When assembling a pipeline and installing various plumbing equipment, it is necessary to firmly seal the joints of pipe parts in order to avoid water or gas leaks. There are various materials for this. One of the most popular tools for sealing is FUM tape. Its use has its own subtleties and nuances, so you need to know how to wind FUM tape correctly so that no problems arise during the installation process.

FUM tape Source wellmart.net

Material properties

The main advantage of fluoroplastic is its high plasticity.

In addition, the material is durable, non-toxic, chemically inert, and thermally resistant. FUM tape is capable of operating at pressures up to 40 MPa (relevant for antler baths).

The temperature range is minus 60 – plus 200 degrees.

When heated above 260 degrees, the structure of the material begins to deteriorate, and highly volatile fluoride compounds are released.

Average material characteristics:

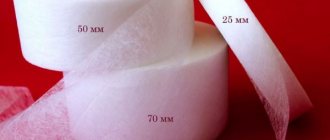

- thickness 0.04 - 0.2 millimeters;

- width – 10, 15, 20, 60 millimeters;

- fracture tension 40 – 60 kg/cm2;

- lubricant content 0.3 – 20%;

- 100% elongation before breaking.

Performance characteristics of the material

Fum tape is available in a wide range, so some performance characteristics may vary significantly.

When choosing, buyers are guided by the following:

- Plastic.

- Non-toxic. It is preserved at low temperatures. If the tape is heated to 270 degrees or higher, the material begins to release dangerous toxic compounds.

- Strength.

- Pressure. The operating pressure at which fum tape can be used while maintaining its original properties is up to 41.2 MPa.

- Operating temperatures. The products can be used in a wide temperature range - from –70 to +260 degrees, with full preservation of the original properties and safety.

- Anti-corrosion properties.

- Chemical resistance. The material withstands exposure to aggressive environments without losing its original properties.

Isn't it better to use oakum?

Tow began to be used by plumbers long before the advent of newer sealing materials. This is precisely what the age-old question is connected with: linen or fum tape, which is better? And although the first option has been tested by generations of installers, it has a significant drawback - you will need skills to work with tow correctly. Fum materials do not require special skills.

Each flax fiber must be separated and straightened. Once laid, the threads cannot intersect. And the amount of tow must be correctly determined; both an excess and a lack of it will lead to the fact that the joint will begin to “tear.” It’s also worth remembering about the layer of sealant that will have to be applied on top with a brush. In general, it’s not for nothing that many have switched to fum!

Each flax fiber must be separated and straightened. Once laid, the threads cannot intersect. And the amount of tow must be correctly determined; both an excess and a lack of it will lead to the fact that the joint will begin to “tear.” It’s also worth remembering about the layer of sealant that will have to be applied on top with a brush. In general, it’s not for nothing that many have switched to fum!

If you still don’t understand how to wind fum tape, the video instructions will definitely help you understand this issue. Happy installation!

FUM1 tape is used to seal threaded connections. It is made from fluoroplastic grade 4D - a synthetic material; a thin elastic white tape is obtained by rolling out a rope. Most often it is used to seal pipeline connections. In this article we will look at how to wrap fum tape around a thread for a strong connection.

Also, read about alternative types of sealants: tangit-unilock and plumbing tow.

Characteristics of fum tape of three types

- FUM tape is produced in three types, depending on the place of its application. FUM tape grade 1 is a premium grade tape designed for sealing threaded connections in systems with an aggressive environment, for example, concentrated alkali or acid. This tape contains Vaseline lubricant, which increases its performance characteristics.

- Grade 2 tape is typically used to seal piping systems that handle strong oxidizing agents such as oxygen and does not contain the protective lubricant of petroleum jelly.

- FUM grade 3 is used in general type pipeline systems, but it can also be used in systems with potent agents. When using a tape of this brand, you should know that this type of tape is less reliable than the previous FUM brands 1 and 2.

To a large extent, the connection density depends on the correct winding of the FUM. How to wind fum tape onto a thread correctly, avoiding leaks?

Correct winding of fum tape onto the thread

First, clean the threads of dirt and rust before wrapping the fum tape. Then all parts of the pipeline should be wiped with solvent or gasoline. The FUM tape must be wound along the thread with careful movements.

Each turn of the FUM tape should partially cover the previous one. To prevent folds and wrinkles from forming on the tape and to ensure that it is wound smoothly, winding should be done with a slight tension.

We should not forget that the smoother the tape is wound, the more reliable the threaded connection will be. There is no need to move the roll of tape away from the winding point too much - the best option is when it fits closely to the thread.

When the tape is wound, you can screw the butt piece to the joint. When screwing, it must move with a certain force - at this moment the FUM tape fills the thread. For clarity, watch the video:

Things to consider

When working with tape, it is necessary to take into account some of its characteristic features.

- The tape is quite slippery, so you need to wind it carefully so that the strips do not move out of bounds. It is advisable not to allow the edge to fall out into the inside of the connection.

How the tape should be positioned on the thread Source abro-ind.ru

- Once the film has already been wound, it cannot be unwound and re-wound - this will break the tightness. Try to process it carefully right away, otherwise you will end up wasting a lot of material.

- Also, the tightness will be broken if there is a need to loosen the connection. In this case, you will also have to rewind the material.

Precautionary measures

- It is not recommended to wind the seal using two or more pieces - this will compromise the tightness and strength of the connection.

- The tape on the thread should not be partially unwound, since if it is applied again, the connection will lose reliability. If winding is unsuccessful, the material should be removed completely and the process repeated.

- If, when connecting the elements, too much tension is created, which can lead to breakage, the tape will not be loosened. In this case, you also need to apply the seal again, removing the old section.

FUM tape is a material that is sufficiently reliable when sealing threaded connections. Its correct use will ensure the tightness of any pipeline even for a person who does not have extensive experience in plumbing work.

Using FUM for a gas pipeline

To fasten gas pipeline parts and install gas equipment, you should use only special FUM tape for gas. It must be supplied with a certificate of conformity confirming its suitability for use on gas pipes.

The special film for gas is yellow. It is made wider - up to two centimeters in width.

Yellow FUM tape for gas Source megastroy.com

The use of the material is possible only when sealing can only be achieved using a sealant. In the case of rubber hoses, as well as metal hoses, the sealing function is provided by a special gasket. In this case, the additional seal will not add tightness to the connection, and may even break it, as it will interfere with the tight fit of the gasket.

Sequence of winding fum tape

For those who want to learn how to wind fum tape correctly, there is a certain algorithm of actions, the implementation of which will ensure a reliable connection:

- First of all, you need to select the desired width and thickness of the tape. For example, if parts of the water supply system have significant wear, then the tape must be selected with a greater thickness, up to 0.2 mm.

- Next, you need to thoroughly clean the parts being joined so that there are no residues left from previous tapes, tow, paint, rust residues, etc.

- Then you should carefully wind the tape onto the part with a smaller diameter, that is, on the one that will be screwed in (or onto which the second element of the threaded connection will be screwed).

- You need to wind the tape strictly clockwise, since according to our standards, almost all threaded connections (in general, everything in plumbing) have a right-hand thread. This is done so that when screwing the joining parts, the fum tape does not fold, but continues to wind together with the part. Understanding how to properly wind fum tape is quite simple. If you want, you can learn this in 30 minutes.

Using these basic rules, you will easily understand how to properly wind fum tape for threaded water pipe connections

It is worth paying special attention to the fact that the tightening force must be selected carefully. This is especially true for water supply parts made of bronze and other soft metals and alloys

The main thing is not to over-tighten! The final result depends on how to wind the fum tape correctly. The main parameter here is the skill of the repairman, but for beginners it is enough to simply tighten it without putting much effort. After starting the water, you need to check the connection and tighten it if necessary. If the water is still leaking, and tightening it further is risky, then you need to turn off the water, unscrew the connection and add a couple of turns of the tape.

Fum tape instructions. Fum tape: main characteristics

The first development of fum tape began in the middle of the last century; since the late 80s, it has already been successfully used in hydraulic systems of industrial equipment. Since the early 90s, it began to be used for sealing various threaded connections, including at the household level.

Fum tape is made from 4D fluoroplastic and consists of thin threads bonded into an unsintered film. It is non-toxic, heat-resistant, and has anti-corrosion resistance. Fum tape, depending on the application, is produced in three brands:

- grade 1 – intended for sealing threaded connections of industrial-type systems and systems with highly aggressive media, contains a lubricant based on petroleum jelly up to 20%;

- grade 2 – used for systems operating on oxygen and other oxidizers, does not contain lubricant;

- grade 3 – used for industrial and domestic systems, made from edge parts of grades 1 and 2.

Regardless of the brand, the warranty period for storing the tape is 13 years.

The thickness of the fum tape should not exceed 0.1mm-0.2mm±0.02mm, although experts working with this product note that Soviet and Russian-made tape is thicker than foreign analogues.

The width of the tape is in the range of 10-20mm, different tape widths are used for different pipes.

Important: it is worth remembering that pipes with a diameter of more than 6 inches (diameter 150 mm and more) cannot be connected using pipe threads; in this case, pipe welding is used.

Due to its high heat resistance, the operating temperature range of the fum tape is -60–+200°C.

Important: at temperatures above +260°, the fluoroplastic from which the tape is made begins to release light, volatile, toxic fluoride compounds.

Fum tape for water supply

Although plumbing appeared more than 3 thousand years ago, sealing connections is still relevant. Over the past few years, there has been a serious debate about which is better - fum or flax. Experts on both sides zealously speak out, supporting and justifying their choice.

The use of flax and sealant (in Soviet times, oil paints or drying oils were used) makes the connection difficult to disassemble, while the presence of excess material on the threads will increase the stress in the fitting and, for example, with a water hammer, such a fitting may crack. It is necessary to work with flax carefully, knowing the characteristics of the thread and the amount of material required.

Foreign literature recommends using fum tape as a covering material for flax. In this case, it prevents the connection from souring and subsequent disassembly. After all, fluoroplastic has minimal frictional resistance, less than that of melting ice.

Fum tape is easier to use. By following the basic rules and recommendations, anyone can work with it. Another advantage of this seal is the speed of installation; it is good to use for minor and urgent repairs.

Manufacturers of pipes and fittings, especially polypropylene, also recommend using only fum with their products and prohibit the use of flax.

But as practice shows, the quality of the tape and its installation directly affects the quality of the connection. Due to an insufficient amount of wound tape, there are frequent cases of leakage of threaded connections after several days of operation. At the same time, fluoroplastic does not shrink.

What is tow and how to work with it

Before fum tape appeared on the market, plumbing tow, which was flax fibers, was used to seal threaded connections of pipes. Optimal results were achieved by coating the layer of tow wound on the thread with a small amount of oil paint. Such a connection was difficult to disassemble after several years.

Now sanitary linen in the form of long silky threads is used along with new sealing materials. Only now a layer of sealing paste is applied on top of the winding, ensuring a reliable and durable connection. The paste protects the flax from rotting and makes dismantling easier if necessary.

Flax fibers are long, thin, strong, fit tightly into the grooves of the thread and do not deform when screwed

Advantages and disadvantages over tow

Flax fiber remains one of the widely used materials for sealing joints on threads, but in many cases it is being replaced by FUM tape due to the following advantages:

- Unlike tow, which is saturated with water and requires additional protection (painting, putty), the fluoroplastic strip is waterproof and does not require additional consumables during installation.

- Sealing with fluoroplastic tape is characterized by simplicity and high speed of work.

- It is almost impossible to detect joints using flax fiber that have an aesthetic appearance - tow often protrudes beyond the dimensions of the joints, being located on the surface, has an inaccurate shape and is painted in conspicuous colors. The connection with the FUM is usually hidden under the fittings and is invisible to the eye; if necessary, it can be easily cut off or left on a light plastic pipeline without disturbing the decorative effect.

- Linen is a natural material and, when saturated with moisture, is susceptible to rotting and destruction; fluoroplastic can work in the system for decades without losing its physical and chemical parameters.

- For the reasons given above (painting after winding), the connection with a fluoroplastic insulator, unlike flax tow, is quick-removable - easy to dismantle without further work on cleaning the threads and surfaces of the parts being connected.

- When sealing tow, it is necessary to exert significant physical effort using plumbing wrenches - this can lead to destruction of the surface of fittings, adapter couplings, and union nuts. Due to its plasticity, when using fluoroplastic tapes, the applied forces are much less and allow you to connect parts even by hand.

- The commercial advantages of FUM tape should also be noted - it is easily accessible, it can be purchased at any building materials store or on the market, and the cost is comparable to the price of flax tow.

Rice.

3 Metric and pipe threads Despite the rather significant advantages, FUM tape has not completely replaced tow for the following reasons:

- The material has insufficient mechanical strength, that is, when used on a metal thread, its surface can be easily damaged (cut) by the sharp edges of the teeth during winding - as a result, the tightness will be broken and the connection will begin to leak water. This drawback limits the use of FUM tape, which is not recommended for use on triangular metal threads with sharp teeth (Fig. 3); the most suitable types are pipe, trapezoidal and any type on plastic products made of polymers.

- The tape is more demanding on the thickness of the winding layer than flax tow; if there is an excess, the surface of the fluoroplastic sealant breaks, while the flax simply compacts.

- Despite its high heat resistance, FUM tape is not recommended for use in heating systems with steel pipes - due to thermal expansion, it is strongly compressed or squeezed out of the thread, and when cooled, it does not completely seal the connection, resulting in a leak.

- FUM should not be used when joining fittings that are subject to vibration during operation.

Note: When using FUM tapes, you must understand the following: it is more suitable for connecting threaded fittings made of polymers, with good skills - with metal trapezoidal and rounded threads, and is excluded when installing steel pipelines in which the threads are triangular in shape and applied using technology Soviet times or independently with dies.

Rice. 4 FUM brands and their characteristics

How to wind tow on a thread

To prevent the flax from sliding along the thread, there are notches on it.

Impregnation of flax with a special paste, coupled with proper winding, guarantees that the connection will last a long time

For winding, a small strand of flax is separated. The length and thickness of the “strand” are determined visually depending on the diameter of the pipe. The winding is done as tightly as possible, the threads are directed along the thread, the free end of the tow is fixed with a finger, and after a couple of turns it is brought into the guide strand. The tightness of the connection is ensured by the optimal layer thickness. It is quite difficult to calculate the density: you need experience and a certain “plumbing” eye.

How to wind fum thread. How to wind Tangit type plumbing thread

To seal threaded connections of plumbing lines, it is rational and convenient to use polyamide or fluoroplastic threads impregnated with special lubricants, which give the threads moisture resistance and also protect the outer surface of the thread from corrosion. In addition, this is a modern, less labor-intensive and reliable solution to the issue of sealing threaded connections in plumbing.

For proper and high-quality sealing and sealing of a threaded connection, it is necessary to strictly follow the technological process for performing this operation, which otherwise will lead to leakage of the connection and its short service life. I place the tip of the thread at the beginning of the thread on the pipe, so that the thread lies completely in the groove between the ridges of the thread to its very bottom.

Tangit Unilok is a highly advertised imported thread. But unreasonably expensive. I use Russian analogues.

In this case, the fundamental factor is the direction of the thread. It is worth strictly considering that the thread is wound along the thread. In plumbing, this is an important factor, since depending on the connections made and connections of sanitary fixtures to water supply and heating communications, there are both left and right thread directions. Otherwise, when twisting the parts, the thread will simply be squeezed out of the connection by the screwed part. Having decided on the direction of winding the sealing thread, I lay it in a uniform, dense first layer along the entire length of the thread. Then, in three stretched turns, I return to the beginning of winding the thread, that is, again to the beginning of the thread, and repeat the operation.

By repeating the winding in this manner, I achieve the required layer of sealing thread sealant, which allows the operation of screwing up the threaded joint to be carried out with an interference fit. Having finished winding the last layer of seal, I return the thread to the beginning of the thread and cut it with a sharp knife. This action is important so that when starting the connection, the wound part initially tightly presses the end of the thread and does not allow it to relax further. Since, depending on the manufacturer of the thread, its diameters vary significantly in relation to each other, it makes no sense to recommend the number of wound layers and you only need to focus on the degree of density of the twisted parts.

Winding the thread crosswise, as in the instructions

The uniform and dense feeling of force during this operation indicates the result of a high-quality connection and optimal adjustment of the thread. When twisting the parts of a threaded connection with an adjustable or open-end wrench, you immediately feel a reasonable force during this action; the parts should in no way be screwed together by hand. Protrusion and squeezing of the thread from the connection indicates an excess of sealant and is fraught with the formation of a defect in one of the parts being connected; often the screwed part can simply burst. The lack of effort when screwing up indicates a lack of application of the sealing thread to the thread, and such a connection will definitely not be airtight and will be guaranteed to leak.

The apparent simplicity of this action at first glance actually requires a serious approach to its implementation. After all, the reliability of the entire system and the absence of emergency situations during its further operation depend on the quality of sealing.

Proper Use

FUM tape can provide reliable connection protection even when used by a non-specialist.

Knowing some of the features will help in creating a sealed connection (watch a video of alternative heating of a private house with your own hands on this page).

In turn, this will save you from the troubles associated with sudden leaks in the pipeline.

The following sequence of actions must be performed:

- the threaded connection is cleaned of debris and rust;

- parts included in the connection are degreased with gasoline or solvent;

- the material is wound onto the external thread in a clockwise direction. It is imperative to give the tape a slight tension, at which the fluoroplastic fits tightly to the thread;

- the end of the tape is brought out in such a way as not to interfere with the element being wound.

FUM tape is wound in several layers to create a tighter connection.

The number of turns depends on the diameter of the pipes (for water supply in an apartment).

When using products with a diameter of 15 - 25 millimeters, three full turns of the seal will be enough. As the size increases, more layers of fluoroplastic are wound.

To the touch, FUM tape is slippery and can cause inconvenience when working. The wound seal cannot be reused.

How to wind it correctly and how many turns of FUM tape you need to make on the thread, watch the video.

FUM1 tape is used to seal threaded connections. It is made from fluoroplastic grade 4D - a synthetic material; a thin elastic white tape is obtained by rolling out a rope. Most often it is used to seal pipeline connections. In this article we will look at how to wrap fum tape around a thread for a strong connection.

Also, read about alternative types of sealants: tangit-unilock and plumbing tow.

Characteristics of fum tape of three types

- FUM tape is produced in three types, depending on the place of its application. FUM tape grade 1 is a premium grade tape designed for sealing threaded connections in systems with an aggressive environment, for example, concentrated alkali or acid. This tape contains Vaseline lubricant, which increases its performance characteristics.

- Grade 2 tape is typically used to seal piping systems that handle strong oxidizing agents such as oxygen and does not contain the protective lubricant of petroleum jelly.

- FUM grade 3 is used in general type pipeline systems, but it can also be used in systems with potent agents. When using a tape of this brand, you should know that this type of tape is less reliable than the previous FUM brands 1 and 2.

To a large extent, the connection density depends on the correct winding of the FUM. How to wind fum tape onto a thread correctly, avoiding leaks?

Correct winding of fum tape onto the thread

First, clean the threads of dirt and rust before wrapping the fum tape. Then all parts of the pipeline should be wiped with solvent or gasoline. The FUM tape must be wound along the thread with careful movements.

Each turn of the FUM tape should partially cover the previous one. To prevent folds and wrinkles from forming on the tape and to ensure that it is wound smoothly, winding should be done with a slight tension.

We should not forget that the smoother the tape is wound, the more reliable the threaded connection will be. There is no need to move the roll of tape away from the winding point too much - the best option is when it fits closely to the thread.

When the tape is wound, you can screw the butt piece to the joint. When screwing, it must move with a certain force - at this moment the FUM tape fills the thread. For clarity, watch the video:

Pros and cons of using

The main advantage of choosing tape is its availability. FUM is sold at a low price, cheaper than flax tow and most other sealants used in plumbing.

The material is characterized by ease of installation. With proper skill, winding the tape occurs in a matter of seconds, but for this you should practice winding it on connections of different diameters for some time.

An important advantage of using tape is that the parts fastened with it can be easily disassembled. The connections do not freeze tightly; they can be disassembled even years after installation.

The main disadvantage of the material is that it is not the most reliable of seals, therefore, as a rule, it is not used for industrial installation. However, for household repairs the hermetic properties of FUM are quite sufficient.

Another disadvantage is that the tape often protrudes outward from the joints, so the pipes may look sloppy because of this.

Tape on thread Source sdelairukami.ru

What to remember

The surface of the material is quite slippery, which can make repairing damage difficult.

Once the connection is sealed, there is no need to unwind the tape back. If it was applied incorrectly, it is necessary to completely peel off the product and rewind it.

If the tape tension is too high

, it must be removed from the thread and a new layer wound.

Fum tape is an excellent material that is used to seal various joints. In order for the product to provide excellent results, it is necessary to choose the right variety, as well as learn how to wind the tape in accordance with all requirements.

When performing installation work, it is often necessary to seal connections

This is important when laying water supply or gas distribution systems. In years past, flax fibers were commonly used for this purpose.

Nowadays, fluoroplastic fum tape is increasingly used as a sealing and sealing material. Below we will discuss the technical characteristics of fum tape, indications for use, and features of its correct use.

Despite the unfamiliar name, many of us know fum tape very well, and most people actively use it in everyday life, calling it silicone tape. Let's take a closer look at what it is, where and when fum tape is used, and how to use it correctly.

In fact, this product is made from fluoroplastic (PTFE-4), which has excellent sealing and heat-resistant characteristics. The tape is produced in the form of white or transparent strips wound into rolls. The width of the tape is 1-1.6 cm. Some types of tape may additionally have a lubricant or a layer of adhesive.

The scope of application of fum tape is quite diverse. With its help, they achieve sealing of almost any detachable connections: threaded, nipple, flanged. It is used in many engineering systems, the operating pressure of which does not exceed 9.8 MPa. In everyday life, it is used for the installation of metal, plastic and metal-plastic water supply systems, when connecting plumbing fixtures, and installation. Fum tape also provides sealing of country irrigation systems.

Fum tape for plumbing has its own symbol, which reflects its brand, length per roll, width and thickness. For example, a designation such as: “FUM 12m x 12mm x 0.1mm” can be deciphered as follows: “Tape 12 m long, 12 mm wide, 0.1 mm thick.”

Where is it used?

Due to its properties and characteristics, FUM tape is used in most situations where sealing treatment is required.

- Water pipes . The most important thing that FUM tape is used for is sealing water connections. The material is water-repellent, which makes it almost indispensable for fastening water pipes and parts during the assembly and installation of equipment.

- Gas pipeline . The film can be made gas-tight, and it can be used to install gas appliances and meters. However, not every FUM tape is suitable for this purpose; you need to purchase a specialized tape for gas.

- Technique . The material is characterized by resistance to various types of influences, therefore it is actively used to repair internal mechanisms of cars and various technical devices.

Heating pipes fastened with tape Source re-st.ru

Which is better linen or fum tape for water?

A professional plumber always has different types of seals on hand:

- fum tape;

- flax and sanitary paste;

- threads (type “Tangit”);

- anaerobic sealant.

The craftsmen know that all seals, when installed correctly, perform their task 100%. But to do this you need to know how to use it, what to use and under what circumstances. The abundance of modern sealing materials has displaced flax from its leading position. But not all masters agree with this.

The fact is that in past decades flax was used together with red lead or oil paint. Today – with Unipak plumbing sealing paste. Its main task is to prevent the flax from drying out and rotting. Connections made using these materials can be adjusted (axially shifted) by 45° without loss of tightness.

Benefits of flax:

- inexpensive price;

- suitable for sealing threads of any diameter;

- the connection will be good regardless of whether the base surface is wet or dirty.

The disadvantage is that any connection made with flax subsequently requires additional twisting and tightening. Another “minus” of flax is that it is not very convenient to work with: the fibers delaminate and cling to clothing and the tools and materials used.

If you compare flax and fum tape, the latter loses in that it does not allow you to adjust the connections without losing the tightness. That is, if you need to slightly turn an already tightened fitting, leaks may form in this place.

We have prepared a detailed guide to choosing and using fum tape for novice craftsmen and those who are used to doing everything in the house with their own hands. Our advice may also be useful to experienced plumbers, because refreshing your knowledge is never a bad idea.

From our guide you will learn who and when invented fum tape for water, what does Apollo 11 have to do with it, how to properly wind fum on a thread and - most importantly - how to avoid leaks.

Go!

Just one tug: a brief history of fum tape

There is not much information on the Internet about the history of the invention of fum tape. There is only one source - Wikipedia. From there you will learn that the material on which the fum tape is made - polytetrafluoroethylene, PTFE or PTFE, was accidentally discovered by one of the employees of the chemical giant DuPont back in 1938. And registered under the trademark “Teflon”. You will learn that fluoroplastics came to the USSR on American ships during the Second World War, and their production in our country was mastered and brought to Union scale at the Kirovo-Chepetsk plant.

We went deeper. What can you do, the craving for interesting facts about the simplest and most common things is inextinguishable in the Santekhmaster Group team.

So. The PTFE material was actually invented by DuPont. Its extraordinary properties became interested in the talented chemist and experimenter Bill Gore, who had a master's degree in physical chemistry and led research at DuPont for 16 years. Bill was truly sick of chemistry; he managed to “infect” his entire family with this science. The company became cramped for him, he dreamed of his own business, and one day Bill Gore left DuPont to open his own company. He did this first in the basement of his house. And then he built one of the most successful American companies in the world, WL Gore & Associates, which is still led by his son, Bob Gore.

PTFE, in the hands of the Gore family, developed its miraculous properties and found application in medicine, heavy industry, and the space industry. PTFE cables were used during the Apollo 11 space mission. A Gore-brand cable connected the craft to a seismograph placed on the lunar surface.

It would seem that if your product has been in outer space, your homeland (including) is proud of it, and the whole world is not so jealous, you can calm down. Launched production and rested on your laurels. But it was not there. Just after the Apollo 11 flight, WL Gore & Associates received a very unusual order. The company's client, in order to develop a new market, needed a cheap, but at the same time durable plumbing tape. And since the Mountains could make cables “for the moon,” then let them make a tape for plumbing.

Bob Gore, who by that time, by the way, was still quite young, had become the head of research at his father’s company, took this order as a challenge. It took a long time to get a thin elastic tape out of a PTFE bundle. And although Bob had all the company’s power at his disposal, he felt that complex technology would not help him; the secret of PTFE lay in something else. The truth is somewhere nearby, as they will later say in one world-famous series.

What was Bob Gore doing? He heated the PTFE bundle and very slowly and carefully tried to stretch it. The tourniquet obediently stretched a couple of centimeters and then broke. When Bob was completely tired of all this - but he was not ready to give up the idea and the order - he decided to experiment. “If before we were slowly stretching the tourniquet,” thought Bob, sitting one night in the basement laboratory of his house, “now I’ll just make a jerk.”

And did. The PTFE harness not only did not break, but stretched - easily and simply - to the entire width of Bob's arms. This movement - the jerk - then formed the basis of the PTFE stretching process, which reaches 1000%.

The experiment, by the way, turned out to be not only revolutionary, but also fun. The next day, at the WL Gore & Associates production facility, everyone was pulling the harnesses in different directions. And Bob’s father, Bill Gore, could not contain his delight after his son’s report. He immediately understood the possibilities of the new form of PTFE and what things could be created based on it. Gore Jr.'s discovery was a turning point in both his career and the history of WL Gore and Associates. Thanks to him, all kinds of medical implants, ultra-durable waterproof fabric for clothes and shoes GORE-Tex and, of course, sanitary fum tape have appeared in the life of a modern person.

How to choose fum tape for water?

Today, fum tape is produced by manufacturers around the world. Italian FADO and VALTEC tapes, Belgian HPX, and Russian BVB-Alliance are considered to be of decent quality. When choosing fum tape, pay attention first of all to these brands.

In general, fum tape is widely represented on the Russian sealing market. Its packaging is standard - a plastic reel with white tape inside. The tape itself - and this is important - differs in width, thickness and length. The length for choosing a beginner is not so relevant, the only question here is consumption, but the thickness and width play a role when winding on a certain type of thread and the scope of application of the tape.

Let's tell you in more detail.

Fum tape can be wide and narrow, thick and thin. A narrow tape is considered to be up to 12 mm, wide - up to 19 mm and more. A thin tape is one that is translucent, i.e. an object is visible through it. But it is not transparent, it does not look like tape. The thickness of the thin tape is the same for all manufacturers - 0.12; 0.75 mm. Thick tape is denser, its thickness is 0.1-0.2 mm.

Why would a beginner need to know this? Then, different threads are sealed with different tapes. For large 1-inch threads, it is better to use a wide, thick fum tape. It is easier to wind and costs less. But for small threads, for example, ¼ inch, a thin, narrow fum tape is suitable, which is first stretched to the state of a thread, placed in each thread, and then several layers of the entire width are made on top.

A good fum tape has the following characteristics:

• high elasticity and strength; • heat resistance (from -40˚C to +150˚C); • chemical resistance to solvents and acids; • environmental friendliness; • resistance to fungi and bacteria; • protection of the thread and the entire connection from corrosion; • unlimited service life.

How to find such a tape? For a beginner - only through experience. If you don’t find the manufacturers we listed above in your local store, buy several tapes of different thicknesses and widths to test them for strength and evaluate the result in advance. Let your tool suitcase at home have at least 4 fum tapes of different models. If you are going to seal the threads with tape for the first time, buy a few fittings as well. Assemble the connection empty to understand how many turns need to be made on the working connection, how to wind it correctly and whether it is convenient for you to use fum tape in general.

Scope of application and winding

Traditionally, fum tape is used to assemble home water supply and irrigation pipelines on the site. It also copes with other simple tasks:

— replacement of rubber gaskets;

— repair of mixers;

— plastic thread seal;

— minor household repairs (as a more aesthetic substitute for electrical tape).

We recommend that the home handyman seal with fum tape those connections in the water supply system in which leaks are easy to notice and fix. But it is wiser, at least at the beginning of your plumbing practice, to use fum tape in safe places - when assembling an irrigation pipeline or for repairing faucets and shower hoses. Get your hands on it first, and then start assembling critical systems.

Winding tactics:

For large threads (but not larger than 1 inch). Leaks when working with water tape occur due to improper winding. Follow these tactics and everything will work out.

- Take a tape 0.1-0.2 mm thick and 19 mm wide.

- Prepare the carving. If it is not new, clean it and wipe it dry.

- When winding the entire width, secure the beginning of the tape to the thread and press.

- Stretch the tape with force and lay it with tension along the thread so that it falls into the turns. Those. The first few layers of tape should fit the turns, they should be visible.

- You cannot wrap the tape without tension, as you would when wrapping an adhesive plaster around a cut finger. In this case, the tape will quickly slide off the thread and leakage is inevitable.

- Make approximately 5-6 turns, assemble and tighten the connection.

If you choose a thinner and narrower tape to seal large threads, it will take longer to wind. Approximately 13-14 revolutions.

For small carvings.

- Take a tape with a thickness of 0.12 or 0.75 mm and a width of 12 mm.

- Prepare the carving.

- Pull the ribbon out until it becomes a thread.

- Place the thread in each turn along the thread.

- Do this in several layers.

- Then wind the entire width of the thread and secure.

- It may turn out to be more than 20 revolutions.

- Assemble and tighten the connection.

The number of revolutions is impossible to predict. There is no universal advice on how to use fum tape for water. It all depends on the size, material, condition of the thread and the type of tape. High-quality fum will require less consumption. The one that breaks more often during winding will have to be reinforced with additional layers. In any case, fum tape cannot be called economical in consumption. Especially if you also take into account the expense for compaction training.

Other disadvantages of fum tape

Impossibility of adjustment.

After assembly, the connection sometimes needs to be “tightened” and adjusted. This is impossible with fum tape. When the thread is untwisted, the tape inside breaks and the connection loses its tightness.

Thread requirements.

Fum tape loves clean new threads. Preferably with notches so that the tape does not slip. For worn threads, regardless of size, it is recommended to use a thicker tape. For large-diameter threads, fum tape is not economical in consumption.

Quality.

You won't know until you buy it. A reel of fum tape can easily be called a surprise box. To determine whether the material can be worked with, stretch the tape slightly before winding. Does it tear quickly? Get a new coil. It’s not for nothing that we advised buying a lot at once.

Price.

Fum tape is considered one of the cheapest materials. This is what attracts newcomers. However, not everything is so simple. The price range for fum is very wide - from 20 rubles to 120. Taking into account the uneconomical consumption, the cost of one connection with a fum tape will be equal to the cost of a connection with sanitary thread, which is a more modern material and is more expensive.

Stock up on various sealing materials. Replenish your collection with modern sealants: winding, anaerobic sealants, threads. Don't rely on one remedy, nothing is universal. And try to keep up with market news.

Comparison of fluoroplastic and flax

Along with synthetics, sanitary flax fiber is still used (which is better, FUM tape or flax).

The material is produced from flax processing waste. Tow is used together with silicone sealant or oil paint to insulate threaded connections.

The use of natural material is a proven method that guarantees 100% tightness.

Plumbers' refusal of flax is due to difficulties in use (how to install a tulip sink in a bathroom is written here).

To properly seal a connection with plumbing flax, you must have certain skills.

Synthetic fluoroplastic does not require this. It can be used without any preparation.

Before winding, the tow fibers are evenly separated.

When applied to threads, skipping turns, twisting of fibers, and overlaps are not allowed.

Then an adhesive sealant is applied to the tow (read what is needed for polypropylene in this article).

Incorrect or insufficient application of flax will result in a poor-quality connection and leakage.

Excess material leads to an overly tight connection, the excess material is cut off with metal coils.

This leads to an increase in stress in the connected parts.

The result will be complete or partial destruction of parts.

Determining the right amount of flax comes with experience.

Working with cast iron threaded fittings and steel products of large diameters does not require professional skills.

It is most effective to use FUM tape for water when connecting metal-plastic or polymer pipes.

FUM tape will not provide a guaranteed seal when working with old metal pipes. In this case, tow with silicone sealant is used.

What is FUM tape and its areas of application

The material for the production of FUM is a chemically produced synthetic polymer polytetrafluoroethylene (fluoroplastic F-4), which initially has the appearance of white flakes, which during further processing are sintered and pressed at high temperatures.

FUM tape - thin elastic strips of various thicknesses and widths made from fluoroplastic F-4, wound on reels, sold in the form of reels, sometimes additionally included with lubricant or glue.

Due to its physical and chemical properties, the tape is widely used in many household areas where hermetic insulation of threaded connections is required:

Water supply . It is well known to use tape FUMs for connecting sanitary fixtures, heating radiators, and connecting pipes made of various materials. Due to its water-repellent properties, the tape is indispensable when installing external water supply lines from HDPE pipes and sealing other types of polymer-based fittings.

Gas lines . FUM tape does not allow gases to pass through, therefore it provides reliable protection against leaks when working in gas lines; in everyday life, it is used to connect gas meters, gas stoves, boilers, cylinders and other equipment.

Automotive technology . Due to its high chemical and thermal resistance, FUM tape is used for repairing all types of equipment; it is not afraid of the effects of automobile fuel and oil.

The following colors are most often found in the retail chain:

white - designed for use in water mains;

yellow - designed for use in gas lines.

Rice. 2 Types of FUM

Anaerobic gel sealants sanitary gel

Another modern material for sealing pipe threads is sanitary gel. Reliable compaction occurs due to the polymer component of the gel. After hardening, sanitary gel does not shrink or expand, is resistant to temperature changes (from -60 to +150) and pressure surges, and has proven itself in various environments: water, natural and liquefied gas, heating antifreeze.

How to seal a plumbing connection: flax, fum tape, anaerobic sealant - a specialist decides

Sanitary gel is produced in three types:

- In green tubes - easy dismantling.

- In blue - medium dismantling.

- In red (Stop Master Gel) – dismantling with heating.

Installation using sanitary gel is simple: shake the tube and apply the gel in a thick layer around the entire circumference of the thread, distribute it evenly (with a brush, a special spatula), and assemble the structure. Excess gel is removed with a rag. Polymerization of the gel occurs in 15–20 minutes.

Technical parameters and brands

Industrially produced fluoroplastic tapes and films are regulated by GOST 24222-80; the PN brand (non-oriented cushioning material) is used as an insulating sealing material; in accordance with the PN standard, opaque matte products from milky to light gray are used.

Tape sealing material made from the PN brand has the following parameters:

- It has excellent chemical resistance to aggressive substances and does not dissolve even in aqua regia - a mixture of concentrated nitric and hydrochloric acids.

- The produced film does not lose parameters in the temperature range from -269 °C to +260 °C, and is a low-flammable material with an ignition threshold of 520 °C.

- When heated above 260 °C, the polymer releases volatile toxic fluorine compounds.

- The material is gas-tight and an excellent dielectric - electrical strength 65 kV/mm.

- The tensile strength of the film in the longitudinal direction is 19.1 MPa or 191 kgf/cm2.

- The film has high elasticity, its relative elongation to break at any thickness is 185%.

- The material has no pores and has a low coefficient of friction.

- According to the above standard, the thickness of the PN film lies in the range from 0.2 to 3 mm, and the width is 40 - 120 mm.

Also, for fluoroplastic tape of grade 4D, made by rolling out a rope, the technical specifications of TU 6-05-1388-86 are adopted, which indicate:

- Scope of application: threaded connections of pipelines made of all types of materials operating in temperature conditions from -60 °C to +200 °C;

- Working medium pressure: up to 9.8 MPa (98 kgf/cm2), maximum permissible values - 41.2 MPa (412 kgf/cm2).

Rice.

5 Application area and dimensional parameters of produced FUMs FUM tape is produced in the following brands:

1 - for industrial working environments, as well as for equipment with chemically active substances - acids, high concentration alkalis, their mixtures and solutions. They are made of the first and highest grades, used with vaseline oils (17-20%) as a lubricant.

2 is a lubricant-free fluoroplastic sealant designed to isolate joints of oxygen-conducting systems or those with other active oxidizing agents.

3 - extreme sections of the first two tapes and the SKL film (wet calendered tape made of fluoroplastic F-4), for use in industrial pipelines, the working fluid of which is industrial components and chemically active substances in the form of concentrated acids, alkalis and their combinations in different proportions .

The main physical characteristics of FUM 1-3 used in the construction industry according to TU 6-05-1388-86:

- tensile strength, MPa: 6.86 and 4.9 for FUM-1 and 2.94 for FUM-3;

- elongation at break, %: 95, 80 for FUM-1 and 40 for FUM-3;

- thickness, mm: 0.1 -0.14 for FUM-1 and 0.12 for FUM-3;

- width, mm: 10 - 60 for the FUM group and 3 - 25 for FUM-3.

Rice. 6 Example of incorrect winding - large layer and channel overlap

Fum tape what is it

PTFE sealing material, or fum tape for short, is a polytetrafluoroethylene film used to seal pipe joints. It is made by rolling out a fluoroplastic rope to the required thickness. The sealant is produced in the form of a tape of a certain size, wound on a reel (similar to electrical tape). Used when installing systems under pressure: water supply, gas supply, central heating. The material functions as a deformable filler and at the same time as a thread lubricant, which improves the sealing of connections.

Types of fum tape:

- fum-1 – designed for sealing pipelines working with aggressive media. Contains lubricant – purified petroleum jelly;

- fum-2 - used in systems in contact with strong oxidizing agents, therefore it is not impregnated with lubricant;

- fum-3 - used in systems working with clean media. Does not contain lubricant.

Plumbing tape fum also varies in size: thickness ranges from 0.075 to 0.25 mm; width starts from 10 mm; length from 1000 mm.

They produce a special yellow gas fum tape with a thickness of 0.15-0.25 mm. For gas pipes operating under low pressure, the use of ordinary plumbing tape is allowed.

Special gas fum tape is denser than conventional plumbing tape

Technical characteristics and properties of fum tape

Main properties of PTFE:

- Low coefficient of friction. Fluorinated plastic polymers (PTFE) have a very low coefficient of friction - they are slippery, which makes it easier to connect fittings. They act as a kind of gasket for pipe threads, improving fit and sealing.

- Heat resistance. PTFE has an extremely high melting point for a plastic - 327 degrees. They are designed for use at temperatures up to 260 degrees (when heated above, they release toxic fluoride compounds). PTFE is an excellent dielectric (electrical insulator), which is an added benefit.

- Plasticity and strength. Resistant to mechanical stress. They operate at a constant pressure of up to 10 MPa and withstand differences of up to 41 MPa. Average service life is 13 years. Prolonged exposure to light slightly degrades properties.

- Chemical and biological inertness. They are highly resistant to acids and alkalis. There is no solvent for PTFE yet. The polymers are uniformly coated with fluorine atoms, which makes the material inert to almost all chemicals. Decomposition is possible only under extreme conditions created in special laboratories. Not subject to rotting.

The ductility of PTFE allows the plumbing tape to stretch and fit tightly around the threads

Specifications

Let's consider the technical characteristics of the FUM tape, which determine its properties:

- the material is characterized by resistance to damage;

- has plasticity;

- retains its properties for a long time and does not need regular replacement;

- is environmentally friendly and does not emit harmful substances;

- heat-resistant, able to withstand a wide range of temperatures;

- the thickness is only two tenths of a millimeter;

- has dielectric properties and gas impermeability;

- elastic, capable of stretching almost twice its original length.

What is better tow or fum tape

Each material has its own advantages and disadvantages. Plumbing flax is used to seal joints of steel pipes (especially rusty and/or large diameter ones).

Advantages of tow:

- the ability to adjust the connection: unscrewing back by 45 degrees is permissible;

- reliable tightness: absorbs moisture well;

- resistance to mechanical stress;

- easy dismantling of the connection.

The disadvantage is the tendency to rot/decompose, since tow is a natural material.

It is preferable to use plumbing tape on small-diameter pipes, plastic pipes, and in the case of thin-walled fittings. It is easier to work with fum tape and takes less time to install.

There is no clear answer to the question: “Which is better – fum tape or sanitary linen?” It all depends on the specific plumbing job. For example, it is more convenient to connect a kitchen faucet with a flexible hose using fum tape, and it is better to seal a fitting on a water pipe using tow.

A better seal is achieved by winding a small amount of flax and then securing it with several turns of tape.

Area of application of the material

Due to the properties of fum tape, it is used for various joints. It is most often used for systems whose parts are made of plastic, metal, or a combination of these two materials. Due to this, it can be used to create a variety of supply systems, install auxiliary structures for them, install and connect plumbing and gas equipment.

For gas

Fum tape is used for sealing joints when working with gas equipment and natural gas supply systems.

For water

Fum tape is often used to form water supply systems, sewerage systems, and when installing plumbing equipment. In addition, owners of summer cottages use the material to seal hoses and irrigation systems.

Fum tape winding technology

We offer step-by-step instructions:

- Thoroughly clean the surface of the thread on which the winding is to be performed. Remove traces of dirt, debris, and rust.

- Wipe all elements with gasoline or solvent. Proceed to the next step after the surfaces have completely dried.

- The tape should be wound from the end of the thread, moving towards its beginning. The direction of movement should be clockwise if the thread is right-handed; for left-handed threads, on the contrary, you need to move counter-clockwise.

- When winding, the tape must be kept slightly taut. This will ensure sufficient density and reliable sealing of threaded connections.

But do not overdo the tension on the tape to avoid causing it to break.

The sealing material is applied in several layers. The number of turns depends on factors such as the diameter of the pipe, the condition of the thread, and the quality of the fum tape itself.

For a pipe with a diameter of up to 20 mm, 3-4 turns will be sufficient; over 20 mm, up to 4-8 layers should be applied

.

It is not advisable to leave the end of the fum tape on the last turn of the thread; bring it out so that it does not interfere with the subsequent screwing of the connecting element.

How to properly wind FUM tape onto a thread - step-by-step instructions plus useful tips

This is almost always done by hand. To seal the connection of two pipes, a higher education is not required. But there are nuances without which you risk wasting your efforts.

For high-quality insulation, do the following:

- Count the number of turns on the part being screwed.

- Prepare the surface. Remove dust and rust.

- Degrease with solvent and dry.

- Press the edge of the tape onto the threaded part of the part with your finger without removing it from the spool.

- Make a turn.

- Crimp with your fingers. The movement is circular. The relief should be visible under the film.

- Continue winding with slight tension. Place it so that it presses into the recesses. Avoid twisting. Don't pull too hard (you might damage it), but keep in mind: the tighter the better.

- Place each turn with tension so that it compacts the previous layer.

- Finish when the relief completely disappears.

- Move the end to the side so that the seal does not interfere with screwing the part.

- Tear it off. The tension will compact the layers more and make the edge narrow.

- Assemble and tighten the connection. Using your hands, screw in the part by the number of revolutions you counted at the beginning. Take the key and press it.

- Check for leaks.

Important: the coils should be overlapped. The next one should overlap the previous one by 30-40%.

I recommend winding the tape directly from the roll. Select the width equal to the length of the thread. The number of layers depends on the following factors:

- film thickness,

- thread pitch,

- fitting material,

- pipe diameter,

- gap sizes.

The standard number of turns is 3 or 4, but sometimes it can reach 10-15. Don't save money. The winding must completely cover the thread. If it is not possible to achieve tightness, dismantle it. Then unwind a new section and lay it down, adding more layers. You cannot use the same strip. It is damaged upon contact with the sharp edges of threaded joints.

FUM tape: how to wind it correctly on a thread - clockwise or counterclockwise?

The direction of the winding is towards the helix . With a right-hand thread (more common), the strip is placed strictly clockwise. But it also happens on the left, then the tape is turned in the opposite direction. Be sure to press it in, as when tightening a nut. Areas protruding beyond the edges are cut off.

Helpful Tips:

- Lay the tape in turns with slight overlap until the surface is completely covered. If its width coincides with the length of the threaded part, then overlap is not required.

- To facilitate subsequent joining of elements, do not apply winding to the last protrusion.

- When winding, avoid tears, folds, and distortions.

- Before twisting the joints, press the polymer firmly by running your fingers around the circumference.

- Do not allow the winding to bulge. Because of this, the throughput of the junction may deteriorate. Clogging is common, so carefully cut off any excess tape.

The film cannot be re-wound. If you need to loosen or strengthen the connection, you will have to repeat the process again.

The best seal

This synthetic material will reliably protect connections from leaks.

To do this, you must follow certain rules.

INTERESTING . Fluorine, which is part of the material, provides strength and heat-resistant properties.

The tape does not tear, does not stretch, and does not react with active substances.

And most importantly, after installing sanitary ware (read about which is better sanitary ware or porcelain here), it does not lose its properties over time.

Caution when using tape

There are a number of simple rules that will protect you from unnecessary and poorly performed work:

1. Winding must be done with a single piece of tape. Otherwise, the sealing will be broken and a positive effect from such winding of sealant on pipes will not be expected.

2. If you applied the tape incorrectly, tear it off and throw it away. Re-gluing the tape is not allowed, since the adhesive layer has already lost its original reliability.

3. If you feel that you have pulled the tape too tightly, it is better to completely unwind it and rewind it again. This way you will save yourself from unnecessary work in the future.

Now you know exactly what you need to pay attention to and how to properly seal at such an important stage of pipeline work as sealing

Product marking

The technical regulations define three markings for fluoroplastic sealants.

The remaining products are subtypes of the main names:

- FUM-1.

It is used as a sealant in general pipelines, in systems working with aggressive chemicals (calgon analogues for washing machines are written about in this article). Added lubricant to the composition – 20% petroleum jelly; - FUM-2. The material is used in pipelines containing substances with strong oxidizing properties. Lubricant is not included;

- FUM-3. Tape is used in communications with neutral media. Available without lubrication.

IMPORTANT! The material is destroyed at temperatures above 520 degrees. Doesn't burn, doesn't explode

Manufacturers guarantee shelf life within 10-13 years.

Varieties, alternatives and selection rules

Flax is good for laying almost all metal pipes, including cast iron, stainless steel, non-ferrous metals, including copper, and their alloys, such as brass. The only exceptions are aluminum and metal-plastic products, as well as those made from polymer compositions. For them, professionals recommend using fum tape.

Fibers of various qualities are available on sale. All of them are produced on the same equipment - a carding machine. They are distinguished by numbers, which contain a description on the label. They vary in the range from 8 to 24. In this case, fibers with a higher number will have fewer impurities and vice versa. They are also characterized by a degree of flexibility, which is less important in their work.

Fibers are packaged in coils, as well as braids of fixed weight and size. Their color can vary from white to light gray, as well as beige due to the use of natural raw materials.

PTFE sealing material

FUM is fluoroplastic-4, PTFE (polytetrafluoroethylene), Teflon. Doesn't burn, doesn't rot. Warranty period – 13 years.

Resistant to aggressive industrial environments and domestic wastewater. Used for plumbing and heating. For gas pipelines it is used only if there is a certificate confirming suitability for these purposes (SP 42.101-2003).

The spread of such a sealant, especially in everyday life, is facilitated by the speed of operation and the absence of contamination after use. Here the question of choice - FUM or linen - was decided in favor of the tape.

Range

According to TU 6 – 05 – 1388 – 86, three grades are produced.

The third is edge trimmings of the main brands. Wavy, the cheapest material. When unwinding freely from the reel, it tends to form a circle.

The lubricant contained in grade 1 tape warns that when sealing cylinders and lines with oxygen, it will spontaneously ignite.

In practice - due to the appearance of imported tape - the size range is much longer. Experts recommend the following specific sizes:

- thickness 0.075-0.1 mm with a width of up to 12 mm when wound on threads 1/16 – 3/4”;

- thickness 0.12-0.2 mm with a width of 19 mm for large threads.

Markings on the reel must be present.

The yellow color of the tape itself indicates the possibility of using it for sealing gas pipes.

Terms of use

FUM or flax, which winds better? If you do this for the first time, it’s equally difficult. The tape itself is slippery. In the water - wet ice on wet ice, breaking.

This means that the joints must be dry, free of dust, dirt (flax is not afraid of this), and free of grease. You have to wind it with force. So that the tape stretches, but does not break through the sharp thread. With certain skills, working with tape is easier.

The number of turns depends on the diameter of the pipe and the thickness of the tape. Up to Ø 20 mm, 4 or 5 turns are made with 0.075 mm tape; above, up to 8 or even 10 turns are made with 0.1 mm tape.

But fluoroplastic is an elastic material. Greater thickness seals better, but vibration may cause the connection to loosen.

The first turn of the thread is left free - see photo of the bend and elbow.

Experienced plumbers twist the tape into a thread and fill the interturn cavity. This technique increases the rigidity of the joint.

FUM tape is wound along or against the thread: both methods must be tried. When winding counterclockwise, moving the fitting clockwise (right-hand thread) will collect the entire tape into a shapeless lump.

This leads to one serious drawback of the tape: during installation, the pipe, fitting or fittings need to be turned only in the direction of screwing and winding the tape. Turning in the opposite direction, even a few degrees, will crumple the tape. A leak is inevitable.

But in most cases it is necessary to set - adjust - the tap or valve to the desired position after full tightening.

If the first time it was not possible to combine the maximum tightening and the desired position of the shut-off or other valves, the pipeline elements must be disconnected. Remove the used tape and wind a new one. There can be five or eight such approaches, but it mainly depends on the master.

This is the answer to the question, what is better than flax or FUM tape for water supply, for example, in a country house. Len packs on the first try.

The next day, it is recommended to tighten the connection to the tape.

Can tape be used on compression fittings?

FUM tape, like thread sealants, is usually not used on compression fittings. In this case, the thread itself does not seal the connection. The sealing here occurs by compressing the slotted ring between the pipe and the nut.