If the washing machine drum does not spin, there can be a variety of reasons. The situation when the washing process has begun, but is not completely completed, is unpleasant, but you should not be nervous and fuss. What should I do if the drum stops while washing? A number of urgent actions need to be taken.

When the washing machine drum does not spin, it is important to determine the cause of the problem.

Common washing machine problems

If unloading does not help, and the drum is still standing in place, then you should pay attention to the points listed below.

There is a foreign object in the drum of a front-loading machine that is preventing it from moving. It is impossible to turn the drum manually - there is clearly some kind of interference.

You can often deal with this problem on your own. But often it is necessary to dismantle the front panel in order to get to the object blocking the operation of the machine.

The rotation of the drum depends on the presence and degree of tension of the drive belt. It is he who transmits rotation to the drum from the electric drive (motor). Belt wear, weakening or rupture can occur both from intensive use and from prolonged inactivity. If the machine is not used for a long time, the belt material will dry out and crack.

In addition, the belt may simply fly off the pulleys, and it will be quite enough to return it to its place. You can also replace or install the belt on the axle yourself by removing the rear panel of the machine body.

Wear of motor brushes. As a result of erasing the brushes, the necessary contact is lost and the supply voltage is not transmitted to the windings.

When the washing machine operates, the graphite brushes gradually wear out, so they become shorter. Over time, the brushes become so small that they no longer tightly touch the commutator lamellas, which is why the engine power first becomes unstable and then disappears altogether.

Call the master

If you are not sure that you will be able to cope with the repair on your own, it is better to call a specialist. Offers can be found online or in newspaper advertisements . You should also ask your friends, perhaps they have already used similar services and can recommend a good specialist.

The cost of work depends on its complexity. The price starts from 2000 rubles. You will have to pay separately for parts.

Before agreeing to a repair, you need to ask the specialist about its final cost and the guarantees he provides. If you cannot find a private specialist, contact the service center.

Failure options

The machine draws water for washing, but does not spin the drum

There are dozens of reasons for the situation when the washing machine will draw water into the tank to start the washing process, but will not be able to spin the drum. First of all, you should manually check whether the drum is spinning.

If it is easy to unwind by hand, then most likely the problem is either electronic or a broken or falling off motor drive belt. If it becomes worn, torn or stretched, it should be completely replaced with a similar one.

Drum does not spin during spin cycle

The washing machine drum may not spin during the spin cycle for several reasons:

- The washing program is set to “No spin” or “Delicate wash”. In this case, spinning will either not be carried out at all, or the minimum number of revolutions will be set so as not to stretch things.

- If the drain is clogged, the water will not be able to leave the tank and the electronic control unit of the machine will not start the spin cycle.

- If the water quantity sensor is faulty.

- There may be problems with the electronics and wiring of the control board.

Drum stopped during washing

The washing machine may stop the washing process if a lot of items have accumulated on one side of the drum. In this case, when there is an imbalance, strong vibrations occur.

At the same time, the electronic control unit gives a signal to stop washing, since an imbalance can lead to mechanical damage to the elements of the device and serious breakdowns.

Clogged hoses or a breakdown of the water level sensor in the tank can also cause the washing process to stop.

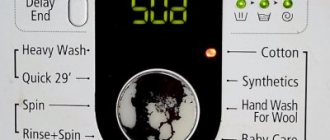

Always pay attention to the display - modern cars display error codes on it.

Washing cannot proceed without heating the water, so if the heating element malfunctions, the temperature sensor will give a signal to stop washing and the drum will stop along with the laundry. Touch the glass of the door: if it is cold, although the heating cycle is selected, then there is a problem with the heating element, most likely it will have to be replaced.

The same is true in the opposite situation - if the water temperature sensor is faulty, then the washing will be completed, since the control unit cannot monitor the current state and, accordingly, give a signal to continue working.

The motor hums, but the drum does not rotate

In a situation where the washing machine motor is running, but the tank does not turn, the cause may be jamming or mechanical damage to the device.

But the most common cause of this phenomenon is defects in the electric motor drive belt. It may tear or come off the pulley. In the worst of all cases - when it breaks, it wraps around the motor shaft, tearing it even more, which can cause damage to other elements.

If foreign objects get into the space between the tank and the drum, rotation may be difficult or completely blocked.

If the heating element or thermostat is damaged, the corresponding signals from the components of the washing machine do not reach the software control board, which leads to the drum not starting to rotate, although the motor is working.

The drum does not turn manually, it is jammed

There are several main reasons for a completely jammed washing machine drum: problems with the motor drive belt, problems with the bearing, and foreign matter entering the space between the tub and the drum through the rubber seal.

First of all, the bearing wedge is best diagnosed by related signs: it degrades for a long time, so unexpected failure is rare. Most often, for a long time the bearing will interfere with a strong grinding and humming noise when the machine is operating. It is also possible that the drum may have some play, and it will seem to rotate with force.

After this, at one point the drum will be completely immobilized, and it will also be impossible to turn it by hand. The reason may be either degradation of the bearing with subsequent failure, or its complete destruction. The second case will be accompanied by strong noise during the last washes before the breakdown.

How to clean?

The latest models of Atlant washing machines are equipped with a drum self-cleaning function. To start the process you need to do the following:

- empty the drum - there should be no things in it during cleaning;

- close the hatch and turn on the device;

- press the button labeled “Self-cleaning”;

- wait for the cycle to complete.

The average duration of cleaning is 1 hour 30 minutes. If the device is not equipped with such an option, then the drum is cleaned using folk remedies.

You can get rid of salt deposits using citric acid. To do this, 3 bags of lemon are poured into the powder compartment, select the “Cotton” program with a water temperature of 90 degrees. Start the wash cycle.

Cleaning should be carried out at least once every 6 months . This will avoid the appearance of unpleasant odors and prevent premature wear of parts.

Reasons why the washing machine drum stops and how to eliminate them

The control module is broken

The drum may remain motionless due to the lack of a signal from the “brain” to start washing. Most often, the control board fails due to voltage surges or natural wear.

Electronics fail for several reasons:

- the supply current parameters deviate from the permissible limits;

- low-quality elements of electrical circuits;

- violation of contacts;

- natural wear and tear;

- program failure.

Initially, you should try to reset the programs. Some washing machine models have a self-test function; by running it, you can determine the cause of the problem. If performance is not restored, removal and diagnostics of the electronic unit will be required.

There are three options to solve the problem - reset the programs, flash the firmware, or replace the module.

Some models have a self-test function. It allows you to determine the source of the problem. How to enable this feature? They don’t write in the instructions, but the starting method depends on the manufacturer and the specific model.

As an example, during repairs, an Ardo washing machine is tested as follows: drain the water, the tank should be empty, set the mechanical program switch vertically down, and set the temperature to zero. To start the test mode, press all the buttons at once.

Each machine has its own way of turning on auto-test: LG - by holding down the power, temperature, spin keys, and then you need to press start three times in turn to test the operation of the drum.

If there is still a need to remove the board, it can be removed quite simply. We remove the top panel, dismantle the upper part of the machine, remove the fixing strips and take out the module.

Repairing the control unit requires special skills - you need to check the parameters of the elements and monitor the chains. We carefully inspect the board.

Remove the board yourself only after the warranty period has expired, and if you do not have the skills for such repairs, you can replace the entire control unit

4 signs that serious intervention is needed:

- The paths darkened, the color changed in some places, and scorch marks appeared.

- Bumps are visible on the caps of the capacitors.

- The varnish coating on the damping coils has faded.

- The main processor has darkened at the installation site.

If any of the above is found and you have no experience with a soldering iron or multimeter, entrust the repair to a specialist.

Failures associated with sensor problems can be resolved independently. Contact groups become greasy and clogged over time; they just need to be cleaned. Remove the program regulator, disassemble the handle and clean it.

If there is a layer of soot on the power coils of the surge protector, brush it off with a dry cloth and brush. We free the hatch lock block from soap deposits.

A belt drive has fallen off or broken, how to identify and repair it

The transmission of rotation from the electric motor to the drum is carried out using a belt drive. A belt breaking or slipping off the pulleys disrupts the connection between the elements. In this case, the drum rotates freely by hand, and the motor hums when voltage is applied.

If the drive belt is deformed, the rotation of the drum will be completely stopped. In many cases, the belt may simply “jump” off its pulley due to strong vibration that occurs during spinning. To restore functionality, it will be enough to remove the back cover and install the belt in its place.

To fix it you need to get to the engine and large pulley. Washing machines use V-belts or poly-V-belts. To install, you need to loosen the engine mount and ensure that the grooves of the mating parts match.

Remove the back panel of the machine and look at the condition of the belt. If it just slipped off, put it back in place, close the lid, turn on the washer and check its operation. In case of complete wear or damage, replacement will be required.

Machines with asynchronous motors have V-belts, while those with commutator motors have V-belts. The first ones are trapezoidal in cross-section and are marked on the outside. This is exactly what is shown in the picture.

They are made of chloroprene rubber, polyester cords, and cotton material, due to which they are elastic and have increased strength characteristics.

The V-belt is tensioned when moving the engine, so you need to loosen the fastenings. When the adjustment stroke of the engine is small or such a maneuver is excluded by the design of the machine, the belt needs to be replaced.

We install the V-belt like this: we wind it around the pulley, then we place the strip in the drum groove and seat it completely there, rotating the pulley.

The tension of the V-belt should be very tight: if you press hard in the middle, a deflection of up to 5 mm is considered normal

The V-belt has a toothed section. The parameters are also marked on the outside. It changes in exactly the same way as the wedge one. But it requires careful position control after final installation.

We measure the middle of the mating part of the engine pulley and drum - the belt is installed strictly along this line. V-ribbed belts are tensioned less than V-belts.

In all other cases, stretching or breaking of the belt requires replacing it with a new one. When choosing a belt, you should pay attention to the original or a worthy analogue if you want the machine to last a long time. A Chinese fake will quickly stretch or tear.

Washing machine electric drive failure, how to fix it

If the drum not only does not rotate in the car, but also does not hear any sounds of a running electric motor, this is most likely the problem. A slowly rotating drum can also indicate engine malfunctions.

In older engine models, the problem is often the starting capacitor, which is shaped like a cylinder and mounted next to the drive. If the capacitor fails, the engine does not start, which is why the drum does not rotate. Replacing the capacitor will help with this problem.

In commutator motors, a common cause is brush wear. Over time, they wear out and become shorter, and therefore the required contact with the lamellas of the engine manifold is not achieved. And the drive does not work simply for the banal reason of lack of voltage on the windings.

To fix this problem, you will have to replace the brushes.

To diagnose and repair the engine, it will have to be dismantled. The work is carried out as follows:

- To remove the motor, you need to remove the back wall of the washing machine by unscrewing the fastening screws.

- Then the drive belt is carefully removed.

- The engine is located on the underside of the machine. To remove it, screws are unscrewed; there may be two or more of them.

- Next, the contact block connecting the electric drive to the control unit of the washing machine is disconnected. If there is a separate ground wire screwed directly to the machine body, remove it too. The removed engine is pulled out.

- Then you need to unscrew the locking screws and pull out the brushes on one side and the other. The brush is considered worn out and unsuitable for further use if no more than 15 mm of its length remains.

- When dismantling old brushes, you should remember in which direction their edges are ground - the new components should be installed in the same way. New brushes must match the model of the washing machine and be of the same quality. If brushes with different hardnesses are installed in the electric motor, it will very quickly fail again.

- After the brushes are in place, you need to spin the motor rotor. If you feel interference or make a lot of noise, the brushes may not be installed correctly. It’s better to check right away - unscrew and reinstall them correctly.

Another possible cause of engine failure is its combustion, which occurs when the winding is shorted between turns or breaks on the rotor or stator. This requires only a qualified approach.

In the event that a burning smell is felt during washing or smoke appears, the power is immediately turned off. And the engine will most likely have to be replaced. If you wish, you can, of course, try to rewind the burnt winding.

However, as practice shows, it is most often impossible to return the engine to factory quality using such measures, which means that after repair it will not last long. Therefore, if the engine burns out, it is recommended to install a new mechanism. Moreover, completely rewinding the engine is also quite expensive, and the material gain, if there is any, will be very insignificant.

The bearing is stuck, symptoms and troubleshooting

The rotation of the drum may stop due to wear of the support bearing. Depending on the design of the washing machine, there may be one or two of these elements. After long-term use, worn out oil seals begin to leak water, corrosion occurs and the bearing jams.

When water gets in or is overloaded with laundry, the drum bearings are destroyed, of which there are always two in the machine, regardless of whether it is loaded vertically or horizontally. Some models use double. But in essence, these are two bearings combined into one housing.

Sometimes situations arise when they overlap. This most often occurs with double bearings.

Determining bearing failure is quite simple. If, when trying to turn the drum manually, it does not move or turns tightly, and this process is accompanied by creaking and grinding noises, then these are the main signs that the bearing and oil seal of the drum axle shaft are damaged.

The problem is solved by completely replacing worn out elements. In addition to the bearing itself, the seals also need to be replaced. We treat the bearing installation site with lithol and return the elements back. Secure with a hammer.

The average service life of these parts is 7 years, after which they need to be completely replaced, otherwise problems will arise when washing.

The oil seal is a rubber insert designed to provide an airtight seal that protects the bearing from water ingress. However, over time, the seal wears out and the tightness of the assembly is compromised.

Moisture begins to penetrate the bearing, washing away the lubricant from it, leading to the occurrence and development of corrosion. Because of this, the rotation unit fails and the drum jams.

To replace the bearing, you will have to almost completely disassemble the machine and remove the tank.

The first step is to remove the cover of the machine - it is usually secured with two screws on the rear panel. Its dismantling is necessary so that dismantling can continue on the façade side. You can immediately unscrew the screws and remove the back wall of the machine.

After this, the upper control panel is unscrewed (or removed from the plastic stoppers, depending on the model) and removed. Here you need to act very carefully, since it is connected by cables (wire handles) to other components and devices of the washing machine. It is best to disconnect all connectors - they are usually made in such a way that it is impossible to make a mistake when connecting them back - they have different sizes and colors.

Next, the front panel of the car is removed along with the hatch door. It should also be dismantled carefully, since due to inexperience, some people forget to remove the connector from the hatch locking device (UBL). This lock is located on the right side of the door in the space behind the panel.

After the internal space of the machine is opened, the heating element is dismantled and all communications going to the tank are disconnected. Next, the massive counterweights are unscrewed and removed.

The drive belt is removed and the engine is dismantled. The heating element is removed. The tank of the machine is disconnected from the water supply and drain pipes, top and bottom.

Then the lower shock absorbers are unscrewed and moved to the sides, and the dismantling is completed by removing the upper suspension springs. After this, nothing should hold the tank in the body - it can be taken out and placed on the floor with the pulley up.

The next step is to remove the drive pulley. It is fixed on the axis on splines, secured with a nut (in some models - with a screw or bolt). Usually the nut is screwed on quite tightly, and it can be difficult to remove it, especially if there has been a water leak here. Therefore, it is recommended to generously moisten the joint with a compound such as WD-40 and leave for half an hour.

Then the pulley must be stopped (for example, with a wooden block), and a striking force with a hammer can be applied to the wrench placed on the nut. After the nut is loosened, it is completely twisted, and then the pulley is removed from the axle shaft.

Now we have to disassemble the tank - otherwise there is no way to pull the drum axle shaft out of the bearing assembly. If the tank is collapsible, then all the latches are removed in a circle, and the fasteners holding the halves together are unscrewed. If the tank is a non-demountable structure, then it is better not to do anything yourself.

The fasteners are unscrewed, the stoppers are removed - and the tank is divided into two halves, opening access to the drum.

After disassembling the tank, the axle shaft is driven inside through a wooden block from the outside - it should come out along with the drum. Now the rotation unit is completely open, and you can remove the bearings and seals. This is done very carefully so as not to deform their installation socket.

After this, the seat freed from the old bearing is cleaned and treated with lithol. Oil seals and new bearings are installed in place.

The bearing is carefully pressed into the seat with a hammer. It is better to carry out this process through a wooden plate, so as not to accidentally damage either the metal part or the plastic of the tank.

After replacing the bearings, the assembly process begins in reverse order. In order not to make a mistake in the sequence, you can photograph the dismantling process.

The electric motor brushes are worn out, how to determine the replacement procedure

The motor brushes of a washing machine may, over time, stop performing their direct function - creating the proper electromagnetic field to rotate the motor rotor. During operation, they gradually, quite slowly, wear out and the induction field from them weakens.

The problem is unique to commutator motors. Currently, they are installed on 85% of washing machine motors.

Usually brushes last for 6-8 years. The service life depends on the frequency of operation of the machine, compliance with recommendations for loading the drum, and the quality of assembly of the unit.

There can be no repairs here other than replacing the brushes. If you have the skills of an electrician, you can change the motor brushes yourself.

But measure the bars first: if they are longer than 1.5 cm, the brushes are not causing the drum to stop.

Be sure to buy two identical, matching models and brushes without defects: installing parts with different hardnesses can result in engine failure.

If the machine is assembled, remove the back wall and belt. We disconnect the engine from the power supply by pulling out the connector with the wires. We dismantle the engine itself.

Next, we lay the engine on its side so that the brush housing is on top, and unscrew the mounting bolts and pull out the spare part from one side and the other.

It is highly advisable to replace them before they are completely worn out. This will help avoid a number of problems - damage to the collector lamellas or the electronic module.

Also, do not forget to clean the collector from black deposits; remove scratches with sandpaper. That's it, now you can install new elements and tighten them with bolts.

The washing machine motor burned out, how to determine it and what to do

In this case, two options are possible: the engine is completely faulty and does not start, or rotation occurs only without load. The winding short-circuits or it breaks off at the stator and rotor.

A characteristic sign of the first situation is that the empty drum rotates normally, but during a full wash the plugs are knocked out. When the second situation occurs, the drum stops rotating altogether.

Repair is possible if the drum has stopped, but the machine is humming when turned on. A complete engine replacement is needed when there is no starting at all, there is a smell of burning, dark smoke, and sparks.

An electric motor is a fairly reliable unit, but it can also stop. Main reasons for refusal:

- wear of commutator brushes;

- short circuit of winding turns;

- winding breakage at the stator or rotor;

- failure of voltage supply contacts.

For diagnostics, the motor is removed and connected directly to the electrical network. To limit the speed, a resistance is used - a heating element. If there is a malfunction, it must be replaced with a new one.

If the winding is damaged, you can rewind it or replace it with winding from another similar motor. After this, the engine will continue to work without any problems.

The fastening systems differ in different models, but the principle is the same - the retaining bolts must be removed. Also, do not forget to disconnect the motor power terminals. The picture shows the bolts

The motor is removed in the same way as when replacing the belt. If it is clamped by the tank, slightly lift the tank and free the engine. Sometimes you have to remove the side wall as well. There are three main faults - brushes, lamellas, windings.

We have already looked at how to replace brushes. You can check the performance of the windings with a multimeter by probing adjacent lamellas one by one. The discrepancy must be less than 5 ohms.

We will also check the short circuit of all windings: we will place one probe on the body, and with the second we will go through the lamellas. If everything is fine, the resistance will be high.

It is easy to determine the unsuitability of the lamellas - completely remove the rotor from the engine, inspect the collector for the presence of burrs, peeling, and broken contacts

If the windings are faulty, it is better to find the same part and replace it. Rewinding will cost more. Minor peeling of the lamellas can be turned on a lathe.

More: Which drum is good for washing?

Foreign object in the tank, signs and solutions

This state of affairs sometimes happens. Things or parts thereof are pulled into the gap between the cuff and the drum. If they are small, they reach the drain pump and block its operation. Otherwise, they are wound on the heating element, shaft or cross.

If the drum is jammed, and there is a suspicion that this was due to a foreign object, then you should try to determine the location. For a better view, you will have to stick your head into the hatch of the machine, and place the switched-on flashlight on the bottom of the washing chamber so that it can illuminate the interior space.

If the obstacle is not visible, or it cannot be reached through the hole in the drum, you can try to remove it through the niche in which the heating element is installed.

In most models, the heating element is installed under the front, but in some - under the rear part of the drum. Accordingly, to get to it, you will have to remove the front or back panel of the case.

Removing the back panel is much easier; you simply unscrew the mounting screws from it and remove it to the side. To remove the front panel, you first have to remove the top cover of the machine and remove the rubber cuff on the round opening of the hatch.

The doors opened in a vertical washing machine, how to fix it

This reason is inherent in top-loading washing machines. If you do not fasten the curtains tightly, they open when they rotate. The laundry falls out. And all this is hooked, as a rule, onto the heater. The washing machine drum cannot spin.

Before washing, the metal doors of the drum are fixed together with a reliable latch. But over time it wears out, which can lead to their opening.

The extent of damage in such a situation will depend on the moment the doors are opened.

If the opening occurred during the “Delicate Wash” mode, then, as a rule, serious damage does not occur. If the doors are opened while spinning clothes, when the machine is running at high speeds, then damage to the tank and deformation of the drum are inevitable. In addition, the heating element may also come under attack.

The worst consequences of this phenomenon can be deformation of the drum and even destruction of the tank.

After stopping, you can try to turn the drum by hand until the loading hatch appears. If the doors open at low washing speeds, you can try to return the washing chamber to its original position.

Sometimes a metal meter ruler or a stiff wire helps - its diameter should be such that it fits freely into the drum hole. The end of the wire must be bent into a hook. You need to push it between the tank and the drum, and try to close the flaps. This is not always possible to do.

General procedure:

- We unscrew the latches of the rear panel and set it aside.

- We move the side to the side and remove it too.

- We photograph the location of the wires and disconnect them.

- Unscrew the screw holding the shaft.

- Close the loading hatch and take out the tank.

- We separate the halves of the tank and take out the drum.

- We clean parts from dirt and debris.

Now we try to close the doors several times. If the retainer is broken, this part can be ordered from the manufacturer and replaced.

If that doesn’t work, try to hook or close the doors with a wire hook, pushing them through the holes and lighting them with a flashlight. In extreme cases, you will have to disassemble the tank, provided that it is collapsible.

We inspect the doors themselves, the integrity of the tank, and damage to the heating element.

Burst drain pump, signs and fix

Please note that if this malfunction occurs, the washing machine will not draw water at all and will not start the wash cycle. But damage to the pump could occur during operation. In this case, the drum does not rotate and the machine will stand still with water.

Step by step steps:

- Stop the program and disconnect from the network.

- Using an emergency drain, remove water from the tank.

- We change the pump.

- Let's restart.

Frozen program or “reset” error

If there were power surges during operation of the washing machine, the program may freeze in some mode, for example, while the engine is rotating. All elements are in good order.

To continue working, you need to reset the frozen program. This is done differently on different models. Typically, the procedure is described in the user manual or listed on the control panel.

The situation with the error is similar. But it is typical for washing machines of the Bosch and Siemens brands. After eliminating the cause of the breakdown, for example, replacing the motor brushes, you need to “reset” the error. This is done using a special procedure. Sometimes it is described in the SMA passport.

Where and how much to buy a new one?

You can buy a new drum in online stores and in retail outlets that sell spare parts for household appliances.

Experts recommend purchasing the assembly together with the drum . This is especially true when doing DIY repairs.

Installing a one-piece structure is easier. The main thing is to know exactly the SMA Atlant model. Otherwise, the new drum may not fit correctly. The assembled structure costs about 7,300 rubles. A separate drum will cost 3,000 rubles.

The drum rotates slowly

What to do if the washing machine drum is spinning, but very slowly. Let's consider several possible options.

- it is possible for laundry to get between the drum and the tub;

- the bearing is dry or damaged, drum rotation is difficult;

- overload, if there are no weight sensors in the washing machine, the process does not stop, but it is difficult for the engine to rotate the drum at high speed;

- incorrect operation of the tachometer that controls engine speed;

- low speed may also be due to a short circuit in the motor winding. Its power drops - this is a sign that it will soon fail.

Adviсe

- Before loading laundry into the wash, carefully check all pockets, turn out duvet covers and pillowcases - this way you will be sure that small items will not get inside the unit.

- Before starting up your new machine, read the user manual carefully. Follow the recommendations regarding the size and weight of the laundry you load exactly.

- There are special bags for washing underwear and other small items. Experts strongly advise using these bags not only for the safety of things, but also for the safety of the washing machine.

- Do not use fabric softeners, bleaches, anti-scale agents, and do not exceed the dosage of washing powder. Components contained in household chemicals can damage the inside of the washing machine.

- If during the washing process the unit begins to make strange noises, cancel the program and unload all the laundry from it. If the situation repeats when you restart it, it means that the washing machine needs diagnostics and repair.

What you can check right away

Make sure the power plug is connected correctly and that the electrical outlet is working properly. You should check whether the backup protection of the RCD has tripped, blocking the power supply. In modern models, it often happens that an error occurred in the program memory and was not deleted. This prevents the drum from starting properly and it will not spin. To solve the problem, simply unplug the power supply for a few minutes. Then try again to start the washing process. If the drum still does not spin, then the search for the cause should be continued.

Why water does not flow into the washing machine: possible reasons and solutions

You need to perform a few simple steps:

- Turn off the machine and turn off the power.

- On the front panel we find the filter cover; prepare a suitable container. It should fit under the drain cover.

- Place a rag next to the machine (in case water spills on the floor) and drain the water into a container.

- Open the door and take out the laundry.

You can immediately try to find out why the drum is not spinning. Try turning the drum by hand. If something interferes with this, you will immediately feel it. Or it’s completely jammed, or maybe it rotates easily.

This will help us determine the cause of the problem and possible steps to solve the problem.

Replacing the drive belt

Sometimes the reason for the drum moving out of its seat may be a heavily worn drive belt. In this case, you cannot do without replacing this part. This is quite easy to do, because each product has markings, which will make it easy to choose a new belt.

The belt is first put on the electric motor pulley, and then installed on a larger diameter wheel located on the tank. To make the task easier, you can pry the belt with a screwdriver, but even a new, undeveloped belt is usually easy to put on by turning the pulley 1 turn, after first throwing the part onto the wheel.

If the drum in the washing machine falls off, then it is absolutely not necessary to seek help from specialized workshops. You can save a lot if you carry out the repairs yourself according to the recommendations given in this article.

DIY repair

If the washing machine drum does not spin during washing, you can try to fix it yourself. However, devices from different manufacturers differ from each other in some design features and technologies used. Therefore, the repair sequence depends on the model of the washing machine.

Indesit

Let's look at an example of repair using the horizontal loading model WIXL83. If the drum does not spin when the Indesit washing machine is turned on, you should immediately check the belt drive and motor. To repair, the washing machine is unplugged, turned around and leaned on something so that the back wall is free. Next, unscrew the screws securing the oblong hatch, behind which there is a belt drive and an electric motor.

If the belt is intact, then you need to check the motor brushes. Power may not be supplied due to worn brushes or a dirty commutator. The electric motor is secured with two bolts; before unscrewing them, the block with wires is first disconnected. After removal, you can check the length of the brushes and the condition of the commutator. The latter, if necessary, is cleaned to a metallic shine. Short brushes are replaced with new ones.

Samsung

Possible reasons for the drum stopping on a Samsung washing machine are similar to other models. When replacing brushes, you need to make sure that they move freely in the brush holders. Sometimes, due to accumulated contaminants, the forces of the springs are not enough, and the contact is broken. When the electric motor operates, coal dust gets into the gaps and the brushes jam. The problem is solved by removing the brush holders and cleaning the holes.

Another reason for stopping the electric motor is a breakdown of the tachometer located on the rotor. It records the engine speed and transmits information to the electronic control unit. In appearance, the knot looks like a small metal ring, sometimes covered with a plastic casing. There are 2 small diameter wires coming from it.

The tachometer is checked with a multimeter (tester) in ringing mode. The wires are connected to the device and the rotor of the electric motor is rotated by hand. If the sensor is working properly, the multimeter will make short sounds (the needle oscillates). Otherwise, replacement will be required.

LG

In an LG washing machine equipped with a direct drive from an inverter motor, the drum does not spin or jerks slightly due to a broken Hall sensor. When you try to turn it on, a whistling sound is made.

To access the engine, you need to disconnect the unit from the mains and remove the back cover, which is held on by four self-tapping screws. Next, unscrew the central engine bolt. To do this, you will have to fix the rotor. A screwdriver is inserted obliquely into the upper vertical slot of the protective disk and pressed against the head of the hidden bolt. Then unscrew the 6 fasteners of the disk with coils and remove it.

On the back side of the removed element there is a Hall sensor. It is fixed with plastic latches, and the connector is disconnected before dismantling. Use a knife or flat screwdriver to pry up the fasteners and the sensor is easily released. Having replaced the damaged element, everything is assembled in the reverse order.

Bosch

When the drum stops in the Bosch Maxx 5 washing machine, error F21 appears on the display. The machine does not carry out the program and does not fill with water. First, after disconnecting from the network, you need to check with your hand the free rotation of the drum. If everything is in order, inspect the belt drive. Access is via the rear hatch.

If the belt is intact, you need to remove and check the electric motor. To do this, perform the following steps:

- remove the belt;

- place the machine on its right side;

- remove the bottom cover (you will need a T20 sprocket);

- disconnect the block with wires from the engine;

- unscrew the 2 mounting bolts;

- remove the engine.

The tachometer is checked by ringing with a multimeter. If it is in good working order, you need to remove the brushes and replace them if necessary. The sequence of disassembly and assembly of the Bosch Max 4 and some other models in this series is similar.

Beko

The main reason the Beko washing machine drum stops is wear on the brushes of the commutator motor. When turned on, the machine draws water, and then stops showing signs of life. The algorithm of actions for replacing them is standard, but there are some features. Access to the engine is through the rear hatch. By unscrewing the screws and removing it, you can inspect the internal mechanism.

Before removing the engine, you need to release the transmission belt and disconnect the block with wires. The electric motor housing is secured with two bolts with heads that have sprocket cutouts; to unscrew them you will need a T40 socket.

The brushes are inserted into special holders, which are secured to the motor housing with screws.

After replacing the worn elements, everything is reassembled in the reverse order.

Zanussi

Replacing brushes in a Zanussi washing machine is not difficult. But you won’t be able to get to the engine through the rear wall. To implement your plan, you need to place the machine on the floor face up. From below there is access to the motor. It is not necessary to remove it. The brush holders are fixed with self-tapping screws; they are removed after first unscrewing their fasteners and disconnecting the connectors.

The lack of contacts may be due to wear, jamming of the brushes in the guides, or contamination of the armature with coal dust or burning. All causes must be checked and eliminated. The plastic brush holder is disassembled into two halves and the metal guides and brush are removed from there. If you don’t have the part you need for this particular model, you can look for a replacement. It is enough to select brushes of suitable sizes from other units, you just have to solder the wires.

Electrolux

The Electrolux dryer also has a drum, which due to malfunctions one day refuses to spin. The main reason for this problem is wear of the support rollers on the engine or housing. The problem is solved by replacing them. To access the internal mechanisms, remove the side walls and top.

The engine is not removed, but only the tension spring on it is unhooked with pliers. After this, the entire assembly can rotate freely. Next, the old video is removed and a new one is installed in its place. The compressor housing interferes with these manipulations, so it will have to be tilted slightly. Before installation, the shaft is lubricated. Then I set the belt straight and put it on the engine. The drum is rolled by hand several times to obtain the parts of the working position. At the end, fix the tension spring and secure the side walls.

"Ariston"

In addition to the listed reasons for the drum not rotating in washing machines, there are unusual cases. One of them is broken wires. This sometimes happens after inattentive self-repair after removing the engine or drum.

In the Ariston washing machine, the electronic unit is located on the rear wall at the bottom left. The blocks with wires are connected from the inside and directed inward. When performing any manipulations or moving large components, an unintentional impact on these elements is possible. As a result, the pads are crushed or the wires are torn off. Moreover, the gap may not be visible, but there is no contact.

Therefore, before repairing the electronic unit, you should carefully check the integrity of the connections with the device; perhaps the malfunction occurred due to missing contacts. Please note that the connecting blocks are made of thin plastic and disassembly must be done carefully.

"Ardo"

A malfunction occurs when a full drum tries to turn during washing, but cannot, spinning does not occur. It feels like there is not enough power. This is typical for washing machines with asynchronous motors, such as Ardo. Power loss occurs due to a decrease in the capacity of the starting capacitor.

If you open the back wall of the Ardo washing machine, the part you are looking for can be found at the top right above the drum. Using a 12 mm socket, unscrew the fixing nut and remove the capacitor. The failed part must be replaced with a similar one. Ardo has a 16 mF capacitor. If you install an element with a larger capacity, the engine will overheat, if you install a smaller one, the power will be lost.

Methods to prevent future problems

In order for the washing machine to serve for a long time and perform its functions correctly, it is necessary to regularly carry out preventive measures.

- do not close the machine door after washing;

- drain the water through the outlet filter and clean it;

- Clean your washing machine regularly;

- use to protect the device from voltage surges and current leakage: RCD, difavtomat;

- do not overload.

As you noticed, there can be many reasons why the washing machine drum does not spin. We hope that thanks to our advice, you can easily identify the cause of the breakdown and easily eliminate it.