all indicators light up simultaneously. Often, when there is an imbalance, the laundry in the drum gets bunched up. Incorrect loading of bedding also causes a program failure. For example, when they were stacked in a tank. To eliminate the imbalance, it is enough to manually distribute the laundry evenly.

Drum overload

Eliminating weight overload is the easiest thing to do. You just have to remove some of the laundry from the washing machine. Or try to redistribute things and restart the “Spin” function. Exceeding the maximum permitted weight poses a danger to the device, therefore, in case of such a violation, an error code is displayed on the display or the entire process stops. The situation can be easily resolved by turning off the power and removing some of the items from the washing tank. To prevent the drum from overloading in the future, you need to load laundry according to the operating instructions

It is important to take into account the fact that wet clothes become heavier, so maximum load is undesirable

Imbalance and overload are equally unsafe for washing machines. The automation stops operation before the start of the most active phase of washing - spinning at high speeds.

The water sensor is broken

The most common problem, because the pressure switch that controls the fullness of the tank is vulnerable to any damage. If it is worn out, a signal will always be sent to the control module that the drum is empty.

This part consists of the sensor itself, a pressure tube and an internal elastic membrane. All these elements are fragile and become damaged over time: contacts short out or oxidize inside the sensor, the membrane becomes hard or depressurizes, and the tube may crack. Some argue that all these problems can be solved by repair, but the experience of our specialists says that these measures are enough for 6-9 months of normal operation, and after that the breakdown will return. It is better to install a new pressure switch. For AEG and Miele equipment, it is important that these are original spare parts.

Why doesn't the tank hold water?

There are several reasons why a washing machine immediately drains water after filling. The simplest and most easily removable:

The device is not connected to the sewer correctly. If the drain hose is below a certain height (for LG and Hansa it is 50 cm, for Candy and Indesit 60 cm), the flow of water, according to the laws of physics, will constantly flow into the drain automatically. To avoid this, check that the drain is connected to the system correctly. If you find errors, invite a specialist.

There is a blockage in the drain. Because of this, the pressure in the drain pipes increases, and the contents of the drum simply begin to be drawn into them. This breakdown is especially common in old houses, where the sewer lines are outdated, covered with plaque and easily become clogged. You can eliminate the problem by cleaning the pipes

Please note that you cannot continue washing when clogged, despite the fact that the machine quickly draws water back; in this situation, the heating element is loaded too much and may burn out.

Other reasons are due to breakdowns of the internal parts of the washing machine. You need to understand them in more detail to understand how to act.

Set valve stuck

One of the most vulnerable parts is located next to the inlet hose and is responsible for promptly opening or closing the flow from the water supply to the drum. If the intake valve breaks, it continuously pours water into the system, and the device immediately drains it. To find out if this is really the problem, stop the wash and set the drain mode, then press pause and listen. If water continues to flow, the valve has stopped working properly.

If the service center offers you to repair this part, it is better not to agree to it. Technologists from the Ardo and Whirlpool factories claim that any damage to the intake valve is irreversible. It is recommended to install an original spare part.

The water level sensor is faulty

The pressure switch is located closest to the washing tank. It checks how full the tank is and transmits this information to the control unit. If the high pressure tube gives a signal that there is not enough liquid, the device begins to draw it to the required level. If this sensor fails, it will not detect that the drum is full, and the security system will drain the excess.

A professional technician with extensive experience can find out that the problem is in the pressure switch. He must replace this part. Although sometimes you can restore its functionality by sealing the tube.

Drain valve does not work

In some cases, when washing in an automatic machine, a siphon effect may occur. This is the dependence of water flow on pressure in the sewer. Sometimes dirty liquid from the drain can enter the tank of the device or flow out of it uncontrollably. To prevent this from happening, a check valve is installed on the drain channel. It simultaneously protects the drum from leakage and protects the system from dangerous pressure drops.

If the anti-siphon is damaged, it will not work correctly and in some cases can cause continuous drainage into the drain. To fix this, ideally you need to replace it, but before you buy a replacement, try cleaning the filter in the valve or get a professional to do it for you.

Control module error

If all previous reasons are excluded, and the washing machine takes in water and drains it immediately after filling, it means that a failure has occurred in the control unit of the device. It controls all processes and processes all signals from other elements.

If the contacts of the control board are oxidized, foam or moisture gets in, a short circuit or any other damage occurs, it is impossible to predict how this device will behave. It can be extremely difficult to repair, although some repairmen offer such services. Manufacturers Miele and AEG strongly recommend replacing it at the first suspicion of a module defect. Otherwise, the system will not be completely safe from errors.

Burnt out heating element

The reason why the machine takes in water and immediately drains it, and does not respond to pressing the buttons, may be a burnt-out heating element. In this case, you can turn off the device only by unplugging the cord from the outlet. Such problems occur when trying to use modes with heated water, while the “cold” wash remains working.

This means a malfunction of the heating element - heating element. The control unit does not detect the presence of hot water and does not proceed to the next washing stage after drawing water. This problem often occurs with older car models. In this case, the indicator of new models or “Indezit” equipped with a self-diagnosis system will display an error code.

You can check the correctness of the assumption using a multimeter:

- remove the back cover of the washing machine;

- remove the heating element by carefully prying it off with a screwdriver;

- put the multimeter in dialing mode;

- connect the ends of the multimeter to the two outermost protruding parts of the heating element.

If there is no response from the device, it means that the heating element is broken and must be replaced. You can purchase it at the store and easily install it yourself. The main thing is not to overtighten the rubber band during installation.

Additional causes of problems with heating elements:

- The presence of scale on the device due to hard water. Solution: you need to remove the heating element, soak it in vinegar and remove the plaque with a brush.

- Loose or oxidized electrical contacts. Solution: clean and tighten connections.

- Failure of adjustment in the thermostat responsible for measuring the water level and turning off the heating element. Solution: call a specialist.

Advice! In order for the heating element to serve for a long time, it is necessary not only to make a loop on the hose, raising it by 60 centimeters, but also to make the drain point itself higher by “extending” a piece of pipe to it. This will prevent unnecessary drainage of water, and the heating element will have to work with less load.

What it is not recommended to do on your own

Let's consider situations where the reason is clear, but you cannot do without the help of a specialist. Fixing the problem yourself can lead to undesirable consequences.

Trying to fix a broken intake or exhaust valve

The inlet (inlet) valve is a device necessary for the dosed supply of water into the tank. When voltage is applied to the coil, an electromagnetic field is generated. It acts on the magnetic rod, drawing it into the coil. At the same time, the membrane opens and water flows into the outlet fitting of the valve. From there, the liquid medium penetrates into the washing machine tank. After it is filled, the power to the coil is turned off, and the membrane takes its original position, blocking the access of water.

You can determine that the problem is in this block in the following ways:

- Check the valve mesh. If necessary, it can be cleaned. If there is a blockage in this place, the washing machine will either not fill the water or the tank will fill slowly.

- If the valve does not open, you need to check the coil. There was probably a burnout. With this malfunction, water will not flow during one of the washing modes.

The pressed-in plastic inserts in the fittings are also subject to inspection. They are responsible for reducing the water supply. If the inserts fall out, the amount of water passing through increases. This valve needs to be replaced.

Replace the pressure switch - water level sensor

The part, which is a sensor for determining the water level in the drum, sends signals to the control module. A malfunction of the pressure switch is quite easy to notice. The machine starts the washing program without adding water. Another situation is that the drum picks up too much or too little liquid. The rinsing and spinning stages are disrupted. A broken sensor may also be indicated by a lack of drainage.

Troubleshoot a tank leak

If the tank is leaking, there may be 2 reasons:

- the tank body is cracked;

- damage to the joints of parts.

It is useless to try to fix cracks yourself with waterproof glue: the result will not last long. Therefore, the tank will have to be replaced or another gasket placed at the junction of the parts.

Replace the electronic control module

One of the most common malfunctions is related to the electronic unit. No well-known brand is immune to this problem. The electronic module is responsible for thermal indication, water level, displays information on the operation of the device on the display, and is responsible for the washing and rinsing speed. Such breakdowns require replacement of the element.

Replace belt

If the drum rotates very slowly during washing, with scraping sounds, or does not rotate at all, an error code appears on the display, most likely the drive element is damaged. If the belt breaks, it can break the wiring or damage the sensors. The causes of this problem can be either improper operation of the machine or wear and tear over its service life. Moreover, narrow washers, as a rule, wear out faster due to the close arrangement of parts.

Failure of the electronic module

If all of the above parts of the unit are working properly, most likely the electronic module - the device that is responsible for controlling all components of the washing machine - has broken down. If it breaks down, it can send incorrect signals to the water level sensor, which lead to unauthorized water intake . There are many factors contributing to module failure - high humidity in the room, power surge, etc.

To repair the washing machine module, you should contact a professional - doing it yourself is problematic.

The quality and duration of the wash depend on the supply of water and its proper circulation - if the washing machine does not hold water, the process will either be interrupted or go into a so-called cycle, when the drum spins endlessly and the machine does not go into rinse and spin mode. How to find the causes of this problem, how to fix it, do you need to contact a specialist, or is it possible to solve it yourself?

Surgical method or second aid to washing machine

We take all precautions by turning off the water and unplugging the washing machine. In the first step, we disconnect the hoses from the valves (which are located at the back of the machine), since water often remains in the hoses, you need to prepare a container to drain it.

- Unscrew the fastenings of the top cover of the washing machine.

- The wire connectors from the coil tend to have bright colors (like blue and red), similar to blockbusters, you need to remember their location and disconnect them.

- Using pliers, remove the fasteners from each of the four hoses.

- Note the location of the hoses and disconnect them. Keep in mind that they may also contain water, so it's best to have a towel ready.

- We unscrew the screw that secures the valve (it is located at the back) and take out the inlet valve itself.

- We install a new water supply valve by placing it in the bracket and securing it with a screw using a screwdriver.

- We attach the hoses to the connectors and secure them with clamps. Connect the coil wires.

- Reinstall the cover of the washing machine, giving it its original position, and secure the cover with screws behind the machine. We connect the hoses to the new inlet valve.

- We connect the water and plug in the washing machine and check its functionality.

- Open the back cover of the washing machine.

- A temperature sensor and a grounding terminal are connected to the heating element. To remove these wires, use pliers and pull out the connectors.

- And then we take a socket wrench and unscrew the nut that holds the heating element.

- Then use a screwdriver, and then with your hands, using up and down movements, pull the heating element towards you, and together with the heating element you need to pull out the rubber seal.

A screwdriver will help here again.

When we insert a new heating element, you must pay attention to its guide, that is, look into the hole formed from the previous heating element. There will be grooves for the part to fit tightly.

It is best to lubricate the rubber seal of the new heating element with dishwashing gel before inserting it so that it can be inserted easily and quickly.

Then we insert the temperature sensor, tighten the nut and connect the wires.

Causes of malfunction

When a washing machine breaks down, water can come from both the sewer and the water supply. You can tell by the color and smell; if cloudy water slowly appears in the drum, then this is clearly water from the sewer.

At the same time, when the machine draws water from the water supply without stopping, the Aquastop system will not save you from overfilling the drum with water. The leakage protection sensor is fixed in the washing machine tray, and water will leak onto the floor. Therefore, even the most advanced protection will be powerless in this case.

But what is the reason that the machine takes on water? There are two reasons:

- water supply valve malfunction;

- malfunction of the siphon valve or its absence;

- the drain system is clogged, causing water to flow back into the drum through the drain hose.

Troubleshooting

So, when you see that the switched off washing machine is drawing water, immediately turn off the water supply tap. Only then proceed to troubleshooting. Do not forget to disconnect the machine from the power supply. If the reason for the water intake is the solenoid valve, then it must be replaced with a similar one. It's not difficult to do this yourself.

Getting to the filling solenoid valve is easy. In front-loading machines, it is located under the top cover of the housing, and this is what needs to be removed. In vertical machines you will have to remove the side cover. But first, turn the machine around so that it is convenient to work, and disconnect the water supply hose. Having seen the valve, disconnect the hoses from it, loosening the clamps, and the electrical wires, remembering the polarity of these wires. Unscrew the valve from the machine body and remove it.

Since solenoid valves cannot be repaired, we take a new spare part and connect it to the hoses. At the same time, we use new clamps to ensure reliable connections. Then, observing the polarity, we connect the electrical wires and fix the fill valve.

Before closing the lid of the washing machine, connect the inlet hose and run a test wash. Check connections for leaks. Once you are sure everything is in order, reassemble the machine and set it in place.

If the drum collects water from the sewer, then first clean the siphon to which the drain hose from the washing machine is connected. Well, if the reason is the connection to the drain, then read the article Siphon for a washing machine.

Precautionary measures

And finally, how to avoid situations where the machine is turned off and takes on water. Everything is quite simple, you need:

- After washing, close the water supply tap; if it is not there, be sure to install it.

- Connect an anti-siphon valve, which will prevent waste water from flowing back into the machine.

- Use a leakage protection system that is installed on the floor. As we noted, the washing machine’s protection system will not help in such a situation.

We hope the information in this article will help you prevent a flood, find the reason why water appears in the drum and quickly eliminate it. Good luck!

Troubleshooting with a guarantee or saving on repairs?

You should not contact your friends or random repairmen - they will not give you guarantees of the quality of the repair, they may install old and substandard spare parts, which means that your claims will not be satisfied.

Manufacturers require compliance with repair regulations, which means that a limited range of spare parts is allowed for installation on the machine. You will not be able to purchase them on your own, because their price for a service center and an individual is noticeably different.

The cost of repair depends on what parts had to be replaced after diagnosis. It can be calculated after the technician finds the cause of the malfunction and accurately determines the list of spare parts for replacement.

Our service center specialists use only new and conditioned components that are covered by the manufacturer’s warranty.

Diagnostics

If breakdowns occur related to draining waste liquid in the washing machine, owners can launch the self-diagnosis function of household appliances. Many models of machines have a similar function, thanks to which the equipment will independently calculate the reason for the malfunction and display it on the information display.

The self-diagnosis function is not provided in all washing machine models. In this case, the owners can independently conduct a kind of revision of the device to find the cause of the malfunction. Let's look at how this can be done.

- First of all, you need to understand that all diagnostic manipulations are allowed to be performed only with the machine disconnected from the network. Try not to forget about this.

- First, you should check the correctness of the set washing program if water accumulates in the drum. As mentioned above, the “Night” or “Hand” washing modes can lead to similar consequences. In such a situation, it is enough to cancel the program and start the drain.

- Carefully inspect the drain hose of the device. The blockage could have formed due to the hose being kinked somewhere. Because of this, excess waste simply cannot go down the drain.

- The siphon could also become clogged if the device is connected through it. To check this, you can disconnect the hose and redirect it to the sink, then start the draining process. If you notice that liquid flows freely from the hose, then the reason lies in the sewer. It is enough to clean it using specialized means or calling a plumber.

If you have completed all of the above steps to diagnose the equipment, but it still does not drain the waste liquid completely (or at all), you can try to restart the device. Disconnect it from the electrical network, let it stand turned off for 15-20 minutes, and then run the program responsible for draining again.

Consequences of untimely repairs

Every problem requires an immediate solution and this one is no exception. If you notice that the machine is collecting and draining water, you should not leave everything as it is and allow you to continue washing. Sooner or later this may turn into more significant problems:

- Due to frequent and various errors, the system itself may fail.

- The load on the parts will increase, this will speed up the process of their wear.

- Large electricity bills.

In conclusion, I would like to note that it is worth paying closer attention to the operation of your household appliances. And at the slightest hint of failure, immediately start looking for the cause or contact the appropriate services. And then the electronics will last as long as possible. Now you know why your assistant constantly fills and drains water.

This kind of “malfunction” occurs all the time if the manufacturer’s recommendations for installing the machine are not followed. Most likely the drain hose is low. Read the instructions, it will definitely say at what height the top bend should be.

Program control problems

A malfunction of the electronic module is indicated on the display of the technical device in the form of an error code. This code tells you where to look for a breakdown. It makes sense to restart the program and turn on the washing machine again. If simultaneous draining and filling continues, professional assistance will be required.

With Zanussi devices, it happens that when water is drawn, after 15–20 seconds it begins to be discharged, and the lights on the display blink. In this case, check:

- a heating element;

- motor contacts or winding breakdown;

- control module electronic board;

- pressure switch;

- brushes on the rotor (extreme wear).

To clarify, the check is done step by step: the drum is turned, the temperature is monitored, and the filling is performed. Deciphering error codes will help to correctly determine the cause of self-draining.

How to eliminate the cyclical supply and drainage of water?

With repeated, cyclical collection and drainage of water, the consumption of electricity and water supply increases, as well as the wear and tear of the most important units of the washing machine: the heating element, the element has to constantly heat the water newly entering the drum. The temperature sensor also turns on constantly. Constant draining and refilling of water also renders other parts and sensors unusable.

It is not always possible to eliminate the cyclical collection and drainage of water on your own. For thorough diagnostics and repair of the washing machine, it is recommended to contact a service center.

Incorrect sewer connection

Such a malfunction causes constant drainage of water and occurs both in a newly installed washing machine and in a washing machine that has been working properly for many years. The problem is that the drain hose is located below the level of the tank, because of this the liquid is not retained, but is constantly drained into the sewer. The machine steadily replenishes lost water. The liquid in the tank does not have time to heat up, so the heating element works constantly, which can lead to its failure.

For proper operation, manufacturers recommend laying the hose at a level not lower than 0.5 m from the floor. This is achieved either by installing it in special latches on the back wall of the machine with a contour around it, or using the included hook-holder, which is then hung on the edge of the bathtub or sink. It is possible to connect the drain hose either to the siphon of a bathtub or sink, or directly to the sewer pipe itself by cutting a branch into it. But then you should make a loop higher than 0.5 m to prevent premature draining of the liquid. This will help prevent unpleasant odors from the drain from entering the washing machine. This type of work can be done independently.

If there is no access to the sewer pipes due to their sealing and it is impossible to see at what level the drain hose is connected or the presence of a loop, you can check for fluid leakage from the machine. To do this, you need to turn on any mode and fill the tank with water. Then press pause and open the car. A falling level means the hose is not connected correctly; to fix this, you will have to disassemble the wall. If the water does not drain in this way, but only while the machine is running, then there is a malfunction in one of the devices of the washing unit.

Advantages of “Polite Service 5+”

Clients turn to us because:

- Our employees are ready to deal with any, even complex, malfunction of the washing machine. They provide proper maintenance to all equipment components, especially extensive experience has been accumulated in solving the problem of irregular intake and drainage of water. We understand that the machine fills a large amount of water, exposing the main elements and components to attack, gradually disabling them. At the same time, the washing machine does not perform its basic functions well: the laundry does not wash.

- We work with models of modern and older washing machines from Samsung, Indesit, Bosch, Zanussi, Electrolux, Beko and others. We know the weaknesses of these household appliances.

- Basic components for repair and replacement are always available. You won't have to wait long for the required spare part to be delivered.

- We use only original spare parts from official manufacturers. That is why we provide a guarantee on services and components for up to three years.

- The cost of repairs and work of specialists depends on the complexity of the fault and diagnostic results. Our prices are available to all users of washing machines.

Main reasons

The normal operating cycle of the machine is accompanied by the supply and removal of water. This happens at least 2 times. However, if the unit does not hold water and constantly drives back and forth, then you will have to deal with the problem.

All reasons are divided into 2 blocks:

- incorrect installation;

- new malfunction.

Water enters the tank. After washing, the machine is released by operating the pump located at the bottom of the structure. Water comes out through the attached hose.

For proper operation of the machine, the end of the hose must be at least 60 cm from the floor, maximum - 1 m. That is, if compared with the level of the middle of the drum, then this value is approximately 10-15 cm above this level.

If the hose is too low, the water flows by gravity into the sewer. At the same time, the washing machine begins to pump again because a vacant place is freed up. A new portion of water leaves the same way, and the cycle begins all over again.

Among the causes of malfunction are also:

- Damage to the water level sensor. This device shows the water content in the tank and is also responsible for sending a command to the inlet valve. The pressure switch determines how full the machine is by the pressure of the water column. If the sensor pressure tube is clogged, the device may provide incorrect information. The consequence of this will be the constant filling of the machine. The sensor will need to be repaired or replaced.

- Problems with the outlet valve responsible for the water supply. The failure may be only one membrane or the entire valve, as a result of which water leaks through it even when closed. The inlet valve, which is responsible for the water supply, is not working correctly.

- Siphon effect. If there is a blockage in the sewer pipes, and the neighboring apartments are still using them, the pressure inside is rarefied and draws in moisture, after which a signal is received that more needs to be filled. So the device constantly takes in water and immediately loses it. It is impossible to wash things in this mode.

- Damage to parts. There are a number of components in the washing machine that are responsible for the circulation of moisture within the system. If one breaks, this leads to the fact that the device will lose and replenish the level of liquid in the reservoir all the time. Finding the source of the malfunction can be difficult; it is better to entrust this to a specialist.

Breakdown of the pressure switch

If the washing machine worked properly for a long time, and suddenly began to constantly fill with water, then the reason lies in the breakdown of one of the components of the device.

Control over the amount of water entering the tank is carried out by a special sensor - a pressure switch. Once the amount of water in the tank reaches a certain level, the sensor is triggered and the washing machine stops drawing water.

The most common reason for non-stop water supply may be a breakdown of the pressure switch. The sensor may become unusable due to oxidation or short circuit of contacts, or loss of membrane tightness.

Tube going to the pressure switch

A faulty sensor can be repaired or replaced with a new one. If cracks are found in the tube leading to the pressure switch, normal operation of the part can be restored by sealing the damage.

If it is necessary to replace the sensor, when choosing a new part, you should base it on the data printed on the old pressure switch. The sensors are marked with a contact and group number - it is with the help of this information that you can select a new pressure switch.

When the pressure switch is working properly, its malfunction can be caused by the formation of a blockage in the pressure tube of this sensor (this can be small debris, sediment or scale). The performance of the water level sensor may also be affected by a malfunction of the hose or pressure switch valve, which can also become clogged.

If the pressure switch tube is clogged, you can clean it simply by removing it from the mount and thoroughly blowing it out.

In order to get to the pressure switch, you need to remove the back wall of the washing machine. In most devices it is located in the upper left section of the case and is a noticeable part against the background of other spare parts. Before removing it, it is advisable to check its contacts for functionality. Cleaning the oxidized contacts can revive the water level sensor. If this does not help, the part needs to be replaced. To remove the pressure switch, you need to disconnect the tube connecting the pressure switch and the compression chamber. The next step is to disconnect the terminals and unscrew the screws. After this, the sensor is easily removed and a new serviceable part is installed in the reverse order.

What to do to avoid machine breakdown?

Washing machine care and maintenance

Proper and timely cleaning of its components is extremely important for reducing the consumption of washing powder and good functionality of the machine. Certain parts of the unit constantly require cleaning, namely: the door seal, the filter, the mesh on the supply pipe.

Proper washing. How to wash bed linen?

Of course, before washing, laundry needs to be sorted. Proper sorting by color and material will help the laundry maintain its original appearance and make life easier for the washing machine.

If the laundry is not dirty and the goal is simply to freshen it, it is necessary to use the cold mode and a short, not complete program. By following these simple rules, you can save energy and take care of your machine drum.

How to understand what is broken

Before you begin repairs, you need to figure out what is causing the problem. If you cannot verify that the machine is connected correctly, perform the following test:

- Start a regular wash program without laundry.

- When the machine is full, press the “drain” button.

- After this, use the “pause” button to stop the process.

The mechanism should stop draining. If you still hear the sounds of liquid escaping into the pipes, then your device is not connected correctly.

To detect the siphon effect, in the evening or morning, when many people are using the sewer along the riser, open the faucet in the sink. If at some point you notice that it began to be drawn into the pipes with squelching sounds, most likely there is a small blockage in the pipes. If you cannot eliminate it, you will have to install a siphon filter. It will maintain the correct current.

In all other cases, we are talking about defects in parts, which we will discuss below.