From this article you will learn:

- What eyelets for awnings look like

- What types of eyelets for awnings are there?

- How to install eyelets on an awning with your own hands

- What other fastenings exist, besides grommets for awnings?

The concept of “eyelet” came to us from the time when the sail appeared. At that time, grommet was the name given to the technology of strengthening the edges of the holes in the sail, intended for attaching the canvas to the rigging. Currently, this term refers to both a method of strengthening holes for ropes and cables in thin materials, as well as parts of rings used to implement this technology. Eyelets are used in equipment, shoes, and clothing. They are used for awnings, advertising banners, tents. In this article we will talk about eyelets for awnings, as well as installing eyelets on an awning.

Where are they used?

There are several areas of activity in which eyelets are often used.

Outerwear production

Most often, such elements are used to create outerwear. In clothing production, such eyelets are used to decorate products and give them a unique look. Such details can often be seen on modern models:

- raincoats;

- sheepskin coat;

- windbreaker;

- jackets;

- winter coats

Shoe making

Many manufacturers use eyelets when creating shoes. In this case, only high-quality and durable components made of durable steel metal are used. Their surface is coated with nickel or copper. This protective coating protects the metal from the formation and spread of corrosion.

Release of home furnishings products

Often lumpen people can be seen on home furnishing products, which are found in almost every home. These elements are found on some types of curtains or curtains. They are also added when making lambrequins or curtains. In this case, simple steel parts are used that do not have a protective coating.

Tourist and holiday destinations

Such components are often used to create country or tourism products. For example, they are used during the production of textile canopies. Grommets are also found in most modern tents used in the tourism industry. In the manufacture of canopies and tents, high-strength steel parts are used.

In commercial activities

Eyelets are considered common parts that are used in commercial activities. Many manufacturers make them and then sell them separately. Most often they are purchased to be used to replace broken elements.

Manufacturing of shipping products

Few people know, but eyelets are often used in the creation of shipping products. Most often, such rings are used to create sails for ships. In this case, large and large parts are used that would withstand the load from strong gusts of wind.

In office and printing

Another area of activity in which eyelets are regularly used is printing and office work. Metal products are used to create calendars, notebooks, and books. They are sometimes found in decorative gift wrappers.

What other fastenings exist, besides grommets for awnings?

The performance characteristics of automobile and construction awnings, household tents, banners, etc. depend not only on the properties of the fabric from which the product is made, but also on the quality of the fittings used, among the wide variety of which we highlight the following elements:

Rivets for awnings

Blind rivets are widely used both in the manufacture of household awnings and canopies, and in elements of clothing and footwear. The choice of material for these fixtures depends on the material of the parts being fastened and the environment in which the fastener will be used. A separate operation of painting the rivet is also allowed, so choosing fittings that match the color of the main product is not particularly difficult.

All materials from which rivets are made are regulated by GOST and can be as follows:

- Duralumin with or without coating (anodized, varnished).

- Cink Steel.

- Stainless steels (A2, A4, or imported analogues: DIN 7337).

- Copper.

- Copper-nickel alloy monel. Contains 70% nickel, 30% copper.

- Polyamide Plastic that is widely used in the textile industry.

When selecting material for fastening, you should avoid the possible occurrence of so-called galvanic couples between the fastening elements, hardware and the fastened part, as well as the fastened parts among themselves. For example, when aluminum and steel come into contact, very rapid oxidation of the former occurs and, as a consequence, its destruction. Therefore, for fastening steel parts, it is better to use rivets made of stainless steel grades A2, A4 or DIN 7337. Galvanized steel for rivets is used less frequently, since the zinc coating wears out quite quickly.

The most universal hardware is a copper (copper alloy) rivet. The main disadvantage of copper is its price, as well as the formation of a green coating (copper oxide) on the surface of the fastener over time. To be fair, it should be noted that the oxidation of copper rivets does not affect the fastening strength in any way. Polyamide does not create galvanic couples, but also cannot provide high fastener strength.

Hooks for awnings

Even such a simple element of awning accessories at first glance, like a hook for securing the awning, has its own specific technological features. The most common are galvanized devices for fastening awnings with two or more holes. The standard shape is round, oval or S-shaped, and the sizes vary greatly.

Recently, plastic hooks have become especially popular. Most of them have a flattened (flat) shape and two holes for fastening. Their price is lower than iron ones, but their service life is also much shorter.

Which is better for tourist awnings: loops or eyelets?

One of the areas where awnings have found their application is tourism. Tents, awnings, and marquees are very popular among those who love outdoor activities. However, tourist awnings are subject to much more stringent quality requirements than ordinary inexpensive products intended, for example, to cover trucks or things on the street.

Tourist equipment must provide high tensile strength during sudden jerks, which largely depends on the design of the attachment points. Usually, eyelets are placed in places where simple and cheap awnings are secured. In order to make a grommet in an awning designed for high loads, you need to strengthen the place where the tent is attached. This can be achieved by installing the grommet through a plastic or additional brass washer. Then the mount will look something like it is shown in the figure below.

But such strengthening and complication of the design inevitably leads to an increase in the cost of the final product. On cheap awnings, they simply punch a hole and secure a ring of two washers in it. Here the eyelets perform not a power function, but a fastening function.

An alternative to quality reinforced eyelets are eyelets, often used in camping gear. These are small pieces of slings sewn into the attachment points, forming devices for awning guy lines. They are, of course, cheaper than high-quality eyelets, but their performance characteristics are lower.

High-quality installed grommets do not have the problems that appear on cheap awnings. Therefore, there are usually no complaints against them. Problems arise when things are used for other purposes. The same shelter canopy is not intended for tourism. Thus, when choosing an awning, think about the conditions in which it will be used.

Tips for installing grommets on a canvas awning

For awnings, linings are selected from a high-strength plasticized mixture. The surface of the parts must be nickel-plated or galvanized. In this case, installation can be carried out using professional equipment. The unit for welding two parts of the lining is best suited for these purposes. The machine guarantees fast and high-quality soldering. For installation on a tarpaulin awning, flaring and a punch are used. A separate roller is provided for each grommet option. But besides them, you can use a compact hand press. In this case, the need for impact force will disappear, and ordinary compression will suffice. In addition, the press comes complete with attachments and settings for the type and size of eyelet parts. The implementation of this installation method does not require physical strength or skills. The listed fixation methods can be used when installing street advertising banners.

How to Prepare a Tarp

First, select an awning of the required thickness and size. Next, we prepare the tools: a hammer, a punch, a marker, a pencil, a ruler - the devices necessary for punching holes. Using a ruler and pencil, we determine and immediately mark the places where we will subsequently install the eyelets. The size of the marks should be equal to the diameter of the ring. We apply everything evenly, making sure that the distances between adjacent elements correspond to the same value. After this, we take a hammer with a punch and begin to form openings in the tarpaulin according to the drawn marks. You should immediately decide on the distance from the edges, as well as the height of the placement of the overlays, so as not to cut out unnecessary holes. Before breaking through, we fold the awning in half for greater reliability of future fastening. Before creating the openings, we place a wooden board under the tarpaulin to absorb the impact of the hammer on the punch.

How to install eyelets on an awning with your own hands

To install the grommet we will need:

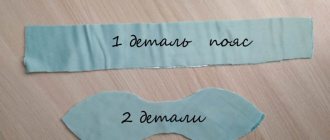

1. Eyelet. It consists of two parts. The first is an inner ring with a sleeve. The second is the outer ring. The material of the rings is usually brass or galvanized (nickel-plated) steel.

2. Installation tools:

hammer; a notch used to make holes in the material; flaring - a device with a conical striker, through which a ring with a sleeve is flattened; an anvil placed under the flaring upon impact; shock absorber, preferably a wooden stump, as it will be convenient to make holes in the material.

3. Material where the eyelets will be installed. They can be installed, for example, on PVC, canvas, leather, hardboard, etc.

Attention! To prevent injury, we recommend wearing protective gloves.

Installation process:

1. Prepare the edge of the canvas by folding it in half. To make the hem more neat, use double-sided tape. Under the edge, in the place where you need to install the ring, we place a piece of wooden board.

2. Make a hole in the desired place on the canvas with a punch.

3. We connect both parts of the eyelet together on both sides of the fabric. We install an anvil under the bottom of the ring, and insert a flaring tool into the hole of the block from above.

4. Using a hammer on the flaring tool, flatten the sleeve and ring.

5. We complete the rolling by hitting the sleeve with a hammer.

6. The grommet is installed.

Advantages and disadvantages of application

This is a functional device with obvious advantages. Firstly, they facilitate the process of putting on, taking off, and attaching. Eyelets also diversify and decorate the design, especially since models of different shapes have appeared. However, a round structure resists deformation best. The grommet is easy to use, so any type of work can be done quickly and without complications. This is a very useful and cheap part with a large distribution, and it is also easy to manufacture. Among the shortcomings, the first thing that appears is damage to the material that is being strengthened. A careless or sudden movement of the lace can cause the eyelet to fly out, at the same time damaging the integrity of the fabric. If we talk about use on curtains and tulles, metal parts make a lot of noise. The hinge fastening method is more convenient in this regard. A common problem is color deterioration, but this depends on the specific material.

Additional tips and tricks

To properly repair an awning, you need not only to follow the standard provisions of the instructions, but also to familiarize yourself with the list of additional recommendations. Among them are the following:

- As a patch, it is better to take fabric from the same material as the canvas itself. The patch should be strong with no frayed edges.

- Do not use tape on the damaged area, since this is an unreliable way to solve the problem. Only certain types of adhesive solutions are able to fix the patch.

- If you doubt your own capabilities, you can always contact a workshop where the integrity of the canvas will be restored. In addition, specialized services can repair even very large defects.

- If the fabric has come apart along the seam, then after sewing with nylon thread it is recommended to apply an additional layer of adhesive solution.

- When performing work, be sure to follow the instructions for using the adhesive composition and the basic rules for gluing the patch to the canvas. In particular, repairs cannot be carried out without first degreasing the surface, since without this the adhesion of the materials will deteriorate.

By following simple tips and recommendations, you will be able to carry out high-quality repair work and restore the condition of the canvas. If the wear is so severe that the awning tears repeatedly with minimal external influence, it is easier to replace the material.

Eyelets: history of appearance

The likely timing of the grommets' appearance remains unknown. It is known that this happened a very long time ago, perhaps during the times of Ancient Greece. Scientists do not know the language in which this word appeared, much less the inventor of this device. The appearance of the grommet is associated with the use of wind power, and the term itself refers to the hole in the sail for threading the fastening threads. In ancient times, this is how the rigging of a ship was formed. Nowadays, the term has expanded its meaning. Now this is an option for strengthening the edges of holes that are less strong than the cable passing through them.

The grommet is often used as a decorative device rather than a means to strengthen the material. Examples include linings in leather products, fiberboard, and foam board. A modern grommet is a mechanism made of a washer and a shaped sleeve. In this case, the material used is mainly metal or plastic.

Installing eyelets with clips

On the skin

Press the eyelet half against the skin in the desired location.

Using pressure marks as a guide, cut a hole. Also cut out an additional piece of leather for reinforcement.

Glue the additional piece, aligning the holes.

Insert the main part of the eyelet from the front side.

Place the second part of the eyelet on the wrong side and release the clamps. Tap gently with a hammer.

On fabric

Reinforce the grommet location with adhesive material (or fold the fabric in several layers or reinforce several layers for additional thickness). Press down on the grommet to create a hole impression.

Carefully cut out all holes following pressure marks.

Fold all layers of fabric, pin around the hole and insert the main part of the eyelet from the right side.

Place the second part of the eyelet on the wrong side.

Release the clamps. Tap gently with a hammer.

Preliminary work

Preliminary preparation is important in any business to obtain a quality result. Before you think about how to make eyelets for curtains, you should:

- Make the necessary calculations.

- Buy material of the desired color for curtains and lining.

- Buy dublerin or grommet tape, eyelets. The width of the tape should be 2 centimeters larger than the outer diameter of the fastener.

- Find a flat surface to work on: you can work on the floor or use an ironing board.

Fabric yardage calculation

To calculate the required amount of fabric, you should find out the length of the cornice and determine the height of the finished product. The length of the cornice should be multiplied by a factor to give the product beautiful folds. The coefficient will be equal to:

- For light fabrics - 1.5.

- For dense materials - 2 or 2.5.

The calculation also includes material for side allowances (up to 15 cm), top and bottom allowances (at least 25 cm). The calculation looks something like this for a cornice length of 1.5 meters: 1.5 2 + 0.15 = 3.15 meters or 315 centimeters.

Counting the number of fasteners

To purchase the required number of fasteners, a preliminary calculation of materials should be carried out. To calculate the required number of eyelets, you need to measure the internal and external diameters of the fasteners, taking into account the standard properties:

- It is necessary to purchase an even number of eyelets.

- The rings should be attached at a distance of about 18 centimeters. The optimal distance for attaching them ranges from 15 to 20 centimeters. When using a double curtain rod, consider the distance between the rods so that the curtains do not touch.

- The distance between the side edge and the center of the first eyelet should be at least 7 centimeters. This parameter depends on the width of the hem and the outer diameter of the fastening. To securely fasten the fittings, you should place them so that the fasteners do not touch the seam.

Preparing fabric for cutting and finishing seams

The curtain is prepared in advance for installation of eyelets. Before installing the rings, you should:

- Decorate curtain fabric. This procedure is carried out by wetting, drying until damp, and ironing the fabric. After this treatment, the fabric does not shrink after washing.

- Sew on the lining and finish the seams.

The seams are processed in strict sequence. The top seam is treated first. The material is processed in compliance with the technology:

- The material is laid out on a flat surface.

- The wrong side is folded and ironed 2 cm.

- Another fold is made to fit the width of the grommet tape.

- Having released the width of the hem from the edges, lay the tape between the layers of fabric.

- The strip with tape is glued using an iron. Iron small sections of the tape until the sides are completely glued. Only after obtaining a high-quality result do they move on to the next section.

- The fabric is sewn along the edge of the lapel, departing 2 centimeters from the edge.

You can sew the side seams using a hem stitch. It is not necessary to use grommet tape - you can use regular curtain tape, after removing the tension cords from it. You can hem the bottom of the product after installing the eyelets at home in order to measure the desired length of the curtain to the floor. In order not to spoil the fabric due to lack of experience, you can carry out all the necessary work on a small piece of fabric.

Self-installation without special tools

You can install the eyelets yourself, without special tools. It is important to smooth the material well before installation.

What else is needed:

- sewing threads matching the tone of the main material;

- sewing needle;

- scissors;

- a piece of chalk or soap for marking;

- roulette.

You can install wooden or plastic eyelets yourself without using special tools.

Algorithm of actions:

- Place about 3 cm down from the top edge of the curtains. Make markings (how to determine the optimal distance between the fittings, you can read later in the article) with chalk or soap.

- Attach the eyelets to the fabric and trace along the inner diameter.

- Use scissors to carefully cut holes.

- Remove all protruding threads and fabric fibers.

- The crumbling material can be carefully hemmed.

- Place the lower parts of the fittings under the canvas, and place the upper parts on top. Press the ring with your fingers until you hear a slight click. Repeat with all holes.

In order for the curtains to slide well, the eyelets must be at least 1.5 cm wider than the rod. Paper folder staples, cords and ribbons, on the contrary, must be narrower than the holes in the rings.

Calculation of the distance between eyelets

The distance between the rings depends on the texture of the material on which they will be attached. The thicker the fabric, the further apart the rings are placed . The exception is paper. Here, the distance between the eyelets depends on the location of the staples in the folder, which will pass through the hole.

For attaching eyelets to tulle or other thin fabric, a distance of about 16 cm is considered optimal. On coarse and dense material, the gap should be about 20 cm. Particular attention should be paid to the rule for calculating the distance between the rings when installing them on thick curtains.

The same spacing will contribute to the formation of even and beautiful folds on the curtains.

It is also important to calculate how many rings will need to be installed.

To do this, you need to use the formula A = (b - 2x): 18 + 1, where:

- A – number of holes;

- c – curtain width;

- x is the distance between the center of the first or last eyelet and the edge of the curtain.

It is recommended to place the outer rings 3-7 cm from the edge of the curtain. This way they will look beautiful and the fabric will form an even wave.

Using grommet tape

Eyelet tape is needed to strengthen thin fabrics where the rings are fixed. If the base material is dense enough, then you can attach the eyelets without compaction.

The tape is a strip of fabric with finished edges. One or both sides are impregnated with a special glue, the fixing properties of which are activated at high temperatures.

How to attach ribbon to a curtain:

- Measure the width of the tape and place a point down from the top edge of the curtain, doubling the measurement result.

- Fold this part of the material in half, wrong side inward, and iron well.

- Apply the tape to the edge of the resulting fold, with the glue side down.

- Iron.

- Wait for the fabric to cool, cut off the excess tape on the sides.

- Use a sewing machine to stitch the top edge of the tape to secure it more securely.

For curtains that cannot be ironed, you can purchase grommet tape that matches the color and simply sew it to the top edge of the curtain. Transparent but dense ribbons are sold for tulle.

Types of grommet rings

The materials from which this type of fastening is made are varied - from metal to plastic of various shapes and colors.

Installation methods also directly depend on this. A plastic eyelet is much easier to install, but a large load on it is unacceptable! If desired, you can remove it and use it again, but the fixation of the edges of the fabric will be very poor - they crumble and become deformed, and the product looks sloppy.

Colored metal eyelets are much more reliable than plastic ones - they hold the fabric perfectly, preventing it from tearing.

Steel fasteners are considered the most reliable for fastening fabrics, leather parts, and cardboard. But before you install eyelets without tools on clothes or shoes, you will need to practice on unnecessary pieces of material. This is necessary to understand how the work is going and not to spoil the thing.

The most popular way to use eyelets is to attach them to curtains. To do this, you additionally need grommet tape, which is sold in specialized stores. It is used to glue the edge of the fabric, creating rigidity.

The mount itself can have a completely different shape - from circles to animals. The color palette is also huge.

Curtain eyelets will help to form smooth, interesting and neat folds. In order to move such a curtain on the eaves, you do not need to apply any force. The fabric does not wear out on the cornice, and, accordingly, its service life is longer.

Installation using specialized tools

You can install the eyelets yourself if you have special tools. Metal fittings are more difficult to fasten; hand strength is not enough for the eyelets to snap into place. Much depends on the width of the ring.

For heavy and thick fabrics, rings with a thick stem are used. In this case, the pressure on the grommet should be very large.

Installing eyelets with clips

There is a type of metal grommet with clips that can be installed by hand using a small hammer. The disadvantage of such rings is the presence of a front and back side. They are usually installed on bags and shoes.

Algorithm of actions:

- Press the ring onto the material so that a dent remains.

- Using the extruded lines as a guide, cut a hole.

- Place part of the eyelet with clips under the material.

- Place a ring with recesses on top.

- Bend the clamps using a hammer.

Then you need to remove protruding threads and fibers of the material.

Installing eyelets using pliers

In specialized stores you can purchase pliers for installing eyelets. The tool resembles pliers. The kit comes with removable attachments of different sizes. They are called punches and matrices.

How to install eyelets using pliers:

- Reinforce the material with grommet tape.

- Attach a nozzle of the required size to the pliers and punch a hole.

- Insert the part of the ring with the leg from below.

- Close with the top half of the ring.

- Install the nozzle into the pliers to close the ring.

- Place the grommet between the closing parts of the pliers and slowly press them down.

It should be taken into account that such eyelets also have a front and back side. It is important to position them correctly relative to the sides of the material.

Press installation

You can install the eyelets yourself using a special press. This tool has a lever and a pressure plane. It is used for eyelets with short and long legs. The set includes punches and dies for rings of different diameters.

How to use the press:

- Strengthen the material with adhesive tape or fold it in half.

- Select a punch of the required size and make a hole.

- Place part of the ring with the leg under the material.

- Place the washer on top.

- Place the desired matrix in the press and gently press the lever.

It is important to ensure that the washer does not slip or move, otherwise the grommet will be installed crookedly. You'll have to remove it and install a new one.

Features of working with the product on a gazelle or truck

If you need to glue a damaged section of an awning on a cargo truck or gazelle, you will need to observe a number of nuances. Before carrying out work, the vehicle must be driven into a garage or other room where the optimum temperature is maintained and there is enough space to access the defect on the canvas.

For convenience, it is better to remove the awning from the car so that you can apply force when fixing the patch and do not have to reach for the damaged areas, but if the design of the vehicle does not allow for the removal of the canvas, then you will have to carry out the work in the existing conditions.

What eyelets for awnings look like

Awnings, camouflage nets, tents, marquees, banners, covers for vehicles and equipment, curtains, clothing, shoes - this is just an incomplete list of products where eyelets are used. As a rule, a grommet is the edging of a hole made in the fabric of the product. The slots themselves are used for threading ropes, cables, laces, belts, etc. through them. Eyelets usually have the shape of a ring.

Types of eyelets for awnings

There are two types of eyelets: plastic and metal.

Nowadays, plastic is widely used as a construction material. The variety of plastic mixtures and a wide range of their properties, combined with relative cheapness, as well as the emergence of new technologies for the production and processing of plastics, make them a very common structural material.

Eyelets for awnings, made of plastic, are characterized by high strength, quality and elasticity. They can have different shapes: rectangular, round, oval, as well as any size and color. The performance characteristics of plastic fittings for awnings are also high. They are not subject to corrosion, do not damage the awning material, work perfectly in any weather conditions, and are not afraid of temperature changes and increased levels of ultraviolet radiation.

Installing plastic edging requires special professional equipment. An example of this is a machine for soldering two halves of a grommet. It ensures high labor productivity, accurate and fast welding, as well as the strength of the finished product. Such machines can be equipped with an automatic feeding and stamping system, which are used for mass installation of eyelets.

One of the varieties of plastic eyelets for awnings are clips, consisting of two halves and attached to holes previously punched in the fabric.

The main disadvantage of plastic rings is the complexity of their fastening technology. This drawback significantly limits their use, which may soon lead to a complete cessation of the use of plastic eyelets for awnings.

Metal eyelets for awnings, as a rule, have an anti-corrosion coating (a layer of zinc, nickel, paint). They usually consist of two elements connected to each other: rings and blocks (“male” and “male”).

The main characteristics of the product are:

The diameter of the hole is the main characteristic, which means that after installing the grommet on the awning, the holes will be of exactly this diameter.

The depth (or height) of the hood at the block, a size that is important when installing the product on an awning.

Profile of cap and ring molding.

As a rule, eyelets have standard shapes and sizes.

Installation of metal eyelets on awnings is carried out using special tools - a punch and flaring. There is a roller for each ring size and shape. The installation process consists of three stages.

At the first stage, a hole of the required shape and size is made in the place of future fastening using an appropriate punch. At the second stage, a block is inserted into the hole made on one side of the canvas, and a ring is put on the block on the other. And finally, at the third stage, using a roller, the block hood is riveted, and the grommet is securely fixed in the right place.

Sometimes a hand press is used instead of rollers. Moreover, each press comes with a set of attachments for different sizes and types of eyelets. Both methods are manual and do not require special knowledge and skills.

Recommended articles to read:

Recently, it has become fashionable to use metal eyelets of various styles and colors when attaching curtains. Curtains with eyelets look very stylish. Rings make it easier to place and remove curtains. A wide variety of shapes and colors of fittings allows you to choose the best design solution for any interior, both at home and in the office.

Another fashionable trend has become the use of eyelets in the design of clothing, shoes, and haberdashery. Jackets, lace-up boots, leather belts, bracelets, bandanas, backpacks and handbags with eyelets, all this will help you create your own unique clothing style and stand out from the general environment.

Today, the method of fastening with eyelets has become very widespread. This is truly one of the most used and useful inventions invented by man.

Installation on leather materials, shoes

When fixing the eyelets on the rings, it is better to use pliers or a press. It is important that the hole is smooth, so you should punch it with a special nozzle. It will not be possible to carefully cut it out with scissors, as creases and cracks will appear on the skin.

Algorithm of actions:

- Strengthen the area where the fittings are installed by folding the material in half, with the wrong sides facing each other.

- Mark the location of the rings with a marker.

- Select a punch of the appropriate size and make a hole.

- Insert the matrix tool of the required diameter, place the eyelet and secure it.

You need to work with leather only on a hard and flat surface so that the material does not deform and the fittings are fixed correctly.

Characteristics

When choosing new eyelets, pay attention to several important characteristics

Diameter

The main distinguishing characteristic of such parts is the diameter of their holes. Determining the optimal diameter directly depends on the purpose for which the part is purchased. In stores you can find designs with a diameter from three to forty millimeters.

Depth

Another important parameter is depth. To determine it, you need to measure the distance between the end of the sleeve and the top cap. Before choosing a part, it is necessary to determine its depth, since this indicator determines the thickness of the installed structure.

Material

It is known that eyelets are made of various materials and therefore this must be taken into account when choosing them. If they will be installed outdoors, it is better to use structures made of plastic or metal coated with copper. Any materials are suitable for residential premises.

Form

Some people believe that such hats can only have a round shape, but this is not so. There are manufacturers who produce fittings in rectangular, oval or square shapes. There are also unique uniform models made in the form of dolphins or fur seals.

Installation instructions yourself

Having all the necessary materials and tools at hand, anyone can independently make an awning or canopy with eyelets at home, which can be used on the farm. This product can be used in various areas, from a tarpaulin curtain at the entrance to a garage to covering an outdoor pool from foreign objects and dirt.

Eyelets are great for securing canvas curtains to gates

Regardless of the area where you plan to use an awning with grommets, first of all, you should acquire high-quality blocks and rings; the overall strength of the grommets will depend on them. Experts recommend purchasing ready-made kits in specialized stores.

Typical eyelet sizes

As for tarpaulin, its choice should be made based on its intended purpose, based on the characteristics of strength, moisture resistance, frost resistance and the like. The shape and size are selected individually.

Preparing the tarpaulin for installation of eyelets

Having prepared all the necessary components and selected a tarpaulin for installing eyelets, you can move on to the next stage - punching holes in the tarpaulin, for which you will need the following tools:

Using a pencil and ruler, you need to find and mark the areas on the tarp where the eyelets will be placed. The mark should be made according to the diameter of the ring, evenly, at the same distance from each other. After this, using a punch and a hammer, holes are made in the tarpaulin in accordance with the marks.

It is necessary to accurately determine the location of the eyelets so as not to make unnecessary holes

Note! Before punching holes, it is recommended to fold the tarpaulin in half to more securely attach the grommet to the material.

If the tarp is thin, you can use a piece of durable fabric or use plastic or brass washers

Before punching holes, a wooden board is placed under the tarp to serve as a shock absorber when the hammer and punch collide.

Installing eyelets on the awning yourself

Having completed all of the above manipulations, all that remains is to secure the grommet in the tarpaulin awning, which, if all conditions are met, will not be difficult.

To do this you will need the following tools:

Materials used

Before purchasing eyelets, you need to familiarize yourself with what materials they are made from.

Steel

Some people think that steel products are the most expensive, but this is not the case. In their manufacture, a material is used whose surface does not have a protective coating. Such parts are considered cheap and unreliable, since over time traces of corrosion appear on their surface. In damp conditions they will deteriorate within five years.

Aluminum

Aluminum parts are considered the most common option for framing openings when making awnings, awnings or other products made from tarpaulins. The main advantage of aluminum is that it never corrodes. This allows it to be used in damp rooms and outdoors.

Brass

Brass products are considered quite expensive and therefore are not used as often as others. This durable metal is known for its durability and reliable rust protection. Eyelets made of brass will last for several decades if used correctly. Then they will have to be replaced with new ones.

Copper

Experts advise using steel eyelets that are coated with copper. They differ from other products in their yellowish coating with a slight orange tint. They will last more than ten years.

Silver

Expensive products are often made of silver. This metal has many advantages and is therefore popular. The main advantage of silver is its resistance to high levels of humidity. The silver coating is also protected from acids.

Gold

Such products are not made entirely of gold, they are gold-plated. Most often, gold-plated eyelets are used in the production of goods for home decoration or expensive curtains.

Tree

Wooden eyelets are considered a decorative element that can be used to decorate rooms. They are often used when hanging curtains or curtains.

Plastic

Products made from plastic are considered the cheapest. Such structures break quickly and are considered to be less resistant to mechanical damage. The advantages of plastic include the fact that it does not deteriorate in high humidity.

What it is?

In the modern world, the use of eyelets has expanded many times, and they can be used:

- in the production of banners for outdoor advertising;

- for tarpaulin awnings;

- in tents for tourism;

- in the manufacture of awnings for cars;

- in clothes and shoes;

- in the manufacture of curtains;

- in accessories and much more.

At their core, eyelets are the edging of a hole, embedded in the material, serving to strengthen it and allowing cables, ropes, harnesses and other guides to be passed through them without causing mechanical damage to the material during use.

The awning can be secured with eyelets using a cord passed through the holes

Or with a strap passed through the staples

In designs that require quick and convenient assembly, eyelets with swivel brackets are used

Eyelets for an awning allow you to give the entire structure the necessary shape and tension, which distinguishes them from other fastenings.

The main characteristics that eyelets have are the following:

- Diameter that must match the hole in the material.

Depending on the material from which the eyelets are made, they can be divided into two types:

Plastic eyelets are secured by soldering two halves using special equipment

Undoubtedly, metal eyelets are more practical and reliable, because they are less susceptible to deformation under constant physical stress, and their installation does not require special devices, as for plastic ones.

Metal eyelets are most often made galvanized or nickel-plated