Automatic washing machines perform a huge number of washes over their entire service life, washing tons of laundry of their owners. Designers develop them as reliably as possible for long-term trouble-free operation, withstanding heavy loads. But for the washing machines themselves to work well, they require us to use them correctly, starting with installation at the site of operation and connecting them to all communications.

The product must be installed in a well-ventilated area on a solid, stable base. The connection to the water supply must provide good water pressure, and the electrical supply must be adequate and stable. But the most important requirement is to connect the water drain to the sewer system.

Incorrect connection of the washing machine to the sewer can provoke spontaneous draining of the washing solution from the product tank.

In this case, the technology of washing clothes is disrupted and a malfunction occurs in the device program. If the drain is connected incorrectly, waste water from the sewer may enter the washing machine, which causes an unpleasant odor from the appliance and requires a thorough cleaning of all internal parts.

To comply with all the requirements when connecting the washing machine, you need to carefully study the recommendations of the device manufacturer.

To do this according to the operating instructions, you need to make big changes to the drain line of your home.

To simplify this procedure, many devices have been invented to help avoid the self-outflow of water from the machine tank or the unwanted ingress of liquids from the sewer into it. One of the options that simplifies the connection of the machine is a check valve for a washing machine on the drain, also called an anti-siphon valve.

Non-return valve for washing machine drain

Currently, a washing machine is an integral attribute in every apartment. Any housewife is interested in keeping her linens crystal clean. The quality of washing depends not only on the characteristics of the machine and powder, but also on the correct connection. The washing machine must not only pump clean water, but also ensure that waste water is discharged into the sewer system. As a rule, there are no problems with water injection. And illiterate organization of drainage can lead to a number of problems. Dirty water from sewer pipes can flow back into your car. To block the reverse flow of water, it is necessary to install a check valve on the drain hose of the washing machine, which is also called an anti-siphon.

Why do you need an antisiphon?

High-quality washing is impossible without an anti-siphon. Its main function is to pass dirty water into the sewer and prevent it from entering back. An anti-siphon is a small pipeline element with a tip for connecting to a hose and a built-in check valve. The diameters of the inlet and outlet pipes are different. Most often, this device is sold complete with a washing machine.

Anti-siphon valve

Without it, high-quality washing is only possible if certain operating conditions are met. The main condition is that the drain hose must be higher than the sewer pipes. Many people organize a drain right next to the floor in order to preserve the interior. This erroneous decision leads to an increase in the siphon effect. But even with a properly connected machine, problems can arise. If the sewer pipes have not been changed for a long time, a “siphon effect” also occurs when draining.

This is quite easy to determine. The operating time increases significantly, the quality of washing decreases, and energy costs increase. These are manifestations of the “siphon effect”. It appears if the drainage is not organized correctly. The diameter of the machine drain hose is much smaller than the diameter of the sewer pipe. Draining leads to a release of pressure, water is pumped out of the drum. The machine is forced to draw water from the water pipe and heat it. As a result, the operating time of the unit increases and water consumption increases. These problems can be avoided by installing a siphon with a check valve.

Operating principle of a check valve

A siphon with a check valve is mounted on the drain pipeline in an arbitrary location. When the drain program is turned on, the pump starts to pump out water. The pressure in the hose increases and water flows freely through the valve. After the drain cycle completes, the water stops flowing and the pressure drops. In this case, the device closes, blocking the passage. A tight connection is formed. In this way, the passage for water to enter the drum from the pipe is blocked. Due to the height difference between the inlet and outlet pipes, the reaction time to pressure changes is minimal.

This is interesting: Pump to increase water pressure in the house: calculators for calculating the required pressure

The most commonly used locking device is:

- polypropylene ball;

- spring.

The principle of operation of the antisiphon

The locking mechanism is a small ball of air. When direct fluid pressure is removed, the ball rests against the sealing membrane. When back pressure occurs, the force of pressing the ball against the membrane only increases. Reverse penetration of liquid is not possible.

No ball cleaning required. Special ribs in the valve body serve for self-cleaning of the ball. A siphon with a spring valve uses a spring as the closing mechanism.

The design of the mechanism makes it possible to install it on any section of the pipeline. The installation location does not affect the quality of work.

All valve modifications are made of high-quality durable plastic. Therefore, the devices have a long service life. The service life can only be affected by water quality. Too hard water in the water supply system destroys the elements of the device.

Types of check valves

There are several types of antisiphons for washing machines:

- collapsible (segmental);

- non-separable;

- wall;

- mortise;

- washing

Types of antisiphons

Double check valve

Wall check valve

It is better to choose collapsible devices for houses with hard water. If it gets dirty, it can be dismantled and disassembled. Without cleaning, the device can quickly fail. In addition, only such valves are suitable for certain brands of washing machines (for example, from the manufacturer LG). This is usually stated in the instructions for the washing machine. If the water is of good quality, a non-separable option is quite suitable. It is much cheaper than segment ones.

Non-separable valves are subject to forced replacement. Devices need to be checked and replaced more often with hard water.

Mortise devices are convenient to use when connecting a direct drain into a sewer pipe. To install the valve, a special mortise hole is prepared in the pipe. This connection option is somewhat more complicated.

Wall-mounted ones have the most aesthetic appearance. But they are significantly more expensive than others. It is mounted between the washing machine and the wall. This is the most compact device.

Wall check valve

The washer is not suitable for washing machines. Their purpose is a sink siphon. There are also many models with decorative inserts. Inserts are usually made of high quality stainless steel. But such models are several times more expensive. But it should be remembered that appearance does not affect quality.

There are no special rules when choosing an antisiphon. The main thing is that the device fits the washing machine and the drainage structure. Therefore, first of all, you need to carefully study the machine’s instructions and the design features of the sewer pipes.

DIY installation

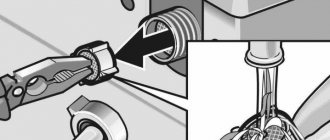

Installing the device is not particularly difficult. The installation principle for all varieties is approximately the same:

- connect the siphon to the valve tube (for mortise ones - install it in a pre-prepared cutout in the pipe);

- connect the second output to the drain hose of the washing machine;

- seal all joints with sealant.

Antisiphon tubes have different diameters. Therefore, incorrect connection is completely excluded. The most important thing is to ensure the tightness of all connections.

It must be remembered that in drain mode there is strong vibration of the hose. High-quality connections will help avoid leaks. Before starting, it is necessary to check the operation of the sewer system. If water flow is poor, the pipes need to be cleaned.

This is interesting: Siphons for bathroom sinks

Which manufacturers are better

Check valves for washing machines can be purchased at any hardware store. The variety of manufacturers and price range is quite wide. To ensure that the device works for a long time, when purchasing, it is better to give preference to trusted suppliers. The table shows the most common devices from well-known brands.

| Manufacturer | Type | Characteristics |

| Alcaplast, Czech Republic | APS2 | Plastic, ? 32 mm, for any hoses, one-piece |

| Siroflex, Italy | 012677 | Mortise, spring. |

| Merloni, Italy | 95101800 | Mortise, plastic |

| McALPINE, Scotland | WMV-32WH | Plastic, ? 19-25×32, one-piece |

| ANI Plast | P-12/M500/APS2 | Minisiphon (wall-mounted) |

Whether or not to install a siphon with a check valve is up to everyone to decide for themselves. But you should remember that without it it is impossible to organize a drain. The quality of washing decreases, washing time, water and electricity consumption increases. An inexpensive device that is easy to install even without the involvement of specialists will help avoid these problems.

Tips and tricks

We have collected tips from master plumbers. We hope you find them useful.

Install in an easily accessible place

The outlet valve of the washing machine, installed on the drain, becomes clogged and breaks over time. And installing it in a place where it is difficult to reach will only complicate your life. In an emergency, you will need to quickly disassemble the valve, clean it or make repairs so that the laundry does not have time to be in dirty water.

Which to choose

List of the most reliable and popular check valves

- Italian exhaust valve Type: mortise. Body material: polypropylene. Installed in a drain pipe or attached to a hose to drain water. The mechanism is based on a spring with a rubber membrane.

- Czech valve from . Wall. The plastic case contains a water seal made of a ball with a spring. Universal: suitable for any hose. The main advantage is the affordable price.

- In third place is another representative of Italy from. The body is made of polypropylene. Installed in a siphon under the sink. The mechanism is spring.

- Mini-siphon from the Russian manufacturer ANI Plast. Mounts anywhere on the pipe. The locking mechanism consists of a spring-loaded polymer ball. The polypropylene body is resistant to aggressive environments and temperature changes.

- Siphon for connecting a washing machine from the Scottish company McALPINE. The beautiful plastic chrome-plated body does not spoil the aesthetics of the interior. Standard water seal with polymer ball and reflector.

Is it really necessary or how can I do it myself?

You can do without additional expenses by making the shutter yourself, using a standard corrugated hose that goes from the machine to the sewer. This is done simply - the hose needs to be organized so that the top point is above the level of the washing machine tank. The laws of physics and gravity will not allow the liquid to flow back into the “washer”.

But this is not a solution to the problem, but only a temporary solution. The fact is that the pump wears out due to the long hose and its bend. The pump has to work hard to move water through such a distance. In addition, cleaning turns into torture, since you have to completely disconnect it from the washing machine.

When connecting a hose to drain water directly to the sewer, use a rubber coupling. It will make the connection more airtight.

With this method, the waste pipe outlet must be raised 50 cm from the floor. Otherwise, the water seal will not work.

The hose may also not be long enough. To extend it you will need a piece of a similar hose and a special coupling. But over time, water begins to leak at the junction.

Necessity of application

If the drain hose is connected to the sewer outlet in violation of plumbing standards, then it is likely that dirty water from the sewer pipe will return to the drum of the washing machine. As a result, at the end of the wash you will end up with stale, foul-smelling laundry. The check valve is designed to prevent such a development of events (which, by the way, is called the “siphon effect”).

A non-return valve or anti-siphon should be installed when it is not possible to install the drain hose at the required height. Another case in which this device cannot be avoided is when the washing machine drain is connected through the sink siphon.

You should also think about installing an anti-siphon if you notice signs of a siphon effect during washing. These include: increased washing time, poorly washed items, increased consumption of water and electricity by the washing machine.

When is it necessary to put

There are several reasons when an antisiphon is needed. See which case is yours. If you have doubts that the washing machine is installed correctly, we recommend reading this article, which shows a working connection diagram:

Step-by-step instructions for connecting any washing machine

With direct discharge to the sewer

The outlet hose is inserted directly into the sewer outlet. Of course, the connection method is very simple.

But there is a risk that used water will return from the sewer to the drum. Especially if the outlet level is significantly lower than the tank level.

Hence the disgusting smell of things after washing. Installing a check valve solves this problem once.

Wrong outlet level

The main rule for installing a drain hose is that its end should be 50 cm above the floor level. Sometimes, for aesthetic reasons, the hose is placed very low and you get that “siphon effect” with all that it entails: dirty water and the smell in the machine.

The sewer system is not done according to the rules

Perhaps the sewage system in the house is outdated or was originally assembled incorrectly. Inappropriate pipe diameter, incorrect slope, lack of water seal.

Unpleasant smell

A nasty smell in the place where the machine is located is an absolute indication for installing a check valve. It will block not only the flow of wastewater, but also the sewer smell.

How does it work?

A check valve is a fairly simple device made of stainless metal or plastic. In appearance, it is a bit like a shut-off valve, and its operating principle is similar. An anti-siphon is needed to regulate the flow of water in the pipe, allowing it to move only in one direction.

Initially, the check valve is in a locked state, but when the drain mode is activated, it opens under the pressure of water. When the drain program is turned off, the valve automatically closes, preventing water from returning.

The valve of the washing machine is broken - how to understand?

After the wash is completed, the water remains in the drum. Water is not being collected. Sewage water flows from the sewer into the tank.

Kinds

There are several types of check valves on the modern plumbing equipment market. They differ in design features, type of installation and scope of application.

Main types of antisiphons:

- collapsible - a metal device consisting of several parts; this type is convenient because, if necessary, it can be disassembled and cleaned;

- non-removable - monolithic structure made of plastic; considered the most budget option;

- mortise - a valve that is installed directly into the pipe, in place of a piece cut out of it;

- washing – check valve intended for use in drain siphons of sinks and washbasins;

- wall-mounted – a beautiful structure made of chromed metal that is mounted on the wall; the most expensive option of all of the above.

This is interesting: Fan pipe: installation and repair

Types of Anti Siphon Valves

There are no special design differences between these devices, since they are designed to perform one, simplest function - to ensure normal drainage of dirty water. But individual washing machines with sewage drainage through a valve (for example, Indesit), when connected to the sewerage system, may have some features inherent to this brand. What to consider when choosing a hydraulic check valve.

There are five types of valves in total:

- whole.

- segmental.

- wall-mounted

- mortise

- located under the sink.

A washing machine with a wall-type water drain valve allows you to save space when installing it in small rooms due to the anti-siphon design. The disadvantage, despite their quite aesthetic appearance, is the high price of the device and somewhat difficult access to it.

In the case when tap water leaves much to be desired in its properties, a segment siphon valve is installed, which provides for the possibility of disassembling it and cleaning it from deposits of water stone and debris.

Even if you have good quality water, when installing a solid anti-siphon, there will be a need to replace it once, approximately every two to three years.

A mortise-type installation valve will be needed when the drain is directly directed into the sewer system. In this case, an insert is made into the body of the sewer pipe, and a check valve is installed directly into it (inset).

Features of use

- Some manufacturers of household appliances add a check valve to the basic configuration of washing machines, but not all do this. Therefore, most likely, you will have to purchase this device yourself in a specialized store.

- If you connect the drain using a check valve, then you do not have to worry about following the recommendations regarding the height of the drain hose. The main thing is to install all elements of the system in such a way that they can be easily accessed in case cleaning or repairs are needed.

- When purchasing a check valve, be prepared for the fact that this device will have to be replaced every few years, as it will be exposed to hard tap water. The better the quality of the product, the longer it will last, but you still shouldn’t overpay - no matter how expensive the device is, sooner or later it will need to be replaced.

Layout of the drain system

The operation of installing a drain system involves the use of certain tools and components. You will need:

- a tool for cutting metal-plastic pipes and welding them (when using this type of outlet and connection);

- drain pipe with tips at the ends or corrugation (depending on the type of connection of the machine to the drain);

- siphon, with an outlet for attaching a drain hose and an anti-siphon valve;

- sealing cuffs (possibly Masterprof), ball valve, elastic hose, sealing silicone glue.

Immediately before starting work, it is necessary to check the serviceability of the sewer system. Make sure there are no blockages, leaks or other malfunctions.

Installation

Installing a check valve is not a difficult task at all; you can easily handle it yourself, without the help of a master plumber. You can get complete information on installation from the instructions for the device, which you must read, but we will only give brief recommendations.

Antisiphons come in different types, but most are shaped like a tube with two holes. One end of the device must be connected to the sewer (by screwing it into the outlet or cutting it into a pipe), and the other must be connected to the drain hose of the washing machine. To prevent leaks, treat all connections with silicone plumbing sealant.

You can clearly see the valve installation process in the following video.

Varieties

Let's take a closer look at all the existing options for the shutter design:

- Ball - we analyzed it above.

- Rotary check valve.

Disc or piston - found, but when foreign objects get in, it quickly jams. For washing machines, a ball mechanism is used. Additional varieties are used mainly on large pipes.

Source

Tips for choosing

- Experts say that not all models of drain valves are suitable for your washing machine. The service center will help you choose the appropriate antisiphon. You can also seek advice from an experienced technician who specializes in repairing washing machines.

- The best recommendations are for check valves from European manufacturers. The equipment receives a large number of positive reviews from the Italian companies Siroflex and Merloni, as well as from the Czech company Alcaplast.

Should it be replaced with something else?

A check valve for a washing machine is not such a rare product, but it is not always possible to find it in stores, especially if you live in a small town. Therefore, many are interested in the question: is it possible to use something else to prevent the siphon effect?

Unfortunately, the answer to this question will be negative. There are no analogues to the antisiphon yet. To do without it, you will have to organize the drain in such a way that all elements of the system are positioned as expected, and then there will be no siphon effect.

Sources

https://o-vannoy.ru/stiralnaya-mashina/obratnyj-klapan/ https://vannayasovety.ru/tekhnika/obratnyj-klapan-na-sliv.html

Washing machine solenoid valve - who killed me?

Limescale Dirt Rust

Achtung! If you want the element to serve you for a long time, clean it regularly. The segment valve is easy to disassemble, clean and reassemble.