Lifting mechanism for a bed: do-it-yourself calculation and installation

- Buy or create

- Types of lifting devices

- Aspects of choosing gas lifts

- Installation of lifts

Hello dear friends! Now I would like to talk with you about how to install a lifting mechanism for a bed with your own hands, why it is needed, what will be needed for assembly and installation, and more.

Beds equipped with a lifting mechanism are found in regular models and in transformers. Colorful examples include table-beds, and also the recently discussed wardrobe-bed with elements of transformation. Such beds represent a flat base, under which there are compartments for storing various things.

Thanks to the built-in mechanism, you can raise this very base or move it to the side, thereby opening up access to the internal space. It's like opening the hood or trunk lid of a car.

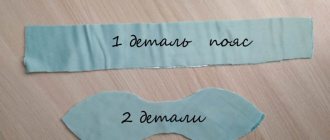

Manufacturing process: step-by-step instructions

Diagram of a bed frame with a lifting mechanism

To make a universal lifting mechanism for a bed with your own hands, you need to prepare detailed drawings of the future model. To avoid irreparable mistakes when installing the bed, you can rely on a ready-made schematic drawing of the frame assembly.

Detailed diagram of the assembly of a bed with a lifting mechanism

You can get information on how to make a bed with a lifting mechanism with your own hands by studying the prepared drawings.

Drawing of a lifting mechanism for a bed

First, a strong, reliable base for the intended bed is built. To make the base of the stock, you need to prepare:

- the bottom, sides of the bed, drawers and headboard are made of MDF or chipboard - all elements of the appropriate size;

- a frame formed from wooden blocks;

- mattress bridges made from slats and boards.

After completing the preparatory work for installation, the bed base is assembled from ready-made elements.

- On a frame made of bars, the bottom for the niche being prepared is secured with self-tapping screws.

- After the steps have been completed, the drawers and sides are mounted on the frame.

- We attach the headboard to the prepared structure using a screwdriver and self-tapping screws.

- After completing the base assembly process, the bed lift is installed. It is sold ready to use, so the lifting structure is mounted on nuts.

Elevator transformation system

The lower steel strip is immediately fixed to the base frame, then the upper element is fixed to the side part.

The gas lift is mounted on a rack base

Installing gas shock absorbers for a bed with a lifting mechanism

To create a reliable sleeping place, a steel base is installed, made of a metal profile, cut with a grinder into parts of the required dimensions and connected together into a solid structure by welding, which is an important working step. After completing the welding work, a timber frame is fixed to the base.

Buy or create

In theory, you can create the lifting mechanism you need without the help of others. This will require proper drawings, verified dimensions, {instructions}, which spells out the installation and how to create everything without errors.

But in practice, I advise you to do without these complex and unnecessary manipulations. You cannot save much by making a folding mechanism without the help of others. Assembly will require separate components, the cost of which in total is not so different from a finished mechanism made by a proven manufacturer and with correctly verified dimensions, parameters and features. Industrial mechanisms calculate for what size and characteristics of a bed one or another model is suitable. This makes it possible to choose the appropriate option if you have a single, single or double bed, the base itself is made of wood, chipboard or alloy, and the size of the bed is 160x200 or 180x200, for example.

It is much more important to understand how to assemble or install a ready-made lifting mechanism kit.

Types of lifting devices

To understand the operating mechanism of the transformer on your bed, you need to find the type of lifting mechanism used.

Today's furniture market provides several options for lifts. They are provided for beds of various configurations, styles and designs.

Depending on the mechanism of operation, there are 3 groups.

- Hand mechanisms with hinges. The most common and cheap options that gained popularity about 40 years ago. At the moment, beds with this lifting mechanism are rarely found, since transformation requires enormous effort. The entire weight of the bed is practically lifted by hand. Nowadays, hinges are installed on cheap models; they often require repairs and do not withstand active use;

- Spring systems. Comfortable, easy to use. In modern furniture production, they are often used specifically on cheap beds. Lifting requires little effort, but the child is unlikely to be able to cope with it. After approximately 5 years, the springs must be replaced as they stretch;

- Gas lifts. These are mechanisms that use gas springs. The most modern, perfect and easy to use. They actually don't require any effort. They work very smoothly, do not make noise, and can lock the bed in the raised position. With the right choice, a gas lift can last about 10 years. The most expensive in terms of cost.

You yourself must decide which specific mechanism to use for a wardrobe bed, children's furniture or your own sofa. But keep in mind that saving on the mechanism does not justify itself. It is better to immediately take a high-quality and easy-to-use product.

Aspects of choosing gas lifts

Let's be impartial. Specifically, gas lifts are the most desirable option for installing a lifting mechanism on a bed.

If the bed is assembled from scratch with your own hands, it is better to calculate the approximate weight of the structure in advance and create a supply of 30-50 kilograms. Based on the planned overload on the lifts, a suitable set and even the required quantity are selected. Any shock absorber is designed for a certain maximum load. But there is no need to choose devices with a load capacity equal to the weight of the bed itself. A certain reserve of strength is definitely needed, otherwise the mechanism may not withstand it or will quickly fail, as it will operate under excessive overload conditions.

Markings are made on the bed for mounting devices. It is recommended to install devices at a distance of at least 40 mm from any edge of the supporting structures.

Manufacturers always include instructions for installation complete with lifts. If it is not there, there is always the opportunity to look at photos and video tips.

How to repair it yourself

If the gas lift has stopped working and the mechanism needs to be repaired, to do this it is necessary to establish the true cause of the breakdown.

- First of all, you need to pay attention to the weight of the structure, since with a small load the mechanism will not work. The spring is compressed in the structure only under full load conditions.

- Elimination of errors made during the assembly process is carried out by dismantling the entire structure. Re-installation is carried out taking into account the correct selection (adjustment) of parts to each other.

- The quality of the fittings influences the good functionality of the bed. Therefore, for gas lift installation, it is better to purchase spare parts from trusted manufacturers.

Important! When installing and repairing, you should use the manufacturer's instructions.

In order to make repairs yourself, certain skills and knowledge are required, the absence of which can lead to poor quality work. To ensure that basic repairs do not spontaneously become major repairs, you need to contact experienced craftsmen to do the repairs.

Installation of lifts

Another supporting source will be the upcoming {instructions}. It is of a general nature, but outlines a more widespread and universally applicable principle for installing lifts.

The installation requires the following actions:

- First, the bed frame itself is assembled. After all, it is to the lower body that the mechanism will be attached;

- The lift itself is assembled, if it is not one-piece, or it comes with parts;

- The device is fixed on the side panel. It is completely normal to take a ready-made lifting mechanism already assembled. It is difficult to assemble such accessories with your own hands; this requires experience and knowledge;

- Now the sleeping space itself is connected to the lift. You may need help here, since the fixation is carried out with the base raised.

At this point, the installation is considered complete. Be sure to check the functionality of the lifting device, perform several lifting and lowering procedures, and make sure that the gas lift is firmly fixed in the raised state.

The main nuance that ensures the correct installation and subsequent operation of any type of lifting mechanism for a bed is the correct calculation of the load capacity and the selection of the right place for fastening.

Since any bed has its own characteristics, there are no general tips for everyone. But there is a large assortment of lifts that take into account not only the buyer’s financial abilities, but also certain requirements, operational characteristics and expected load.

Lifting and transformation mechanisms are used everywhere. Take, for example, folding chair beds or, to a greater extent, a children's loft bed, where real sleeping places are also formed with ordinary movements and the additional capabilities of the furniture are revealed.

Beds with lifts are frankly comfortable and multifunctional. These are the same regular beds, but with expanded capabilities. Models with drawers can serve as candidates.

Thank you all for your attention!

Subscribe, leave comments and ask burning questions!

Materials and tools for assembling a wooden structure

A person who starts assembling furniture with his own hands needs to prepare the following basic tools and materials:

- A figured and regular screwdriver (ideally, if it is a screwdriver with many attachments), a screwdriver.

- A regular hammer is small or medium in size.

- Reversible key.

- Manufacturer's instructions with assembly diagram. It should be included with the kit you purchased.

Before you start assembling the bed, you need to carefully review the instructions

Please note that this information must correspond to the configuration and include all those elements that come with the bed. The instructions should be clear, not vague, with numbered parts

Move all the sealed parts of your bed to the room where you plan to assemble it. After checking all the components and main parts and comparing them with the quantities according to the instructions, you can get down to business.

Advice: All actions must be performed not alone, but together. You can involve your family members in the work.

How to attach the lifting mechanism to the bed?

| 1) Attaching the lifting mechanism to the base with slats. As a rule, the first hole on the headboard side is drilled at a distance of 10-15 cm. and the subsequent holes along the upper mounting bar of the lifting mechanism will fall into their required places by themselves. But there is no clear definition, because There are different lifting mechanisms from a number of manufacturers, and also different types of beds with different headboards can change the position of the mechanism. In our online store there are bed base kits with a lifting mechanism, where all the necessary holes will already be drilled in the right places. Already after connecting the lifting mechanism to the base, the attachment points are “caught” on the side frames of the bed; to do this, you need to try the base with the mechanism in the closed position in the bed box. The lifting mechanism can be set to open not along the length of the bed from the legs, but from the side, you just need to take into account that gas springs (gas lifts) in this case are needed one and a half to two times weaker. It may be possible to introduce a lifting mechanism without using an orthopedic bed base with wooden slats, i.e. use, for example, a sheet of plywood as a base. |

2) Attaching the lifting mechanism to the bed frames. It must be secured to the side frames with bolts (do not use screws - it won’t hold up, it will tear out). The bolts should better pass through the side frame and be secured with nuts and washers. If the outer part of the drawer is decorative and it is unacceptable to drill through, then furniture bushings are used, into which the bolt rotates (a non-through hole is drilled and a bushing - nut is inserted into it). On YouTube you can find many videos on this topic to see clearly.

3) Installing the base (frame) with slats into the bed. There are different types of beds with a lift; the base can be sunk inside the box or placed on top of it. If the base with slats under the mattress sinks, then iron corners are attached to the inner corners of the bed on which the base is placed on the side of the legs; often these corners are already in the beds as corner fastenings. In addition to the corners, there are other holders - for example, a plastic frame stopper, which rotates onto the inner drawers of the bed from the side of the legs. The bed frame should be divided into two parts by a central drawer. Both horizontal and vertical divisions are allowed. The central drawer is needed for beds with a lifting mechanism with a width of 140 cm or more. it plays the role of supporting the base (frame) in the center; in its absence on wide beds, the base can simply bend in the center. For example, bed bases with a width of 140 cm or more without a lifting mechanism on legs (supports) have, in addition to the corner ones, a central fifth support. From time to time, two additional supports are placed in the center. If the base is placed on the drawers, then the central drawer - the box divider (frame support) will be the same height as the perimeter of the bed; if the base sinks, then it is lower than the perimeter at a distance from the floor (bottom) to the recessed base (frame). The bottom of the bed linen box can be made from fiberboard or plywood, or, as almost all manufacturers of beds do, the material is fibertex (special felt with a print).

5) Selection of gas spring (gas lift) force for the bed. There is a popular belief that, for example, a gas lift force of 1000 N is a lift of 100 kg. This is conditional and not entirely correct; there are many characteristics that affect the lifting of a particular structure, such as: lifting angle, gas spring angle, area of the lifted surface, center of mass of the surface. There is a special formula for selecting gas springs. But if you go into the details of the production calculation, you can derive a conditional recommendation. Almost all furniture factories standardly equip a bed measuring 160/200 cm with 800N gas lifts (2 pieces of 800N each, naturally - on the right and left parts of the lifting mechanism), provided that a regular mattress is used. If the mattress is high and heavy (usually the most expensive models), then set to 1000N. In proportion to this, on a bed measuring 180/200 cm they put 1000N and 1200N with a heavy mattress, on a bed measuring 200/200 cm 1200N. And to the smallest extent: for a bed 120/200 and 140/200 cm 600N with a heavy mattress 800N. For single beds 80/200 cm 500N. If the bed opens from the side (horizontally) and not in length (vertically) as usual, then on a bed of size 160/200N a force is placed less - 500N and in proportion to the size +/- 100/200N. For wardrobe-bed devices, gas springs are used with a huge force from 600 to 2000 N, depending on the size and type of opening (horizontal or vertical). Such gas springs (from 1200N) are reinforced and are made with larger diameters of the rod and cylinder (14/27 mm), thickened, reinforced fasteners, due to which they cost significantly more. There is also a “Universal” lifting mechanism, its highlight is that with the same gas lift you can adjust (+/- 200N) the force of the gas spring due to the configuration of its angle in the mechanism. Whether the gas lift force is applied to the bed or not, it must be tested at full overload on the base, i.e. with a mattress. Without a mattress, the base may open spontaneously and it may seem that the gas lift is very powerful. Read more about gas lifts in the notes on the use of gas springs. 6) Placement of a gas spring in the bed lifting mechanism. As indicated in the instructions for using gas springs, the gas lift must be installed in the mechanism with the rod down, because Otherwise, it won't last long. The gas spring contains compressed gas (nitrogen) in the cylinder, which applies pressure to the rod and hydraulic oil to reduce the friction of the rod stroke. At the point where the rod enters the cylinder there are special gaskets (pistons) that hold pressure. The oil in the cylinder wets the gasket from the inside and prevents it from drying out with the inevitable appearance of microcracks through which gas under pressure will escape along with the oil and the gas spring will have to be changed (based on the principle of storing wine in bottles at an angle). In addition, the gas lift does not need to be tightened with a nut very much, it is necessary to stop the possibility of rotation, because When opening and closing the bed, it changes its position on the fastenings.

7) Devices. The main devices for a bed with a lifting mechanism are a mattress holder and a strap. The mattress holder is an iron bracket that is attached to the base (base) of the bed in the center on the headboard side; it serves to keep the mattress from moving when lifting (opening) the frame with the mattress to access the linen compartment. On wide beds measuring 180/200 and 200/200 cm, two pieces can be placed at an equal distance. From time to time, mattress holders are placed on the base and on the side of the legs and are used as a handle for opening and closing the lift-up bed. A synthetic fabric strap is usually used just on the base on the leg side to open and close the bed frame. With wardrobe-bed mechanisms, they use straps that tie the mattress to the base. There are also such devices for a bed with a lift as: a protective plastic mechanism box, a mechanical gas lift lock, sliders, headboard connectors and a transverse frame lock. The protective plastic box serves to protect laundry from getting into the moving parts of the lifting mechanism and plays a decorative role. It is simply attached to the drawers with brackets or screws. Headboard sliders are used to connect the headboard and the perimeter of the bed. They allow you to simply remove (unfasten) and put back (fasten) the headboard to the perimeter of the bed. The gas lift clamp is used on the gas spring rod as a lock to keep the bed from closing (this clamp is a faster psychic gadget, because the bed cannot suddenly fall on your head, even if the gas lift fails, the base will slowly lower due to the second gas lift). The transverse frame lock is a fascinating and necessary gadget; it is attached to the edges of the bed frame towards the legs. Serves to protect the decorative upholstery from scratches that occasionally appear from the frame towards the feet when the box is frequently opened/closed. Also, this clamp occupies the gaps between the base and the drawer and prevents the skeleton from playing to the right or to the left.

Manufacturing stages

After completing the preparatory stage, you can safely begin assembling the bed with a lifting mechanism. The elements are mounted in the following sequence:

- main frame;

- lifting structure;

- directly lifting mechanism.

At the final stage, cladding and decoration are carried out. The process must take place strictly in the specified order, otherwise the assembly will not be completed correctly.

Main frame

Any lifting bed must have a reliable frame at its base. It consists of several elements:

- side drawer, back and front edges, bottom for installing drawers;

- mattress covering, which is created from slats or wooden boards.

To make the main frame of a regular bed with side aspect ratios of 2 to 1.8 m, you will need many parts. For the side edges you will need a pair of boards 2 meters long. For the end parts, it is better to also take two boards, but 1.8 meters each. Next you need to connect them using self-tapping screws and several corners. This stage of assembly is the most critical, so you need to make sure that the formed angles exactly correspond to 90 degrees. If glue was used, its protruding excess must be removed immediately, otherwise difficulties may arise during further processing of the surface.

When making a large bed, it is necessary to install a stiffener through the longitudinal axis. If the project includes legs, their fixation should be done at the very end. The simplest option is to use four wooden blocks. To strengthen the structure, you can make an additional leg in the center. Finally, it is recommended to coat the resulting frame with varnish.

Lifting design

The process of creating and assembling a lifting frame consists of two points: joinery and carpentry operations and processing. The first stage begins with the manufacture of a box from calibrated boards. It is better to do the work on the floor to avoid distortions. Next, using corners, all elements are combined. The joints can be further strengthened with furniture glue.

It is important to pay attention to the heads of the screws - it is necessary that they go under the wood, but only slightly. When creating a large bed, you will need to lay an auxiliary partition along the frame

Now we need to fasten the slats. Screw them with self-tapping screws inside the side surfaces. First, the parts must be aligned parallel to the bottom edge of the box. Elements are necessary for attaching the slats. The dimensions of the slats should not exceed 9 cm in width. For slats, you can take the same blanks, but only with a length equal to the width of the future bed. Plywood is also suitable for this purpose, but you will have to make a central partition.

All that remains is to process the lift. The structure can be refined with sandpaper or varnished. One of the significant nuances in preparing the frame is the quality of the plywood, which is laid on the slats to evenly distribute the load.

Installation of the lifting mechanism

Installing the lifting mechanism is the easiest part of the assembly. First, its upper part is attached to the bed frame using a special steel strip. Next, the remaining parts of the lifting mechanism are attached, which provide control over the highest lifting height of the bed frame and mattress. The lower bar is attached to the main frame. The installation is complete, all that remains is to check the strength of the fixation and test the mechanism in action.

Sheathing and decoration

The final stage in the creation of any furniture product is the covering and subsequent decoration, which must correspond to the style of the room. For this use:

- fabrics;

- leather or its artificial analogues.

The selected material must be used to cover the main frame and headboard of the bed. To give the upholstery volume and airiness, sheet foam rubber is placed under the fabric. An ordinary construction stapler is suitable for fastening textiles - its staples even penetrate wood, thanks to which they hold the material tightly. If desired, sheathing can be done at intermediate stages of work.

It’s not easy for novice craftsmen to figure out how to properly make a bed with a lifting mechanism. However, if you carefully study the process in the video and continue to follow all the recommendations, you will definitely be able to make furniture. You just need to put in a little effort when assembling and use your imagination in the decorating process.

How the bed lift mechanism works: installation, assembly and disassembly

A bed with a lifting mechanism is a flat base, under which there are niches for storing things. The integrated mechanism allows you to lift the base up or to the side, and provides access to spacious boxes. This is exactly the option when functionality and healthy sleep on the right surface are combined.

Beds equipped with lifting devices are more popular because they handle several multifunctional loads at once: they provide proper support for the spine, are free of joints and unevenness that sofas suffer from, and also allow you not to clutter the room with additional furniture, because they themselves have storage space. In this article, we propose to dive into the insides of the bed, understand the mechanisms of operation of lifting devices, as well as methods for installing and disassembling them.

Operating principle and technical characteristics

As the layer rises, the gas expands and presses on the piston. It lifts the bed up, reducing the person's effort. The use of an oil seal in the housing ensures smooth operation. Due to the absence of a shock absorber when installing a friction mechanism, you can stop the movement of the device at any time.

Externally, the design is a small cylinder with several latches and a movable lever.

The cylinder, rod, piston and bearing points are made of steel.

Main technical characteristics:

- ability to work in the temperature range -30 - +80 degrees;

- maximum rod speed - up to 300 mm/s;

- the pressure inside the cylinder does not exceed 160 bar;

- The thickness of the cylinder wall is at least 1 mm.

It should be noted that the mixture inside is under very high pressure, so it is not recommended to disassemble gas lifts yourself.

Types of lifting devices, their mechanisms of operation in bed

Today, the furniture market offers a number of types of lifts that are installed in beds of different sizes and designs. They differ in price, design, durability, and the physical effort that needs to be applied to lift them. According to the mechanism of operation, they are divided into three groups:

- Manual mechanism on hinges. The most common, cheap option was extremely popular in the 90s. At the moment, there are relatively few beds with such a lift, because it requires significant physical effort (the weight of the base is completely on the person’s hands) and can provoke deformation of the body (most often, hinges are installed in cheap models made of chipboard, which, with frequent use, do not support the weight of the base and deteriorate). To be fair, it should be noted that the lift itself is quite strong and occasionally breaks down.

- Spring lift system. A successful, easy-to-use mechanism. It is considered an economical option, and accordingly, it is installed in cheap beds. It doesn’t require a lot of effort to get up, but still, a child can’t handle it. Springs will only partially offset the weight of the base. A significant drawback is the short service life, about 5 years, after which the springs stretch and require replacement.

- Mechanism with gas shock absorbers or gas lift. Today it is more improved and easier to use. In fact, it requires no effort on the part of a person. It works smoothly, without noise, and firmly fixes the raised base. The system is considered reliable and can be installed on any bedroom furniture, even children’s. With properly selected shock absorbers, it can last more than 10 years. Its cost is higher than that of other devices, but is fully justified by the comfort and safety of use.

How to install a gas lift in a bed

This lifting mechanism is the most popular among manufacturers; about 50% of all furniture is equipped with this particular lift. How to assemble and install a gas lift on a bed? We offer a step-by-step summary.

Step 1. Assemble the bed frame. Installation of the lifting mechanism cannot be carried out without a finished lower housing, because it will be attached specifically to it.

Step 2. Assemble the lift and secure it to the side panel. This is the most important task. Assembling a mechanism is a careful job that requires knowledge and design thinking, which is why experienced furniture makers advise receiving an already assembled device. It does not require countless manipulations, only correct placement relative to the sides (left and right), and strict symmetry.

Step 3. Attach the orthopedic base to the lifting mechanism. The top of the bed, or the orthopedic base on which the mattress will rest, needs to be assembled first, and only in its finished form should it be mounted on a lift and gas springs. It is important to note that fastening must occur with the base raised.

The installation process is complete, you can demonstrate the operation of the lift, tighten loose parts, and lay the mattress on the bed. The method is quite simple, if you follow the instructions, you can handle it just fine. The most important thing is specifically the gas lift; in order to choose it correctly, calculate the best load, it is better to contact a specialist.

How to disassemble the lifting mechanism and in which cases it is needed

Disassembling the bed lifting device is quite a painstaking task. If you are planning to transport furniture, then you should not disassemble the mechanism itself; it is better to throw it on the side slats, remove the mattress, orthopedic base, and carefully pack all the elements in protective film.

Disconnecting the lift into parts is only necessary if it breaks down. The following symptoms may indicate a malfunction of the gas lift (Symptom from Greek - case, coincidence, sign - one separate sign, frequent manifestation of a disease, pathological condition or disruption of any vital process)

:

- the orthopedic base lowers spontaneously;

- the mechanism sometimes jams and does not perform its lifting functions;

- When operating the mechanism, creaks or other unpleasant sounds are heard.

If you can’t call a furniture specialist to your home, you can disassemble the bed yourself, remove the lifting device and take it for repairs. The method of action is reverse assembly, i.e. First, the mattress is removed, the orthopedic base is disconnected, and then the lift is dismantled. It is better to film this process, or create step-by-step photos, so that in the future there will be no problems with the installation of a repaired or new device.

When to contact specialists

You need to contact professionals in two cases:

- If there is no desire or time to identify the malfunction using your own resources and resources.

- If you were unable to identify the defect yourself.

With the first option everything is clear. As for the second, we are most likely talking about incorrect distribution of gas in the piston. Its excess or deficiency often leads to problems in work. There are two possibilities here: the base of the bed either lowers too slowly, it has to be pushed down, or it “shoots out,” which can also lead to rapid wear of the part.

It is unlikely that an unprepared person will be able to cope with this problem on his own. To do this, you will need to replace the gas cartridge in the furniture unit using special tools that are available only to repair team workers.

Bed Furniture

How to choose a bed with a lifting mechanism

When choosing an ergonomic sleeping place, which is a bed with a lifting mechanism, it is important to take into account the following aspects:

- the dimensions of the room and the desired size of the sleeping area;

- type of lift, for whom it is intended;

- placement of the rest of the furniture relative to the bed and method of lifting it: vertical or horizontal;

- the side in which the base will rise;

- the presence or absence of additional lift parts: amplifiers, blockers, etc. (especially important if the sleeping space is huge, with a heavy mattress).

All these aspects can influence the level of comfort; their correct calculation will allow you to design a comfortable sleeping space, with spacious niches, good parameters, and a long service life.

Necessary materials

When preparing the necessary material for the manufacture of a sleeping bed, it is worth taking into account the load created by the mattress on the shock absorbers, mechanical device strips, frame and fixation points.

During the installation of a piece of furniture you will need the following materials:

- lift;

- MDF and chipboard;

- wooden slats;

- boards;

- bars;

- upholstery fabric;

- foam;

- mattress;

- metal profile to create a reliable structure.

A common and inexpensive material among furniture makers is chipboard sheets. You can use chip boards, OSB and others. The choice of material depends entirely on the preferences of the owner and the availability of money. The upholstery fabric is selected taking into account the interior of the sleeping area where the homemade bed will be installed.

Having prepared the working material, you need to stock up on the tools that you will need to make the frame of the sleeping area.

Pros and cons of 3 types of bed lifts

In this article I will look at the pros and cons of a bed lift mechanism. I will list the individual varieties: gas springs, spring and lifting hinges. I'll look at the system and dimensions. I'll tell you about the features of the assembly. I will provide a diagram and a drawing, as well as a calculation, which will help you correctly assemble a double ottoman.

- Pros and cons of a bed lift mechanism

- System and dimensions

- Varieties

- Gas springs

- Spring mechanism

- Lifting mechanism on hinges

- How to choose the right bed lift mechanism

- DIY assembly

- Necessary materials and tools

- Base assembly

- Installing the feet

- Mounting the lifting mechanism

- Installation of frame and mattress support

Pros and cons of a bed lift mechanism

This device helps to significantly save space. When supplemented with it, the couch will be characterized by the following advantages:

- Additional storage space will appear.

- There is no need to take additional furniture and clutter the space.

- Simplifying the process of cleaning the room.

- The lifting system does not affect the design of the bedroom interior in any way.

Among the negative features, only the highest cost can be noted. It can be quite difficult to find a suitable mattress. It should be light and not interfere with assembly.

Tools for furniture assembly

- Electric screwdriver. Indispensable for screwing in screws and attaching fittings.

A screwdriver will help you speed up the assembly process

Drill for drilling holes in chipboard, it is desirable that the drill has a reverse

Drills for wood and metal of different diameters

A jigsaw is needed for sawing off parts

You may need a rubber hammer if you need to knock something and put it in its place.

Hex key for confirmation for assembling cabinet furniture

Construction hair dryer for gluing edges

Furniture clamps for fixing, gluing, joining parts

A stapler will be very useful for stuffing the back wall of fiberboard

Remember to be vigilant and cautious when using these tools. Don't act hastily

It is best to invite an assistant.

Fixing tools have an important role in twisting furniture, and also as important “helpers”. These and other gear perform the function of installing fragile parts (mirrors and handles). They help attach and adjust doors.

System and dimensions

Standard bed dimensions:

- The length is 2-2.2 meters and is designed for use by an adult. For a baby - 1.2-1.9 m.

- Width: adult - 1.2-1.6 m, children's - 0.9-1 m.

Manufacturers allow you to add a vertical or horizontal lifting mechanism to the bed.

Most often, the sleeping space is opened using the book method. The side lift helps save a lot of space. If the weight of the bed is very large, then it is proposed to use an elevator lifting system.

It is convenient to store bedding in the hollows

Varieties

The lifting system is most often used due to lack of living space. Thanks to this, it is possible to simply transform one piece of furniture into another.

Gas springs

They independently manage the rise of the bed and take the load upon themselves. Average solution for a child or a lady.

Additionally, the system is equipped with a damper and piston. For normal operation of the shock absorber, it also includes alloy plates, axles and a lift on the gas system.

But not everyone can afford it because of the high price.

The lift is very convenient and adapted

Spring mechanism

To raise the bed, a spring system is activated. Thanks to it, a person will need to expend less force to move the furniture.

Springs wear out quickly during intensive use and therefore require replacement.

Lifting mechanism on hinges

The bed is set in motion using ordinary hinges. The sleeping space differs in the applicable cost, which is mixed with the highest degree of reliability.

Transformation is done through the force that a person applies

Do-it-yourself gas bed lift repair

Modern double beds are most often equipped with a lifting mechanism.

This system is called a gas lift; it ensures a smooth lifting of the bed along with the mattress into a vertical position. This feature of the beds makes it possible to remove them if necessary, which significantly saves space during the day. If the bed is in the bedroom, then with the help of such a mechanism access to the linen drawer is provided.

How to choose the right bed lift mechanism

In order to choose the right mechanism for the bed, you will need to carefully analyze the following properties of the future structure:

- Position of the bed in the room.

- The need for additional storage space.

- The frame will open along a vertical or horizontal axis.

- The composition should include amplifiers and blockers.

- It is recommended to choose familiar manufacturers.

- The design and style of the furniture should fit perfectly into the rest of the design.

DIY assembly

Any owner dreams of purchasing not only a convenient, but also a comfortable bed. The lifting mechanism is easy to assemble. But before starting the planned manipulations, it is recommended to read the annotation.

Necessary materials and tools

To perform the manipulations you will need the following devices:

- Hardware.

- Screwdrivers, wrench and screwdriver.

- Tape measure for measuring distance.

- Level.

- Hammer.

- Paper and pencil.

Base assembly

To collect the base you will need to perform the following manipulations:

- Take the elements out of the box and check the integrity of each of them.

- Lay out the drawers and screw the backrest to them. Beforehand, they are connected to each other.

- If the model uses power elements, then it is recommended to use screws to fix them.

Assembly diagram

Installing the feet

The legs can be already built-in or separately screwed to the upper part of the drawers. Before installation begins, markings are made. It is not recommended to immediately tighten the screws to the end. Then it will be easier to adjust the level of the bed.

Mounting the lifting mechanism

The lifting mechanism is considered the most important in this design. To secure it, take the following steps:

- Fixing the frame in an open form.

- Smoothing with a gap between the top and base.

- The lifting mechanism is secured by a cylinder. For additional fixation, locking rings and washers are used.

- The nuts are not tightened all the way. It is required to throw a free move for the convenience of the upcoming implementation.

Possible difficulties during work

Without practical experience in assembling furniture or making minor mistakes, you may encounter difficulties. The following installation difficulties are common:

- Need to drill additional holes. Recesses for fasteners are required in many parts of the structure, and if third-party elements are used, then new holes must be made on the body, having previously made markings.

- Gas lift installation. The process of installing the lifting mechanism is the most difficult step, so it is important to be careful and follow the exact sequence of actions.

- Incorrect markings on the furniture frame. If you make a mistake in the markings, you will not be able to assemble the bed correctly, so you need to check the measurements several times.

See also

Ideas for beautiful garden path design and DIY options