To increase efficiency and overall well-being, the body needs quality rest. The most important aspect of good rest is good sleep. What will help improve your sleep quality? First of all, a comfortable sleeping place.

A comfortable mattress gives you sound sleep and good health. Therefore, you should pay special attention to your mattress.

A properly selected mattress will ensure a sound sleep. Manufacturers offer a wide selection of various materials with various fillers. Models range from budget to premium. To take into account all individual needs, you will have to shell out a large amount.

Finding a comfortable, high-quality mattress at a low price can be difficult. Sometimes it's easier to make a mattress yourself.

If the amount turns out to be too large for you, there is a way out - to make a mattress with your own hands. This solution will allow you to save money, create an ideal sleeping place for yourself, and thereby ensure healthy, sound sleep.

A mattress made by yourself can be no worse than an analogue from the manufacturer.

There are several types of mattresses that you can actually make yourself. These include:

- foam;

- orthopedic;

- from pillows.

With your own hands, you can create any mattress to your taste: either from ordinary foam rubber or from pillows.

If you have an old, worn-out mattress, just renovate it, it’s even cheaper!

An old mattress can easily be turned into a new one - you just need to properly repair it and replace the cover!

Do-it-yourself foam mattress - an interesting and exciting process

Before creating a mattress, be sure to take into account some points presented:

- Quality – a good product requires accuracy, perseverance and patience. Only a scrupulous approach to the issue will help to obtain the expected results.

- Theory - without basic knowledge and special skills, preparation is required. Before sewing, you should familiarize yourself with the types of fillers, their properties, rigidity indicators and types of covers.

- Materials - the choice of filler, specialized glue, cladding requires responsibility. In some regions it is difficult to find high-quality, durable, safe products. You should prepare in advance for a long search.

Important! Good tools and ready-made sketches of the future creation will facilitate the process of creating an orthopedic product for personal use.

See also: Choosing compartment doors for a dressing room with photos

Case

You can also make the cover yourself if you have the appropriate cutting and sewing skills. If you don't have them, this is a great alternative. Take measurements of the frame of the already assembled mattress base with filling and take it to a clothing and linen tailoring store.

You can also arm yourself with handkerchiefs, thread and a sewing machine and make patterns that you will use to make a full-fledged mattress cover yourself.

The bedspread must be made in such a way that it fits tightly to the mattress, it gives additional strength and elasticity, and at the same time does not shrink or sag. Correct dimensions are very important here.

It is recommended to make the mattress cover removable. To do this, you can sew a snake on one of the sides. It is very convenient and practical.

I believe that the technology is really very simple and you should not have any problems making a foam mattress.

Share your own impressions, ideas and unusual solutions! Thanks to everyone who reads us! Subscribe, ask questions, leave reviews and don't forget to invite your friends to join us!

Selection of tools, material and filler

The main filler that ensures comfort and durability of products in modern production is polyurethane foam or foam rubber. For products without springs, it performs load-bearing functions, in other cases it is responsible for insulating the spring block.

They are produced with different markings, presented:

- brand - first letters;

- density of the material (measured in kilograms per cubic meter) - the first 2 digits;

- rigidity or compression resistance indicator - the next two signs.

There are 6 types of foam base:

- HS (soft) – not used for bedding;

- ST (standard) - made of polyester, the density determines the stiffness indicators, ST 3542 is suitable for sewing, but it can be used by persons weighing up to 80 kg;

- EL (moderate hardness) – reinforced reinforced polyurethane foam; EL 3245 is suitable for obtaining a high-quality base;

- HL (extra-hard) - characterized by durability, reliability, able to withstand the load of the body weight of a full person, the expensive variation HL 4065 is used for springless types;

- HR (highly elastic) - consists of 4 polyols, the high cost is justified by the long service life and increased load-bearing capacity, brand HR 5535 will last 15 years;

- VE (highly elastic) - a new product in the production of polyurethane foam, VE 5020 is distinguished by its quality, durability, anatomical effect, but not everyone likes its enveloping properties.

Preliminary preparation requires purchasing:

- Polyurethane with increased rigidity of the HL level and a thickness of more than 5 cm - for making a frame around the perimeter. If the products will be used by obese people, then an additional base is not needed. In ready-made types for consumers with a large weight, the base is supplemented with a Euro frame.

- The main filler is from the brands EL, HR, VE. Type ST can be used when creating mattresses for the cottage or for guests, with rare use.

- A layer of coconut coir - the material is not included in the list of required ones. Included in the project to enhance rigidity in the form of layers or on one of the sides.

Additional materials and tools are provided:

- tape measure;

- marking marker or felt-tip pen;

- long ruler - to create straight lines;

- a sharp knife to help cut the foam;

- a sheet of plywood - as a substrate when forming the base;

- specialized glue - sold in furniture stores, on websites selling polyurethane foam;

- fabric for the case - jacquard, quilted with insulation, softening lining, bamboo fiber, terry on a waterproof membrane base;

- threads, long zipper;

- scissors for cutting the mattress cover.

Important! Among the required tools is a sewing machine.

See also Sliding wardrobes for the bedroom: beauty in the photo, savings in price

What type of foam is suitable for a mattress?

The most common filling for a homemade mattress is polyurethane foam (PPU), better known as “foam rubber”. There are many varieties of this synthetic material. All of them have different hardness, density, elasticity and are used in different areas of production depending on their properties and characteristics.

Foam rubber for bedding must satisfy two conditions: firstly, to be soft and elastic, and secondly, to quickly restore its shape after load. The main indicator by which the quality of polyurethane foam can be assessed is density. It ranges from 25 to 40 kg/m³ and when marked is indicated by two Latin letters, followed by numbers corresponding to the hardness index.

For the manufacture of mattresses, it is recommended to use the following brands of foam rubber:

- ST - standard, has a density of 25 kg/m³ or more, used in children's products.

- EL - increased rigidity, withstands loads up to 100 kg. Inexpensive foam rubber brand EL2240 will last no more than 5 years. Filler marked EL2842 is considered more durable and wear-resistant. Products made from such material can last more than 10 years.

- HR and VE are highly elastic foam rubber used for the manufacture of luxury furniture. This is the brand that experts recommend for making bedding. Products made from latex polyurethane foam support the body in the correct position, have good breathability, sufficient softness and elasticity.

Before choosing foam rubber for a mattress, you need to check the labeling of the filler and make sure that its characteristics meet the standards.

DIY foam mattress

The simplest model from a polyurethane foam block is made according to step-by-step instructions:

- Measurements are taken on the inside of the bed frame.

- Strips-bars for the frame are cut out: the height of the strips is equal to the thickness of the mattress, the assembled rectangle must correspond to the previous dimensions.

- The pieces are laid out on a flat surface and glued together.

- A base made of foam rubber of lower rigidity is placed inside the solid frame base, the ends of the two parts are glued.

Important! If desired, one side of the product is reinforced with a slab of latex coir (made from coconut palm fibers and latex). It is also glued to the top surface.

See alsoUseful furniture for the home: banquette for the bedroom

Making a mattress

After all the tools and materials have been found, you can begin sewing a mattress for the bed with your own hands. The step-by-step instructions will look like this:

- First, you should measure your sleeping area and decide on the size of the future mattress.

- Afterwards you can begin assembling the frame. The design is necessary in order to eliminate possible displacement of the filler to the sides and to keep its shape well. To do this you will need dense foam rubber 10 cm thick. In accordance with the dimensions of the frame, bars are made and laid on a clean and flat surface in the shape of a rectangle. The elements are glued together using glue; the composition must be sprayed at the junction points.

- The filler is laid. When using one large piece of filler 15 cm thick, it is enough to adjust the material to the dimensions of the frame.

- When using several unequal filler elements, auxiliary manipulations will be needed. If you do not fasten the foam rubber elements together, then over time they will creep apart and the structure will lose its appearance. To do this, a protective (bonding) layer is applied based on the adhesive composition used. The material is sprayed over the entire surface of the layer, after which it is attached to the auxiliary layer. Coconut coir and polyurethane foam can be used as such. The result of such work will be a durable structure with orthopedic properties. The surface will be characterized as hard. A mattress consisting of two layers of struttofiber and a layer of foam rubber between them will be no less comfortable.

- It’s difficult to find foam rubber of the required thickness on the open market, but it won’t be difficult to find thin ones. The solution is simple - glue several layers of polyurethane foam together.

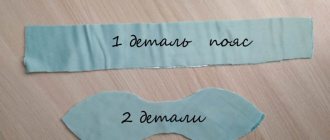

How to sew a mattress cover

In order to make a mattress cover at home, you will need: a sewing machine, thread and a piece of fabric.

After a control measurement of the assembled frame with the placed filler has been carried out, you should begin to cut out the individual elements of the cover. The allowance on each side will be 4 cm, which will be needed for the seams. The cover should fit snugly on the mattress, but not overtighten (deform) it. This will help give the structure additional elasticity and strength. It is impossible to do this on your own, so you will need outside help. At the final stage, one of the sides will be fastened with a pre-sewn zipper. It is not recommended to use buttons. When making a cover, it is recommended to use only natural fabrics that are not capable of causing an allergic reaction. This element is equipped with a zipper, but is not removable. Used as a protective element designed to protect the main structure from contamination. If necessary, a removable mattress cover is made separately.

After sewing the product, it is a good idea to ventilate the mattress. This will help get rid of foreign odors. Anyone who has sewing skills can make a mattress based on foam rubber with their own hands. Only high-quality materials are used as filler.

How to sew a mattress cover?

For the case, natural materials at hand are used, linen or calico. The fabric must not have wool and meet certain standards presented by:

- increased density;

- strength;

- hygroscopicity - easy absorption of liquid;

- resistant to dirt and dust.

An important criterion for a material is the ability to maintain its original shape. There are several variants of cases with their own requirements for execution:

See also: How to choose bedside tables for the bedroom?

Single layer with corner elastic bands

Based on preliminary measurements, a rectangle is cut out with an addition of 3-5 cm at the edges, the corners are cut out according to the template. The further scheme is carried out in stages:

- a layer of fabric is laid out on a flat surface, padding polyester on top and again fabric;

- corner points are aligned, cuts, borders are pinned;

- the product is swept away around the perimeter;

- the case is quilted along the lines that are marked with pins;

- fitting is carried out with trimming of excess edges;

- rubber is fixed on the inside;

- a bias binding is cut out with a width equal to that of the finished part, multiplied by 4, plus 2 cm is added for thickness;

- its pieces are sewn at an angle of 45 degrees;

- in a tense state, one side is stitched to the main part;

- The binding is sewn from the outer section so that the end can turn inward.

Finally, go over the corners with an iron.

See alsoMetal shoe rack in the hallway - a standard of order, emphasizing the classic style of the interior

Option with sides

It is performed using two methods:

- in the shape of a rectangle with stitched sides, rounded corners - used for large mattresses;

- a quadrangle, with an addition to the size of the width of the sides, backing and allowance - a simplified method leads to sharp corner points and a not very neat appearance.

After selecting the appropriate model, the parts are assembled:

- the side strip is prepared - the lower edge is created by folding the closed side, and a hole is left there for the elastic;

- the strip is stitched to the main product;

- the cut is overcast.

Important! The process ends with retracting the rubber band and checking the functionality of the product.

See alsoDesign of a TV stand in a classic style

How to make a mattress smaller at home?

If the calculations are incorrect and the product is too large, you can shorten or narrow it. The process takes place in 5 steps:

- the casing is ripped from the inside;

- Use a marker and a long bar to mark the pattern;

- a section of the block is cut off;

- the sheathing is shortened or narrowed.

The last stage is carefully sewing the cover.

See alsoCreating an interior using modular systems for the living room

How to make a mattress harder or softer?

A thin topper is used for adjustments. To add additional softness to the bed, you can use products based on latex, holofiber (cotton wool, batting) or polyurethane. Latexed coir will help increase the level of rigidity.

Important! Like the mattress, the topper can be sewn with your own hands.

See alsoChildren's transformable bed with chest of drawers and changing table with photo examples

Other tips

In conclusion, here are some tips:

- Accurately measure the dimensions of the components and the dimensions of the sleeping area - the mattress should be dense and not falling apart. And in its place it should lie tightly, without moving to the sides ;

- Do not make mattresses from foam rubber and batting - these materials will not allow you to create a mattress with orthopedic properties and anatomical effect;

- Do not use synthetic fabrics for sewing covers - they can cause allergic reactions and irritation;

- Do not use Bonnell spring blocks to make orthopedic mattresses yourself - on their basis it is almost impossible to create normal mattresses with orthopedic properties.

By following our recommendations, you will make an excellent orthopedic mattress.

approximate cost

The total amount for creating bedding varies between 3-7 thousand. The final price is less than the cost of purchasing a finished product.

The cost depends on many factors and the overall design. If you need a small mattress to cover the sofa while you sleep, its price will not be too high. When a person tries to create a full-fledged orthopedic mattress for a bed with his own hands, he will definitely have to prepare for serious expenses.

See also Furniture decor: decoupage, aging, painting, replacement of upholstery

Results

To make a mattress with your own hands at home, you just need to study the relevant instructions in detail, purchase materials and create a sketch. Foam blocks are an affordable product; when purchasing, you can choose the desired size, height, hardness, and density.

After completing the process of creating a polyurethane mattress and before sending it to the bed, you need to vacuum the product. To eliminate unpleasant odors, just take it out into the fresh air and leave it there for several hours. When ventilating, avoid exposure to moisture and direct sunlight.

Before you throw away your tools...

It is important to have an understanding of mattress sizes and types, foam types and the all-important sleeping position before doing anything. This will help you save time, money and effort.

Standard mattress sizes

- One - 30 x 75

- Twin - 38 x 75

- Double XL – 38 x 80

- In full - 54 x 75

- Queen - 60 x 80

- king - 76 x 80

- King of California - 72 x 84

Types of mattresses

- Innerspring mattresses are also known as the traditional mattress that most of us are familiar with. Springs use a coil system as the basic support structure.

- All foam mattresses are exactly that: all foam. They come in different types such as memory foam and latex or foam blends.

- Hybrid mattresses - A more modern take on innersprings, hybrid mattresses also use a coil system as a support structure, but also use foam as a comfort and base layer.

Foam Types

- Memory Foam - Developed by NASA for use on the space shuttle, they released the design for public use in the '80s, much to the delight of mattress manufacturers. Memory foam is more elastic than regular foam and easily molds to the shape of the human body. Manufacturers have also added their own slight tweaks to memory foam and come up with open-cell foam (to make it more breathable) and gel memory foam (to make it cooler ).

- Latex Foam - Those who are more environmentally friendly usually choose a more natural mattress and latex mattresses are usually made from natural rubber tree latex (Talalay and Dunlop latex). Some latex mattresses may be made from synthetic latex or a mixture of synthetic and natural latex.

Sleeping position and firmness levels

- Side sleepers are for those who sleep strictly on their sides. Side sleepers will benefit most from sleeping on a soft to medium soft mattress. This relieves pressure on the shoulders and hips.

- Rear sleepers are for those who sleep strictly on their back. Back sleepers will benefit more from sleeping on a medium to firm mattress. This helps control the alignment of the spine.

- Stomach sleepers are for those who sleep strictly on their tummy. Stomach sleepers will sleep best on a medium to medium firm mattress. This helps support your hips while keeping your spine straight.

- Combination sleepers are sleepers that switch between different sleep positions. They will benefit more from a medium to medium soft mattress as it provides maximum support for combination sleepers.