Plumbing fixtures today are often equipped with technically advanced devices that simplify operation and increase comfort. These include a toilet lid with a built-in microlift. Is not it?

But due to natural wear and tear of parts and incorrect operation, the system tends to fail. Of course, you can entrust the repair of the toilet lid to plumbers, but in order to save time and money, you can do it yourself. Moreover, in practice it is quite simple to implement.

In this article we will understand the operating principle of a microlift, consider the main types of breakdowns and tell you what is needed to fix them. For clarity, the article contains photo and video materials that reflect the essence of the issue.

Content:

- General description.

- Device.

- Possible malfunctions and ways to eliminate them. Identifying the problem

- Trouble-shooting

- Bolts broke

- The support system has weakened

- The spring burst

- The bushing is broken

- The bolts and nuts are rusty

- Piston microlift lubrication

How often do you call a plumber?

- The wife fixes everything. 35%, 1348 votes

1348 votes 35%1348 votes – 35% of all votes

- My husband fixes everything. 30%, 1174 votes

1174 votes 30%

1174 votes – 30% of all votes

- Everything fixes itself. 20%, 771 votes

771 votes 20%

771 votes – 20% of all votes

- From 1 year or more. 10%, 407 votes

407 votes 10%

407 votes – 10% of all votes

- Once a year. 5%, 187 votes

187 votes 5%

187 votes – 5% of all votes

Total votes: 3887

Votes: 3797

January 17, 2018

×

You or from your IP have already voted.

Loading…

general description

The device for smoothly lowering the seat is a practical addition to the classic lugged bushings. To understand how to repair a toilet lid microlift, you need to find out information about its structure and operation. Another difference is that the device is built into the toilet seat initially.

For the production of devices, hard plastic with a base of formaldehyde and phenol and reinforcing additives is often used. This is justified by the high demand for lightweight, inexpensive polymer seats. Less commonly, for heavy structures made of wood and metal, the microlift is made of stainless steel. Such closers must be periodically lubricated, which can sometimes be difficult.

The purpose of the device is to protect plumbing equipment from possible damage after impact from the lid or seat. In addition to this significant advantage of using a microlift, other positive aspects are noted:

- no noise when moving accessory elements;

- increasing the service life of the product due to careful handling;

- User safety is ensured by preventing the lid from spontaneously falling onto the back.

Plus, the sanitary bowl is always closed, and odors do not penetrate outside. The ease of installation and the permissibility of installing automated systems are also highlighted. But it is not recommended to install and repair compact chairs with a microlift yourself. The reason for this is the relative fragility of duroplast and ceramics. Suitability for troubleshooting may be limited by the design features of the closer.

Features of the mechanism

Despite the fact that the cost of plumbing products with a microclimate is slightly higher compared to conventional ones, they have a number of positive qualities, among which the following can be noted:

- Closing and lifting the lid is silent.

- Extends the life of the plumbing fixture, as it prevents the appearance of microcracks on its surface due to constant impacts. Accordingly, the service life of the plastic structure itself increases, since plastic is a rather fragile material, also prone to cracking.

- Easy to install, making it easy to install the seat yourself. Moreover, if necessary, the lid can be easily removed, for example, to wash.

- More expensive models can work automatically, that is, they raise the lid when a person appears, and also close it if no one is in the room.

Device

The smooth release mechanism is always considered as an integral element of the accessory as a whole. Therefore, before starting repair work, they find out the question of how to remove a toilet seat with a microlift, and not a separate part. Thus, a classic plumbing fixture consists of a seat, a lid, an elevator and a rim with a closer.

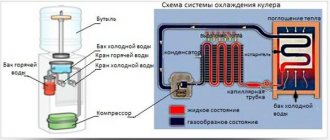

Regarding the design solution, closers can be of 2 types. The common elements remain the hinge and the bushing, which are responsible for the rotational movement. Models from inexpensive series have rods with springs. And more expensive mechanisms consist of a piston and cylinder. The package also includes response clamps that are attached to the toilet.

There are 2 door closers installed. Each is separately responsible for controlling the lid and seat. As a rule, the first one fails earlier, since it is activated more often.

Repair of wall-hung toilet

A suspended structure has many advantages compared to a traditional floor structure, but it is more difficult to install and repair. When using this model, some malfunctions may occur that you can fix yourself:

- If leaks appear, it is necessary to check all connections, and it would also be useful to improve the tightness of the joints.

- If the drain tank malfunctions, repairs are made through the inspection window; the process is described in more detail below.

- If water stagnates in the toilet, you need to check the slope of the drain (must be at least 45 degrees).

- If the structure is wobbly, it is necessary to tighten the fixing bolts.

Possible malfunctions and ways to eliminate them

The nature of all malfunctions is either natural or violent. This means that the mechanisms have a limited service life, or the user violates the rules for using the product. Most often, breakdowns occur due to the latter.

Identifying the problem

The simplest problem that any user can deal with is damage to the seat or cover. Then it will be enough to use adhesive or acetone in the case of Duroplast, fix the product in the desired position and wait the required time. In other cases, before disassembling the lid microlift, you need to make sure that the action is appropriate. This need not be done if the malfunction lies in the loosening of the nuts. Then you only need to tighten the fasteners and continue to operate the structure with the same intensity.

The third option regarding malfunctions involves failure of the elevator mechanism. This could be a broken bolt, joint, rod, spring, cylinder or piston. Less often, defects are associated with excess or lack of lubricant composition. The first can be seen, and the second can be heard, as a characteristic creaking or intermittent movement will appear.

More often than not, the spring breaks. The manufacturer selects the element in accordance with the weight of the cover and seat. It should shrink naturally without outside pressure.

How to distinguish a faulty spring from a broken bushing without disassembling the mechanism?

To do this, just use pliers to rotate the rod. If it turns with little resistance, then the spiral part is fine.

Fastening system

Pay attention to the cover fastening system. It can be plastic or metal. Fastenings of the latter type can also be quick-release. These seats can be removed literally with one movement of the hand, which makes cleaning much easier.

In addition, the fastening system can be simple rigid or adjustable. In this case, the position of the seat can be slightly aligned relative to the toilet bowl.

So, today, the most optimal is a seat made of duroplast with a metal quick-release fastener.

Trouble-shooting

In what cases is repair impossible a priori? Plastic elements that are subjected to one or another load cannot be restored. Non-removable devices are only acceptable for complete replacement. Some components are difficult to find on sale in accordance with specific technical characteristics and physical parameters. A non-standard approach (and not always possible) may be to reconstruct the part using a 3D printer. The material is ABS plastic and is easy to sand.

Bolts broke

If the bolts are broken, you can handle the replacement yourself. To do this, you need to use the instructions for installing a toilet seat with a microlift. First, dismantling is carried out in the reverse order, replacing the old parts with the same new ones. Then installation is carried out in accordance with the algorithm of actions specified in the passport.

The support system has weakened

When the problem is a loose fastener, its position is adjusted and tightened. How to remove the microlift from the toilet in this case?

The method is selected based on the design solution:

- press the latches and lift the product;

- press the buttons located on the inside of the hinges;

- remove the protective caps from the legs where the hexagon socket is provided, turn the fasteners a little and remove the toilet seat.

Another option could be a single accessory and support system. Then you just need to unscrew the nuts. The gaskets may need to be replaced.

The supporting elements in the holes on the sanitary bowl move freely. Therefore, their position must be corrected by moving the parts. Then they are tightened with a tool (wrench or adjustable wrench, pliers) or by hand.

The spring burst

If the spring fails, then it can only be replaced. Then the microlift will have to be completely disassembled and reassembled. The process can be complicated by two points:

- the mechanism cannot be reconstructed due to the integrity of the structure;

- it is necessary to find a part in strict accordance with the faulty one in terms of size and stability relative to the load.

Work with a closer may also be limited by the monolithic nature of its execution. If disassembly is allowed, then repairs, as a rule, can only be carried out in a service center. This can be explained by the fact that they have special machines with tools and experience. In this situation, it is easier to replace the parts yourself

.

The bushing is broken

It is no longer possible to repair a mechanism with a faulty bushing. But there is a solution to restoring the toilet seat's usability. True, this does not apply to a smooth descent, since the equipment will work by analogy with the classic one.

The materials you will need are the following:

:

- a pair of bolts up to 40 mm long and counter extended nuts of M8 grade;

- two screws with a diameter of M6;

- a piece of polypropylene pipe measuring 20 mm.

The tube will serve as a replacement for the microlift bushing. You must first install a nut in it. This can be done like this:

- heat the edge of the workpiece with a hair dryer;

- insert the nut so that it does not protrude beyond the edges of the part;

- place the pipe under cold water so that when compressed, it securely fixes the metal part inside the cavity.

The location of the screws is revealed by applying the seat to the plumbing fixtures. In the intended location, holes with a diameter of M6 are drilled on the hinges. And on the cover, using the same algorithm, they create an installation opening for M8 bolts. After assembling the entire structure, you can start using the system.

The bolts and nuts are rusty

How to unscrew metal bolts and nuts that are covered with rust? There are only 2 solutions to this problem

. For the first option, you will need an active agent whose action helps destroy rust. The most famous product is called liquid wrench (WD-40). It is applied to the parts, left for some time and tried to unscrew the nut again.

If nothing has changed for the better, then you will have to take a hacksaw. It is more convenient to saw off the bolt when the toilet is offset relative to the drain. To do this, it is disconnected from the sewer, the remaining water is drained and moved to a freer place. In the case of plastic analogues, you can use a knife. In this case, the cutting blade is preheated.

With a radical approach, earthenware should be protected from contact with metal blades. You can use cardboard or rags for this. Then scratches do not form on the glossy coating, leading to contamination, destruction or biological damage.

Piston microlift lubrication

Regarding the lubricating gel composition, it should be enough for proper operation. If there is a lot of working mass, the risk of clogging increases; if there is little, work becomes difficult, creaking appears, parts wear out, and as a result the mechanism becomes faulty. The third option involves hardening and delamination of the mass, which must be completely replaced.

For microlifts, it is permissible to use silicone-based damper lubricant. The viscosity should be above 100,000 units. The mass is filled into the built-in capsule. Other technical oils cannot be used.

To replace the gel composition, you will need to gain access to the internal space of the closer. How to remove a microlift without the help of specialists? The process looks like this: each block with a closer is removed one by one, the piston is squeezed out of the cylinders by unscrewing the screw with a hex key. Inside the case there is access to the capsule. Assembly is carried out in reverse order.

Replacing the seat cover

Having decided to replace a broken structure, you must first take correct measurements of the plumbing.

To remove the microlift cover, you will need to prepare the following tools:

- pliers;

- rags/cardboard;

- hacksaw/knife;

- socket wrench;

- silicone (oil, grease), treat dried elements.

Dismantling begins by lowering the cover and then unscrewing the pins. To avoid damage to the plumbing, it is recommended to cover it on top with cardboard or rags.

The next step is to unscrew the clamp and bolts using pliers. If, due to the long service life, the fastening points are covered with plaque, the bolts have grown together with the body or are clogged, you can use a hacksaw instead of pliers or use a knife after heating the blade on fire. The remaining hot plastic on the surface of the toilet bowl can be easily cleaned off after hardening.

The new cover must be installed in the same sequence as during initial installation:

- insert rubber inserts (2 pcs) into the cover, ensuring a soft fit of the device to the seat;

- insert into the mounting holes;

- screw the fasteners, and additionally use rubberized seals;

- secure the cover with metal or plastic bolts;

- adjust the device;

- check how firmly the structure is secured.

Installing an accessory with a microlift

Installing a working toilet seat yourself is acceptable. Knowing the instructions, it will be easier to figure out how to remove the toilet lid with a microlift for the purpose of washing plumbing equipment, repairing structural elements or replacing them. The algorithm of actions is as follows:

- Determining the suitability of an accessory for a faience appliance. If there are discrepancies in size, then using such a system will be uncomfortable. You will need to return and purchase a new product with physical parameters adjusted.

- Ensuring a tight seal between the seat and the lid. On the inside of the latter there are small recesses for this purpose. They contain soft rubber seals. In addition, these 2 inserts perform a compensatory task regarding vibrations.

- Fastening the seat. For this purpose, there are 2 small holes in the plumbing equipment. Fasteners with clamps in the form of bolts or rubberized elements with clamps are inserted into them.

- Seat height adjustment. This is done using a special bowl. Such an event is aimed at eliminating distortion and loose abutment of structural parts. Then the risk of breakdowns will be reduced.

- Final fixation of products. When the balancing has been carried out and all the spacers have been placed, proceed to the final tightening of the nuts on the underside of the support base on the toilet. In the case of polymers, it is important not to use excessive force. This can cause the threads to strip or the bolt to burst. Then you will have to replace the fastener with a new one. If we are talking about metal, then overdoing it is rare, but it provokes a split in the ceramic unit.

There are removable models. For this purpose, special hinges with a functional rod are provided. It has grooves for fixing the toilet seat, and on the microlift of the product there is a button that loosens the grip on the fastening.

Installation work

Removing the old cover

So, a new seat has been purchased, before installing it, you need to remove the old one. This operation does not require a large amount of time.

The only thing that might come in handy are some tools:

- Socket wrench;

- Pliers;

- Hacksaw.

Instructions for removing the cover are as follows:

- Regardless of the type of construction, the seat is fixed with two nuts . Before using the tools, you may try to unscrew them by hand.

- If the nuts do not “give”, use a socket wrench.

- In some cases, the bolts will be able to turn . To prevent this, pinch them with pliers.

- If it is not known why the fasteners could not be unscrewed, the bolts must be cut off with a hacksaw . But, before taking drastic measures, you can lubricate the thread with silicone or oil and try to unscrew it again.

Types of accessories with microlift

All products are classified based on their intended purpose. These can be universal products, children's or for users with disabilities. Here's what the features of each option look like:

- Classic seats with a cover are installed by most owners. They differ from simple ones only in the fact that they are equipped with a microlift. This type of product is suitable for almost all modern toilets.

- There are several extras for children. It can be not only color, pattern and compactness. Such accessories have an anatomical shape and are equipped with a backrest, safety ledges, handles, steps or stands. Another design is represented by a combined version of a universal and reduced design with two seats and a common lid.

- Highly specialized models are equipped with handrails that can be adjusted in width, height and tilt. This approach makes it easier for older people and people with disabilities to use plumbing equipment.

There are also seats designed for travel use. This way tourists can safely visit any toilet room. Comparatively less popular designs are designed for pets.

The best manufacturers

Recommended manufacturers of seats equipped with microlifts:

- Ifo Orsa (Sweden). The soft closing device itself is made of high quality Duroplast. White color. The seat is hard. The design is suitable for Kolo Primo and Keramag Flow toilets;

- Gustavsberg Nordic. The mount is made of high quality metal. The seat is hard. It is clearly fixed on the bowl. The model type doesn't matter. Suitable series - Nordic Duo / Nordic 2300 series / Nordic 2200. The set includes 4 pillows that act as supports for the bowl;

- Suntek Consul. Designed for both toilet and bidet. Seat material – duroplast (hard plastic). Fastener material – metal alloy. Model - any;

- Roca Mateo. The color of the product is silver, the material is metal. Suitable for mounting on any device.

Judging by the reviews, the quality of Roca's products is worse than that of other manufacturers. Seat seats often fail, and leaks are observed against the background of liquid leakage from the microlift. The main advantage of this manufacturer's products is their low price. But, given its unreliability, much more money is spent on repairing or replacing the structure.

The average cost of the system on the Aquasan company website is 1500-2200 rubles. You can also find seats with more advanced microlifts on sale, the price of which ranges from 3,000 to 6,500 rubles. More detailed information can be found on the website akvasan-shop.ru.

Rules for choosing equipment with a microlift

The choice of a toilet seat with a microlift is based on the parameters of the toilet, the structural features of the devices and the materials from which the component elements are made. The Aquasan store offers products from reliable manufacturers for sale, including a tank with similar functionality to the lid. You can place an order for goods at any convenient time of the day.

Here's what to consider before making a purchasing decision:

- compliance of the accessory with the dimensions of the seating part of the sanitary bowl and the location of the holes for support fasteners;

- use of high quality materials and warranty period of service;

- comfortable use and a design solution that is relevant for the interior.

Another selection criterion is based on hygiene standards. As a rule, they limit the service life of the toilet seat to 6-9 months. You can use stone, earthenware and duroplast longer. But wood is inferior in strength and resistance to moisture. Cracks cannot be restored and are a risk zone for biological damage.

Here is a short overview of the characteristics of popular materials

:

- Plastic is cheap, lightweight, but remains cold, turns yellow, and has low strength.

- Duroplast is comparatively harder and retains its shape and color for 15 years. But it is more expensive and hardly heats up in a warm room.

- Metal is rarely used for installation on earthenware units, but it is durable and practically not damaged during operation. The truth is heavy and must be protected from corrosion.

There are plywood models with soft lining. This chair is comfortable to use. The basis can be fiberboard or chipboard for cheap models, but natural solid wood lasts longer. Materials are subject to mandatory treatment with antiseptics and water-repellent agents.

Upholstery and filling are characterized by poor resistance to moisture, mechanical stress and a relatively short service life. The PVC coating peels off relatively quickly at the ends of the lid or seat and cracks. Due to the violation of the tightness of the finish, a favorable environment for the development of bacteria appears.

Plumbing equipment cannot be returned as it belongs to the group of hygiene products. Therefore, before paying, it is necessary to check the product visually and to ensure that the microlift is working correctly. The component elements should be free of unnecessary inclusions, nicks, irregularities, chips and thread failures.

The presence of sealing gaskets and liners must be monitored. They are needed so as not to damage the ceramic toilet. Such parts are installed in the places of fastening elements, on the underside of the seat and cover.

Universal mounts for toilet seats in the Leroy Merlin catalog

The toilet seat (toilet) is an important element that ensures comfort and ease of use of the toilet. As a rule, the seat comes complete with the toilet, but if necessary, the user can always separately buy a toilet seat and fastenings for its installation, which presents absolutely no difficulties. If it is necessary to replace broken fasteners, you can easily dismantle them and install new ones - thanks to the universal design of the fastenings, you can easily select the required set. The main difference between toilet seat mounts is the material used.

Features of types of toilet seat mounts depending on the material of manufacture

Fastening elements for a toilet seat are of the following types:

- plastic: the most budget option. Plastic is not afraid of moisture, that is, it is absolutely not susceptible to the formation of corrosion and oxides. That is why such a mount will always be easy to replace - it will easily unscrew;

- brass: as a rule, to protect against oxidation, a brass part is coated with a layer of chromium, so the product has a white color (metallic). Brass fasteners are characterized by increased strength and durability. The price of such a set of toilet seat mounts will be higher than that of plastic;

- stainless steel: characterized by good strength and durability, however, rust can still appear on such a surface due to accidental contact with abrasive substances during the cleaning process of the toilet, low quality “stainless steel” (insufficient chromium content), which will cause difficulties when dismantling becomes necessary. The solution to this problem is plastic inserts.

In the Leroy Merlin online catalog you can choose and buy universal toilet seat mounts in various configurations, made of plastic, brass, and stainless steel. We offer the best prices and reliable quality. Detailed photos and descriptions will give you a complete idea of the parts that are included in this or that kit.

Leroy Merlin offers a wide selection of goods at low prices for residents of Moscow, as well as the cities of the Moscow region: Balashikha, Podolsk, Khimki, Korolev, Mytishchi, Lyubertsy, Krasnogorsk, Elektrostal, Kolomna, Odintsovo, Domodedovo, Serpukhov, Shchelkovo, Orekhovo-Zuevo, Ramenskoye , Dolgoprudny, Zhukovsky, Pushkino, Reutov, Sergiev Posad, Voskresensk, Lobnya, Klin, Ivanteevka, Dubna, Yegoryevsk, Chekhov, Dmitrov, Vidnoye, Stupino, Pavlovsky Posad, Naro-Fominsk, Fryazino, Lytkarino, Dzerzhinsky and Solnechnogorsk. You can order the necessary goods online with delivery to all these cities or visit one of our retail stores in Moscow and Moscow Region.

Preventive measures

To prevent malfunctions from occurring, you must follow the rules for using the mechanism. The first thing to remember is that you cannot put additional pressure on the lid or seat. It should work at a slow pace initially.

Every 2-3 months it is necessary to monitor the position of the toilet seat. If deviations occur, adjustments are made. To do this, you need to loosen the supporting fasteners, align them and fix the structure again.

Cleanliness must be maintained. Blockages provoke corrosion of parts, interference with movement, and as a result, failure of individual elements or equipment in general. In addition, pollution becomes a comfortable place for the development of bacteria and the appearance of an unpleasant odor.

Main causes of breakdowns

Closer systems produced by leading manufacturers are renowned for their high quality. But natural wear and tear of functional elements and incorrect operation of a “smart” device lead to disruptions in the operation of the system.

The main sign of failure of the mechanism is the appearance of a loud sound that occurs when the lid is lowered due to its falling

The causes of malfunctions in most cases are attempts to manually close the lid “out of habit.” The mechanism's built-in spring is designed for gradual compression. If physical force is used, the mechanical impact disables the device.

The easiest way to solve the problem is to completely replace the cover with a new one, since reinstalling damaged mechanisms is not always advisable. But still, in order to save on expenses, you can repair a broken toilet lid microlift on your own, by trying to disassemble the device and replace its failed elements.

Image gallery

Photo from

Typical failure of the lid microlift

Study of the technical condition of the microlift

Identifying the cause of microlift failure

Buying a new soft close lid

The nuances of proper glass painting

Don’t think that painting on glass with stained glass paints is an expensive pleasure. You can save on buying paints. To do this, purchase not individual containers of paints, but the entire set.

By purchasing a set of paints at once, you get the opportunity to save money and also diversify your design

To make the painting process safe, do not forget about some precautions. Avoid contact of the paint and the painting itself with food and drinks

The paint should not get into the oral cavity. Therefore, when decorating glasses, glasses and saucers, they should not be used in the future for their intended purpose. Their main current function is to serve as a decorative item. This is if you want to completely protect yourself. However, painting of “functioning” tableware is also entirely acceptable, provided that a minimum distance of 1.5 cm from the top edge of a cup or glass is observed. That is, your lips and nose should not be in direct contact with the paint.

Competently applying a pattern with stained glass paints to glasses for permanent use

Modern man strives more and more for beauty, the desire to create beauty in everything gives rise to a large number of exclusive things made with his own hands. You can always decorate your home, give it a touch of perfection, give it zest and originality, especially if you master painting with stained glass paints. Drawings on glass will help make any room exclusive, and if you paint it yourself, then there will be a lot of light and joy in the house.

Toilet closer repair

If the microlift breaks down, it is better to contact specialists with the proper experience. They will help determine the cause and type of malfunction, and will also professionally make a replacement and fully restore the functionality of the “smart” system.

Work on self-repair of the built-in mechanism should be carried out with extreme caution, having thoroughly studied the instructions for the product before starting work.

This is especially true if you have to deal with a design that is equipped with several additional functions at once.

Replacing failed bolts

The most common malfunction that can be fixed on your own is broken fastening bolts.

Work to eliminate the defect is carried out in the following sequence:

- Dismantling the device (you can take the installation instructions and repeat the steps, but in reverse order).

- Replacing broken bolts , screwed on the back side with nuts, which connect the back of the cover to the elevator mechanism.

- Assembling the system is carried out in the reverse order with strict adherence to the installation of each part in its original place.

The nuts are screwed onto the plastic bolts from the underside of the toilet. The work is carried out carefully so as not to damage the fasteners.

If you have to screw in brass parts to prevent damage to the surface, you should use intermediate plastic or rubber washers that soften the pressure of the fastener

If it is necessary to dismantle the seat, it is convenient to unscrew the holders manually or using pliers.

Tightening up loose supports

To tighten one of the metal supports securing the seat cover to the toilet body, you need to remove the caps on each leg of the fastener. They are equipped with hexagon holes, although some models do not have holes in these caps.

After this, all that remains is to remove the seat and cover without making excessive efforts. To do this, when open, simply gently lift it up.

The metal fasteners move freely in the holes, so to adjust the position of the lid relative to the tank, you just need to move them slightly forward or back, and then carefully tighten the caps or fastening nuts. In this case, the microlifts themselves do not need to be disassembled.

Elimination of other breakdowns

There are situations when, for some reason, the toilet lid itself breaks. If you wish, you can try to glue it together. “Liquid nails” do an excellent job with this task. If cracks have formed on the plastic seat, they can be eliminated using dichloroethane or acetone.

To do this, drop a little liquid onto the accident site and join the edges, fixing the lid in a stationary position for several minutes. If the cause of the failure is the accumulation of lubricant, which is a viscous and transparent substance, then to eliminate the defect you need to carefully remove it.

If, when closing/opening, the lid makes a prolonged creaking sound, this indicates that the lubricating gel-like materials have been used up

Is the problem caused by a broken spring? In this case, it will not be possible to repair it so that the device works fully. Most microlifts are non-separable structures, and it is almost impossible to select a spring that is suitable in length and diameter.

Problems with the stock are also unlikely to be corrected on your own. It would be great if you can find a similar failed mechanism in which the rod is functioning properly. In other cases, the only correct way out of the situation is to replace the structure with a new one.