If you want to repair a cooler with your own hands, surprising your household or co-workers, read our material. Here are the typical causes of breakdowns of household and office dispensers, as well as ways to eliminate these faults. And if you want to receive the title “master - golden hands,” then take 15 minutes of time and read the article to the end.

Adviсe

- Before disassembling and lubricating the cooler, blow it out and clean it from dust.

- Remember the sequence of steps so that there are no problems during assembly. Take photos of each stage. Leave notes with a marker.

- When choosing a lubricant, consider its refractoriness and ability to create an oil film. Compare the characteristics of several lubricants and choose the best one. Read the latest reviews on specialized forums. The manufacturer can change the characteristics by updating the range.

- Clean and lubricate the fan regularly, otherwise it will fail and require replacement.

If you have read the article to the end and still have doubts about the need for this procedure, perhaps they are justified.

Only good, expensive coolers are worthy of washing and rebuilding. Sometimes it's better to buy a new fan if it costs less than your time. Source

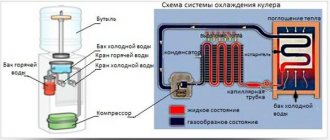

Cooler circuits

The design and design of the cooler depends on its type and purpose, as well as on the water filtration technology.

Flow cooler diagram

A flow-through water cooler consists of a four-stage filter, an ultraviolet lamp, containers for hot and cold water with corresponding elements (heating and cooling). The use of a large number of filters and a UV lamp is due to the fact that the water supply system (pipeline) is used as a water source. They interfere with the reproduction process of viral and bacterial particles.

The flow cooler has a four-stage filter and an ultraviolet lamp, which are necessary for the preliminary purification of tap water.

The compressor cooled cooler consists of the following components:

- sediment filter (Sediment Filter) - purifies water from 90% of suspended particles larger than 5 microns; The sediment filter traps all foreign particles larger than 5 microns

- carbon pre-filter - removes chlorine and organic chemicals, and also improves the taste of water; The carbon prefilter is used to remove chlorine and various organic impurities

- ultrafiltration filter (UF Membrane Filter) or reverse osmosis membrane (RO Membrane Filter) - purifies water from bacteria, viruses, fine particles, dissolved minerals and salt crystals; Ultrafiltration filter purifies water from viruses, dissolved minerals and salts

- Post Carbon Filter - removes odors, tastes and organic substances remaining after passing through a reverse osmosis membrane or ultrafiltration membrane;

- containers and taps for supplying hot and cold water;

- compressor - creates the pressure necessary to convert the refrigerant into liquid and its further evaporation with the absorption of excess heat; The cooler compressor performs the same functions as in the refrigerator, ensuring the evaporation of the refrigerant

- booster pump - sets the pressure to ensure optimal system performance. A cooler with a compressor cooling system consists of a four-stage filter, a compressor, a booster pump and pipes through which the refrigerant circulates

Choosing a drinking cooler is a rather important step, since the quality of water, and accordingly, people’s health, will depend on its type and design. When choosing a cooler, you should focus on the following characteristics:

- Device size.

- Filtration technology. The most preferable would be a device with a multi-stage water purification system.

- The presence of an ultraviolet lamp, especially if children are expected to drink the water.

- The temperature of the water inside the device. It is better if it is +98 o C for hot water and +4 o C for cold. An additional advantage will be the ability to regulate the temperature.

- Availability of additional functions: child protection, dispenser, timer (programming the cooler to automatically turn on/off).

Algorithm - how to disassemble a water cooler yourself

Disassembling the device will not be difficult. The main thing is to strictly follow the established sequence of actions and not scatter the parts, but carefully place them side by side so that there are no problems during assembly later.

Since the cooler is a household electrical appliance, before disassembling it, first of all you need to make sure that it is disconnected from the network.

Any analysis begins with removing the top cover. To do this, you need to remove the screws with a curved screwdriver. You are unlikely to need to completely disassemble the cooler, so first diagnose the reason why you need to do this, and then get down to business in accordance with the algorithm. Typically, analysis must be carried out in case of the following malfunctions or prevention:

Descaling

To do this, all your attention must be directed towards the water heating tank, which is usually located at the top of the device. First of all, remove the drain plugs (depending on the model, their number varies from one to two) and drain the remaining water

Use wrench No. 15 to remove the rubber seal, and from under it, use a small shaped screwdriver to unscrew four screws. Then the power and grounding wires are removed, and then the temperature sensor. Next, you can dismantle the water heating tank. For preventive purposes, the presence of thermal paste is checked; if it is missing, it is applied in a thin layer. Often, the water heating tank is wrapped in fiberglass for insulation purposes; this must be removed for further work. Afterwards, we remove the lid itself from the container (this may require biting off the retaining clips).

Checking or repairing the heating element. Externally it looks like a metal spiral. It is located inside the water heating tank, so you can check it during preventative descaling. First, it is removed and subjected to visual inspection for the presence of microcracks. If they are absent, the operating resistance of the heating element with the passport data is checked with a multimeter.

If there are no deviations or the cleaning was successfully carried out, then the cooler is assembled in the reverse order.

Sanitizing the cooler from germs:

This procedure is best performed before loading a fresh bottle of water.

- First of all, turn the switch to the Off position. (OFF) and unplug the power cord from the outlet. Wait 10-15 minutes for the hot water in the tank to cool down.

- Remove the water bottle and unclip the wall holder from the back of the cooler. Turn the back of the device away from the wall.

- Drain the water from the cold and hot taps into clean containers. Open the rear drain holes and drain the water from them. Avoid direct contact with hot water. Keep children and pets away from the device while draining water. Place the lid and silicone stopper so that they do not get lost. Always maintain the sequence when draining: first you need to drain from 2 taps, then from the drain hole. For desktop coolers, the drain plug is located at the bottom of the cooler. Electronic coolers have two drain plugs on the back of the cooler.

- Remove the water inlet (bottle inlet) by turning it counterclockwise. Add water to the top of the reservoir. It is recommended to do a full cooler cleaning with the bottled water you drink. If you don't have that much water available, you can use tap water.

- Add 50 ml of Cryodez disinfectant (or soda per 1 tbsp. 1 tsp or other product) to the tank. Open the taps to fill the tank faster. When water comes out of the taps in a continuous stream without air, the tanks are completely filled. You can close the taps.

- Mix the water in the tank with Cryodes. Leave the product in the disinfection tank for 30 minutes. You cannot remove the taps at this time, since the tank is filled with water. Otherwise, water will flow out of the taps along with the disinfectant.

- Using brushes and brushes, clean the internal parts of the water inlet, the separator (separator), the cooling tank and the water courses at the bottom of the tank.

- Every 10 minutes, pour water into a glass and pour it into the reservoir. So 3 times in 30 minutes. Five glasses of 200 ml or one liter mug.

- Then drain the disinfectant solution.

Washing removable parts

Now you should rinse the removable parts of the cooler (after disinfection, you can rinse the water inlet; after complete descaling, you can rinse the taps, pipelines, and drip trays). The pipelines are located between the tank and the taps. The taps are unscrewed counterclockwise.

Remove the pipelines. Wash them with a sponge and brush with dishwashing disinfectant and rinse with water

Then put them in place. Attention! When removing the tap, you should keep in mind that taps in coolers come with external threads and internal threads. With the latter option, the taps are removed after disassembling the cooler. The water inlets for some coolers may consist of 1 part, for other models - of 5 parts.

After disassembling the faucet into parts, wash it with a brush and a disinfectant detergent.

It is also necessary to clean the waterways of the faucets on the cooler.

Clean the front panel of the cooler housing (under the taps). Mister Muscle can be used as a disinfectant detergent. You must not scratch the faucet inside or outside, as the inside of the faucet can be damaged and water will leak from it. On the outside, scale will settle faster at the scratch site. Before putting the taps in place, you should wrap fum tape around the threads of the taps. If this is not done, water may leak through the threads.

Water regularly leaks and drips from the faucet

Regular leaks are often associated with damage to the water container. Microcracks on the body are practically invisible visually. To determine the cause of the leak, it is recommended to perform the following actions:

- on the rear wall of the unit, turn off both toggle switches;

- disconnect the device from the power supply;

- remove the water bottle;

- unscrew the plugs on the drain valve;

- drain the remaining water;

- replace the plugs and close the taps;

- install a new water tank;

- check tanks and locks for leaks.

If, while checking the operation of the unit, water continues to drip or flow out, it is necessary to check the drain plug for leaks and look for other causes of the malfunction. The service center is contacted when no possible faults are detected, the entire module needs to be replaced, or the fault cannot be eliminated on its own.

Cooler is leaking

- In 95% of cases the problem lies in the bottle itself. Cracks in the bottle

lead to an imbalance in the cooler's hydraulic system, which is why water leaks. It may seem to you that water is flowing from the bottom of the cooler - this is true, with this problem it flows through the entire cooler and spills onto the floor. This problem can sometimes not be diagnosed simply by visual inspection - try installing another bottle and checking if the leak is fixed. - The problem may also be that the drain plug

on the rear panel of the cooler is not screwed on properly. Try tightening it more tightly or purchasing it and replacing it with a new one. - One of the silicone

supply or outlet tubes is leaking. For diagnostics, unscrew the back panel and check the integrity or tightness of the tube connections. If there are cracks, you can buy and replace the tubes yourself. - If you have a cooler with water supply by pressing with a cup, then check to see if the part above the lever has unscrewed, or if cracks have appeared in the plastic

. Check for cracks both outside and inside, under the panel. - Check the heating tank or cold water tank

. If there are drops on them and water collects from below, then you should contact a specialist to replace the necessary spare part.

Often when there is a problem, they try to find other reasons, where it is written exactly that the cooler is leaking from underneath. In case of any breakdown accompanied by a leak, the cooler will leak from BOTTOM, since water flows downwards - this is physics J. Your task or the task of the master is to determine where the leak begins, and not where it leads.

The faucet leaked after replacing the bottle

It happens that just yesterday a working faucet begins to drip immediately after replacing the bottle. The cause of such a breakdown in 9 cases out of 10 is a hygienic seal forgotten on the neck of the bottle. If you forget to remove the paper sticker from the neck before changing bottles, the remaining seal will end up in the silicone tube or get stuck in the faucet lock assembly.

To fix this problem, you need to remove the bottle, dismantle the tap, rinse the silicone tubes and valve, and reassemble the device in the reverse order. There is no need to change the shut-off assembly and tubes. To flush the internal water supply, lower the end of the silicone tube into a bucket and place a half-empty bottle on the stem.

How to disassemble a water cooler

The algorithm for disassembling dispensers is as follows:

- Use a figured screwdriver to unscrew the screws.

- The back cover is removed.

- The device is inspected internally to determine if there is a malfunction.

- If the water heats up weakly, inspect the metal tank with hot water (at the very top of the device) for scale deposits. To do this, first unscrew the drain plugs located at the bottom of the tank, at the back, so that the tank is free of water. There may be two traffic jams, but there may also be one.

- Using a small curly screwdriver, unscrew the 4 screws under the seal.

- Next, use wrench No. 15 to remove the rubber seals.

- Using pliers, cut off the clamps from the pipe and other connecting pipes.

- Electrical and grounding wires are disconnected after unscrewing the screws.

- The temperature sensor is disconnected from the tank.

- The tank is removed.

- The condition of the thermal paste is checked and, if necessary, applied in a thin layer.

- If there is a fiberglass insulation coating, it is removed, after which the tank is cleaned inside.

- If the heating tank is in order, inspect other components and connections.

Cleaning a water cooler: subtleties and nuances

Before you begin processing yourself, you must take into account that this procedure requires the allocation of free space and takes quite a lot of time. Therefore, it is necessary to prepare in advance a clean bowl for rinsing “trifles”, a soft lint-free cloth, a brush (or a clean toothbrush), and detergent (Mr. Muscle will do for a start). It is advisable to carry out this procedure in the intervals between replacing the container - this will reduce the likelihood of bacteria getting inside again.

The presence of foreign substances on structural elements leads to their coarsening and shortening their service life.External sanitization

First of all, you need to disconnect the dispenser from the electrical network, then remove the bottle and drain the water. Since disassembling a water cooler with your own hands does not involve any particular difficulties, all external elements must be dismantled: the drip tray, decorative panels (if any), as well as the neck opening with a needle for water supply.

Bacteria, getting inside the bottle and settling on the walls of tubes and other elements, can cause serious harm to human health.

All external surfaces should be thoroughly wiped with a soap solution, to which you can add a little iodine or ammonia

In the latter case, it is advisable not to forget about precautions. It's not just the front that needs a thorough cleaning - the back and even the power cord also need a good cleaning.

Sanitizing any cooler is a mandatory event that must be carried out periodically with your own hands or with the involvement of professionals.

Cleaning the cooler: washing removable parts

All removed parts can be washed in a bowl of cleaning solution (or dishwashing detergent). In this case, before rinsing, it is necessary to thoroughly clean the resulting deposits and accumulated dirt. For hard-to-reach places, it is better to use a special brush or toothbrush.

Please remember that plastic parts must not be rubbed with scrapers or a metal sponge!

As an additional measure, you can spray the removed parts with a disinfectant solution and leave them there for 10-15 minutes. This procedure should be performed after primary processing. In most cases, washing a water cooler at home requires following a simple rule - it is better to put the cleaned parts separately.

After washing, they should be handled with rubber or disposable gloves.

Processing of internal parts

Deep cleaning of the dispenser is carried out using a previously prepared solution. For this purpose, both special products produced by industry and the usual ones can be used: vinegar or citric acid. Typically, cleaning a cooler is carried out in two stages:

- Disinfection and descaling.

The prepared solution is poured into storage containers until they are completely filled. In this case, both taps are left open to remove air pockets and allow the cleaning liquid to fill all water supply channels and pipelines. Remove the bottle receiver - the device is unscrewed, and citric acid diluted with water is poured into the resulting hole.

After this, you need to turn on the dispenser and wait until the heating indicator goes out. Then, at intervals of 10 minutes, you need to drain a glass of water, alternately from each tap. The drained water returns back to the cooler. The recommended duration of the entire procedure is about half an hour.

Washing. At this stage, you should thoroughly rinse all internal parts that came into contact with the solution. To do this, you need to carry out a final spill with four times the volume of a standard 19-liter bottle. Despite the fact that flushing a water cooler at home requires significant excess water consumption, it is prohibited to use city water supply as a source!

Pour part of the disinfectant solution into the water tank, leave it there for 10 minutes, then drain through the taps.

Additional cleaning

The final stage of cleaning is washing and disinfecting the internal removable parts that are in direct contact with water: plastic tubes and lines, taps, separator, as well as all kinds of holders.

When using any detergents, pay attention to the instructions supplied with the device. Not every model can be treated with universal tools

It should be remembered that some cooler models allow the installation of taps with internal threads - you need to be careful when dismantling them. Otherwise, cleaning is carried out using the surface washing method described above.

If you wash the device regularly, severe contamination will be avoided.The power of knowledge or the “painful” experience of the past?

Proper handling of the water cooler is at least a 90% guarantee that it will work without breakdowns for many years, so teach your household, office employees and other people who have constant access to the cooler to use it correctly. But in public places (i.e. with free access to the dispenser), you can only hope that the actions of your customers will not cause a breakdown of this equipment.

- Cooler from “A” to “Z”: installation, operation and care

- What is purifier

- Cooler failures

How to choose a lubricant for a cooler?

For coolers, it is necessary to use inert organic silicon, that is, silicone grease or a mixture of silicone + Teflon.

The best option is to use silicone lubricant from the manufacturer. It lasts about 4-5 years and then dries out.

Branded MX-4 lubricant in a syringe

If such a lubricant is not available, Litol-24 will do. This is a refractory lubricant that is not afraid of heat.

The third option is solid oil. The principle of action is the same.

Synthetic or semi-synthetic engine oil creates a surface film at any temperature. As a result, there is less noise and almost no wear. Motorists usually have leftovers in cans in the garage. But it is best to use it together with Litol-24.

WD-40 is well suited for lubricating non-separable coolers. The tube attached to the can can be conveniently inserted into the gap between the body and the impeller. Adhere to the following rules:

- Insert the tube as deeply as possible so that the lubricant (at least partially) penetrates the bearings and does not spray all over the gap.

- When inserting through the gap between the impeller and the housing, do not use much force to avoid damaging the parts.

- If after this procedure the problems remain (noise, “wedge”), repeat the process.

Poor quality packaging is one of the most common reasons why a water cooler leaks.

For some people, the cooler can work properly for many years, while others constantly face the problem of leakage. The reason lies in how correctly the dispenser was used. And this is sometimes very difficult to control. After all, the device can be used by several family members or a large team of office employees.

Although it also happens that a cooler can leak, even if it has one very thrifty owner. Therefore, before the puddle that forms under the dispenser ruins your mood and entails unplanned expenses, you should figure out what problems can be prevented by everyone who bought this useful device.

There is a possibility that the dispenser itself does not need repair. It happens that the integrity of the bottle itself, which contains purified water for the cooler, is broken.

Why doesn’t my computer or laptop turn on after the procedure?

Sometimes after you have cleaned the cooling device yourself, the device itself refuses to start.

This happens for two reasons:

- Incorrect assembly.

- Damage to contactors and wires.

Try to disassemble it again for initial diagnostics. Check if everything was assembled correctly.

Why did the fan start to chirp?

It's worse when all the components are working, but the annoying noise has not disappeared. On the contrary, it is intensifying. This also means that you made a few mistakes during assembly. Most likely the impeller blades are touching the housing or radiator. Often they touch the power wires in some way.

Try to hang it evenly.

Algorithm - how to disassemble a water cooler yourself

Disassembling the device will not be difficult. The main thing is to strictly follow the established sequence of actions and not scatter the parts, but carefully place them side by side so that there are no problems during assembly later.

Since the cooler is a household electrical appliance, before disassembling it, first of all you need to make sure that it is disconnected from the network.

Any analysis begins with removing the top cover. To do this, you need to remove the screws with a curved screwdriver. You are unlikely to need to completely disassemble the cooler, so first diagnose the reason why you need to do this, and then get down to business in accordance with the algorithm. Typically, analysis must be carried out in case of the following malfunctions or prevention:

Descaling

To do this, all your attention must be directed towards the water heating tank, which is usually located at the top of the device. First of all, remove the drain plugs (depending on the model, their number varies from one to two) and drain the remaining water

Use a #15 tool to remove the rubber seal, and from under it, use a small shaped screwdriver to unscrew four screws. Then the power and grounding wires are removed, and then the temperature sensor. Next, you can dismantle the water heating tank. For preventive purposes, the presence of thermal paste is checked; if it is missing, it is applied in a thin layer. Often, the water heating tank is wrapped in fiberglass for insulation purposes; this must be removed for further work. Afterwards, we remove the lid itself from the container (this may require biting off the retaining clips). Checking or repairing the heating element. Externally it looks like a metal spiral. It is located inside the water heating tank, so you can check it during preventative descaling. First, it is removed and subjected to visual inspection for the presence of microcracks. If they are absent, the operating resistance of the heating element with the passport data is checked with a multimeter.

If there are no deviations or the cleaning was successfully carried out, then the cooler is assembled in the reverse order.

Pinch or contamination of the hose

This can be considered a consequence of incorrect manufacturing assembly of the device. This specifically concerns the fastening of faucets. They can be screwed on incorrectly. As a result, the tube through which water is supplied will be pinched. This in turn will block the water supply.

To eliminate the problem, you will have to disassemble the cooler. It will be difficult for a person who does not know the technical intricacies to do this on his own. Defects are often discovered immediately after purchase. If the cooler is under warranty, you won’t have to pay anything.

Recommendations for further use of the cooler

To avoid the need to carry out preventive cleaning of the cooler more often, it is important to consider the recommendations for its operation:

- Before each bottle change, you should thoroughly wash your hands with soap.

- The protective film and label must be removed from a new bottle to prevent debris from entering the reservoir. You also need to wipe the surface of the container with a damp cloth so that less dust gets into the bottle receiver.

- It is necessary to empty the liquid from the pan daily and wipe the taps at least once a week.

Never use tap water! The cooler does not have a filter, so if you fill it with untreated water, scale will form on the heating surfaces faster. Also, untreated water may contain a large number of potentially dangerous microorganisms. They will not only accelerate the process of biofilm formation on the internal walls of the device, but can also cause a deterioration in the taste of drinks and even poisoning.

What to do if the water stops flowing altogether, reasons

Sometimes the water dispenser does not dispense water. The liquid stops flowing for the following reasons:

- the sticker on the neck of the bottle has not been removed or has been partially removed;

- an air lock has appeared;

- the water supply tube is pinched;

- There is a foreign object stuck in the system.

The empty container is removed. Install a new bottle after removing the label. The cork is removed by shaking the container. At the same time, open the tap, holding it until water flows. Foreign objects from the pipes and gaskets are removed after unscrewing the panels. You can open the case yourself only in situations where the warranty period for the dispenser has expired.

How to clean a water cooler yourself

Before starting work, read the operating instructions. For different models, some manufacturers' recommendations may differ, although the general principle of washing is the same for all.

- Disconnect the electrical appliance from the network.

- Remove the empty bottle.

- Make sure the hot water has cooled down. Then open the taps and drain the liquid into a previously placed container.

- Drain the liquid from the system by opening the special drain valves. They are located on the bottom panel or at the back of the unit.

- Cleaning is carried out with a special solution made for washing coolers. They can be purchased from the company, the supplier of the device, or in a specialized store, or you can prepare them yourself. To do this, use food grade citric acid by dissolving 100 grams of powder in 5 liters of tap water.

- Pour the solution into the cavity of the device, having first removed the bottle receiver. To remove the bottle receiver, turn it counterclockwise. Or, an empty bottle is filled with cleaning solution and attached to the device.

- Connect the equipment to the network and wait until the system is completely full. The process takes approximately 10 minutes.

It’s easy to check readiness; just open the taps. If the stream runs full, without interruptions, then the tanks are full.

- Turn on the heating function.

- After the heating indicator goes out, the switch is moved to position “0” and the cable is disconnected from the network.

- After 5 - 6 hours, the detergent composition is drained from the system by opening the taps and valves.

- Then the channels are flushed with clean water. To do this, pour 4–5 liters of liquid and drain it by opening the taps. The procedure can be repeated again.

General provisions

Before looking at the taps that are installed on the cooler, let's pay a little attention to the device itself:

Structure of a floor cooler

Diagram of a conventional floor-standing water machine

| Designation in the figure | Name |

| 1 | Bottle installation location |

| 2 | Green cooling indicator |

| 3 | Red heating indicator |

| 4 | Yellow power indicator |

| 5 | Cold water tap |

| 6 | Hot water tap |

| 7 | Collection container for drops |

| 8 | Cooling system |

| 9 | Cooling thermostat |

| 10 | Green cooling switch |

| 11 | Red heating switch |

| 12 | Cooling radiator |

| 13 | Network connection wire |

| 14 | Drain valve |

| 15 | Grounding |

As you can see from the given structure of the water dispenser, the faucets are indeed precisely the part with which a person who decides to drink from the cooler comes into contact. Consequently, the requirements for it must be special.

It's not a refrigerator, but it's cold

When the resistance of the temperature sensor (thermistor) drops below 33 kOhm, the semiconductor element and the cooling fan turn on.

From the cooling radiator (Fig. 4), on which the fan is installed, a coil goes into the water tank, which absorbs the cold emanating from the semiconductor element, and the water temperature drops.

In practice, this element and the fan can work for several hours in a row (especially in summer, when the ambient temperature is +25 ° C or more).

At other times of the year, as a rule, the cooler turns on automatically for a short time of 5-8 minutes.

As the water in the tank cools, the resistance of the thermistor increases. In table Figure 1 shows the resistance values of the thermistor MMT-1, MMT-4 (designation on the NTC board) at different temperatures. These parameters were established through the author's experiment.

Table 1. Dependence of the resistance of the standard thermistor on temperature

| Temperature, °C | NTC resistance, kOhm | Cooling time to +5° C, min |

| Room regular +22 | 11,8 | 8 |

| Hot summer +25 | 10 | 12 |

| Hot summer +30 | 8,2 | 25 |

| Chilled tank +5 | 33,3 | — |

Thus, the cooler automatically turns off when the thermistor reaches a resistance of 33.3 kOhm.

It is clear that in the hot summer, for hot office guys, the water temperature of +5° C may not be low enough. So, we will have to work on further cooling the water.

Rice. 5. View of the printed circuit board of the cooler temperature monitoring and control device

There are no “manual” adjustments on the board.

It would be possible to change the resistance values in the voltage divider (in the comparator arms), but, in my opinion, this path is irrational and expensive.

Option one

I recommend this as the easiest way to cooling.

Thermistor connection locations are indicated by red lines. Nearby, a circle indicates the location for connecting an additional resistor (marked on the board as RNTC, but not connected).

In order for the cooler to work longer, even after passing the +5° C threshold, it is necessary to replace the MMT-4 resistor (designated NTC) with another one: with a resistance (at room temperature) not 12 kOhm, but slightly lower - 8.2 kOhm or at least 10 kOhm.

Then, when the temperature reaches +5° C, the resistance of the thermistor will increase to 27.7 kOhm and water cooling will continue (this has been established experimentally) - until the moment when the resistance of the thermistor reaches the range of 32-34 kOhm. (there are different values as a result of the experiment). The water temperature at this moment will drop to +1° C. All that remains is to place a glass in the cooler and shudder...

Types of dispensers

Taking into account the principle of operation, equipment and size, coolers are divided into several types, each of which is suitable for use in different conditions. Models are available that supply only cold water, cold and hot, and models with liquid at room temperature. According to their design and operating principle, they are divided into:

- Floor-standing. Free-standing cabinets with a height of 80 cm or more have different designs. The model can be supplied with a bottom or top loading bottle. Floor-standing devices are characterized by high performance and functionality. They are used when chilled or hot water is needed and can operate at high speeds, which is why they are often installed in large companies.

- Tabletop. They are compact in size and have low liquid consumption, suitable for home or small offices. They are installed on the windowsill, kitchen table or countertop, as well as other surfaces. They often operate on the electronic cooling principle and do not waste a lot of electricity.

- With storage space. An additional cabinet can store dishes, cups and food. A number of models have an ozonizer in the cabinet. Ozone disinfects the surface and kills harmful microorganisms.

- With a refrigerator. The built-in chamber allows you to effectively use every part of the cooler. The compressor cooling system regularly maintains the desired temperature. Premium devices have LCD displays that display all the set parameters. A cooler with a refrigerator will be useful in the office.

- Built-in. The model saves space in the room. It can be installed in kitchen units, as well as in cabinets with a special niche. The dispenser is connected to the bottle installed behind the wall using a flexible hose. This system makes it possible to harmoniously fit the equipment into the interior.

- Flow-through. The dispenser does not need to be regularly maintained and the bottle changed. Thanks to the direct connection to the water supply, water enters the system automatically. To prevent contamination of the device and the entry of debris into the drink, the cooler has several filter elements. Therefore, it requires periodic maintenance and cleaning.

- With carbonation. The device has cylinders of carbon dioxide, which is mixed with liquid. This option is suitable for people who prefer sparkling water to regular water. The volume of the container is enough for 1000 servings.

When your water cooler leaks, it's helpful to refer to the instructions.

By looking through the cooler's operating manual, you can also familiarize yourself with options for eliminating the main causes of leaks. However, most dispenser users throw away such instructions. The real lucky ones are the owners of floor coolers with a counter-flow system. But it happens that this option also needs fixing. Often in such systems, the seal on the bottle receiver slips, or the needle falls through.

Detailed cleaning instructions

There are several basic methods for cleaning a cooler; we list the main stages of sanitary work. This method is perfect in a situation where the water has not yet been heavily polluted. Cleaning a water cooler at home is quite simple; you just need to fulfill a few conditions. The most convenient time for professional cleansing is when the liquid runs out. Next, you need to turn off the device and give it time to cool down so as not to get burned when cleaning. Remember that you cannot turn on the device again while you are doing maintenance, otherwise you may damage the heater. Cleaning a water cooler yourself is easy and won't make you sweat at all, you just need to follow the instructions.

Preparatory work

You need to open up the product you usually use to clean dishes and mix it with water to clean the body of the appliance. It would also be a good idea to purchase citric acid; it will cope well with microorganisms and “centuries-old” plaque.

External surface cleaning

Disinfect your hands with an antiseptic, which can be alcohol, good soap, or simply wear medical gloves. Wipe the surface of the machine thoroughly with a damp cloth; it can be pre-soaked in dishwashing solution.

Pay special attention to the grille and the back of the device, you need to remove all traces of dust. After this, you should go over the body again with a dry towel.

External washing is of great importance, as it eliminates bacteria that subsequently enter the machine.

How to wash the inside

To do this, use a prepared mixture of citric acid and water in a ratio of 100 g of product per 5 liters of liquid. If you are wondering: how to clean a fan? – then there is nothing complicated, you need to thoroughly wipe it from dust. Next you need to disassemble and clean the cooler.

Cleaning, disinfection

To perform internal disinfection, unscrew the bottle receptacle counterclockwise. Pour the diluted mixture inside the device so that it fills the receiving tank. Be careful: the liquid must completely fill the tank. To do this, you need to open the taps and monitor the thickness of the jet, which should be the same as during normal operation of the cooler. If the water flow is weak, then you need to add detergent to the tank.

Scale

The method described above, that is, a solution of citric acid, will not only destroy bacteria and algae, but also rid the device of scale. To effectively remove the deposits that have formed, you should plug the device into a power outlet and wait until the water heats up. Then turn off the cooler and drain the water after five hours. How to wash the device? Quite simple: pour clean water and repeat heating, release the first batch and enjoy using it.

Cleaning removable parts

After you have managed to wash the device from the inside, you should move on to cleaning the removable parts. Remove the drip tray and taps and rinse them thoroughly. Don't be afraid to use a brush and dishwashing chemicals. After the procedure, you should wipe these elements dry and put the parts back in place. If you find it difficult to remember the location of the devices, make a note with a marker.

Rinsing

Rinse the container and equipment from the mixture or special compositions purchased in the store and intended for cleaning, fill with clean water. If you feel a sour taste, you need to repeat the procedure several more times.

The washing machine is broken

Life hack, it may be useful to someone, but I’m not sure it will work on all washing machines. My wife started washing, the machine stopped with half a tank of water and issued E03. The forums said: 1. The pump is broken 2. The outlet pipes are clogged 3. The water level sensor is broken. There are instructions for everything about everything, how to disassemble and repair. I got lazy. First, unplug it from the socket and shake it, turn it on, the error goes away. Turned it on. 5 minutes and the error appeared again. My wife has already sat down to look at the new washing machines being delivered. And I... and I remembered my plumbing past. He pulled the drain hose out of the canal, took in more air and blew three times. The washing machine responded with bubbling in the tank. Well, the air has flowed, which means the water will flow. I turn it on, there is no error, I put it on spin and I hear water flowing into the channel. That's it, the machine has spun out and is already humming for the second wash.

gromt

4 years ago

To what temperature does the cooler cool the water?

The reservoir of the device is divided into two halves. In one, the water can be heated to +96°C, and in the other it is cooled using a compressor or electronically using the Peltier principle. In the first case, models are produced with floor installation, and the water temperature drops to +5°C. The electronic model is compactly installed on the table, but the water is not cooled below +10°C.

The name of the device for changing the temperature of water in bottles comes from the English “cool”, which means “cold”. The first device was called a cooler because initially it could only dispense cool water. Modern equipment brings it almost to a boil and the speed of this action can compete with a kettle.

The needle falls out or breaks

This kind of breakdown occurs more often than dispenser owners would like. After all, it is possible to repair the needle only on some models that allow dismantling the stem or the entire bottle receiving unit. Replacing the needle involves completely dismantling the bottle receiver. This part is rotated in the mounting socket and pulled up when the slots of the bottle receiver come out of the mounting sockets (at this moment you will hear a characteristic sound). After this, the old part is thrown away, and a new unit with a working needle is put in its place.

If you don’t want to deal with broken needles, buy a bottom-loading dispenser. Such a device does not have a bottle receiver and a rod that pushes the shut-off valve into the bottle cap.

Why clean your cooler and how often should you do it?

The main factors that contribute to drinking water contamination and increase the likelihood of developing diseases:

- harmful particles enter the cooler and begin to actively multiply in a favorable environment (acceptable liquid temperature), which leads to the formation of plaque inside the walls of the device;

- Considering that one of the functions of the cooler is heating, you can expect the formation of scale on the surface of the heating element, which reduces the quality of the water;

- There may also be bacteria outside: on taps, buttons, the front panel, drip tray, from where harmful microorganisms enter the human body along with the liquid;

- There may be algae spores in the water, which is a consequence of poor water purification; as a result, the liquid begins to “bloom” - it acquires a green tint, and a coating of the corresponding color remains on the internal surfaces of the device.

If the water in the cooler has acquired a greenish tint or the flow has decreased, you need to rinse the device to remove deposits as soon as possible

Cleaning is carried out regularly when changing water manufacturer. In addition, the device must be cleaned after a long period of inactivity, as well as after completion of repair work. If the device is used regularly, dirt should be removed quite often.

The manufacturer of such equipment recommends washing once every 6 months. However, it is better to do this even more often, for example, monthly or every 3 months. As a result, the likelihood of the formation of complex contaminants is reduced. These recommendations are suitable for equipment of any brand: Bosch, Family, etc.

Why is the cooler tap leaking?

Push-in taps often fail due to deformation and cracking of the silicone seal. Intense loads lead to rapid wear of the locking element. Most often, mechanisms for hot water break down, as well as plexiglass rods. When worn, defects in the form of discoloration of the plastic, cracks and other damage are visible on the body. The faucet on the water cooler needs to be replaced. Reasons for leakage include:

- scale from the heating tank getting onto the gasket;

- unwinding of the part, which occurs with frequent pressure with a glass;

- cracking of the body, rod, deformation of the gasket.

Types of cranes

Taps are distinguished by the method of supplying drinking water. Lever and pressure devices are interchangeable. The former are appropriate for situations where blocking accidental water distribution is important. The second ones are suitable for those who are used to using disposable cups. Push-button and keyboard analogues are made for a specific model of water dispenser. Difficulties often arise when replacing them.

Lever

To pour liquid, a person needs to use both hands. One needs to hold the cup, the other needs to press the lever. This dispensing method protects the user from burns if he accidentally touches the locking mechanism. Spare parts with a polystyrene rod are more wear-resistant.

Crane-push

The push model or push tap is easy to use. To pour water, the user just needs to press the trigger with the glass. This type of faucet should not be installed in water coolers that may be used by children. When purchasing a new locking mechanism, you should consider the type of thread.

Push-button or keyboard

These mechanisms are installed inside the housing. They are reliable. There are devices with mechanical and electromagnetic control. The first type is non-volatile. When the device is de-energized, it is possible to supply liquid at room temperature. The second type dispenses water automatically after lightly touching the button. Without power supply, the water dispenser will not work. If it fails, the entire module will need to be replaced.