Household appliances / Washing machines / How to choose a washing machine

For a long time now, the presence of an automatic washing machine in the house has become common and natural. It is almost impossible to imagine how people could manage without it before? Using the machine is easy and simple. You don't need to be incredibly talented to run the automatic wash program you want. Even for people who are not very “friendly” with technology, operating a modern machine does not cause any particular problems.

But the apparent ease of use does not negate the fact that this type of household appliance is a rather complex device, composed not only of mechanical parts, but also of various electronic modules and sensors. Few users have any idea what the operating principle of an automatic washing machine is. And even more so, what kind of algorithm forces the machine to execute this or that program. To better understand how to operate it correctly and what can be done if problems occur, you should at least to a small extent understand how an automatic washing machine works and by what laws it operates.

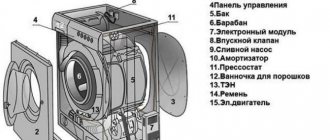

Design of automatic drum-type machines

So, the basis of such machines is a cylinder-shaped drum, which is placed in a tank suspended inside the machine body on springs. The position of the tank/drum unit is controlled by a system of shock absorbers and counterweights. Water is drawn directly into this very tank through a solenoid valve. Its quantity is controlled by a special device called a water level sensor or pressure switch.

The rotation of the drum is ensured by a drive motor and a bearing system. The drive can be belt or “direct” (the motor is directly connected to the shaft of the drum cross). A heating element is placed in the water tank, whose task is to heat the water. To control the water temperature, the heating element is supplemented with a temperature sensor, which is located in the tank body or directly in the heating element itself.

Water is drained from the tank using a special drainage pump. Automation of the process is achieved using an electronic control module, which is the “brain” for the washing machine. The entire operating algorithm completely depends on this element.

Control block

This unit of the washing machine commands all other elements, so it can safely be called the “brain” of the device. It is also called a programmer, electronic board or control module. It is from such a block that commands are issued that are carried out by the fill system, heating element, drum, drain pump and other parts.

The control unit is the most complex and expensive part of the washing machine. Its device has a digital indicator, thanks to which the user knows everything about the operation of the device. In most models, if there is a malfunction, such an indicator begins to show an error code. Having learned its decoding, you can determine what the breakdown is and whether it can be dealt with without calling a technician. If the module itself fails, you should contact a specialist to repair or replace it.

How does a machine wash automatically?

The principle of washing remains the same - it is a mechanical interaction with the laundry. Only, unlike activator-type machines, this effect is carried out by the perforated walls of the drum.

The implementation of the selected program is ensured by the degree of water heating, its quantity, washing time and detergent for automatic washing machines (no matter liquid or powder). And for a more intense or, conversely, delicate mechanical action on the laundry, a special algorithm of drum movements is responsible. It can rotate in opposite directions with the same or different frequencies (depending on the program). Or not even make a full rotation, but rather rock the laundry for the most delicate washing.

From different manufacturers, the walls of the drum can be standard (smooth with a system of holes), or they can be of a special shape and are designed to provide a better washing result (for example, a honeycomb drum). Of course, each manufacturer claims that its drum is the best, and its movement algorithm is the most effective.

Heater

The heating element located inside the washing machine is responsible for heating the water during the washing process. The heater power most often ranges from 1800 to 2200 W. It is located at the bottom of the tank and is considered one of the most vulnerable elements of such equipment. Its breakdown is one of the most common and most often occurs due to the accumulation of scale on the surface of the heater.

Pre-launch stage

To ensure automatic operation, the machine is permanently connected to the water supply and plugged into an electrical outlet. The required amount of detergent for automatic machines must be added to the powder dispenser or directly inside the drum. The drain can also be stationary or done into a sink or bathtub using an adapter hook on the drain hose.

Through the loading hatch, laundry made of a certain type of fabric and a certain color is placed into the washing machine. The program corresponding to this type of laundry is set on the control panel. If necessary, spin speed and temperature conditions are adjusted. Additional washing or rinsing parameters are set (if they are provided for a specific machine model).

Dosing compartments

Various machine models are equipped with 2-4 compartments for cleaning and care products:

- soaking section;

- for softener or stain remover;

- for powder or gel;

- for rinse aid, conditioner.

Chemical products are washed automatically, depending on the operating mode of the machine and the stage. When the program is finished, the cleaning agent compartment is cleaned to prevent contamination.

You can also use external containers for automatic supply of laundry detergents, mounted close to the device.

How does automatic washing work?

The process is started by pressing the “Start”, “Start” button or something else designated. The water begins to flow through the fill valve while the drum rotates to more evenly wet the laundry. Some modifications of washing machines additionally have a device that supplies water from above the hatch to optimize this process.

As the tank fills with water, the pressure in it begins to change. Based on this parameter, a special sensor (pressostat), when the water level required for a specific amount of laundry is reached, sends a signal to the control unit about the need to stop its supply. The control module, in turn, closes the solenoid fill valve. During the pouring process, powder is washed out of the detergent dispenser and dissolved with water in the drum. If fabric softener is used, the moment it is taken out is determined by the installed program.

Under the control of the control module, at a certain moment, the soap solution is rinsed out several times. The most advanced automatic machines are often equipped with a water transparency sensor. Then rinsing will be carried out until the remaining powder and contaminants in the water are completely washed away. Everything ends with draining (the drain pump is turned on) and spinning by turning on the engine at a given speed (if the program without spinning is not installed).

General information

The first machine for washing clothes was described in 1752 under the name "Yorkshire Maid". It consisted of a wooden tank that could be closed with a lid and filled with laundry and hot soapy water. In the center of the lid was a wooden block with a handle at the top for turning, and at the bottom there was a wooden disk with recessed wooden pins that moved the laundry in the soapy water, turning back and forth. The size of this machine and its manual operation made it suitable for small households.

Automatic washing machine programs

Absolutely all washing machines have three main programs – cotton, synthetics and wool. Everything else is their varieties or additions to them, which help to change or supplement them to enhance the effect or reduce washing time. Programs for synthetics and especially wool are considered delicate types of washing. The reel rotation algorithm for these programs usually changes.

- Cotton. The most intensive washing with the ability to adjust the spin speed and temperature. Usually there is an option for accelerated washing by reducing rinses. Divided into a program for light or dark laundry.

- Synthetics. A more gentle program with shorter washing times and limited spin speed.

- Wool. The most delicate wash. As a rule, washing occurs at low temperatures and with minimal or no spin. If the “stop with water” function is activated, after finishing washing the wool, you need to separately set the drain with spin or only drain.

Most modern automatic machines have a “Short wash” subprogram (15, 12 minutes, etc.). It is difficult to consider this type of program a full-fledged wash and expect that in such a short time, its result will be comparable to longer programs. Rather, it is a convenient way to refresh not particularly soiled laundry.

Water supply

The supply from the common line is carried out through hoses and solenoid valves that open and close at the right time. A flow regulator is also installed in the valve, which helps control the pressure regardless of the pressure in the line.

If it exceeds 10 bar, a pressure reducing valve is additionally installed. A pressure value below 1 bar also requires additional measures.

There is a filter in front of the valve to prevent particles from entering. Usually about 1-3 valves are installed, in the latter case a valve is provided for each compartment in the care dispenser.

Additional elements of automatic washing machines that you should know about

- Fill filter. This is a small removable mesh that is installed at the point where the inlet hose connects to the machine. As it becomes dirty, this filter can be easily removed with pliers and cleaned of contaminants caused by poor quality tap water.

- Drain filter. During draining, this filter protects the pump from foreign objects entering it that could block the operation of the pump. In cases where the machine refuses to drain water, the first thing to do is clean this very filter. It is always located on the front of the machine body at the bottom. To remove it you just need to unscrew it.

This somewhat simple, but in some ways complex device serves faithfully in our homes. With knowledge of the principle by which an automatic washing machine works and how it is designed, it is quite easy (if any problems are detected) to figure out - what, exactly, is the problem? This means that fixing the problem is much easier.

—

Tank and drum

The tank is considered the main and most voluminous element of an automatic machine. It can hold 35-60 liters of water. To prevent the machine from vibrating excessively during washing, the tank is not rigidly connected to the body. To support it, there are two or four springs at the top of the machine, and two or four shock absorbers at the bottom. In addition, to eliminate imbalance and strong vibration of the tank during washing, concrete counterweights are attached to it. Thanks to this design, the body remains motionless during operation of the equipment, despite the vibrations of the tank.

Inside the tank there is a drum connected by a belt drive or direct drive to the engine. Laundry is loaded into the drum, and after the washing program is turned on, water and detergent begin to flow into it through many holes. At the front, the tank is connected to the drum by a rubber cuff, which ensures tightness, and at the rear, the drum shaft passes through the tank to the bearing unit.

Stainless steel is usually used to make the drum, and the tank can be either steel or plastic. The second option is cheaper, but is more fragile and has a shorter service life. Often the tank has two halves, which are connected with bolts or with a clamp, but in many machines there are non-separable tanks.

Water supply control

The duration of the supply depends on the level, which is determined by mechanical or analogue controls. Mechanical ones are implemented in the form of a cell with a membrane, connected to the bathtub with a hose. When the desired level is reached, the pressure increases and the water supply stops.

The analog controller is triggered by an increase in level, it reacts by changing the resistance.

Read more ► The washing machine takes in water and immediately drains: the main causes and their elimination

Sensors are also used to protect the heating element - it turns on only when a certain level is reached in order to avoid damage to the heater.

Independent replacement of radio components

If you have the knowledge and ability to work with a soldering iron, you can try to repair the faulty module. To achieve the desired result, a diagram will be useful. Some manufacturers do not consider it necessary to make it easier for users to repair their products, but this is not a problem; any diagram of any module can easily be found on the Internet.

Before starting work, you should remove the board, clean it from dust and examine it carefully, preferably under a magnifying glass. Some faults, such as a burnt resistor, are much easier to detect visually than with a device.

Principle of operation

The description of the structure of a drum-type washing machine and the procedure for performing operations to obtain clean laundry make it possible to formulate the principles of its operation:

- The process consists of the mechanical action of the drum on the laundry. Elements such as ribs, together with a perforated surface, when rotated, create manipulations similar to washing by hand.

- Possibility to wash clothes from almost any material. The control unit allows you to select a program for the most delicate fabric (delicate wash, hand wash, etc.).

- A wide range of temperatures used (30°C—95°C) in combination with proprietary powder makes it possible to obtain high-quality laundry.

- The drum volume allows you to load a fairly large number of dirty items at a time, increasing productivity.