If you want to repair a cooler with your own hands, surprising your household or co-workers, read our material. Here are the typical causes of breakdowns of household and office dispensers, as well as ways to eliminate these faults. And if you want to receive the title “master - golden hands,” then take 15 minutes of time and read the article to the end.

Hot water tap does not flow

If you open a hot tap and the water barely drips or does not flow at all, you need to replace the bottle. But if cold water flows from a hot tap, then in this case you need to:

- Wait 15-20 minutes until the heat exchanger radiator heats up and try to get hot water again.

- Check the power supply - the dispenser may have been disconnected from the network, and without electricity it only dispenses cold water.

- Turn on the fuse - when overheating, the cooler is disconnected from the network, de-energizing the heating circuit.

What to do if there is a full bottle on the cooler and it is plugged in? Of course, contact the specialists from the service center. In this case, repairing coolers yourself is impossible. The technician will have to disassemble the device, remove the broken or clogged heat exchanger, wash it and put it back in place. Along the way, he will check the wiring and change the fuses. This work cannot be done without a special tool.

Even the most experienced craftsman will not be able to make a dispenser at home. Therefore, do not waste money on calling specialists - immediately take the cooler to the service center.

General provisions

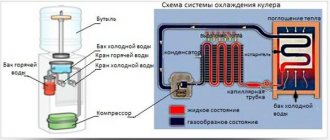

| Designation in the figure | Name |

| 1 | Bottle installation location |

| 2 | Green cooling indicator |

| 3 | Red heating indicator |

| 4 | Yellow power indicator |

| 5 | Cold water tap |

| 6 | Hot water tap |

| 7 | Collection container for drops |

| 8 | Cooling system |

| 9 | Cooling thermostat |

| 10 | Green cooling switch |

| 11 | Red heating switch |

| 12 | Cooling radiator |

| 13 | Network connection wire |

| 14 | Drain valve |

| 15 | Grounding |

As you can see from the given structure of the water dispenser, the faucets are indeed precisely the part with which a person who decides to drink from the cooler comes into contact. Consequently, the requirements for it must be special.

Water does not flow from a cold tap

If lukewarm water flows or drips from the “blue” tap, and not what you expected, try again in 20 minutes. Perhaps the cooler did not have time to cool the liquid. But what to do if neither cold nor warm water flows from the tap? To repair this problem, do the following:

- Unplug the device or raise the temperature on the refrigerator. Sometimes a cold pipe freezes, cutting off the flow of fluid.

- Turn on the water supply and listen to the hum of the compressor. If the stream starts flowing, but the device does not “purr” like a refrigerator, you need to call a technician. Only a specialist can repair the compressor.

- If the compressor hums, but no water drips, change the tap or dispenser needle. These components may not be replaceable. In this case, you will have to buy a new cooler.

To change the needle (rod) of the dispenser, just remove the bottle from the cooler, unscrew the broken unit from the mounting hole, and screw in a new part. Fixing a faucet is another matter. This work requires special skill, so we will consider it separately.

Would you like iced tea or...

I remembered after this post: A knife that heats up and marketers that heat up

About 12 years ago, I worked in a computer store in a warehouse. The task was quite simple: an order comes from a client, you need to find one or more items in the warehouse and bring it for pick-up. The rest of the time the tasks were minimal and it was possible to get tea/coffee. There was no cold water in the warehouse, only a kettle and a tap, which meant we had to wait until it cooled down. As always, while this is happening, work arrives, you forget about your seagull, and when the time comes, it is already cold. Sometimes I brought a bottle of water, but it’s a waste of time, you need to make a detour to go to the store and it’s expensive, especially considering that it wasn’t just me who used it, who would ask permission?)) This is generally a separate topic for conversation, taking food without asking.

After the weekend, when I went to work I came across a processor cooler, or rather just a radiator without a fan, no one knew where it came from or what to do with it, there was no marking, kit or box, and the inventory didn’t give anything, we shouldn’t have such a position . Don't throw it away. For some time he just lay nearby on the table, and attempts to find out his fate led nowhere (cameras were difficult at that time, the quality was poor and they did not always work for recording). In another rush, I pour myself some tea, thinking that I won’t drink it again, while I’m sitting my eyes fell on this same radiator, it looked something like this:

I remember exactly that it was two-section, and the number of copper tubes was from four to six. The thought came to mind: “after all, these things cope well with hot processors,” what if we try to cool tea with it? I wiped it off from dust and placed it in a mug for a couple of minutes. And I clearly underestimated the capabilities of these towers! When I took the radiator in my hand, it was close to hot, but when I tried the tea, it turned out to be almost cold, the tower took almost all the heat from the tea. Empirically, I determined the time it takes for the tea to be brought to the desired state; ~20 seconds is enough. After several shifts, when I came to work, I didn’t find the radiator, no one knew its fate...

alban85

3 years ago

How to fix a cooler faucet with internal threads

To change a clogged tap with internal thread, you need to follow the following plan:

- Unplug the device and remove the water bottle. You will have to partially disassemble the supply line, and this work should only be done with the electricity turned off and the water tank removed.

- Remove failed fittings. To fix a faulty supply line, you need to remove the shut-off device from the pipe. To do this, turn the shut-off fitting counterclockwise, moving it out of place, and twist the broken assembly from the threaded fitting or fitting.

- Buy replacement parts based on the brand of your cooler. Some models support mug pressure, others - hand pressure. If you are not sure that you understand the characteristics of your valve, take it with you to the store and show it to the consultant.

- Before replacing a part that comes into contact with drinking water, it is worth washing it inside and out. Therefore, wash it in a solution of soda or soap, under a strong stream of hot water.

- Put on gloves, pick up the washed fitting, screw it onto the thread, turning it clockwise.

Finally, you need to check how the liquid flows from the new valve. To do this, place a bottle on the cooler and open the valve. At the very beginning, air will come out of the pipe. The water will appear a little later, at first it drips in a thin stream, and then flows in a wide stream. Wait for a steady stream and close the valve. Your dispenser can now be plugged into a power outlet.

Using the same scheme, you can repair a device in which hot or cold water drips from the tap with the valves closed.

Start of cleaning

The question “how to disassemble a cooler” is quite easy to deal with. The first step is to disconnect the computer from the network and disconnect all existing cords. The next step is to remove the housing cover from the left side, while carefully placing the unit on the right side. Next, you need to clean the internal parts of the computer from dust and foreign contaminants.

Since the cooler’s job is to properly distribute air flows, the part, accordingly, removes a lot of dust and small debris from the environment. Most of the unnecessary dust contaminants settle on the radiator and other important components.

Cleaning can begin with the most general actions, for example, using a regular vacuum cleaner. But it’s better to finish more thoroughly - wipe the parts with a napkin moistened with any alcohol solution. You can use both cologne and vodka. Any alcohol-containing substance is good because it does not react with air, dries quickly and does not cause metal corrosion (which is typical for water). Depending on how finely and deeply the cleaning was carried out, the further operation of the computer depends.

How to replace taps with external threads

If your valve stops supplying water or starts leaking when the valve is closed, proceed with the following plan:

- Turn off the device and remove the bottle. A cooler that is turned on cannot be repaired even in theory.

- Remove the back panel by unscrewing the screws with a Phillips screwdriver.

- Locate the silicone tube connecting the faucet to the faucet that is dripping water.

- Feel at the point where the fitting and the silicone pipe meet for the lock nut that presses the faucet to the body.

- Unscrew the locknut from the threaded fitting, turning it counterclockwise. If there is not enough space in the housing, then try fixing the nut and unscrewing the tap, but be careful not to twist the silicone tube. After unscrewing the nut, pull the tap, removing it from the silicone tube.

- Now, to fix the cooler, you will need a new faucet. Take the old valve and go to the store with it. Consultants will help you choose the same model.

- Don't forget to clean the valve before putting it back in place. If you don't do this, you may get an intestinal upset.

- Installation of the valve begins with unscrewing the locknut. It is put on a silicone tube, after which the valve is inserted into the hole in the housing. Then the tube is pulled onto the valve fitting and tightened with a lock nut. That's it, your cooler is now repaired and ready to go.

If these manipulations are too complicated for you, call the experts at home. They will repair a dispenser whose “spouts” are leaking water, without taking the device to a service center.

The main causes of leaks and methods for eliminating them

When a boiler leaks, the first thing you need to do is determine the cause of the leak. There may be several reasons - we tried to list only some of the most common ones.

Hull deformation

Deformation of the outer shell of the boiler - this problem may appear the very next day after installation. The fault here is not the manufacturer’s, but yours, because, as a rule, this situation arises when, when installing a boiler, they forget to connect the safety valve. Install it on the water supply line to the product between the shut-off valve and the entrance to the container. It is this small device that protects the tank from overfilling, which leads to deformation: as soon as the tank is completely filled with water, the valve is activated and shuts off the water supply. As a result, the boiler leaks in less than 24 hours.

If the valve has been installed, but water flows through the supply pipe, then the valve is simply dismantled and a new one installed - any home craftsman can handle this type of repair, even one who has never undergone special training.

Deformation could also occur due to the fact that low-quality pipes were used during installation of the device. In this case, hydraulic shocks due to pressure changes will be transmitted to the internal container, slowly destroying it.

Manufacturing defects

If the source of leakage is located somewhere in the upper part of the boiler, but visual deformation of the container is not observed, the magnesium rod was installed during connection, as required by the rules, and it was replaced during operation, then there may be a manufacturing defect. If the product is under warranty, then you need to return it to the organization that sold it before you flood your neighbors below.

Modern water heaters are designed in such a way that the tank cannot be repaired and cannot be welded: when welding is used, the enamel layer around the hole is damaged, and corrosion will form, corroding the tank in another place. The cost of repairs in this case is almost equal to the price of a new boiler, and modifications made to the appearance of the repaired product will not decorate the interior of your bathroom.

Spent heating element

If water leaks from under the lid of the storage tank of the product, most likely, too much scale has accumulated on the heating element and needs to be replaced. First of all, you need to purchase a similar heating element from a store with spare parts for water heaters, dismantle the old one, clean the inner surface with ordinary vinegar and soda - this mixture corrodes any scale well.

Poor installation of the device

Liquid may leak from under the heating element's O-ring - try tightening the nuts more tightly to eliminate the leak. Sometimes a leak forms along the mounting bolts of the heating element; if this develops negatively, you will have to buy a new heater - welding cannot be used, because the thin walls of the internal container will warp.

A common cause of leaks on cold water inlet and hot water outlet pipes is a loose connection. This often happens with DIY installations if the wrong sealing materials or low-quality fittings are used.

Gasket wear

When water flows through the inspection hole in the plastic cover at the bottom of the water heater, most likely, the rubber gasket on the flange has lost its elasticity. To determine this for sure, you need to turn off the device, remove the bottom cover and visually determine the cause of the leak.

If the gasket is faulty, you just need to replace it. In the store we purchase a strictly similar one - when purchasing, tell the seller the model number of your boiler so that the new product fits perfectly.

Water does not drip from the tap, but flows from somewhere inside the body

You came for water and found yourself in a puddle. What to do in this situation? How to fix a global leak? Let's figure it out together. And we’ll start with the reasons for this breakdown:

- Most often, a puddle under the cooler is caused by a not tightly closed drain valve. Repairing such a breakdown is more than simple - you need to tighten the plug a couple of turns, turning the plug clockwise. If the leak cannot be repaired, remove the bottle, twist the cap and buy a new one.

- The second most common cause of leakage can be a defective bottle. What should you do in this case? Of course, remove the questionable container and put another one in its place.

- Very rarely, the cause of a breakdown can be a burst pipe. To find such a defect, you will have to open the housing and wipe all the pipes with a dry cloth (or toilet paper). If a wet spot appears on the paper, then there is nothing to do here - call a specialist. Such a defect can only be repaired by a specialist.

- Sometimes the heater coil may be the cause of the leak. It happens that the storage tank bursts in the cold and begins to drip. This happens if the dispenser was stored in an unheated room without necessarily draining the liquid. The radiator can only be replaced at a service center. It is impossible to repair such a breakdown with your own hands.

Before replacing the bottle, do not forget to disconnect the dispenser from the electricity. Also, drain the hot water by cooling the disconnected heat exchanger. Otherwise, you will have to change not the bottle, but the device itself. Wiring burned out from a leak is very difficult to repair even in a service center.

Very often, customers contact us about water leaks.

The working cooler suddenly begins to leak inside, and a puddle of water forms under it. In 99% of cases, the reason is a defective bottle - it has a microcrack through which air is sucked into the system - the cooler tanks overflow and begin to leak over the edge. This is a defect of the bottle, not the cooler. You just need to replace the bottle with another one, drain 1 liter of water from each tap and the problem is solved. To do this, you don’t need to take the cooler to a service center or call a specialist - everything can be solved by simply replacing the bottle.

The faucet leaked after replacing the bottle

It happens that just yesterday a working faucet begins to drip immediately after replacing the bottle. The cause of such a breakdown in 9 cases out of 10 is a hygienic seal forgotten on the neck of the bottle. If you forget to remove the paper sticker from the neck before changing bottles, the remaining seal will end up in the silicone tube or get stuck in the faucet lock assembly.

To fix this problem, you need to remove the bottle, dismantle the tap, rinse the silicone tubes and valve, and reassemble the device in the reverse order. There is no need to change the shut-off assembly and tubes. To flush the internal water supply, lower the end of the silicone tube into a bucket and place a half-empty bottle on the stem.

Why is the cooler leaking from below, the problem is in the tank

The seal of the water column cannot be maintained if there is a crack somewhere. In such a situation, the storage tank overflows and a puddle appears under the device. In this case, water flows down the inner, not outer, walls of the cooler. Most often, cracks in the bottle occur from below (at the bottom) and are formed during rough transportation of the container.

But sometimes microcracks appear on the side walls of the bottle. In such cases, the dispenser initially works normally, but begins to leak when the water level drops below the microcrack. If you see a puddle under the cooler, immediately check the storage tank.

If the water cooler is leaking from below (there is a puddle under the device), most likely the storage tank is full. This means that the seal of the bottle is broken and needs to be changed. But if the tank is not full, then the problem is in itself, or in the tubes coming from it. Or in the check valve, which is connected below the tank.

Dispenser noise is too loud

What to do if the dispenser does not flow, dispenses both hot and cold water without a hitch, but makes noise like an airplane? How can I fix the noise? We won’t bore you - this is easier to do than it seems at first glance. After all, the source of dispenser noise is the vibration of the compressor installed with a slight or significant distortion relative to the horizontal.

To remove noise, place the device body level. This work does not require much effort - most floor-standing models have adjustable legs that allow you to change the height of each corner. And desktop models can be placed on a rubber mat or rubber pads of the required thickness can be placed under the corners of the dispenser.

If the source of noise is a constantly boiling dispenser heat exchanger, replace the device’s thermostat before water vapor explodes the tank and storage tank.

The needle falls out or breaks

This kind of breakdown occurs more often than dispenser owners would like. After all, it is possible to repair the needle only on some models that allow dismantling the stem or the entire bottle receiving unit. Replacing the needle involves completely dismantling the bottle receiver. This part is rotated in the mounting socket and pulled up when the slots of the bottle receiver come out of the mounting sockets (at this moment you will hear a characteristic sound). After this, the old part is thrown away, and a new unit with a working needle is put in its place.

If you don’t want to deal with broken needles, buy a bottom-loading dispenser. Such a device does not have a bottle receiver and a rod that pushes the shut-off valve into the bottle cap.