While the washing machine works without failures, few people are interested in its structure.

But as soon as household appliances break down and do-it-yourself repairs are planned, detailed information about where individual elements are located and how they work will help carry out the work competently, quickly and efficiently.

We will tell you about the design of Indesit washing machines in the article.

Let's list the main elements

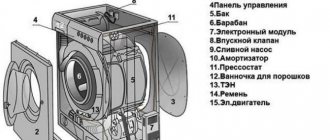

The washing machine device includes both main and additional modules. Your unit will only work if all components are in smooth contact with each other. A car of any model contains:

- electric motor;

- tank and drum;

- drain pump;

- control panel with electrical module support;

- spring shock absorbers;

- special unit with bearings;

- the main body, the rear wall of which is made in the form of a hatch cover;

- liquid intake valve;

- tubular electric heater and parts for it.

Please note that this is a completely basic set of parts for any washing device. If you understand what and how the circuit works, you can easily analyze the behavior of your Indesit washing machine.

About the features of automatic washing machines

Each device is supplied with a housing. There is a metal frame with a front panel. Additional elements - a wall at the back, a lid with a base. Working units and mechanisms are located inside the housing. They are responsible for performing the functions assigned to the units. LG and many other models are no exception to this, the same can be said about the design of the Indesit washing machine, which will be discussed further.

How does the technology work?

The Indesit washing machine is equipped with a plastic tank. To avoid deformation of the tank, it is not so rigidly connected to the body so that excessive vibrations are not created, which destroy the tank. After all, the tank moves very actively during washing and, especially, spinning, but the body remains motionless, which actually ensures the safety of the tank. Plus, two shock absorbers are placed below for support, and springs are placed on top.

During washing, the drum rotates thanks to a special pulley to which it is connected through a cross. The pulley, in turn, receives revolutions transmitted by the electric motor through a belt drive. All these actions cause the pulley to rotate, and since it is attached to the drum, the drum also rotates, due to which our clothes are washed. The drum itself is built inside the tank with a mount.

The so-called “intelligence center” of the washing machine is the control board; it is it that sets the sequence of operations and the coordinated interaction of all components of the unit. For example, supplying a washing machine with water includes a number of actions of different parts: the inlet valve draws water from the water supply, the heating element heats it to the required temperature, the pressure switch controls the volume of water, and a special pump removes contaminated water after the washing process is completed.

Now you can roughly imagine how your washing machine works and how it works, but to add more details, you should look at the operation of each module separately.

Main container and drum

Drums are predominantly made of stainless steel, as are the tubs of some washing machines. This material is more durable and, as a result, your machine will last much longer. However, if you prefer a more budget-friendly and lightweight option, take a machine with a plastic tank. It is not as durable, but it is cheaper and easier to carry. In the most common models, the tank is located horizontally, although some manufacturers also produce machines with inclined tanks.

All modern Indesit washing machines are equipped with plastic tanks.

So, the tank is the main capacity of any washing machine. As we already understood, there is a built-in drum into which you load your laundry. The drum usually has a huge number of holes through which water from the tank penetrates into this container. Yes, water is drawn from the water supply into the tank, where it is heated and mixed with the powder, and enters the drum during the washing process. In addition, the surface of the metal tank is very corrugated, which improves the quality of washing. To avoid leaks and other troubles, no foreign objects should get into the tank.

About electric motors

Washing machines use several main types of motors:

- three-phase stepper is the rarest. They are supplied to premium Indesit cars;

- asynchronous three-phase - characterized by operation without additional noise;

- collector - the simplest models. They are installed in economy class equipment.

Types of engines

Revolutions per minute are the main characteristic for the engine of any washing machine, including Indesit and LG. They help to understand how efficiently the device works.

Heating the mixture of water and powder

A tubular electric heater, or abbreviated as a heating element, which is built into the lower part of the machine, is responsible for heating the water in the tank. When the washing machine is actively used, the heating element is subject to the greatest damage, because scale forms on its surface, which gradually disables it, and, in addition, the heating elements always fail faster than other electrical appliances. The more often you wash in hot water, the faster problems will arise with the heater.

According to the technical characteristics, it is worth saying that the energy consumption is approximately 1800-2200 W. This is equal to the average energy consumption of any heating mechanism. Therefore, if it seems to you that the washing machine “eats” a lot of energy, then the problem is clearly with the heating element.

Call the master

If you are unable to fix the sensor failure yourself, call a specialist. You can find them on Avito; many craftsmen offer their services at home, and they charge less than employees of official service centers.

To avoid running into a scammer or an unscrupulous professional, read reviews from people who have already used the services. If this is a worthwhile specialist, his profile will definitely have reviews from grateful clients.

The price for private services is discussed individually. In equipment repair companies, replacing a pressure switch costs from 1,600 rubles. Do not pay for the service in advance to avoid becoming a victim of an attacker.

The specialist must have with him instruments that will help identify a malfunction of the pressure switch. If everything is fine with it, the technician will determine what the problem really is.

What makes the drum move?

Remember we already talked about the connection between the drum, pulley and electric motor? It is the electric motor that powers the device. Indesit uses commutator motors in order to save money and, as a result, to reduce the cost of goods. However, commutator motors do not have any enviable strength, and in addition, they are very susceptible to voltage drops, so it is better to connect them through a stabilizer.

Brushed motors quickly lose their level of functionality, and eventually stop working altogether if they are not carefully maintained (you will have to, for example, change the brushes regularly).

Typical faults

By studying various information on SM Indesit, you can identify certain typical problems. Thus, one of the reasons for breakdowns of WISN series machines is the heating element. Due to the lack of coating, the heater quickly corrodes, and carbon deposits quickly accumulate on it. This series is also distinguished by a voltage surge sensitive surge protector. A breakdown occurs when the machine refuses to turn on. It is not difficult to repair it. Most often you just need to replace the capacitor.

The situation is more complicated with repairs related to processor failure. It is unlikely that you will be able to repair the board yourself. You will have to change the entire electronics board. The engine sensor is the weak point of the WISE series, but its repair is simple. Typically, the operation of the SM is restored after replacing the capacitor located in the data transmission circuit from the meter to the electronics board.

Drum bearings can only be removed for models up to 2014. The stabilization system, which includes two springs and a shock absorber, is quite good on all models, with a significant margin of safety. However, as a result of improper installation and increased vibration, it may break. In this case, characteristic sounds will appear during the spin mode. Restoration consists of replacing the stretched spring.

Mechanical problems also include leaks in the cuffs. Like in the WIN series. The reason is a violation of their integrity. Can only be repaired by replacement. If it is determined that the rotation of the tank is difficult, then the cuff can be carefully trimmed from the outside.

Thus, in some cases you can repair the SM yourself, especially if purchasing a failed part does not cause problems. But if you doubt your abilities, then it is better to contact a service center.

How do you like the article?

Water supply and removal

Water is supplied from the water supply to the tank according to this scheme.

- A specialized module “orders” the intake valve to open;

- The valve opens, and since it is under high pressure, water immediately begins to penetrate into the tank.

- The pressure switch controls the volume of water so that exactly as much as is needed (the same happens when draining water, so this sensor is indispensable for any machine);

- When the required volume has been reached, the pressure switch signals the module, and it, in turn, signals the valve that there is enough water and needs to close.

- The valve closes and the water supply stops.

As soon as the wash is completed, the control module begins to interact with the pump. The pump receives a signal to drain water and begins to push it into the sewer through the drain hose. Thus, water is pumped out from the tank. Then, using the same operations, the machine draws in water to rinse the laundry, and then drains it in the same way.

The drain pump is faulty

Symptoms: The water takes too long to drain or the water does not drain at all.

If all possible blockages in the drain system have been checked and eliminated (drain filter, hose, pipes, sewer), then the cause of poor drainage is most likely the drain pump (pump).

The pump usually fails as a result of prolonged use and clogging: if cleaning the pump does not help, then it will have to be replaced. We advise you not to try to repair the pump yourself: this work requires thorough disassembly of the washing machine and diagnostics, in addition, finding a suitable replacement model is very difficult.

The “brain” of the washer

The control board is responsible for all parts of the machine, except for the control panel (it includes all the buttons, indicators, etc.). There is a separate fee for this. Both of these devices are combined and perform the function of the “intelligence” of the machine: they issue commands to the modules for the coordinated operation of the device.

Washing programs and modes are pre-designed algorithms for certain actions that are recorded on the control board. Accordingly, it is responsible for the operation of any program that you choose. The board structure consists of many semiconductor elements (these include triacs, thyristors and other parts).

Contacts between parts are made through special electrically conductive tracks, which are also located on the control board.

The control panel board has a slightly different purpose. While the control board coordinates the interaction of parts, this one coordinates the interaction between the operator and the control board. That is, its task is to “explain” to the control board what exactly the user wants to do, as well as inform him about all the details of the wash (by displaying information on a special screen or through indicators).

Auxiliary elements

We have figured out how the basic parts of the Indesit washing machine work. However, there are many more. Their role is not so fundamental, but without them your washing will not happen either. Here is their list.

- Parts that prevent the harmful effects of vibration on the tank are springs and shock absorbers. They dampen vibration.

- To prevent water from flowing out from under the hatch cover, there is a special cuff. This is a kind of rubber seal that tightly seals the hatch when washing.

- Hatch blocking device - abbreviated as UBL. This detail also helps to completely close the hatch and prevent accidental or independent opening. As long as the UBL is in good working order, water will not pour out of the machine.

- Drive belt. The one that directs the rotation to the pulley, and the pulley, as you remember, helps rotate the drum. Therefore, for the drum to operate, you cannot do without this part.

- Counterweights. Counterweights are very large stones, both in volume and weight, that are installed inside the body, increasing its mass. Due to these parts, the machine has the ability to resist centrifugal force during spinning. Otherwise, the washing machine would move very actively around the room due to pressure on the side walls.

- Hatch door. There is no need to describe the significance of this detail. Without it, washing is basically impossible.

- Powder receiver. There you place detergent and conditioner, which are dosed into the tank during the washing process. As a rule, it includes three compartments for different types of detergents.

- Pipes. Through them, water moves into and out of the tank. Built into the body.

Now, knowing all the details of the operation of the Indesit washing machine and the features of its design, you can easily analyze its behavior and condition. If a problem occurs, you will know what to look for first, and you will probably be able to carry out simple repairs yourself. Remember that if you treat it with care, your device will last you much longer and will delight you with its quality much more.

Interesting:

- Top-loading or front-loading washing machine…

- Design of Bosch washing machines

- Dimensions of a front loading washing machine

- Best top loading washing machine

- How to disassemble a Zanussi washing machine

- How does an Electrolux washing machine work?

Reader comments

- Share your opinion - leave a comment

About additional details

Front-type counterweights are present only on some models. This is necessary to compensate for the imbalance. The shape, material, and weight of such inserts may vary.

Counterweight

The counterweights themselves are blocks with a fairly large weight. They can be plastic or concrete. The latter have a serious drawback - the ability to deteriorate and crumble over time. But most often serious problems arise due to mounting on counterweights. Because of them, the seat of the bolts is destroyed.

Counterweight to avoid vibrations

To transfer torque from the electric motor to the drum, you need a special belt. Most often, rubber is used to make such parts. But some manufacturers put belts made of polyurethane, neoprene and nylon inside their cars.

Drive belts are available in several varieties:

- groups Z - almost every device from Russia is supplied with them;

- H - found in small cars;

- J is a diagram for devices with large dimensions;

- 3 L - found in foreign analogues. LG, for example.

Drive belt

A wheel is attached to the drum shaft, which is called the driven drum pulley. It also participates in transmitting the movement of the drive belt. The diameter of this structure determines what the maximum number of revolutions in the machine will be during operation. Aluminum alloys are very fragile materials, from which this pulley is almost always cast. This also applies to Ardo models.