The washing machine sooner or later fails: natural wear and tear, improper operation, power surges and other factors lead to various malfunctions over time. Replacement and repair of some parts may require complete disassembly of the device. It’s good if your machine is under warranty and you can contact the service - otherwise you will have to call specialists, whose services are not cheap. In this article we will tell you how to disassemble a washing machine with your own hands.

Having some experience with electrical engineering, using tools and relying on diagrams, you can independently disassemble the washing machine and fix minor breakdowns

Regardless of the brand (Samsung, LG, Indesit, Bosch, Ariston, Zanussi, Kaiser, etc.), automatic washing machines have a similar design and operating principle. In our article you may find some differences with your model, but they are minor and do not affect the disassembly process.

It’s worth mentioning right away that not all breakdowns can be fixed on your own. For example, diagnosing and repairing an electronic control module and motor requires special knowledge and skills, and replacing bearings, especially if the washing machine has a soldered tub, will require special tools, as well as physical effort, time and ingenuity.

Main rules of disassembly

Before removing the drum from the washing machine, users watch an instructional video that gives them confidence. After watching, you get the impression that disassembling a washing machine is a simple task that can be completed in a couple of hours. But this is a misconception. In fact, this is a delicate process that conceals a lot of nuances unknown to home craftsmen. Without knowing about many little things, you can completely break the device - so much so that it cannot be restored.

Before disassembling the drum on an automatic machine, you need to gain access to it. You have to almost completely empty the body of all parts - they are removed so that nothing interferes with the removal of the elements of the washer. When disassembling the machine, you need to follow the rules that apply to all SMAs:

- The knot must be removed with extreme caution. 90% of washing machines have tanks made of plastic, which is not able to withstand serious mechanical stress.

- Take an assistant - it will be difficult to disassemble the device alone.

- If you have to saw the element to be removed, drill holes along the seam for future fastening. This will avoid displacement. A large number of bolted connections will allow the sawn halves to be tightly connected. Use waterproof sealant generously.

- When you unscrew the screw connection that holds the pulley, act extremely carefully. You need to apply force, but in such a way as not to damage the faceted surface of the screw head - otherwise there will be more problems.

- To remove the rear part of the SMA, you have to knock on the shaft - but you should not hit it hard.

Why do you have to glue it?

Sealing and gluing the washing machine tank is a forced process that owners of some SMA models have to deal with. Washing machines with a non-removable tank are offered, for example, by brands such as Ariston and Indesit. Manufacturers, making this element monolithic, do not intend to disassemble it. If the bearing breaks, the unit must be completely replaced. But such a replacement costs a lot of money and our people simply cannot agree with this order of things. As it turned out, you can halve the drum, remove the bearing, replace it with a new one, and then connect the halves

It is important to know how and with what to seal the tank

Replacement features

As a result of prolonged use or due to a manufacturing defect, the drum of the washing machine may become damaged. Usually the following damages cannot be repaired: damage to the walls with the formation of a hole or destruction of the bushing seat. In such cases, there is only one solution - to install a new element. Replacing a washing machine drum is a very labor-intensive procedure, as it involves disassembling the entire main device.

Manufacturers usually do not supply drums separately. They are sold complete with a tank.

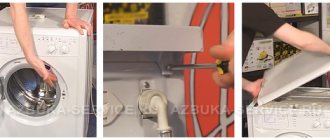

The process of disassembling the washing unit will differ slightly depending on the type of product: top-loading or front-loading. But before starting work, you should perform the same steps for both models: unload the laundry, unplug it, remove the inlet hose.

In a horizontal (front) loading machine

In such models, the drum is mounted in one place - to the rear wall. This feature requires the following actions:

- Unscrew the screws that hold the back wall;

- remove the entire cover (including the powder container, control panel);

- pull out the hatch cuffs;

- remove the wiring and disconnect the bolt that holds the drum at the back.

It is better not to completely unscrew the control panel, but simply move it to the side to avoid damage. If removed, it is recommended to photograph the wires to make it easier to return everything to its original place.

In a top loading machine

In such models, the drum is attached to the walls on both sides, which naturally complicates its removal. The operating procedure is as follows:

- unscrew the screws on the front and rear walls;

- remove the side panel;

- remove all wires and unscrew the remaining screws.

The second side panel is removed in a similar way. Then you need to remove the screw for attaching to the shaft and pull out the drum.

Specialists strongly recommend taking photographs of all the main stages of work, so as not to confuse the sequence of actions later.

Collapsible drum

Most models of modern washing machines, this is true for models from famous manufacturers: LG, Samsung, Ariston and others, have a collapsible drum, which significantly simplifies any repair work associated with it. Structurally, it consists of two halves, which are bolted together. Along the joint line there is a gasket or a layer of sealant, which ensures ease of disassembly and tightness of the drum.

Most often, disassembly is not particularly difficult, you just need to perform a number of actions in the following sequence:

- place the drum on a flat surface with the hatch down;

- jam the pulley using a small wooden block;

- Use a socket wrench or a socket with a ratchet to unscrew the bolt securing the pulley;

- after the pulley is removed, use a wrench of a suitable size to unscrew the connecting bolts;

- The halves are easy to separate; you may need to apply several light blows to the shaft with a mallet or a regular hammer through a wooden block.

When planning to unscrew a pulley, you must be prepared for the fact that the bolt will resist. If this is the case, you should not try to unscrew it “forcibly”; it is easy to tear off the edges, or even break the rod, as a result of which the repair will take a long time. Before unscrewing any bolts inside the washing machine, you should use WD-40, this will make the work easier and ensure the safety of the original fasteners.

After the drum is disassembled, you can proceed directly to replacing the bearings or removing foreign objects that have jammed the machine. If the task is to remove old bearings, it is better to use a screw-type puller. You can preheat the bearing, but you must use a torch or blowtorch with extreme caution so as not to damage the drum itself.

When changing bearings, it is important to pay attention to the condition of the sealing seals. If they have lost elasticity, there is a lot of wear or mechanical damage, the seals are replaced along with the bearings. Afterwards all that remains is to assemble the car; this is done in the reverse order. Of course, before assembling the drum, a layer of sealant must be applied to the parts being connected.

Non-separable drum

Some manufacturers make the drum non-separable “disposable”. The goal is clear. On the one hand, it’s easier to manufacture, there are no bolted connections, on the other hand, you can make money on repairs, because the owner of such a machine, if a cheap bearing fails, will have to buy the entire drum.

Certified service centers are unlikely to agree to disassemble a non-separable drum, however, this can be done in a home workshop. As a result of such repairs, you will be able to save a lot of money, because you will only have to pay for the failed bearings.

In essence, disassembling this drum differs from working with its collapsible counterpart only in that it will have to be sawed. This is not very difficult, it is more difficult to choose the best tool for this. There are several options.

- A hacksaw for metal gives a thin, even cut, but when heated, it often gets stuck, plus the blades break easily.

- A hacksaw for wood does not heat up, does not get stuck, or breaks, but it produces too wide a cut, and even with torn edges. In other words, it is easy to cut with such a hacksaw, but difficult to assemble the drum afterwards.

- A jigsaw allows you to get a thin, even cut, but in some areas it is extremely inconvenient to use.

Such a popular tool as a grinder is not considered at all for this operation. The disk rotates at a very high speed; one wrong movement is enough to ruin everything.

There is no ideal tool for sawing a drum, you will have to improvise. Some experts recommend using a regular hacksaw and a piece of cloth with a homemade handle for working in hard-to-reach places.

Preparation

Disassembling a washing machine cannot be done with just a screwdriver; you will need a whole set of tools and tools:

- socket and open-end wrenches;

- set of heads and knobs;

- a set of flat and Phillips screwdrivers;

- hammer;

- multimeter;

- bit;

- hacksaw for metal;

- pliers;

- WD-40 product;

- awl.

In order to disassemble the washing machine, you need to prepare a set of tools.

Please note that the presented list of tools and tools is as wide as possible and allows you to perform almost any repair. Perhaps only a small part of this list will be in demand

For example, if you do not plan to check the operation of contacts or sensors, then most likely you will not need a multimeter, and if you are not going to cut a non-separable tank, then you can do without a hacksaw.

Repairing equipment is an unpredictable process; it can last more than one day, and removed panels and parts take up a lot of space. Therefore, if possible, move the unit to a garage, shed or any other utility room where it will not interfere.

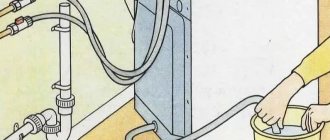

If you have to disassemble the equipment in the bathroom, prepare the surrounding space: clear a section of the floor measuring at least 2 x 2 m and cover it with film or old newspapers. Disconnect the washing machine from all communications and, if possible, carefully disconnect the hoses.

Do not forget that there is always some water left in the tank, which must be drained before starting repairs. Place a dry cloth under the machine, prepare a small container, unscrew the drain filter and wait until all the water flows out of the hole.

If you plan to remove the control panel, it is better to immediately remove the detergent tray. Usually, to do this, you need to pull out the container, press the latch located in the middle, and at the same time pull the part towards you.

Washing machines with collapsible tank

50% of SMAs are collapsible. It is this solution that allows craftsmen to change bearings without problems. In the collapsible version, the halves are connected by bolts. The joint of the parts is lubricated with sealant or sealed with rubber - all this is done to prevent leaks. Disassembling a glued drum:

- A wooden beam is placed in the drum pulley and jammed. In this case, the tank is located with a hatch in the floor.

- Take a socket of the required size with a ratchet to unscrew the bolt securing the pulley to the shaft.

- Remove the pulley. Next, unscrew the bolts connecting the halves of the tank.

- Having unscrewed the bolts, they hit the shaft lightly. Remove the rear part of the element being dismantled.

- Use a blowtorch to heat the bearings and then pull them off with a puller.

What do you need to remove the drum?

Before starting disassembly work, it is worth preparing the tools. Almost everything listed below is available to any home craftsman:

- screwdrivers of various types;

- pliers;

- spanners;

- hammer;

- hacksaw saw (for a non-separable drum).

If you have found everything you need, you can get to work.

This is interesting: The dishwasher does not drain the water: there is water in the dishwasher

Divide the tank into two halves

It will not be possible to saw the tank located in the machine - you need to take it out. Despite the apparent lightness, this knot is very heavy, so it is better to enlist an assistant. Next, we grab the edges of the drum, swing the container to the side, lift it slightly and pull it towards us. The tank should move and leave its seat.

Having freed the tank, we inspect it. You need to make sure that the container is solid and really needs this manipulation. If so, let's get to work:

- prepare the place for cutting: put a tire on it, which will increase stability;

- Place the tank on the tire vertically, seam side up;

- take a saw or a hacksaw for metal and halve the tank strictly along the seam.

It is necessary to act extremely carefully, since the slightest deviation to the side in the future will affect the tightness of the container. Having finished cutting, remove the upper part of the tank and turn the lower cross upside down. The bearings are “hidden” right under the shaft, so we move on to the next stage - removing the seals and “rings”.

Assembly Tips

The assembly of washing equipment from different manufacturers may differ, but general recommendations from professionals will help to carry out this work efficiently.

After sawing, the two parts of the body can be glued together with silicone glue - this is the best sealant for this purpose, connecting both metal and plastic well. They need to carefully go around the edge of the cut, but try not to use it in large quantities. Before installing the new bearing, the seating area must be cleared of dirt and small debris. You can tap it not only with a hammer, but also through an insulating washer made of getinax

It is very important to hammer the part all the way. After removing the bearings, the drum shaft is thoroughly polished, and there is no need to remove the spider. Before checking the machine, it is also important to clean all parts of the equipment, including washing the drum and descaling the heater. It is better to place the tank on the springs with two people, but it is also possible to fix the spring at the top and then tension it.

If you are repairing the unit yourself, remember that assembly must be carried out strictly in the same sequence as disassembly.

Tricks for repairing a washing machine tank in the video below.

The main reasons for drum failure

The drum of an automatic washing machine is one of its most important components; it is the basis, at least, of its mechanical component. Like any other component and assembly, it can fail, which will entail the need for repairs. In addition to the most common malfunction - bearing failure, repairs may be required in a number of other cases.

Drum jamming caused by foreign objects getting inside. Unfortunately, this happens quite often. A torn button, a fastener, a metal object forgotten in a pocket - all this can end up in the space between the body and the drum, get caught on the heating element, fall into the hole, blocking rotation and destroying the tank.

The use of certain types of detergents can cause rapid wear of the seals, they lose elasticity and crack. The seal does not cope with its task, water seeps through it, which negatively affects the operation of the machine as a whole and can cause an accident.

You cannot do without dismantling the drum even if the shaft is damaged. A broken drive belt, a skewed pulley - all this may lead to the need for serious repairs involving complete disassembly of the device.

A common reason for a machine to suddenly stop working is the failure of the electric motor or the need to replace the commutator brushes. To repair the engine, it is not necessary to disassemble the drum, but you definitely cannot do without removing it.

Is it worth taking the job?

Most often, the washing machine drum is disassembled in order to replace failed bearings. It is not difficult to identify this breakdown; you just need to turn it manually and listen. If resistance to rotation is felt, extraneous noises are heard, usually crunching and crackling noises - the bearings need to be changed.

Without a doubt, replacing bearings, like a number of other works, can be performed by a specialized service center, but the cost of a specialist’s services is often unreasonably high, this is especially true in the case of repairing a machine with a non-separable drum. Not a single service center will undertake repairs of this kind, offering to install a new module instead of replacing the bearing.

If it is expensive to repair in a workshop, you have the time, desire, tools and experience of this kind of work, you can disassemble any drum yourself, it is only important to be extremely careful and attentive.

Causes of breakdowns

The situation when, after starting the washing machine, after some time it stopped rotating and the drum jammed, is familiar to many owners of household appliances. The reasons for the failure of a household unit may be related to mechanical damage, wear of parts, structural components, malfunctions of electronics, and problems with wiring. To eliminate the malfunction, it is very important to establish the root cause of what exactly caused the malfunction of the household device, and for this the device will have to be disassembled.

Reasons that led to drum failure:

- ingress of foreign objects into components, structural parts, drums - buttons, coins, underwires from women's bras. The drum is jammed, does not spin, and turns with difficulty. To establish the causes of malfunctions, it is necessary to dismantle the heating element, after which third-party objects can be removed;

- jamming, wear of bearings, flanges, seals. The problem arises with the frequent use of household cleaning products. The cuff wears out over time and water leaks into the bearings. The bearings fall apart, the drum shaft jams, and the drum does not spin. It is best to entrust replacement to washing machine service specialists;

- broken drive belt, which is equipped with machines with commutator motors. The problem occurs when automatic washing machines are idle for a long time. The belt material loses its properties, cracks appear on its surface, which lead to rupture during operation of the machine. In this case, the most vulnerable spot is the electric motor pulley. Before replacing the belt, remove the back cover of the unit and examine the markings on its outer surface;

- The drum drive motor is not functioning. During operation, the operation of the motor wears off the material of the brushes, and an unpleasant specific smell appears when the washing machine operates. If the brush life is exhausted, the drum stops rotating. Before installing new brushes of the appropriate size, the commutator is cleaned;

- malfunction of the electronic programmer module, which, depending on the model modification, is responsible for the water supply valve, operation of the drain pump, collector motor, thermistor, timer. In fact, the electronic module is responsible for the performance of the main parts and engine components of washing machines.

The drum may jam and not spin if the tachometer fails, the electrical wiring is damaged, or the capacitor burns out. In this case, it is necessary to carry out serious diagnostics. The reason why the drum does not spin may be overload with laundry or clogged filter. All of the above reasons require troubleshooting, so you cannot do without disassembling the washing machine and removing the drum.

Inoperative state of the electronic module

Foreign object in drum

Belt break

Bearing wear

Drum motor malfunction

Reassembly and inspection

The reverse assembly process follows the following algorithm:

- we mount the tank in its original place (suspended on springs);

- install shock absorbers (for this work it is convenient to place the machine on its side);

- connect the drain hose;

- we connect the wiring to the heating element and the engine (it is convenient to carry out the work when the machine is positioned vertically);

- install the drum cuff and secure it with a clamp;

- connect the water intake, control panel;

- install a counterweight;

- fix the lid of the washing machine;

- We connect the washing machine to the sewer.

You can check the operation of a repaired washing machine only during the washing process. The machine is plugged in, select the required program on the control panel, and press the “start” button.

DIY washing machine tank repair

A washing machine is no longer a rarity and is a mandatory attribute of every home.

Its breakdown is always a nuisance, so there is a desire to quickly return the washing unit to work.

The tank of a washing machine is its main and main part.

In this article we will look at how to fix a problem with a washing machine tank.

What is a washing machine tank

It is in the tank that the moving parts of the washing equipment and the drum are located, among other things.

The tank washes the laundry, despite the fact that it directly interacts only with the walls of the drum.

It is into the tank that water flows and it seems that such a durable, but at the same time, mechanism that apparently does not perform the main job cannot break.

However, there is something in the tank that can go wrong. Repairing a washing machine tank is quite a labor-intensive job, and in order not to redo it, you will have to work conscientiously.

If you need to get to the heart of the car, you will have to disassemble it completely, then take out the tank and disassemble that too. The last stage of work after repairing the washing machine tank is reassembly in the reverse order.

Types of tanks

Tanks can be made from:

- enameled,

- stainless steel and

- plastic.

Today it is rare to find an enamel tank.

A stainless steel tank is reliable and can last for decades, but its production is quite expensive. Therefore, this type is found in expensive models.

A plastic tank is found in most modern cars. They are simple to produce, weigh little, and heat water quickly.

The disadvantage of a plastic type tank is its fragility, but with proper use it can last quite a long time.

Tank malfunctions

What can break in the tank?

- Bearings. A very inexpensive part, but it will take a lot of effort and time to replace it, risking serious damage to the shaft, pin and other parts. Bearings are located in the tank and are moving elements.

- Drain hole at the tank. Or rather, the drain valve, which usually breaks or becomes clogged and requires cleaning.

- Shaft. Typically, a problem with a shaft is the consequence of unrepaired bearing failure.

- Tank walls. Also the consequences of improper operation of bearings and shock absorbers, which lead to deformation of the tank walls under the influence of the centrifugal force of the drum.

Many serious failures begin with a bearing failure. Sometimes untimely repairs can lead to replacing the entire tank.

Disassembly

Repairing a non-removable washing machine tank is much more difficult.

The question arises: why not make all the tanks collapsible? Because when temperatures change, the tightness of the part is lost due to loose fasteners.

- Before you begin disassembling the part, you need to inspect the body from all sides and find the location of the soldered seam. It will be needed to drill holes for fasteners for reassembling the part.

- Armed with a drill and a thin drill, you need to drill 15-20 holes in a circle along the seam.

- Next, this seam must be sawed to get inside the tank. This is done with a hacksaw for metal. It takes a lot of time, you will need patience. The maximum recess when sawing the tank should not be more than 5 cm, otherwise irreparable damage to the walls of the tank can be caused.

- After this stage, the non-separable tank became collapsible and consists of two parts - front and rear. The front is an irregularly shaped plastic ring with a hatch and a rubber cuff in the middle.

The rear one consists of a drum with a drive mechanism, which we will remove. To do this, turn this part over with the hatch down and begin to disassemble the shaft. - Be careful with the screw in the middle. In order to unscrew it, you will need to attach a metal rod to which you need to hit with a hammer. After these steps, the screw can be unscrewed with a screwdriver.

- Now it's the shaft's turn. It is removed using 3 wooden blocks (1 small and 2 large). The tank is placed on large bars and a small block is hit with a hammer, which is installed on the rod. Despite the fact that the rod looks strong, the blows must be of a certain force - weak, stronger and even stronger, so as not to damage the part. As a result, the drum should separate from the tank.

- You don't have to dismantle the bearings if there is no problem with them. A damaged tank may be to blame.

- But often bearings or oil seals still have to be changed, then you will need a metal rod, with the help of which gentle blows are applied with a hammer to the edges of the part. It is under no circumstances recommended to tap on one edge to avoid drilling out the part. Both bearings must be replaced if they are faulty.

After the work has been completed, the machine is assembled in the reverse order.

Assembly

How to glue the washing machine tank after repair?

The sawn parts of the tank are lubricated with sealant and connected.

Cold welding can be used.

Bolts are inserted into the drilled holes and secured with nuts.

The size of the bolts will depend on the diameter of the holes you drilled.

If the tank is plastic

If the tank is plastic, it may have cracks and cause water leakage.

We immediately dismiss the option of soldering the crack, because this is a conditional repair of washing tanks that will not last long.

The best option is to replace it with a new tank. The price of a metal tank is more expensive than a plastic one.

If the tank is made of stainless steel

If we consider the possibility of repairing a stainless steel tank, then the option of using welding is quite justified. Of course, it is better to trust an experienced welder who will do everything carefully and quickly. After welding, you can paint over the seam with waterproof enamel to increase the service life of the part.

Keep in mind that sealant, no matter what quality, and cold welding will not solve the problem.

Eliminating problems

Disassembling the drum

The tank in the washing machine consists of 2 halves. Some tanks are fastened together, while others are soldered.

To disconnect the tank, you just need to unscrew the mounting bolts.

At this stage, the oil seal becomes accessible and if it needs to be replaced, you can remove it using a screwdriver or pliers.

It's more difficult with a bearing. It will have to be knocked out using a metal tube and a hammer. I think there is no point in talking about accuracy, and that’s understandable.

You can also replace the crosspiece, again, if necessary.

Important! Before replacing a new part with an old one, the installation site is treated with lubricant. If the tank is not dismountable, it is more difficult to carry out repairs on your own; you may need the help of a professional

If the tank is not dismountable, it is more difficult to carry out repairs on your own; you may need the help of a professional.

Changing the bearing

In what cases is it necessary to replace a part and how to remove a bearing from a washing machine drum?

For example, if a puddle has formed under the machine and there is a strong hum and vibration during operation. Why did this happen? There is a high probability that water got into the bearing and caused it to fail. In general, the service life of this part is not short, from 7 to 11 years, but sometimes trouble happens and you have to replace it ahead of time.

Troubleshooting shock absorbers

Shock absorbers are responsible for the smooth operation of the drum during washing and spinning. There should be no knocking.

How to check their serviceability?

Just. Open the car hatch and pull the drum towards you. Now let go. What happened?

If the drum, like a swing, swings from side to side and does not fall into place, this is a sure sign of the need to replace the part. Moreover, the shock absorber must be replaced in pairs.

To do this, you don’t have to disassemble the car, as is the case with bearings, but this is true only in LG, Veko, Ardo models. It is enough from the bottom, unscrew the fasteners and change the parts. But with the rest of the models you will have to tinker.

- – The top cover is removed and the dispenser is removed.

- – The control unit is disconnected.

- – Remove the rubber seal with the clamp.

- – The front part of the machine body is removed.

- - Details change.

Removing the foreign object

What does foreign object mean? It can be:

- coins, even rhinestones,

- buttons and other clothing items.

If you do not reach and free the drum from these things, the consequences can be tragic, including jamming and breakage.

What other problems can you solve on your own?

Changing the cuff

There are many reasons for cuff failure. This could be: wear due to long-term use, due to mold, due to cracks and tears, due to limescale, etc.

If there is water left under the machine after washing, check the cuff. After all, this is a dangerous business. The power supply may short out or the machine may fail completely.

What is needed to replace the cuff and how to remove the rubber from the drum of the washing machine?

Firstly, you need a new cuff, which must match the old one 100 percent, otherwise an incomplete fit may occur.

To replace an old rubber band with a new one, you need:

- Remove the front panel of the machine, remove the powder compartment, remove the front of the machine.

- Remove the cuff. In the usual version, the cuff is screwed to the tank with two metal clamps. You just need to pry the spring of the clamp and pull.

- After the first clamp is removed, you can remove the top of the rubber band, which ensures its correct location in the tank. The cuff will be released without any problems and can be removed after removing the second clamp.

- When installing a new rubber band, use the marks on the rim of the hatch as a guide.

- Before installation, it is necessary to carry out cleaning work on the rim of the hatch, at least with just a soap solution.

- The cuff is pulled over the hatch. If the top is pulled, the bottom is held in place; if it's down, then vice versa.

- Next, all the parts are assembled in reverse order.

All that remains is to check the work done by running the wash without laundry. If there are no leaks, everything went well and you did it!

Vertical loading

Top-loading appliances are very convenient in rooms with limited space. The service life of the drum in a washing machine of this type increases several times, since it is secured on both sides. Accordingly, its disassembly will be slightly different from the previous version:

- Unscrew all the screws from the bottom front and on the back wall.

- The side panel is removed.

- All wires are removed, after which the remaining screws are unscrewed.

In order not to spoil anything and not get confused in the sequence of your actions, experts recommend photographing the main stages of disassembly.

Sometimes the plastic cover can be tightly soldered; you will have to get rid of it with a drill. As for the second side panel, it must be removed in the same way as the first. After all this, the screw that secures the shaft is removed and the drum is removed.

Required Tools

Before you begin, make sure you have all the necessary tools and materials on hand.

You may need:

- a set of screwdrivers, including Phillips and standard slotted;

- set of stars and hexagons;

- screwdriver;

- hammer;

- wire cutters and pliers;

- set of socket heads with ratchet;

- hacksaw for metal.

You don’t necessarily have to use all of the above equipment - the complexity of the work depends on the model of the washing machine. Some units are very easy to disassemble, but in order to remove the drum from others, you will have to work hard.

For washing machines with different types of loading, the procedure for disconnecting the drum may differ significantly. Let's consider the sequence of actions for devices with front and vertical loading. Remember that for any model of washing machine, work on removing the drum must begin by disconnecting the unit from the electrical network and disconnecting the water intake and drainage hoses.

Extraction

In each model of washing machine, be it the recognized brands Indesit, Samsung and Ariston, the drums are different from each other, but they all have the same disassembly principle.

Before starting troubleshooting work, you need to arm yourself with a screwdriver, hammer, pliers and wrenches of different sizes. Let's start disassembling:

- First, we dismantle the top and back panels of the washing machine and release the drum pulley by unscrewing the bolt in the center counterclockwise.

We additionally use a wooden block to prevent the pulley from turning. Please note: before unscrewing, the central bolt must be heated with a gas burner, because it is mounted on glue, which does not allow it to unscrew spontaneously. - Next, remove the loading hatch and lock by unscrewing the screws and screws.

- Then we remove the corrugation and valves that supply water to the machine and proceed to dismantling the box for powder and hoses made of rubber.

- We take an assistant and carefully pull out the plastic drum from the machine body, having first removed it from the three suspension springs. We also remove the counterweights.

Now the drum needs to be disassembled.

It is divided into two parts, which are connected to each other with self-tapping screws along the entire perimeter, thereby ensuring its tightness so that water does not leak.

Having disassembled the plastic drum, we take out the metal laundry tank and inspect it.

You may be interested in an article on how to replace the cuff of a washing machine hatch.