The Tefal steam generator has found application in everyday life and among professionals. When it comes to ironing, cleaning clothes, and freshening the air, a steam generator will come to the rescue.

But, like any other device, it is not immune from breakdowns. To know what to do in a given situation, you need to find the source of the problem.

In this article we will talk about the main malfunctions of Tefal steam generators and do-it-yourself repair of a household appliance.

List of the most common breakdowns and tips for self-repair of steam generators

A steam generator is a necessary device. With its help you can get rid of wrinkles on clothes. Even the most finicky fabrics can be treated with steam. The equipment is used to clean furniture and even to fight bedbugs.

Therefore, when the device fails, this causes certain inconveniences, because the steam generator requires repair.

If the breakdown is not serious, then you can deal with it yourself. In other situations, professional help is required.

Disassembling the case

How to disassemble a Tefal iron correctly? They provide a multi-level fastening scheme. The following features are available:

- The top cover cannot be removed along with the main body.

- To get to the electronic components, you need to unscrew the screw in the nose. It is visible in the area of the water dispenser through the translucent plastic.

Steam supply devices are accessible after removing the top cover. To do this, you need to remove the buttons that block access to the mounting screw. By unscrewing them, you can remove the top cover and gain full access to all components of the device.

The initial dismantling of the Tefal case is no different from the scheme used in other brands:

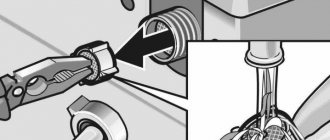

- You will need to remove the clamping screw or screws that are located under the cover at the rear of the case. They must be screwed in deeply to unlock and remove the cover.

- Under the cover there may be several more fasteners located under the water tank or under the plastic head of the thermostat.

- The plastic case must be lifted carefully. In addition to screws and self-tapping screws, it can be fixed with latches. You can find them with a thin strip of steel (knife blade or screwdriver) by running it along the body.

- To access the electrical part it may be necessary to remove the protective cover. It is also attached with several self-tapping screws, which are not difficult to find.

After removing the upper body and internal protection covers, the disassembled iron looks like this:

It does not matter which model of iron is disassembled for repair and diagnostics. Devices with a steel sole or branded Ultragliss have the same components. Problems may arise due to the failure of a disposable thermal fuse, oxidation of contacts, clogging of steam outlets, contamination and the effects of corrosion due to moisture entering live areas.

Typical faults and step-by-step instructions for fixing them yourself

Depending on the breakdown, instructions for fixing it will differ . Let's look at the most common malfunctions of steam generators and ways to repair the product at home.

Doesn't produce steam - what's the reason?

A common malfunction of the device is the lack of steam after it is turned on. You can cope with the problem yourself if you correctly determine the cause.

The most likely problems and ways to solve them:

The steam supply hole is clogged with scale or limescale . To fix the problem, you need to fill the boiler with water with the addition of citric acid. 10 g of powder per liter of liquid is sufficient.

You can also use store-bought Calgon. When the water with the selected oxidizing agent is inside the device, it is turned on and the unnecessary fabric is steamed for 3-5 minutes.

Turn off the device and leave it to cool and descale for 2 hours. Drain the water from the boiler. Rinse it with clean water until it becomes clear. The channels became clogged with particles that fell off the inner surface of the boiler . As a rule, this happens in inexpensive devices that have manufacturing defects. If the deformation was minor, you can try to rinse the water tank yourself.

When this measure does not give the desired effect, you must contact a workshop or service center and request warranty service. Sometimes the device needs to be replaced.

- The coarse filter is clogged . To fix the problem, you need to unscrew the hose, remove the mesh using tweezers and rinse it. Most often, this breakdown occurs after repairing the water supply system and pouring rusty water into the device.

- The relay or heating element of the boiler has failed . You cannot do without replacing a broken part; you need the help of a specialist.

- The water tank is not installed correctly . To deal with the problem, you need to remove it and put it back in place.

- The steam button is not pressed . It is necessary to check its operation.

- The steam generator did not heat up to the required temperature . As a rule, this is indicated by a color indicator. You need to wait until it lights up steadily or turns off (it all depends on the model of the device).

- The steam generator is being used for the first time . During initial operation, some steam generators do not supply steam immediately, but after 30 seconds. This time is spent starting the engine. This feature is indicated in the user manual.

- There is not enough water in the tank . Before contacting the workshop, you need to check the level in the device.

What to do if it doesn't turn on?

If the steam generator does not turn on, the reasons may be as follows:

The power cord is damaged . It is difficult to independently determine the broken location of the wire, unless there is visible damage. Need help from a specialist.

The smell of burning wiring requires immediate disconnection of the device from the network. Self-repairs are not carried out; you need to contact service;

Instead of steam, water comes out of the device

If water flows from the steam generator, the causes of the breakdown may be the following:

The iron turns on but does not heat

If the iron turns on (the indicator is on), but does not heat up, it means that current is supplied to the device. The cause of the breakdown may be a burnt heating element or thermostat. To determine the malfunction, you need to examine both elements.

Checking the serviceability of the heating element

As a rule, heating indicators are connected to the terminals of the heating element. Therefore, if the light continues to burn and the sole remains cold, the cause of the malfunction may be a burnt-out heating element. The element is usually tightly mounted into the sole and cannot be replaced.

To check the heater, you need to check its contacts with a multimeter. If there is no resistance, we can conclude that the part is faulty.

Checking the serviceability of the thermostat

If the iron does not heat up and the light is on, the problem may lie in a faulty thermostat. To get to this unit, the device must be completely disassembled.

After removing the housing, it is necessary to visually assess the condition of the contacts and connections for breaks and oxidation. If external damage is visible, it is necessary to clean it with fine-grained sandpaper. If not, determine the performance of the part by measuring the resistance, or checking the voltage with a screwdriver with an indicator, sequentially pressing it against the contacts

Since the iron must be plugged in to test with a screwdriver, extreme care must be taken when taking measurements.

As a rule, in models from well-known manufacturers, the thermal fuse is built into the gap in the contacts of the heating element on one side, and the thermostat is built into the gap on the other. For example, if your Philips iron does not turn on, one of the listed items may be faulty. In this case, there will be no resistance between the contacts of the heating element. Accordingly, to detect the true cause of the malfunction, it is necessary to ring each section, starting with the fuse (the likelihood of detecting a burnt-out thermostat with a working protective element is extremely low).

When do you need professional help at home?

The help of a specialist is required if it is impossible to determine the causes of the malfunction in the steam generator, or if it is not possible to eliminate them yourself. Most often this happens when a part fails.

In order not to make a mistake in choosing a specialist and not to contact scammers, you need to adhere to the following recommendations:

Private craftsmen most often do not give guarantees for their work, or promise the proper functioning of the device in words. Therefore, it is better to contact the service.- After completion of the repair, you must request a receipt and warranty service.

- You should trust word of mouth. Recommendations from friends can help you find a good specialist.

- The technician will not charge money for diagnostics. Professionals do it for free.

- You should not leave the device in the workshop if the workers do not provide paper confirming its receipt.

- All documents must be stamped with information about the organization and its address.

The cost of repairing steam generators varies widely. The more complex the work and the more expensive the model, the higher it will be.

What kind of water should I put in my clothes steamer?

There are several such reasons; we will need to examine each of them in more detail.

Cause

This is not a hardware failure, but this point should not be ignored. When purchasing, many consumers want to purchase more powerful equipment, but this may be the fault of the manufacturers. Let us note right away that such a problem can only be solved by replacing the equipment; in rare cases, purchasing a new iron with a hose can help.

Cause

The steam generator is spitting - perhaps the reason is a faulty valve. If all the rules for operating the equipment are followed and water leaks occur, the reason lies precisely in the shut-off device. But you need to make sure that this part is faulty.

When drops of water appear, make sure that the shut-off valves have not blocked the access to moisture. The valve requires replacement. You will need to contact a service center. Get help from specialists.

Cause

Errors during operation of the steam generator and its maintenance. The control of the operation of steam generators is equipped with a temperature regulator, on which there are special marks indicating the time when the steam supply can be turned on for a steam boost.

If the soleplate of the iron has not heated up to the specified value and steam should not be supplied, it is not recommended to try to rush and turn on its supply. Such inattention may be one of the reasons.

Otherwise, water will drip from the steam generator openings instead of steam jets.

If the indicator goes out, but water flows, the sole heating regulator may have failed. In this case, you will need to visit the service center and replace the part. Performing minor, simple repairs, replacing an inexpensive part, or disassembling an iron with a steam generator costs much less than buying a new device.

The filler cap in the water tank must close tightly until it clicks, otherwise water will splash out and get on your laundry or clothes.

In this position, even after a few minutes of operating the equipment and turning on the steam supply, if the hose is even slightly pinched or the location of the iron is opposite the steam outlet of their equipment, and the hose itself is much lower, water may come out along with the steam.

This creates a water plug and prevents water from flowing into the steamer. Thus, the circulation of water in the system is disrupted and steam cannot pass through the plug without capturing a small amount of water.

You can get rid of such an unpleasant situation by simply placing an iron with a hose above the steamer. After 10-15 seconds, the water will drain and the water plug in the hose will collapse. In case of a large traffic jam, you will have to turn off the steam generator and let it cool.

Eliminate leakage of water and steam; it may be necessary to descale the steam generator. To do this, you will need to pour in industrial products or folk substances to remove alkaline deposits, then turn on the heating of the water to the maximum temperature.

Then the water with scale is drained, clean water is poured in and the operation is repeated. To remove alkaline deposits, anti-scaling agent, simple citric acid are used, even Sprite and cola successfully remove scale.

If you select the wrong water for a steam generator or steamer, the intensity of scale formation will be very high, and this will lead to the holes in the sole becoming clogged and efficiency will be reduced.

Let's consider several options for water that should not be used:

- Use of distilled water. This is water that is almost 100% purified from salts and other impurities included in the liquid. Since this water requires a higher temperature to evaporate, it is not recommended to use it in a steamer;

- Using tap water. If you know that the water in your area is too hard, then try to mix it in a 1:1 ratio with demineralized liquid.

- It is also not recommended to use boiled water because it contains sediment. This water can accelerate the appearance of plaque.

- It is not recommended to use bottled water or water from a cooler. This water has a high level of mineralization.

- Despite attractive proposals to use special liquids with aroma designed for irons, they should not be used either. Such liquid can not only ruin your clothes by leaving a stain on them, but also lead to damage to the iron.

It is recommended to use only purified water in the clothes steamer.

As you can see, the list is quite large. Make sure you do not use such liquid.

From this article, you were able to find out which steamers can be repaired and which ones need to be taken to a service center. If you are not sure that you are carrying out the cleaning procedures correctly, we advise you to read the instructions that come with the equipment.

Important Tips

Self-repair of the device requires compliance with the following recommendations:

- when checking the functionality of the device, you need to direct the steam stream at an item that cannot be worn;

- any repair work must be carried out when the device is disconnected from the electrical network;

- It is forbidden to press the “start” button if the device is directed towards a person;

- The smell of burning or the appearance of sparks is a reason to stop working with the device and contact service.

Disassembly process

To clean or replace the oxidized plate yourself, you will need to disassemble the Tefal iron. This must be done taking into account the following design features of the device:

- The top cover should be removed separately from the main body.

- Access to the electronic elements can only be gained by unscrewing the bolt located in the nose of the device. It is easy to see through the transparent plastic that the water dispenser is made of.

- Removing the top cover will allow you to open the steam supply. To remove it, you need to disconnect the buttons covering the fastening screw. After this, access to all main elements will be open.

The body of the Tefal iron is disassembled in the same way as the body of any other iron. The dismantling process involves a number of the following actions:

In the rear part, unscrew the clamping screws (or one screw) located under the cover. Disconnect all fasteners that are located under the thermostat head and under the fluid reservoir. Carefully lift the plastic housing. In this case, one should take into account the possible presence of latches that additionally secure it.

To find them, just run a screwdriver across the body. Remove the back cover, secured with self-tapping screws and protecting the electrical part of the iron.

Ironing devices produced by Tefal have a complex body shape. There are a large number of fastening points and fasteners of open and hidden types

This must be taken into account when dismantling and carried out with extreme caution so as not to damage structural elements

After disassembling any model of the device, you will see inside it:

- disposable thermal fuse;

- Temperature regulator;

- tubular electric heater (TEH);

- temperature control knob;

- heating indicator light.

Devices equipped with a steel sole or the proprietary Ultragliss sliding surface have the same basic components. Malfunctions in their operation can occur due to the breakdown of a disposable fuse, clogging of steam outlets, oxidation of electrical contacts, corrosion of live surfaces due to moisture getting on them.

Reasons why the steam generator sprays water instead of steam

Any owner of a steam generator may encounter such a problem as water leakage from the device. If there is no opportunity to contact specialists, then you can try to deal with this problem at home.

Before understanding the causes of the breakdown, it is worth studying the principle of operation of the steam generator.

The TEFAL GV8962 iron is leaking: we describe it in detail

With the advent of the steaming function, a malfunction began to occur in the ironing equipment - water flows out of the iron. Instead of steam, liquid flows or drops appear from the holes on the sole. The problem is typical for devices from all manufacturers. Most rarely, the cause is defective; sometimes a leak can be caused by damage to internal elements, but most often the fault is due to improper use of the device. Some breakdowns can be repaired manually, others only at a service center.

Operating principle of the device

The operating principle of a working device is as follows:

- water is poured into a special reservoir;

- Due to the valve device, water from the reservoir enters the soleplate of the iron and turns into steam.

Important! It is necessary to use distilled water for the device to prevent scale from appearing. Boiled water should also not be used, as it contains a large amount of salts.

Using the valve, you can regulate the amount and speed of flow. This publication will tell you which steam generator to choose for ironing and cleaning.

Features of disassembling irons with the Easycord system

Some Tefal iron models, such as Ultragliss FV4650 or Supergliss FV 3535, are equipped with the Easycord system, a distinctive feature of which is the special design of the rear panel of the device. The bolts are on a stand connected to the handle. Having unscrewed them, remove the cover covering the installation site of the cord, and then proceed to disassembling the steam supply system. The buttons are located on a removable block, which can be removed by bending special latches.

After this, you can remove the handle by gently pulling it up. The next step is to remove the screws. 2 of them are located on the back of the iron, and another one is located on the front, under the removable block. Next, disassemble the iron in the same way as standard models.

Why is steam generator failure dangerous?

If the steam generator breaks down and starts spitting, the following problems may occur:

- Instead of steaming, the device begins to wet things. A puddle of water may form, which is dangerous when using electrical appliances.

- The item will be poorly steamed and wet. In this case, when it dries, it will become wrinkled again. An unpleasant odor and mold may also develop.

- Droplets of water, possibly rusty, will get on your clothes. They will cause stains.

Important! If water begins to leak from the equipment, then immediately disconnect it from the network. Then you need to determine the cause of the failure.

Scale or limescale

Many manufacturers in advertising their products indicate the possibility of filling the boiler with simple tap water. This option is available in some regions where tap water has a low salt content. But even in such conditions, over time, deposits form on the walls of the boiler and on the steam outlet pipe, interfering with the normal operation of the steam generator.

According to the instructions, most devices must be filled with distilled or filtered water, but most housewives do not follow this recommendation. Therefore, there comes a point when the steam passage channels are blocked by scale or alkaline deposits, and steam cannot pass through them. Solving the problem of correcting the situation is simple. To do this, the steamer is cleaned of plaque using special industrial or folk remedies.

The advertised "Calgon" and simple citric acid will also do the job - the choice is up to fans of steam generators. The product is placed in a boiler, purified or distilled water is poured. Turning on the device, the mixture cleans the surfaces of the channels and the walls of the container. This is how the simplest canal treatment is performed using a ladder. After this, all parts are rinsed with water and the device is ready for use.

Large accumulations of alkaline deposits may require contacting a service center to disassemble and wash the parts.

Deformation of the coating of the internal surfaces of the steam generator

You will need to contact specialists if the surface layer of the coating, the inside of the boiler and the channels are shed. This failure leads to clogging of the steam exhaust channels. In this case, it is better to entrust the work to specialists. You will need to disassemble the steam generator and clean the boiler and ducts of particles. Expensive parts may need to be replaced, in which case it may be better to buy a new device or trade in the device if it is under warranty. But don't buy a cheap and unreliable Chinese steam converter again and face the same problem again.

If the paragenerator does not supply steam, it is necessary to check the contacts and the entire electronic control circuit.

If the device works, but steam is not supplied, in this case, in the absence of professional skills, there is a direct path to specialists. The device is working. Then the steam immediately stops flowing at high water temperatures. The problem can be solved, but you will have to disassemble the equipment housing and use a multimeter to dial the entire electrical network. Maybe the contact just burned out, but this is the easiest way to break it.

More serious problems arise when the generator electronics and individual control units fail. Such a breakdown will require financial costs and experience. The thermostat, pump, and other generator parts and devices may not work.

The smell of burning cables will require stopping the steam generator and contacting a repair shop.

On the forums you can find more extravagant methods, but, according to consumer reviews, to combat the breakdown of the steam generator. To do this, connect the idle device to the network and press the power button. Now let's remove the plug from the socket without turning off the button. If you reinsert the plug into the outlet, steam may form in the generator. The method is unscientific, but people write that it is effective.

In conclusion, some tips to help buyers of steam generators.

When going to the store, every buyer should understand that the cheapest equipment cannot be of high quality and durable. Cheaper materials and components can lead to quick replacement of a broken generator paragenerator. It is best to buy products from trusted manufacturers.

Be sure to fill the boiler with distilled water, this prevents the formation of alkaline deposits. At the first sign of serious damage, the device must be unplugged and allowed to cool. You should not try to fix a serious breakdown yourself - this will lead to unnecessary parts after assembly and more serious problems. Replace the descaling cartridges as soon as the indicator lights up.

By choosing a reliable, high-quality steam generator and responsibly servicing it, you increase the trouble-free life of the device.

How does the steam supply work?

The steam supply in the steam generator is arranged as follows:

- The water in the tank is heated to such a temperature that it turns into steam.

- Hot dry steam flows through the tube.

- When you press a button on the handle, steam comes out of the holes in the sole.

After water is poured into the tank, it is necessary for time to pass - from 2 to 10 minutes. It depends on the steam generator model.

Read how to use the Tefal steam generator here.

What to consider when choosing spare parts for Tefal?

The Tefal steam generator may need to be replaced:

- soles;

- gaskets/seals;

- steam valve;

- back of the case;

- power cord;

- solenoid valve coils and more.

When choosing a particular part, you should take into account the model of the steam generator. It would be a good idea to consult with a specialist.

You should not buy spare parts at the first store you come across . Trust only trusted companies that specialize in selling “original” parts.

It is not the best solution to buy suitable spare parts from other manufacturers. Parts must be designed specifically for your device model.

Main causes of failure

There are several reasons why a steam generator can fail and start spraying water. There are only three main reasons. Below they are discussed in more detail.

Broken valve

To make sure that the cause of the breakdown lies in a valve malfunction, you must do the following:

- Close the valve.

- Turn on the device in any mode.

- Start swinging the iron in different directions.

If drops of water appear, you need to make sure that access to moisture is not blocked. The solution to the problem in this case is to replace the valve.

Incorrect operation

If the soleplate of the iron does not reach the set temperature, steam cannot be supplied. Otherwise, water may escape from the device.

Important! Before you start ironing, you need to set the required temperature and select the type of fabric. Then you need to wait until the indicator turns off.

Only when the device is completely heated and the indicator turns off can you begin the steam release process. Before the iron heats up, it must be kept in an upright position.

Once fully heated, the indicator will turn off immediately. Otherwise, instead of steam, water will come out of the device used. The filler cap should always be tightly closed until it clicks. Otherwise, the water will ruin your clothes.

Careless kinking of the hose

Water along with steam will be released in any case, even if the hose is slightly pinched or the iron is located opposite the steam outlet, or the hose is much lower. Water, in this case, will begin to come out within a few minutes, this leads to a traffic jam. Because of this, water cannot enter the device being used.

Attention! Water circulation is disrupted and steam condensate is formed. Steam cannot pass through the holes without taking with it a stream of water. When there is a lot of water in the plug, it is possible for water to flow back into the niche and moisture collection container.

Checking the electric heater

The heating element in modern models is a reliable unit and rarely breaks. When this problem occurs, it is better not to buy a new heater. It's easier to buy a new iron. But first you should make sure that the problem is in the heating element.

In all models, the heater contacts are soldered to the device contacts and connected to an indicator lamp. If the lamp is on, but the iron does not heat up, then the malfunction is related to the heating element.

On some models, the thermal fuse is included in one heater circuit, and the regulator is included in another. If the fuse is faulty, then a false “diagnosis” can be made, suspecting a faulty heating element. To accurately determine the cause of the device failure, it should be completely disassembled.

What should I do if water is leaking from the steam generator?

To fix the problem, you need to install an iron with a hose above the steamer. After about 15 seconds, the water will rise and the plug will collapse. If there is a lot of moisture in the plug, you must first wait for the device to cool down. Next, the hose is disconnected from the device. It is located above the sink. The water is drained from the iron.

It is possible that to eliminate the cause of water leakage, descaling of the device is required. To do this, you need to pour in a special product or a folk remedy to remove plaque. Next, the device turns on at maximum temperature. Then the water is drained and the procedure is repeated again.

The water will touch the hot heating element. The contact of cold and hot, as well as the impact of the product, will allow the scale to lag behind the walls and exit through the holes in the sole.

Advice! Some models of steam generators have a special rod for collecting scale. It needs to be cleaned periodically.

To do this, place it in a solution with citric acid for several hours. The rod is then reinserted into the device. After cleaning, ironing must be done on unnecessary scraps of fabric, as scale will come out. If after cleaning the problem is not solved, then you need to contact a specialist.

If the valve breaks, you can try cleaning the nipples at home. To do this you need:

- Mix one part citric acid with five parts water.

- Pour the resulting mixture into the tank.

- Turn on the iron.

- After the soleplate has heated up, you need to press the steam button.

If the above steps do not help, the device must be taken to a service center. You should not repair the nipples yourself. If the leakage is due to improper use, then there is no need to take the steam generator to a service center. It is only important to start using it correctly.

Problems with the thermostat

The temperature control is carried out by a round wheel. It is located in the Azur iron and in other models on the body under the handle. When you turn the wheel to the right, the heating temperature increases, and to the left, it decreases until the heating element is completely turned off.

The wheel acts on the thermostat through a special bushing or steel angle and is attached to the body using latches. In the Scarlet iron and other models, it is enough to pry the adjustment disc with a screwdriver so that it comes off.

The operating principle of the thermostat is based on the various properties of metals. In the manufacture of this unit, two plates made of metals having unequal linear expansion coefficients are soldered together. Thanks to these indicators, the plates each behave differently. Outwardly, it looks like this: under the influence of temperature, the common plate bends, causing the circuit to open, and the iron turns on.

The handle of the device and the plastic parts of the body are attached to the metal parts with latches or self-tapping screws. Even one manufacturer has many models, and they all have design features. But all species have common points.

To disassemble the iron, you need to examine its sharp part, where there is one attachment point. For example, a Philips iron hides a self-tapping screw under the steam control knob. To unscrew the screw, turn the handle all the way to the left and pull up. After removing the adjusting unit, you can unscrew the screw. In the Brown model, the screw is hidden under the nozzle cover. You can remove the nozzle by slightly pulling it towards you. After its removal, free access to the screw opens. Other screws or latches are located under the back cover of the device.

After the plastic part of the body has been removed, you should consider the iron's thermostat. In cold mode the contacts must be closed. If there is a special device, it is better to ring the node. If you don’t have the device, you can clean the contacts with fine sandpaper and then plug in the iron.

Leak prevention

In order for the steam generator to operate without problems for a longer time, it is necessary to follow a number of rules:

- The frequency of steam use should be reduced. Enable this mode only when really necessary. The more this function is used, the faster the device parts wear out.

- After ironing, the remaining liquid must be drained.

If you follow these simple rules, you can significantly reduce the likelihood of breakdowns and save on repairs.

Important! If the breakdown is not complicated, then you can repair the device yourself. The most common cause of failure is scale buildup. Therefore, the device must be cleaned on a regular basis.

There are several ways to clean a steam generator - using folk or industrial products. Some devices also include a special cleaning rod. It also needs to be cleaned periodically. You can find out how to clean a Tefal steam generator from scale here, and Philips here.

Useful tips

To ensure that the iron works properly for a long time and does not have to be repaired, you should follow simple recommendations.

If the device has a self-cleaning function, you must use it at least once a month. It is important to monitor the condition of the iron sole: remove plaque and carbon deposits from it in a timely manner. To do this, use a solution of vinegar or citric acid, special cleaning pencils

Under no circumstances should solutions be poured into the tank - they can damage small parts and gaskets, resulting in depressurization of the tank. You should use only soft water: filtered, boiled, melted, distilled or special water intended for irons. This will help prevent scale formation. The cord must not be kinked. After ironing is completed and the device has cooled, the wire is carefully wound around the body.

If there are serious breakdowns that cannot be repaired on your own, you should contact Tefal service centers located in Moscow and other large cities of Russia. More detailed information can be found on the manufacturer's official website. There you can also order the spare parts necessary for repairs.

Briefly about the design

Regardless of which manufacturer produces a steam generator, for example, Bosch, Philips or Tefal, all devices are characterized by three main parts:

- electronic control unit;

- stand or so-called base;

- iron.

The household appliance is also equipped with special attachments.

Let's consider the principle of operation of the steam generator:

- The boiler heats the water.

- As a result, steam is formed.

- The generated steam is supplied to the iron through a special hose device.

- There is perforation at the base of the iron.

- The steam escaping from the holes processes the fabric, smoothing out any kind of folds.

Important! The quality of steaming is not affected by the size of the clothing or its density. Thus, the steam generator has the ability to simultaneously process bed linen, jeans, suits made of wool blends, various synthetic products, as well as materials that require very delicate handling, such as silk clothing.

A household steam generator station manufactured by Tefal differs significantly from household appliances with steaming from exactly the same manufacturer:

- a significant difference is the size - the household station is much larger and more voluminous, while occupying a lot of space in the room;

- in the steam generator, water is supplied to a separate compartment of the boiler, in which it is heated until steam is formed;

- the steam generated is not wet - it is dry with an approximate temperature of about 160 degrees;

- clothes and linen are processed without a device in the form of an iron coming into contact with them, so when processing with steam there is no damage to the clothes and there is no need to worry about the integrity of things.

Power cord

The electrical cord is often the cause of poor operation of the appliance. Breakage may occur due to damage to the insulation where the cord is bent or curled. One or more wiring may be partially or completely damaged. Because of this, the iron stops turning on and the soleplate does not heat up well.

If the cord is damaged, it should be replaced in any case, even if it is not the cause of the breakdown. If this is not possible, then you need to carefully insulate the damaged areas. To check the cord, run it with a multimeter. During the test, the cord must be twisted and bent in various places, especially where there is damage to the insulation. If this causes the multimeter to stop ringing, the cord needs to be replaced. It is also replaced if one or both pins of the plug do not ring.

troubleshooting

Why does the steam generator not work and how to disassemble it? When operating household appliances, situations sometimes arise in which various malfunctions occur. Some of them can be diagnosed by characteristic signs - this knowledge allows you to carry out repair work on the steam generator with your own hands.

How to repair a steam generator with your own hands? It all depends on the original cause. If steam generators refuse to function correctly and fail to cope with the responsibilities assigned to them, then in this case there are a number of reasons that cause damage:

- The station stopped supplying steam - the heating element or its contacts burned out. In addition, sometimes there is incorrect functioning of the boiler switch. It also happens that the steam button on the device is simply broken.

- If the pressure stops regulating, then the switch is simply broken.

- The device supplies steam, which is characterized by the wrong temperature - the temperature fuse has blown, the thermostat has stopped functioning.

- There is no voltage - you need to check the power cord, perhaps one of the wires is broken.

- Insufficient water heating - you need to check the container; there may be a lot of different deposits accumulated on its walls.

- If the water level indicator does not turn off, but is constantly on, then the cause may be a broken sensor.

- There is a constant release of steam through the safety valve - perhaps there is not enough water in the container.

- Water has formed under the steam generator station - somehow there is a leak, so to isolate the fault, you should turn off the device.

Important! In order to fully diagnose the device and carry out repairs yourself, it is necessary to have special equipment, since the presence of one soldering iron and multimeter allows you to solve only simple problems and eliminate minor damage.

Checking the simplest things

Often the iron does not work due to problems with the cord. During operation, it often bends, the insulation is damaged at the bend points, and sparks may even appear. Therefore, the first step when repairing an iron yourself is to inspect and test the cord. To test, you will need a multimeter (read how to use it here).

Disassembling the iron is the very beginning

Checking the power cord

Sometimes, to make sure that the problem is in the cord, you can plug in the iron. If everything is in order, the indicator lamp lights up. This is usually a green LED. Based on whether it is constantly on or goes off periodically, we will monitor the condition of the cord

We twist and bend it, paying attention to the state of the signal light. If it blinks, then the power cord is really at fault. It is better to replace it, but, if desired, you can find the problem area (often it is visually easily identified) and correct the situation

It is better to replace it, but, if desired, you can find the problem area (often it is visually easily identified) and correct the situation.

Typical problems with the iron cord

If these are problems with the insulation, and the conductor itself is intact, using insulating tape the fault is eliminated. If the wires are damaged, they are cut, connected in a new way using soldering, and the junction is insulated. This repair is a temporary measure, as problems will soon appear again - not far from the "restored" place. Therefore, it is still better to replace the cord.

Terminals and contacts

If there is no external damage to the cord and it does not work, you will have to disassemble the iron. At the first stage there are usually no difficulties - there is one bolt at the back. This is perhaps the only fastener that cannot be hidden. Unscrew it and remove the cover.

Removing the back cover is usually not difficult - just one bolt

Under the back cover there is a terminal block to which the wires from the thermostat and the heating element are connected, and our power cord is connected to the other. The terminal block may look different. Some manufacturers, like Bosch, have it hidden under a plastic cover. The cover must be removed. How to get to it depends on the model. Sometimes you just need to pry and pull, sometimes you have to remove some parts

It’s important to get to contacts

Overheating may cause the block or cord to melt.

Often the reason that the iron does not heat up is not hidden in the heating element, but because the contacts are clogged or oxidized. Sometimes water gets on the contacts (the container leaks), sometimes dust gets baked in there, sometimes the contact just weakens. If there is one of these problems, fix it. Perhaps repairing the iron yourself will end there.

Checking the cord for wire integrity

If the contacts are normal and clean, we test the cord to check the integrity of the wires. We take a tester/multimeter and put it in dialing mode. With one probe we touch the cord pin, with the second we “sort out” the wires on the terminal block. If the wire is intact, one of the pairs should “ring” - you should hear a beep.

Iron cord test

The iron cord is three-wire, two wires go to the pins of the cord, and the third is green or yellow-green - grounding. This is a metal plate on the fork of the iron. When you touch it and the green wire on the block, you should hear a “squeak” from the multimeter. If at least one wire does not ring, we change the cord.