Any equipment fails sooner or later. Washing machines in the budget category, for example, Indesit brand models such as WISL 82, WISL 83, WISL 102, WISL 103, WISL 105, IWSC 5105 (especially those that have been in use for a long time), often require repairs. Failures can be very different, and in order to correctly determine the cause of the malfunction and eliminate it, as a rule, the machine needs to be disassembled.

To determine the cause of the malfunction and eliminate it, it is usually necessary to disassemble the washing machine

Sometimes it is enough to simply remove one of the housing covers, but there are times when you need to get to a bearing located in the drum or to another hard-to-reach part. Then the owners of the equipment are faced with a serious task, the solution of which must be approached with full responsibility.

If you want to save money, try performing repairs without contacting a service center. In our article we will tell you how to disassemble an Indesit washing machine with your own hands so that you can easily reassemble it later.

Preparation

Before you begin any repairs, you need to make sure you have the necessary tools. You may need:

- a set of flat and Phillips screwdrivers;

- socket and open-end wrenches;

- set of heads and knobs;

- hammer;

- multimeter;

- bit;

- hacksaw for metal;

- pliers;

- WD-40 product;

- awl.

To disassemble a washing machine, you may need a variety of tools.

Please note that the presented list of tools and tools is as wide as possible and allows you to perform any repair. In some cases, you can get by with a much smaller set.

You must understand that troubleshooting can take more than one day, and the removed parts will take up a lot of space. Therefore, if possible, move the unit to a garage, shed or any other utility room, where it will not be in the way, and spare parts can be neatly laid out.

Before disassembling the automatic machine, find the warranty card and make sure that the warranty period has expired. Remember that the manufacturer is not responsible for equipment that was repaired at home, so if the warranty is still in force, contact a specialized service center.

If there is no free space, organize the work on site: prepare a section of the floor at least 2 x 2 m in size, removing carpets, furniture and covering it with film or old newspapers. Disconnect the washing machine from all communications and carefully disconnect the hoses.

It is imperative to drain the remaining water from the tank so that during disassembly it does not get on other parts. To do this, place a dry cloth under the machine, unscrew the drain filter and wait until all the water drains from the hole. Also remove the detergent tray (usually to do this you need to press the latch located in the middle and at the same time pull the part towards you) and set it and the filter aside.

In order to disassemble a washing machine, certain skills are required. If you are not confident in your own abilities, it is better to entrust the work to professionals.

So, the Indesit washing machine is ready for disassembly, what should you do first?

List of required tools

- First, prepare the necessary tools. Everyone has most of them in their home; if one of them is missing, they turn to neighbors for help or go to the store.

- Then a well-lit, spacious place is prepared, the floor is covered with rags or paper so as not to lose small parts and bolts.

For disassembly you will need:

- a screwdriver with a set of bits or a set of Phillips screwdrivers;

- wrench;

- flat screwdriver;

- hexagonal wrench 8 mm;

- multimeter;

- pliers, pliers;

- hammer;

- colored markers;

- transparent sealant;

- CV joint lubricants, VD-40;

- clean rags.

When cutting a tank, a fine-toothed hacksaw, a drill with a long drill bit, bolts or self-tapping screws, and a sealant gun will be useful. It is advisable to stock up on tools in advance.

How to remove main parts

The washing machine consists of many parts, most of which are hidden inside the body.

Here is a schematic representation of the main parts of the washing machine

We begin to disassemble the case from the top panel , which is secured with two bolts located on the back side of the machine; they need to be unscrewed first. Then, standing at the front of the unit, pull the panel towards you and lift it slightly.

Next we move on to the rear panel , which is held on by six self-tapping screws. You can unscrew them using a screwdriver. Directly behind the cover you will see the drive belt; it is better to immediately remove it too, carefully turning the pulley wheel clockwise.

The diagram shows in which direction you need to rotate the pulley to remove the belt from it

To dismantle the dashboard , unscrew several screws located in the niche of the detergent tray. Then we disconnect the wires and the pipe, remove the panel from the latches and put it aside.

During the disassembly process, the location of the parts and the connection diagram of the contacts can be photographed so that after the repair you can quickly and correctly reassemble in the reverse order.

At the top of the washing machine there are: a counterweight (stone), a pipe connecting the powder compartment to the tank, a water intake valve and its contacts, as well as a pressure switch, its tube and contacts. We remove all these details.

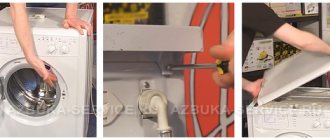

Before removing the front panel , remove the hatch door and rubber seal. We begin dismantling with the cuff - bend it with a screwdriver and carefully remove it. We dismantle the door by unscrewing several bolts that hold the hinge. Then we remove the screws that hold the front panel in place and move it to the side.

Remove the rubber cuff by carefully bending it using a screwdriver

In the lower part of the unit, it is necessary to dismantle the electric motor, tubular electric heater (TEH), lower counterweight, drain pipe and shock absorbers on which the tank is supported.

The heating element is easy to find by the end, which is visible under the tank. Remove all wiring from the heater contacts. Unscrew the nut located in the center between the contacts. Having loosened the element, remove it from the groove. We remove the power supply and ground wire from the engine, and then unscrew the bolts securing it.

The heating element is located under the tank, to remove it you need to disconnect the contacts and unscrew the nut located in the center

To remove the shock absorbers and drain pipe, you need to place the washing machine on its side. Using pliers, remove the clamp and disconnect the drain pipe from the pump. Then unscrew the shock absorbers.

To dismantle the drain pipe, you need to loosen and remove the clamps holding it

After dismantling all the parts, remove the tank. But what if this is not enough? How to disassemble the drum of an Indesit washing machine located inside a non-separable tank?

Hatch locking device

When starting to check, it is important to understand what type of lock is installed in your model of automatic washing machine (WMA). In older SM releases, manufacturers installed blockers with an electromagnet. However, they were ineffective without electricity

If the electricity was turned off during washing, the hatch automatically unlocked

However, they were ineffective without electricity. If the electricity was turned off during washing, the hatch automatically unlocked.

Another thing is the hatch door lock based on bimetallic plates. They are used everywhere due to their efficient operation.

The structure consists of three main elements:

- thermoelement;

- bimetallic plate;

- fixing device.

How does UBL work? Everything is tied to electronics. The electronic board supplies current to the thermocouple, which heats up quickly. This, in turn, is applied to the plate, which, increasing in size, pushes out the latch. Typically, when you start a cycle, you will hear a click, which means the door is locked and ready to draw water.

The principle of operation of the lock has been disassembled. Now let's talk about its problems: for what reasons does a breakdown occur?

Reasons for the malfunction of the lock in the washing machine

There are two main causes of breakdowns: physical wear and tear and electronic problems.

- Constant deformation of the plates when heated leads to damage and destruction of the element. In such cases, fixation does not work at all.

- Power surges in the network can lead to breakdown of the thermoelement. Then it does not heat up, therefore, the plate remains in place. The short circuit of the control triac results in the door not opening. Current is continuously supplied to the parts, so the latch does not turn off.

What should I do if there is a problem? Check the lock of the washing machine and replace it if it is faulty.

How to check the UBL of a washing machine with a tester?

The first thing that catches your eye when a breakdown occurs is the abnormal operation of the equipment. Here are the signs that indicate problems with UBL:

- The hatch does not open even several hours after the wash is finished.

- A code was displayed on the display of the washing machine, which indicates a problem with the blocker.

- The door will not unlock even after disconnecting the appliance from the power supply.

- During startup, the lock does not work and the hatch does not close.

Most often, either the element itself or its wiring and control module fail. A multimeter will help you accurately determine the cause of the breakdown.

To perform diagnostics, you will need the electrical diagram of the device. It may be different for each model, because manufacturers arrange the contacts differently.

What you need to find out:

- Where is the “neutral” contact located?

- Where is "general" located?

- Where is the “phase” located?

Prepare a multimeter and adjust it to measure resistance. You can get to the lock the same way in all front models:

- Open the door.

- Unscrew the two mounting bolts.

- Bend down the sealing collar.

- Place your hand behind your body.

- Get the UBL.

- Disconnect the wiring.

Now place one tester probe on the neutral contact and the other on the phase contact. Three-digit values are considered normal.

Next, place one probe against the neutral contact, and the other against the common one. The device is considered broken if the values are 1 or 0.

The tester did not find a fault, but the lock does not work? Inspect the lock itself; perhaps the reason is the wear of the bimetallic element. The lock cannot be repaired; it must be replaced immediately. Buy an identical part from the store, connect the wires and install it in its original place. Watch the video for details:

How to perform diagnostics if the sunroof is blocked? There is an easy way to open it:

- Take a thin ribbon.

- Pass it between the door and the SMA body.

- Pull firmly on both ends.

- The latch should give way.

Lastly, the control board is inspected. Its triacs often suffer from oxidation and burns. The reason for this is unstable voltage in the network and high humidity in the room. It is better to entrust module repair to a specialist.

To maintain the functionality of the washing machine electronics, connect the equipment through a voltage stabilizer. Before starting repairs, unplug the plug from the outlet.

Bad7

Interesting18

Super

How to disassemble the tank and drum

Washing machines of the Indesit brand usually have non-separable tanks, that is, if any element located inside fails, the manufacturer recommends replacing the entire part. Such repairs can be expensive, so if it is necessary to replace, for example, a bearing, it is still better to disassemble the tank.

In the photo you see a non-separable washing machine tank in which the drum is located

Dismantling begins by removing the pulley (the wheel through which the belt passed). The bolt that secures this part is subject to significant stress, and it is important that it holds tightly. Therefore, when assembling a machine, it is often not just screwed on, but also additionally secured with glue. It is better to use a T40 hexagonal star wrench and loosen the bolt, gradually loosening it. If the part does not give in, spray it with WD-40 or carefully knock it off the glue with a hammer.

In order to unscrew the bolt securing the pulley, you need to use a T40 hexagonal star wrench.

Next, we lay the tank on its side and carefully cut it with a hacksaw along the seam (where the two halves of the part are soldered). First, use a drill to drill holes around the entire perimeter of the seam (during assembly, the halves can be easily fastened with bolts).

When the tank is open, unscrew the bolts securing the drum, unfasten the fastenings and remove the tank wall. Now you can disassemble the drum, that is, remove the oil seal and bearings from it.

We start with the bearing located closer to the outside of the drum. We lay the part with the hatch hole down, place the chisel on the outer rim of the metal ring and hit it with a hammer.

You will need a hammer and chisel to remove the bearing from the drum.

We carefully monitor the position of the chisel when knocking out the bearing - if the tool slips and the inner ring is struck, it may fly out, and it will be quite difficult to remove the remaining bearing from the seat. We dismantle the inner bearing in the same way, and then remove the oil seal.

Disassembling the drum of the Indesit washing machine (video)

To prevent tank repair from being a constant ritual, you need to ensure that unnecessary objects get into the space of the tank and drum. But if damage could not be avoided and repair or replacement is now necessary, you need to contact a specialist. It is a qualified worker who will be able to select the necessary parts for the machine and install them without worrying about the remaining bolts. Until the technician arrives, you need to stop using the washing machine in order to ensure the safety of repairing your own apartment and the apartments of your neighbors.

Attention, TODAY only!

A washing machine, like any other type of equipment, is subject to wear and tear. Of course, we really hope that breakdowns will bypass your equipment, but if this does happen, then diagnostics and repairs are inevitable. And in order to diagnose some failures of the washing machine, it is necessary to remove the top cover of the washing machine. Most often, repairs begin with this procedure, so almost every owner of a washing machine may be faced with a situation where he will need this knowledge. For example, when the handle on the washing machine door breaks and you need to get to the lock through the top of the machine.

Here we will tell you step by step and explain how to remove the top cover of washing machines LG, Electrolux, Zanussi, Candy, Ariston, Indesit, Samsung, Ardo, as well as older Bosh and Siemens models.

Before starting repairs, be sure to turn off the power to the washing machine.

Features of disassembling units with vertical loading

How to disassemble an Indesit top-loading washing machine? The procedure will not differ much from that described above, because the device contains the same elements as a front-loading washing machine (pressure switch, water intake valve, drum, tank, control board, pump, etc.). The main differences are that the axis of the “vertical” drum is structurally made on two bearings, and sometimes a self-positioning sensor is located on the tank (fixing the drum with the flaps up).

In the photo you can see the structure of a top-loading washing machine

We begin to disassemble the unit from the control panel by unscrewing the screws holding it on the sides or simply prying the part with a screwdriver and sliding it towards you, not forgetting to disconnect the contacts. Under the panel there is a control board, which we also dismantle.

Then remove the top cover (its fastenings are usually located under the control board) and side panels, carefully disconnect the clamp from the drum.

Further actions will consist of sequential removal of all parts. The bearings in a top-loading washing machine are located on both sides of the drum, so removing them will take a little longer.

We will be glad if our article helps you repair your washing machine yourself. Follow the instruction manual, take your time, be careful, and you will succeed!

Lock device

Note that there are a large number of variations of locks. Manufacturers of washing machines install different locks on their models, which differ in shape, size, and method of fastening. They also differ in their operating principles. There are mainly two types used:

thermal;

electronic.

One of the UBL options

Thermal UBL

At the heart of the thermal lock is an RTS resistor and (or) a bimetallic plate. After closing the hatch and starting the washing program, a voltage of 220 volts is supplied to the resistor. It begins to heat up quickly and simultaneously heats the plate, which bends.

As a result, it blocks the hatch hook using a latch, preventing it from opening during the wash cycle. The bimetallic plate also closes the control contact, as a result of which the selected program begins to be executed.

The diagram and principle of operation of such a lock is shown in the figure below.

Note that markings in the form of letters: N, L and C are often present on the UBL contacts, which makes it easier to check. Instead of an RTS thermistor, a winding made of high-resistance wire can be used. And also two resistors are used in some models, which does not change the principle of operation.

Let us repeat that locks vary in shape, size and fastening, and if you need to purchase them, you need to select them according to the product number of the machine.

Simple thermal lock

This type of lock opens itself after the wash is completed. This is both a plus and a minus. The main disadvantage is that the opening takes place after 2-3 minutes, since the bimetallic plate needs time to cool and take its original shape, thereby releasing the tongue that holds the door. Most washing machines have a light indicator for holding the hatch.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

Important! Neglecting the cooling time leads to breakage of the lock mate, which is located directly in the door. Such UBLs are used in inexpensive models “Indesit”, “Ariston”, “Beko”, “LGi”, “Samsung”, “Ardo”, “Whirlpool”

Such UBLs are used in inexpensive models “Indesit”, “Ariston”, “Beko”, “LGi”, “Samsung”, “Ardo”, “Whirlpool”.

Electronic lock

An electromagnet is added to such a locking device, which is controlled by pulses coming from the module. And also in such UBLs there may also be an RTS resistor. In this case, the thermistor with a bimetallic plate closes the control wire, and the electromagnet moves the latch that blocks the hatch.

The castle is shown schematically in the figure below.

Such devices are installed on models of the mid-price level and above, such as: Electrolux, Zanussi, Kandy, Bosch, Siemens, AEG. There is only one drawback: the verification is difficult.

A hatch with such a UBL can be opened only if the following conditions are met:

- the machine is connected to the electrical network;

- none of the programs are running;

- there is no water in the drum;

- The engine does not rotate.

Note that washing machines with such locks are equipped with emergency opening devices, which are usually located in the area of the drain pump filter cover.

Burnt electronic lock

Removing the cover from machines of famous brands

Most often you have to deal with the following brands:

You can remove the cover from the LG washing machine by first unscrewing the cover on the hatch and removing the cuff. The cuff is held in place by a clamp, which is tightened with a small screw. The screw can be easily found by lifting the edge of the clamp using a flathead screwdriver and walking around. To release the drum, remove the weight located on top of it, and only then remove the drum out.

Samsung machines are designed in such a way that the loading tray is secured with two screws. Their heating element is located under the cover in front, at the bottom of the loading tank. Models from Bosch come with a key located in the base. The drain pump is located there - below.

Oil seals and bearings for Ariston machines are an eternal problem for any master. Despite the fact that the model appears to be beyond repair, a solid tank can be flared or the metal or plastic base can be carefully cut using a special tool.

Such work requires certain skills, and an incompetent person should not take it on.

It is better to remove the drum from the Atlant machine by getting inside from above. Before this, remove the counterweight and dismantle the control panel. This drum consists of two parts, tightened together with bolts.

The Electrolux model is equipped with a removable front panel. Thanks to this, you can freely reach its main nodes. The bearings and seals are fixed with removable supports, so there is no need to completely dismantle the tank.

Models of automatic washing machines (WMA) are reliable and durable, but they sometimes break down. In case of breakdown...

If you encounter difficulties and for some reason you cannot remove the cover, it is better not to risk it, but to seek help from a service center for repairing household appliances.

Nuances when working with washing machines

Removing the top cover is usually not difficult, but certain points should still be taken into account. Indesit WISL 105 and other models are easy to handle because they have the same disassembly principle. Rarely can you come across models that are understood a little differently. Let’s say the manufacturer Ardo produces cars that have untypically removed top covers. You need to remember this, as you may encounter an unusual model.

As always, you will have to first disconnect the device from the network. Just in case, it is better to wear rubber gloves to avoid electric shock. After this, the unit will need to be moved away from the wall. You need a place to work, otherwise it will be difficult and even impossible to unscrew the screws.

The lid will have to be moved forward rather than backward. That is, if a person is standing behind the unit, then you need to move the element away from you. The cover can only be moved at an angle. Otherwise, nothing will work. You will have to determine the angle yourself, as it may differ. It is worth trying different slopes until you achieve the result.

On older washing machines, there are sometimes bolts attached to the front panel. This is even more convenient, because there is no need to move the unit. All screws are covered with plugs, which must first be removed. After this, you will need to unscrew the bolts, remove the fasteners and lift the cover, pushing it forward.

As a rule, Indesit machine models are disassembled according to the standard scheme. People have no problems interacting with the device

You should act carefully so as not to damage the plastic element. In addition, you need to try not to leave scratches

It will be difficult to remove them from the front panels later. If you follow the instructions, you will be able to remove the lid from the Indesit washing machine yourself. The main thing is to correctly return it to its place, so that later there are no problems with the functioning of the device.

Causes of breakdowns and ways to eliminate them

- The washing machine does not turn on;

- water is not collected;

- water is collected very slowly;

- the water remains cold throughout the entire wash cycle;

- The washing machine turns off during the wash cycle;

- the drum does not rotate;

- water does not drain;

- the machine is very noisy;

- water is leaking from the machine;

- The washing machine vibrates very strongly;

- the door does not open.

- Incorrect program selected.

- The door is not locked.

- No power supply. (Check the electricity in the apartment, the socket itself, whether the plug is inserted into the socket).

- Check if water is flowing into the machine.

- Damage to the electrical wiring in the machine. You need to turn off the power to the machine, remove the back cover and check the terminals; if they are oxidized, you need to clean them. The wires should be checked for possible breaks.

- Sometimes the cause may be a timer. To check whether this is true, you need to select different programs; if the washing machine works on one of them, then the timer needs to be replaced.

No water coming in

- Check the presence of water in the water supply and whether the taps are closed.

- Check the integrity of the inlet hose and whether it is clogged.

- Check the cleanliness of the inlet filter. To do this, you need to turn off the water supply, unscrew the inlet hose and unscrew the filter with pliers. Rinse it thoroughly under running water and put everything back in place.

- Intake valve clogged. Dirt that has passed through the filter can damage the valve. In this case, you need to find the inlet pipes and replace the valve.

- The water regulator is broken.

When the required amount of water has accumulated, the gas is compressed in the compartment with the pressure regulator. The switch is triggered, the water supply stops and heating begins. Essentially, it’s a tube; if it gets clogged or broken, the machine won’t work.

Repair:

- First you need to check how the tube is mounted on the switch. If the end has hardened, you need to cut it off a little and put it on again.

- To check the switch itself, you should blow into the tube; if you hear a click, it means the switch is working.

- There is a hose between the pressure chamber and the tank; you need to check the clamp on it and, if necessary, loosen it a little.

- Wash the camera and check it for damage.

- The water level regulator is broken. If it is faulty, then the machine does not understand that the required amount of water has already been collected and does not turn on the heater. The regulator should be checked and replaced if damaged.

- Scale on the heating element. Due to hard water, the heater becomes coated with deposits over time; you need to periodically descale the machine. If you do not do this, you will have to completely unwind the machine and clean the heating element itself.

- Broken wires leading to the heater. The wires are checked for breaks and the terminals are cleaned.

- Thermal relay failure. If it is faulty. It is possible that the heater is turned off too early.

There can be many reasons: a power outage, a water supply, a blockage in the drain or inlet hose, a broken pump, a thermostat, a heating element, a timer, or a motor.

In this case, you need to check the supply of electricity and water; if this is not the case, then the machine is disconnected from the water supply and electricity. The water is manually drained and all other components are checked.

- The drive belt is loose or broken. You need to spin the car and check the integrity of the belt. A normally tensioned belt should move 12 mm when pressed. If the machine is equipped with a belt tension regulator, the engine moves down slightly and the bolt is tightened. If there is no such function, then you will have to change the belt.

- If the door latch breaks, the drum will also not rotate.

- The engine is broken.

- Check whether delayed washing or pause is selected.

- Check the drain hose for blockages or kinks.

- Check the exhaust filter. If clogged, clean, if broken, replace.

- Check the pump. You need to remove it and check for foreign objects. Before removing it, you need to place a rag for water, loosen the clamps that secure the hoses to the pump. Check how the impeller rotates; if it is very tight, then loosen it a little. Check to see if the threads are wrapped around the rotating shaft. If there are no blockages, then it needs to be replaced.

- Check the fluid regulator, timer.

In case of leaks, you need to check the integrity and fastening of the hoses and the door seal.

Causes:

- Excessive load.

- Uneven distribution of things.

- The machine is standing on an uneven surface and not level.

- The ballast is loose.

- The suspension springs have broken or weakened.

- Check the tank for small objects. The most common reason is forgotten coins in pockets.

- Check the door latch.

- If you hear a squeal during operation, it means the belt is slipping. It needs to be tightened or replaced.

- Crack. Most likely the bearings have broken.

Training video

Step-by-step instructions for troubleshooting yourself

To remove and repair a faulty part, first determine the location of the pump, which depends on the manufacturer and model of the equipment (you can view instructions for disassembling washing machines of different brands here).

Location of the pump inside the device

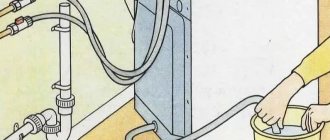

In washing machines from LG, Samsung, Ardo, Indesit, it is easiest to get to the pump, since the part is located at the bottom. To get to it, just lay the car on its side, covering the floor so as not to scratch the body, or simply tilt it.

Disassembly and cleaning

The instructions for repairing the pump of a washing machine with your own hands look like this:

- before removing the pump, the washing machine is disconnected from the electrical network;

- the water supply is shut off before disassembly;

- the machine is placed on its side so that the pump is at the top;

- remove the protective panel on the bottom (if any);

- Having unscrewed the screws on the bottom, remove the lower pan (if any) or unscrew the lower part of the front panel, gaining access to the pump with a filter attached with screws;

- remove the pump protective cover;

- then they feel the pipes, determining the presence of blockages, loosen the clamps, and pull them off the pump;

- unscrew the fasteners holding the pump;

- Disconnect the wiring and take the pump out.

If the pump is attached to the volute, it is disconnected from the pump by unscrewing the fasteners or turning it counterclockwise (depending on the model). At the same time, they determine how easily the impeller turns - it most often fails. A working impeller rotates irregularly due to the rotating magnet in the coil.

If the part rotates easily, without delays, or, conversely, movement is difficult and there is no debris inside, you will have to disassemble the pump. To do this, perform the following steps:

- disconnect the impeller by prying the housing latches;

- The crosspiece, which cannot be disassembled, is heated with a hairdryer at low temperature and pryed off with a screwdriver;

- remove the magnet with the impeller, the part, and clean the joint;

- the shaft is disconnected from the magnet, the bearing that appears is cleaned and lubricated;

- the bearing located at the bottom of the housing is also lubricated;

- worn gaskets, rubber seals are replaced with new ones;

- assemble the pump, make sure that the o-ring fits tightly into place;

- Don’t forget to inspect the oil seal and replace it if necessary.

Attention: Test the pump with a multimeter by placing probes on the pump contacts. The indicators “0” and “1” displayed on the screen indicate a malfunction of the unit and the need to replace it. We offer you to watch a video on how to check the pump of a washing machine:

We offer you to watch a video on how to check the pump of a washing machine:

Bearing replacement

The reason for the incorrect operation of the pump is not only the accumulation of debris and small objects. Bearings often fail, causing friction between the volute and the impeller, which causes noise and knocking to be heard during shaft operation. In advanced cases, the pump may stop completely.

The problem is eliminated by installing new elements, which are purchased at specialized points of sale and service centers that service household appliances (read about how to repair or replace bearings here).

If it is impossible to postpone the wash and a new part is not at hand, emergency measures are taken: the impeller blades are shortened by 2 mm. Do this with a sharp knife, carefully so as not to cut off too much and reduce the performance of the pump. Then the body with the blades is returned to its place in the coil and secured with latches. All that remains is to check the functionality of the repaired part.

After installing the pump and connecting the machine to the network, it will launch diagnostics and display the results on an electronic display. If the repair is performed incorrectly, an error code will appear on the display. If the car model does not have an information display, the test is carried out with a multimeter by connecting the probes to the contacts. A three-digit number indicates a malfunction of the electronic control module, a two-digit number indicates a malfunction of the pump.

We offer you to watch a video on how to replace a bearing in an LG washing machine:

Countries of assembly

First of all, let's learn to recognize the parts of the marking that tell us about the country of assembly of the Bosch washing machine. You can determine the origin of a washing machine, first of all, by the letter index, which can be found at the end of the marking designation of a particular model.

- OE - tells us that the machine was made in Russia, Belarus or Ukraine.

- EE - this index indicates that the machine was assembled in Spain.

- BY - tells us that the Bosch washing machine was made in Eastern Europe.

- GB - this index tells us that the Bosch machine was assembled in the UK.

- EU - this index indicates that the washing machine was manufactured in Eastern or Western Europe.

What this or that index prefix means is very important, but you need to understand that not all designations have such prefixes. Moreover, it is impossible to accurately determine the country of origin using the index. A three-digit letter code at the very beginning of the marking will help you do this with a specific Bosch washing machine.

Let's give specific examples

A three-digit letter code at the very beginning of the marking will help you do this with a specific Bosch washing machine. Let's give specific examples.

- WAS - means that this model is assembled in Germany.

- WLX - these cars are also assembled in Germany.

- WAE – this code denotes cars made in Poland or Turkey, with the exception of the model with the marking WAE28441, which is assembled in Germany.

- WLF - in most cases, this code denotes equipment assembled in Germany, if the numeric code ends with 4 or 5 - in China.

- WAA is the designation for models made in Turkey.

- WOT – Bosch cars from France.

- WOR - this equipment is assembled in Poland.

- WFX is an old designation that identifies washing machines assembled in Poland.

- WLM is a code that identifies Chinese equipment.