When purchasing a washing machine (hereinafter also referred to as SM, ASM), most people expect that the unit will operate quietly. However, this does not always happen, and the owners do not know what is happening - maybe the machine is supposed to work this way. In fact, the washing machine makes noise during the spin cycle for several reasons.

Noise during operation of the washing machine causes a lot of trouble for owners

Small object or foreign part

The washing machine hums and whistles during the spin cycle due to the fact that some small item has gotten into the space under the drum. Let's look at the main reasons why they get there:

- Clothes pockets are considered one of the main problems. Saving just a few minutes before washing, which you need to spend on double-checking, develops into a real disaster.

- Loading items with buttons, beads, accessories and bras comes with additional risks. Small items of clothing may come off during the main or spin cycle. Try to use laundry bags whenever possible.

- A child can quietly place a toy in the tank or something small in the powder tank.

Important : Always check your clothing pockets before washing.

In the long run, foreign parts can ruin the operation of the machine. To prevent this from happening, you need to extract the excess by following simple steps:

- Disconnect equipment from electricity.

- Remove the top and then the bottom walls.

- Find the heating element, disconnect it and unscrew it.

- Carefully remove all objects and debris from the hole.

- Assemble the car, performing the steps in reverse order.

Most models are equipped with a special sump with a debris filter. As a rule, it is located at the bottom of the front panel. In this case, it is enough to open the door and remove the dirty filter for cleaning. If the washing machine does not start spinning clothes silently, return to parsing.

Precautionary measures

In order for the machine to work for a long time, you must adhere to certain rules.

- You need to be vigilant and carefully inspect things for small parts that may come off during washing and get into the tank. It is better to put such things in a special laundry bag.

- Remove money and other small items from your pockets that could damage the machine during the washing process.

- Protect the heating element from scale that forms from hard running water. To do this, you need to use water softening and descaling products.

- It is necessary to move the washing machine at least once every six months and check the serviceability of the hoses, as well as flexible wiring and pipes for damage.

- Wash and clean the drawer for powder and rinse aid. If this is not done, hardened powder particles may accumulate in the machine, which will interfere with the normal operation of the equipment.

- After each wash, leave the powder container and the machine door open. This is necessary so that the internal parts of the washer dry thoroughly.

All these recommendations will help extend the life of the washing machine and protect it from frequent breakdowns and calls to service centers.

Some types of repairs can be carried out independently, but still, if the breakdown is serious, it is best to contact a service center and call a specialist to your home.

Bearings

One of the most common reasons why a washing machine is noisy during the spin cycle is problems with the bearings. The only element that protects them from water and air is a rubber seal. It is not surprising that over time, leaks occur on the part, and as a result of corrosion, the washing machine begins to whistle and make unpleasant sounds. Usually the oil seal lasts for 5-7 years of stable operation, after which it needs to be replaced.

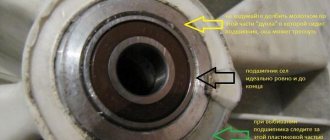

To detect bearing failure, you need to manually rotate the tank. If you hear a crackling sound or feel play, it is necessary to urgently lubricate or replace the problem unit.

Important : bearing repair is a very labor-intensive process and requires compliance with all manufacturer’s recommendations. If you are not confident in your abilities, it is better to contact a specialist.

Step-by-step instructions for self-replacement:

- You need to start by removing the top and back covers, after draining the water and relieving the voltage from the device.

- Remove the powder dispenser and then carefully remove the control panel. Most often it is secured with simple latches or a few screws.

- Similar to clearing debris, remove the heating element, and then the pipes and counterweight.

- Dismantle the weights that are located below and above the tank to facilitate removal of the drum.

- Remove the belt from the drum and engine pulleys, and then unhook the part from the shock-absorbing springs.

- Carefully remove the assembly and unscrew the pulley to get to the bearing. This can be done using a hammer and a blunt chisel. It is worth noting that in some models you will have to disassemble the drum.

Important : use only lubricants recommended by the manufacturer.

The replacement process is quite simple. It is necessary to remove old parts from the sockets, and then clean the metal rings from dirt. The next step is to install the new parts in place and apply lubricant. A thin layer is sufficient for the seal, but the bearings must be thoroughly treated.

Assemble both the bearings and the seal correctly. The latter, if installed incorrectly, will begin to let air and moisture through again.

Washing machine noise level standards

Depending on the model, washing machines vary in noise level. The noise limit is always indicated in the technical documentation. To reduce sound production, manufacturers equip devices with special systems. The amount of noise produced by the machine depends on the type of drive:

- belt version (gear drive) - volume varies within 60-75 dB;

- direct drive - the sound threshold is reduced to 50-70 dB.

Important! There are no absolutely silent SMAs, but the indicated audibility is quite comfortable for the user.

Identifying a problem by sound

The noise of the SMA intensifies during the spin cycle, since at this moment the drum rotates fastest. If the device has a noise level of 75 dB, excessive volume is completely normal. To determine the fact of a malfunction, listen to the sound:

- increasing, uncharacteristic rumble with each wash;

- very strong vibrations during the spin process;

- a loud noise that sounds like grinding, banging, or clanging.

Metal parts of things can lead to similar sounds. But constant violations indicate serious and minor failures.

When the shaft, oil seal and bearing wear out, screens are accompanied by a change in the color of the water during draining, rusty spots on clothing, leaks and jamming of the drum. Identifying the broken part and fixing it requires professional diagnostics. You can only identify common problems yourself.

Bolts for transporting the tank

To deliver equipment from production to your apartment in good condition, special fasteners and packaging are used. But with a washing machine everything is more complicated, since it consists of many moving parts. Manufacturers install shipping bolts that secure shock absorber springs.

Since the bolts secure the tank in a stationary state, it is strictly forbidden to turn on the machine with them. If the washer is working, it is recommended to cancel the program. It is necessary to unscrew all the bolts located on the rear wall of the machine. The number of clamps is indicated in the instructions; as a rule, there are 4, 3 or 2 of them.

How to remove bolts correctly:

- Unscrew the screws using a simple wrench or adjustable wrench. Loosen them, carefully remove them and store them.

- Close the resulting holes with special plugs or plugs. Otherwise, dust and moisture will enter the washing machine.

Tip : Don't throw away the shipping bolts as they may be needed in the future.

Main reasons

A washing machine is a piece of equipment that is used almost every day. Even if you take care of the washing machine and treat it with care, over time the parts wear out and require replacement.

Location of transportation bolts.

Main causes of noise:

- The transport bolts have not been removed.

- The bearings have failed or fallen apart.

- The presence of a foreign object between the drum and the wall.

- The drum pulley is loose.

- The counterweight is poorly secured.

- The hatch needs replacing the seal.

- The machine is not installed correctly.

To repair the unit, you need to know the exact cause of the noise. To do this, you should listen to the nature of the extraneous sound, whether it increases during greater load. Repairing equipment at home is not always a justified idea.

Failure of the centrifuge rotation axis

The centrifuge is responsible for the movement of the machine drum during washing and spinning. There are many causes of breakdowns, so it is difficult for an ordinary user to fix the problem on their own. Below are the main reasons:

- The tank is overloaded with laundry or water. The rated power of the element is limited, so any load above the norm may cause breakdown. Also, unevenly distributed laundry causes the tank to sway.

- Ingress of foreign bodies that block the rotation of the drum.

- A breakdown of the tachometer is characterized by a sharp change in the number of rotations, too high or low speed, and the items are wet or poorly wrung out after washing.

- The water sensor is faulty - it does not work or gives false readings. Signs include insufficient or excessive amount of water, turning on the heating without water.

The problem can be determined experimentally by first reducing the weight of the laundry per wash. If this does not help, you need to clean the insides of the machine from foreign parts, and then analyze the operation of the sensors and replace the faulty elements.

When spinning, the drum knocks loudly: what can you do yourself?

When the washing machine is operating in spin mode, the rotation of the drum reaches its highest speeds.

Noise and vibration inevitably occur. In some cases, such as improper installation or malfunction of certain parts, it may shake and make more noise than expected. It is not recommended to try to repair serious faults at home, as this risks damaging fasteners, the tank cross and other parts. However, if you notice excessive noise or shaking during washing, follow these steps:

- Switch the machine to spin mode and after it has drained the water, open the drum and remove some of the laundry. Then turn it on again. If the knocking and vibration stop, then the problem was overload.

- Start the unit at idle speed, then turn on the spin program. If the centrifuge continues to rattle, then the problem is most likely a malfunction of the internal mechanisms.

- Bend the hatch cuff and inspect the space between the tank and the drum. If there is a foreign object there, try to remove it.

- Open the filter hole by first inserting the tray. Clean it of small debris.

Has your washing machine started making an uncharacteristic knocking noise? This happens sometimes.

And this is not always a sign of a unit malfunction. Perhaps it is metal or large plastic parts of the laundry (buttons, zip runners, carabiners) knocking against the glass of the hatch and the drum. It is recommended to wash items with large fittings inside out or in special washing bags: this way there will be no knocking or damage to the machine.

If you loaded only soft clothes, and the knocking sound is clearly heard, then there is definitely a problem with the washing machine. Sounds uncharacteristic of washing occur due to a number of malfunctions. Only a specialist can correctly diagnose them, sometimes only with special equipment. But based on some signs, you can figure out on your own what happened to the assistant.

Attention! Before performing maintenance, disconnect the machine from the power supply and water supply!

Counterweight is poorly secured

Also, when spinning, the washing machine makes a lot of noise and rattles due to problems with the counterweight. The part is necessary to make the tank heavier, reduce vibration and provide stability. Counterweights are made of cast iron, plastic or concrete, and the latter break and crumble more quickly.

The most common problem with counterweights is poor fit. Over time, the washing machine, operating at high speeds, weakens the fastening. At the same time, the counterweight begins to vibrate and rattle during the spin cycle.

To solve the problem, simply remove the back panel of the machine and check the tightness of the mounting bolts. As a rule, this helps. If it is visually discovered that the counterweight is damaged, it needs to be replaced.

Unevenly distributed laundry

This problem is typical for older models. Modern devices practically do not rattle, of course, if they are in good working order and installed correctly. Good alignment is facilitated by the presence of electronics, which allows you to distribute things more evenly and prevent imbalance in the drum. Old devices cannot assess how well the drum is centered, and whether there are crumpled laundry in it. Spinning occurs in any case, and then the drum may knock on the walls or other elements of the washing machine.

Initial installation failed

The lack of qualifications of self-taught craftsmen taking on responsible work is indeed the cause of breakdowns. As a result, after a couple of days it backfires on the owners of the equipment – the washing machine is knocking

Inattention to such a significant detail as a completely horizontal surface costs the washing assistant his life. After all, the drum, which gains maximum speed during push-ups, destroys itself if it is positioned unevenly, skewed

To precisely regulate the height of each corner, the washing machine has legs that unscrew after performing rotational movements. If there are slight distortions, try tightening the stands one by one and you will understand where to make them higher and where to remove a centimeter in height. It's a good idea to have a regular builder's level on hand to ensure the floor and installation are level. After completing the adjustment, check the stability, then arrange a wash test.

Installing a washing machine by levelReviews

Alexey, Mr. Belgorod

The wife said that the washing machine began to make noise when taking in water and when draining, but the operating process itself proceeded as usual. I checked the operation of the SMA myself and decided to look for a possible cause on the Internet. Judging by the signs of malfunction, the drain pump has failed. I opened the back wall of the machine, as indicated in the description, took out the pump and replaced it with a new one. The noise stopped. Thank you for the useful article.

Ilona, Rostov-on-Don

I noticed that my beloved SMA began to work with excessive noise. I was scared because I decided that I would have to buy a new device. But after turning to the Internet for help, I realized that the reason could be in foreign objects. Having finished washing, I took out the change that had fallen out of my pockets. And when my husband came home from work, he looked at the channels and took out debris that was between the heating element and the drum. Thanks for the advice .

In what cases is noise at high speeds normal?

Engine operation and drum rotation at high speeds cannot be silent. During spinning, the sound intensity increases, and its maximum value will depend on several factors:

- quantity and distribution of laundry in the tank;

- machine design (type of transmission, presence of counterweight, etc.);

- washing programs, speed;

- unit models.

What should not alarm the owner:

- The hum of the motor when the drum rotates (both during washing and spinning).

- The noise of the drum itself while spinning clothes.

- Increases sound when turning on higher speeds.

Tips for avoiding malfunctions

In order for the “helper” to last longer, you must strictly adhere to the operating rules. Among the most important rules are:

- do not wash more clothes than is provided for in the machine’s passport;

- clean the drum for preventive purposes;

- programs that provide high water heating should be used to a minimum;

- after each wash, the hatch must be open;

- if necessary, wash several times a day, take a break between cycles;

- use of water softeners.

It is also important to turn items inside out before washing.

These precautions will help your washing machine last longer.

Loading hatch rubber

Extraneous squeaks cannot be avoided when the washing machine is operating if the cuff stretched over the hatch does not fit in size. Moreover, the knocking will appear immediately when the drum rotates and will remain until the program is turned off. Another sign is rubber shavings stuck to the surface of the cylinder. More often, discrepancies in size are eliminated using sandpaper. How should I proceed?

- Take a piece of sandpaper.

- We place it on the rubber cuff and press it with the hatch door.

- Let's turn on the quick program.

- We wait until the sandpaper smoothes out the rubber after half an hour of the cycle.

- At the end of the program, take out the paper.

- Run a rinse to get rid of the chips.

- We clean the garbage filter.

If the washing machine starts to make noise during the draining stage, then there is a high probability that the pump is broken. In this case, it is recommended to test the part with a multimeter.

Video

From the following video you will learn how to restore the spin cycle if one of the above problems occurs.

About the author:

She graduated from the Institute of Tourism of the Federal Pedagogical University with a degree in Management, loves to travel and communicate with people. She is interested in psychology, enjoys dancing, and studies English. During the five years of maternity leave, I thoroughly mastered housekeeping, not forgetting about my own development. He skillfully uses words and can support a conversation on any topic thanks to his interest in different areas of life.

Found a mistake? Select it and click the buttons:

Ctrl + Enter

Interesting!

Astronauts, while in Earth orbit, solve the problem of dirty things using an original method. Clothes are dropped from the spacecraft and burn up in the upper atmosphere.

How to avoid such problems?

Knowing what it can be, it is easier to take care of the machine in advance and prevent the occurrence of hum and vibration. You just need to remember a few simple rules for operating the machine. These are the simplest recommendations.

- Do not exceed the maximum permitted weight of laundry.

- Do not run the cycle several times in a row, giving the machine a break.

- Alternate cycles with high and low temperatures.

- Clean the machine in a timely manner, especially the garbage filter.

- Carefully check items loaded into the drum for items forgotten in pockets.

- Wash woolen clothes, as well as items with metal inserts and locks, in special protective bags.

- If very hard water flows in the water supply, then it must be softened with special means.

- At the end of the wash, run an “empty” cycle to wash the machine and remove soap deposits from the surfaces.

If your LG washing machine is making a loud noise, then this “symptom” cannot be ignored. It is necessary to urgently begin diagnostics, otherwise the problem will only worsen and lead to irreparable consequences.

Differences between direct and belt drive washers

Rotational motion can be transmitted from the motor to the drum shaft through a belt or electromagnetic system. LG owns a patent for Direct Drive technology, which is installed on most modern washing machines.

In a direct drive SMA, the speed is set by an electromagnetic system , and the inverter motor rotates the drum without direct contact with it. This allows you to eliminate some breakdowns (for example, belt stretching, brush wear), increase the maximum speed and increase the tank load.

With identical technical characteristics, the inverter SMA promises to be quieter than the belt one. Due to the reliability of the direct drive, the risk of abnormal noise during spinning is also lower.

The belt drive also has an important advantage: if the weight is unevenly distributed in the tank, the rubber belt acts as an additional shock absorber. Direct drive mechanisms are more sensitive to uneven load distribution in the drum.

The engine broke down

If the washing machine makes noise, but this is not accompanied by any movement inside, then the motor is not working. Make sure once again that the drum is standing, not moving, and nothing is interfering with the engine - that means it is “covered.”

The causes of engine breakdowns lie in the disruption of the windings of the unit itself. If the breakdown turns out to be too serious, you will have to buy completely new equipment or wash your clothes by hand. Don't be too upset, you can order it to be repaired. Although this sometimes turns out to be expensive and perhaps irrational. In a simpler case, the problem can be easily solved by simply replacing the motor brushes.

Do not neglect the condition of your machine, because the sooner you notice that the unit is rattling during operation, the more likely the result of the whole matter will be pleasant for you. In particularly advanced cases, it cannot be repaired in any way.

Do not let your electrical appliances, which are necessary for tidy housekeeping, reach this state.

Motor for washing machine