At the beginning of the last century, factories began to sew outerwear with polyester fiber insulation. Later, polyester filling was made from it to sew demi-season and winter coats.

Since that time, the material began to be used almost everywhere. Today, well-known brands and companies that sew clothes for the mass market use new technologies in production. Manufacturers can create different types of linings to make it easier for everyone to find a warm jacket.

First, you should find out what kind of material is used for winter clothing. Polyester is a man-made raw material developed from fibers.

To make high quality fabric that is close to natural fabrics, new high-tech equipment is used. Clothes with such fillings can be worn both on chilly autumn days and in winter frosts.

About 100% polyester insulation

Often in the store the question is asked what kind of insulation is 100% polyester. This is a non-woven material made from polyester fibers. Each manufacturer uses its own technology and creates its own fabric, which differs from others in its ability to store heat, tolerate machine washing and wear resistance. It is rare to find true polyester in its pure form. You should not trust the labels and tags on the clothes and products you purchase. It is mainly combined with other fibers:

- Cotton - 65%. The resulting fabric becomes durable when worn, is not exposed to solar radiation, and does not wrinkle;

- Viscose - 30%. The most popular option. The material does not deform and does not fade;

- Polyamide. Becomes resistant to temperature, does not allow moisture to pass through, and gains additional elasticity;

- Spandex. Interacting with polyester, it acquires an airtight and stable structure;

- Yarn. There is a higher quality of finished products. They do not stretch, do not wrinkle and last a long time.

The use of synthetic fiber is presented in a wide range of products: tracksuits, curtains, hosiery, jackets. It is absolutely safe, does not absorb moisture and is heat resistant.

On the ready-made clothing market, 100% polyester insulation is found:

- holofiber;

- padding polyester;

- fleece;

- Polartek;

- holophane;

- thermofinn;

- Junsen;

- isosoft.

Any material consists entirely of polyester. Additionally, special clothing uses insulation materials designed for special conditions and low temperatures:

- Americans developed Thinsulate for astronauts;

- Thermium has a base made of aluminum film with fibers woven into it;

- Jopfil is designed for workwear.

Synthetic insulation material, regardless of the production method, does not cause allergies. It is completely synthetic, which means moths will not spoil it.

Polyester fiber undergoes a complex purification process. The quality and safety of the finished product depends on compliance with the technology. The seller may set a high price. In order not to be deceived, the insulation material and fabric must be crumpled and smelled. Low quality will give off a sour smell and feel of fiberglass in the hand.

Types of fillings in jackets

What is polyester in a jacket? When buying a coat or other outerwear, people primarily focus on the weather and climate of their region. But this may not be enough, because polyester in jackets has different properties. You can ask a store consultant for more information about padding. Information about this is indicated on the tag. There are fillers that are easy to distinguish by tactile sensations (for example, padding polyester).

Thinsulate

Down of artificial origin, which in its properties differs little from natural fluff. Thinsulate was used to insulate astronaut suits. Today they are used to stuff winter clothes for sailors and sleeping bags for mountaineers. To what temperature is polyester suitable? Things insulated with Thinsulate can be worn at 30-60 degrees below zero. It all depends on how dense the layer is. The stuffing is suitable for sewing children's clothes. Thinsulate fiber produces lightweight and at the same time warm clothing that is highly breathable.

Its density is 100-480 g/m². Due to its softness and light weight, Thinsulate is in many ways similar to swan's down. It is in many ways identical to natural, but does not cause allergies. Thinsulate consists of microfibers that are surrounded by air membranes. This polyester insulation is thin enough, so you can sew elegant winter coats from it. Things made from this filler have one drawback - the high price.

Holofiber

Holofiber does not absorb moisture, as it quickly evaporates from it. At the same time, warmth can be retained in clothing. There are halofiber balls inside the outer sides of the material. This polyester jacket will keep you from freezing and sweating. The raw materials are used to sew children's clothes. It is safe for allergy sufferers and suitable for everyone. The properties of holofiber largely imitate down. It can withstand machine washing on a delicate cycle.

The density of the material ranges from 70 to 300 g/m². How many degrees is holofiber suitable for? It is recommended to wear it at temperatures from 5 degrees Celsius to 30 degrees below zero. It is wear-resistant and does not lose its thermal insulation properties for a long time. Winter jackets made from holofiber can be worn in low temperatures and strong gusts of wind.

Sintepon

At one time, the structure of this material was changed, and since then it has been used in the production of jackets and coats. Sintepon 150 g/m² is the minimum density of the material, the highest is 400 g/m². It perfectly retains its shape and retains heat; items made from it are sold at reasonable prices. Many people are interested in what temperature is a padding polyester 200 g m2 designed for? It is recommended to wear things with such padding at the end of autumn or at the very beginning of winter, if the temperature has not dropped to 10 degrees below zero. Things that can be worn at 25 degrees below zero are insulated with padding polyester with a density of 350 g per m².

Sintepooh

This polyester insulation is reminiscent of bird down in its properties. The polyester fiber in it is glued in it in a special way. Synthetic fluff is wear-resistant, does not wrinkle, and dries quickly. For the winter months, when the temperature drops to 25 degrees, you can wear jackets with synthetic down, the density of which is 250 g/m². In five-degree frost, a filler with a density of 60 g/m² is sufficient. According to its structure, such polyester insulation can be homogeneous or elastic.

Isosoft

This material comes in different types. One of them is isosoft, the fibers of which are made in the form of balls. It is easy to care for: after washing it dries quickly and is not subject to deformation in the machine. Isosoft is thin enough, so down jackets made from it do not look bulky. Density ranges from 80 to 300 g/m². At the same time, the layer retains heat well. It is several times better than synthetic winterizer in its thermal insulation properties.

Isosoft is very soft and elastic, wear-resistant and at the same time breathable. A relatively thin layer of isosoft will prevent you from freezing in frosty weather. You can wear a coat with this insulation both in winter and in the off-season.

Manufacturers advise you to find out the density of isosoft and at what temperature it can be worn:

- from 200 to 300 g/m² – severe winter up to 35 degrees below zero;

- from 100 to 150 g/m² – up to 10 degrees below zero;

- from 40 to 80 g/m² – not lower than 0 degrees.

To improve the thermal insulation characteristics of isosoft, you need to put something thick under your coat (for example, a fleece sweater). This is how you can insulate a demi-season down jacket made of isosoft if the weather unexpectedly changed on a trip and you didn’t have any warmer things with you.

Certain types of polyester linings are suitable for different temperatures and weather. When purchasing items with synthetic padding, it is worth asking a consultant about how and what the interlayer is made of, what its density is, as well as other properties.

Experts advise asking what brand of outerwear is and reading reviews. The main thing is to know at what temperature you can wear it, what the density is, whether it can withstand machine washing and what the quality of the layer is.

The first insulation is synthetic winterizer

Material made of 100% polyester, synthetic winterizer, divided into:

- old;

- new.

Old ones include material consisting of 2 or more layers of fibers directed in the same plane. It is recommended to wear it in the off-season, in cold weather no more than 5 degrees below zero. The bond between polyester threads is weak. The insulation quickly wears out, begins to roll off and break through the upper material.

In the new padding polyester, 100% polyester insulation has an air layer and thermally bonded fibers. It is lighter in weight, retains heat well, and lasts a long time.

Improved polyester insulation provides a large number of advantages compared to its predecessor.

After washing, up to 50% of the thickness is still lost.

Advantages of padding polyester

- spring durable fiber structure;

- light weight;

- heat retention at external temperatures down to -25 °C;

- does not allow moisture or air to pass through;

- washable at 30°C, does not require additional heat treatment;

- dries quickly;

- not deformed.

Such insulation will preserve the appearance of clothing, its primary color and structure for a long time. This is especially important in winter. In windy and frosty weather it will reliably protect against hypothermia and keep you warm.

Disadvantage of padding polyester

- cannot be machine washed;

- it is contraindicated to twist;

- temperature up to 40 degrees;

- dry vertically.

Polyester insulation - padding polyester, is used by manufacturers when sewing inexpensive clothes.

Description of fabric, cost

So, what is polyester in jackets, what is such a filler? This, if you don’t go into details, is a loose mass of a huge number of very thin polyethylene fibers, movably fastened together. The air that is trapped inside it retains the heat generated by the human body. Moreover, the volume of this air in the thickness of the polyester insulation directly determines how effective the latter will be.

- Simple polyester fillings for jackets, “working” according to the principle “thicker layer - more air cavities in the weave of fibers - better heat retention.” These are padding polyester, padding polyester, holofiber, etc. They will not cost much at all. The thinnest padding polyester, for example, will cost about 200 rubles. per linear meter.

- More modern polyester insulation. They are more difficult to produce and cost more, but are more efficient in operation. Manufacturers have achieved a reduction in the required filler thickness due to the special structure of the fibers and the addition of calender layers on one or both sides. The lower price level for such materials is 250-350 rubles (various fleeces) per 1 linear line. m., upper – 2500 rubles (branded Polartek, USA).

The second insulation is holofiber

Non-woven polyester fabric was developed by Russian specialists. The material, which is hollow inside, holds heat well and does not wrinkle. Between the two outer layers, the fibers are arranged perpendicular to the surface or twisted into balls.

A distinctive feature of insulation is its ability to create optimal conditions for humans. Excess moisture comes out through the loose surface. The heat is retained. The body does not freeze and does not sweat.

Holofiber insulation is approved for sewing children's clothes. It is used to make clothing for winter sports. It is completely safe even for people prone to allergies. The characteristics are similar to natural bird down. It tolerates machine washing well in a gentle cycle. Things made of 100% polyester last a long time and retain their appearance.

It turns out that holofiber and comforter are about the same thing. Polyester fiber, after special processing, is crumpled into small balls approximately 5 mm in diameter. This type of filler is called holofiber in English and lomforel in French. The quality of this material is superior to synthetic winterizer, but still inferior to Thinsulate.

What to choose in the end

Which insulation is better to choose for a winter jacket is a controversial question. If thermal insulation properties come first, then a down jacket with natural filling or shelter is better. When you need a more affordable option, holofiber is suitable.

For women's down jackets, maintaining their shape is important. It will be provided by high-quality natural or synthetic down, isosoft, holofiber, and thinsulate. The latter is also the thinnest, which is important for creating a slender silhouette.

For children's jackets, lightness, hygroscopicity, wear resistance and low cost are more important, since clothes have to be changed often as they grow. It is optimal to choose holofiber or a more expensive option - Thinsulate or Isosoft.

Third - isosoft, hollofan, Thinsulate and others

Foreign manufacturers call polyester insulation differently. The material they produce differs mainly in the shape of the fibers inside the fabric.

Hollophane got its name from a combination of the words in English: "hollow" and title. The void is filled with polyester fibers twisted into springs.

Belgian isosoft contains hollow fiber balls inside. Released.

Both insulation materials are similar in quality to holofiber. Significantly warmer and stronger than synthetic padding.

Other insulation materials can be supplemented with hollow and bicomponent fiber. Have different structures and technologies for bonding fibers with acrylic glue and other substances. Their cost is higher. They are found less often in the store.

Polyester has become widespread. The world leader in its production is Fellex, which operates at the Ziran plant in China.

Thinsulate - artificial down. There is a legend that it was originally intended for use in space. In any case, it is much better quality than padding polyester. It retains its shape well after washing, keeps you warm in severe frosts (down to -30°), and the products are very light. Does not cause allergies. Clothes made from this material are used by athletes, climbers, and oil workers.

The fiber in this insulation has the shape of a spiral. Air is collected inside this spiral, which retains heat.

History of origin and manufacturing technology of filler

It all started in Great Britain, in the 30s of the 20th century, when industrialists mastered the technology for producing nonwoven materials. Around the same time, the production of polyester fibers began, which later showed excellent results in the manufacture of fillings for jackets and other warm clothing. Russia began to adopt this experience a little later: polyethylene fibers began to be produced in 1949, and insulation materials from them began after 1960.

The process of making insulation for jackets in general terms:

- Preparation of raw materials (polyester fibers).

- Forming the foundation.

- Bonding the fibers in this base together.

- Finishing of the finished filler. Depending on its type - rolling the fibers into balls, laying them in layers, placing calenders (protective layers of non-woven fabric) on these layers.

As you can see, the question of which is better, polyester or synthetic winterizer, is not correct, since the second is a derivative of the first. Essentially the same thing.

Please note: the performance qualities of the finished insulation directly depend on the type of fiber (regular, spiral, hollow, solid), the method by which the base fibers are bonded and the nature of the final finish. We wrote about the qualities that 100% polyester fabric can have in our other article.

More information about fellex 100% material

This type of filler comes in a variety of shapes and is made in the form of balls or solid sheets.

A distinctive feature of the material is that the insulation layers are fused using high temperatures. Fellex 100% polyester insulation (120, 220, 250, 300 g/m²) has a high level of wear resistance and does not require additional special care.

How warm is it in clothes with fellex filling?

The peculiarity of outerwear is its lightness; the manufacturing process of fellex insulation, which includes 100% polyester 250 g m², differs from the production of padding polyester. The material does not contain an adhesive base that holds the fabric together, so the insulation does not roll off during wear, quickly taking its original shape.

This is a light and thin filler, it warms well in severe frosts, trapping heat inside the lining.

Insulation from the fellex company is an excellent replacement for natural filler, but its cost is much lower. Due to its advantages, this material has become widespread among manufacturers of winter jackets for both adults and children.

Its lightness ensures comfort when wearing clothes, and ease of care and long service life do not burden housewives with additional problems

Same characteristics

Polyester and synthetic winterizer are synthetic materials . The basis for them is polyester fibers. Since the composition of the materials is approximately the same, they have several similar characteristics:

- High hygroscopicity.

- Thermal conductivity.

- Long service life (if the composition meets quality standards).

- Protection against the development of bacteria and microbes (due to artificial components).

- Hypoallergenic.

The products are easy to care for and can withstand long-term wear without changing shape or color.

In the manufacture of down jackets and winter sets, both of these materials can be used: polyester as a fabric, synthetic padding as a filler and a warm lining.

To impart additional uncharacteristic properties, natural materials (cotton, wool, silk) can be added to the fabric and filling. These products have become the most popular among synthetics due to their many quality properties.

Insulation for winter clothes

Holofiber SOFT. Lightweight, elastic and heat-resistant material. Even in frosty weather and temperatures of -25 °C it will retain heat and protect against hypothermia.

Thinsulate. Its structure resembles natural fluff. New technologies allow it not to lose its shape, repel moisture and participate in heat exchange. Provides excellent warmth at -30°C.

Belarusian Fibertek. Hypoallergenic, lightweight and durable. Temperature fluctuations up to -40 °C. An ideal solution for long walks in the fresh air.

American brand PrimaLoft. The basis for the creation was the imitation of the characteristics of down, but with an improved structure and use of fiber. This type is designed specifically for outdoor activities and winter sports, provided that the temperature does not reach -20 °C.

Belgian Isosoft. The presence of a double spunbond fabric gives additional density and lightness to the filler. The possibilities are limited by temperatures of -20 °C.

Reviews

Sergey. When I first bought a jacket with Thinsulate as a filler, at first I couldn’t understand what was going on. I’ll put it on, go out, and at first it’s hot, and then I’m all wet and freezing. And then I started reading reviews about polyester insulation in jackets and among them I found a problem similar to mine: the polyester filling itself is very warm, which is why it sweated, but the fabric of the jacket is a membrane that should remove moisture from the body. But for all this to work, what is worn underneath must be synthetic. And I wore cotton turtlenecks and T-shirts, which themselves get wet and don’t release moisture. In general, everything is fine now, I wear the jacket with pleasure.

Natalia. I would like to add a review about a polyester down jacket. My husband has a work pea coat with this kind of insulation. I don’t know what specific type, it’s something very voluminous, the jacket is very thick. But at the same time it weighs relatively little and is very warm. I can’t say anything about how it handles washing, because I’ve never washed it before. It was inexpensive, so even if it fails in one season, it’s no big deal.

Irina. Of course, I like down jackets, but polyester filling is more practical. There is much less fuss with washing and drying. Is it warm - yes, I am satisfied with the insulation in this board. Throw the fluff balls into the machine, and buy a special product, and then shake out any more lumps if you get any. A jacket with polyester as a filler can simply be washed on a delicate cycle. It seems like it should be dried flat out, but I'm using it on hangers, because the insulation is not thick and is well quilted.

Read positive reviews about polyester insulation in another article.

Advantages of clothing insulation:

- withstands temperatures down to -25 degrees;

- easy to wash and straighten after washing;

- does not lose shape regardless of the number of washes;

- There are no allergies to polyester. It is completely safe for the skin, the only limitation is that this material is best not worn on bare skin and by pregnant women;

- clothes with polyester insulation can be worn not only in winter, but also in spring and autumn. This quality significantly distinguishes polyester from other insulation materials, because versatility is always good;

- clothes made from polyester are very light, but warm several times better than jackets made from natural fillers;

- durable;

- does not require special care. Most jackets made from natural fillings require special care from time to time using expensive products. With a polyester jacket there will be no such problem;

- does not cause excessive sweating. Thermal underwear is made from polyester and, accordingly, retains heat well;

- wear resistance, polyester can last for quite a long period without losing its important thermal insulation properties;

- thanks to the manufacturing method, the material does not become electrified and quickly restores its shape;

- the thermal insulation characteristics of the material are identical to those of natural materials;

- the cost of jackets with such filling is much lower than analogues with natural insulation.

Properties, pros and cons

All polyester insulation has low thermal conductivity. It is most important. Other properties depend on what technologies were used in the production process of this material. For example, certain types of Polartek have additional layers that provide hydrophobicity and protection from wind. And Thinsulate is such a filler that is resistant to repeated creasing that it can even be used in shoe making as insulation. It’s impossible to list everything, so we’ll just talk about the typical pros and cons of polyester fillings for jackets.

This is interesting: How to sew a fleece hat

Advantages of polyester as a filling for winter jackets:

- Low thermal conductivity, so much so that one can argue on the topic “polyester or down, which is warmer,” and it is not a fact that natural material will be better.

- Light weight.

- Plasticity, ease of sewing.

- Quick return to its previous shape after creasing.

- Wide price range.

- You still won’t be able to save much, since cheap types of polyester filler for winter jackets can quickly wrinkle during use, losing some of their heat-protective qualities.

- At high temperatures (from +40 C°) it can become deformed.

- Polyester insulation, not protected by calender or jacket fabric, easily gets wet and cannot serve its intended purpose until it dries.

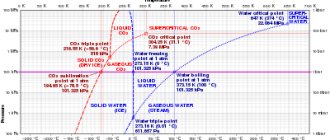

- They are afraid of high temperatures and exposure to benzene, gasoline, ethyl acetate and acetone.

Polyester: proper care and washing

Even though polyester material is so versatile and practical, it does have a number of disadvantages that you should consider. Not suitable for long-term wear, may cause allergies, and has poor heat conductivity. Polyester, as insulation in clothes and fabric for sewing them, also needs special care:

- hand wash at a temperature not exceeding 40 °C;

- Machine washable. In an automatic washing machine, you must select the “Delicate” or “Hand” wash mode. The temperature should not exceed 40 °C. Choose a spin speed of about 800 rpm to avoid damaging the item. Use a softening conditioner;

- Clothing that is too dirty will require pre-treatment with stain remover and soaking;

- Dry only in a well-ventilated area. Avoid exposing the fabric to direct sunlight;

- ironing exclusively in the “Silk” mode.

It is strictly forbidden to treat polyester material at high temperatures or boil it. Otherwise, the fabric structure may be damaged and the product may be deformed.

Manufacturers offer a wide selection not only in models and sizes, but also in technical characteristics. This makes it possible to choose outerwear in accordance with the season and temperature; for each temperature there is a certain amount of filler in clothing. For example, clothes with a density of 40–70 g/m2 are suitable up to 0°. m. Jacket with a density of 100–150 g/sq. m. will warm up to -10°, and frost down to -40° will withstand a density of 200–300 g/sq. m.

Synthetic fillers have a number of advantages over natural analogues. They are lighter, easier to maintain and durable. The ability to retain the amount of heat needed to maintain comfort is an important criterion when choosing clothes with polyester insulation.

It is also worth considering that clothes with synthetic fillers can have different variations of styles. This makes winter clothing more elegant and sophisticated.

Part one. Polyester thread

A simple, banal polyester thread. Very durable, cheaper than cotton, non-toxic and non-allergenic, like all other polyesters. Disadvantages: almost zero hygroscopicity, difficult to paint, not very pleasant to the touch. The main application is fabric for bed linen, the so-called polycotton. In principle, you get quite decent and budget-friendly underwear, the main thing is that the polyester content in the fabric is no more than 40%, otherwise you will sleep like on plastic. Recently, even the so-called polysatin has appeared, with satin weaving. In my opinion, this is a very controversial innovation. Anyone who has money for satin will not regret 100% of the money.

Another advantage of polyester thread is that semi-synthetic and 100% synthetic threads allow you to use thermostep technology to stitch something to something else, which is several times cheaper than quilting with threads. Used for the production of budget bedspreads, mattresses, mattress covers, etc. Occasionally in the production of quilted pillows.

Positive and negative qualities

Positive properties of materials:

- lightweight, retains heat at low temperatures;

- shape-stable, reliable, wear-resistant;

- there are cheap types;

- Even things that are not cheap or moderately priced are more affordable than natural down ones;

- easy care, resistant to dirt;

- does not deteriorate under the influence of inorganic acids and alkalis;

- does not admire insects, microorganisms, mold;

- multifunctional - suitable for winter and demi-season items;

- many options protect heat better than real down.

Disadvantages of polyester filling:

- accumulates electricity resulting from friction (using an antistatic agent will solve the problem);

- the canvas is slightly stiff;

- cheap options cause an allergic reaction;

- the unquilted cheap types become matted in clumps after five or six washes and stop keeping warm;

- if you accidentally spill solvent, gasoline or acetone, the fibers will dissolve;

- most polyester fillers quickly absorb water and reduce thermal insulation;

- cheap materials do not breathe well.

To reduce the number of disadvantages and be content with a good moment, when choosing a jacket, you should carefully study the type of filler. If you can spend more, you don't need to save.

History and current production

Polyester was invented in the 30s of the 20th century in England. At that time, geotexile production technology was invented. Soon it began to be used in clothing as a heat insulator. In our country, fiber began to be made by the end of the 40s, and filler - in the 60s.

Polyester - what kind of filler? Polyester fibers are produced from petroleum products: terephthalic acid and ethylene glycol. A decade and a half ago, many stages of chemical and mechanical processing were needed. How the PE filler is now performed:

- preparation of raw materials - cleaning and loosening;

- formation of a fibrous base;

- joining fibers mechanically, physico-chemically or by temperature;

- lining of the finished heat insulator.

First of all, cleansing from impurities and by-products. They are harmful to human health.

Synthetic or natural materials

There can be no question which is better - polyester or synthetic winterizer. It's all the same. But padding polyester is the most affordable type of polyester; it retains heat worse than other material options. This means that it is necessary to select it only when there is no opportunity to purchase something better. For example, during warm winters, for demi-season wear, or for working outside.

What is better to choose, polyester or down:

- Real down warms better than most types of polyester. However, there are artificial options with similar or better properties. For the northern winter you need to choose Thinsulate.

- Down absorbs any moisture and dries for a long time. Due to its naturalness, it is considered a breeding ground for microbes and insects.

- Synthetic material is easier to care for. The down jacket requires special care. To avoid freezing in it after washing, you will need to beat it with your hands.

Polyester fillers can vary in price. It's easier to find something that fits your budget. Down products cost approximately the same and are not cheap.

Where is it used?

Polyester filler is used in most industries:

- insulation of houses;

- car seat filling;

- insulation of sports items, outerwear;

- making quilted lining;

- the inside of pillows, blankets;

- filling soft toys, sides of cribs;

- production of thermal underwear, sleeping bags;

- making the insides of autumn and winter boots.

Various materials are made from polyester fibers. They are becoming more and more relevant.

Lining fabric

Polyester lining material is used for the following products:

- trousers, dresses, skirts, suits;

- jackets, jackets, coats;

- winter jackets and suits.

The polyester lining does not wrinkle or stretch, and remains in its original form for a long time. It does not allow moisture and heat to pass through. Winter polyester lining fabrics are supplemented with thermal insulation.