We continue to understand how the process of mixture formation in internal combustion engines has changed and how this affected the operation and maintainability of engines.

We communicate a lot with ordinary car owners and service specialists at various levels, so we receive a lot of feedback or questions. Over many years of active cooperation with consumers, conducting all kinds of product tests, we have developed a huge database of repair stories for a wide variety of cars. Today we continue our series of publications about common problems of modern engines. Under no circumstances do we want to make any claims to automakers. All information was collected through personal communication, studying forums and from the personal experience of LAVR experts.

Today we will look at how engines have gotten hotter over the past 20 years, what changes the mixture formation process inside the internal combustion engine has undergone, and how this has affected its operation and maintainability.

Symptoms of a clogged EGR valve

Unstable engine operation (speeds fluctuate), the engine stops working from time to time (situations are especially common under load). There is intermittent movement of the machine. Solid particles from the exhaust and chemicals settle on the shut-off valve mechanism, preventing complete closure. The result is the formation of a vacuum in the intake manifold. Then the engine runs on a rich air-fuel mixture. It needs to be cleaned every 60 - 80 thousand km, but many car owners do not go through cleaning, but wait until the USR system stops functioning.

Signs that your device is heavily soiled

The USR valve ensures proper circulation of exhaust gases and controls their amount returned to the intake manifold for final complete combustion.

There are certain signs of significant contamination, knowing which the driver can clean the unit in time and avoid car breakdown:

- The first and main sign of contamination of the EGR valve is a violation of traction.

- The car does not move well.

- The engine stops frequently.

- The idle speed fluctuates.

- While driving, jerks appear, the engine “troubles”, and detonation occurs.

- During acceleration, engine power decreases noticeably.

In cars running on diesel fuel, the USR valve must be cleaned of carbon deposits after every 100 thousand mileage. When using gasoline as fuel, such an operation is required after 150-200 thousand km.

The product of the functioning of a car engine is nitrogen oxides, an increase in the level of which leads to disruption of the operation of the main components of the car and environmental pollution. During operation, the valve itself and other components of the system (intake manifold, sensors) become covered with a layer of carbon deposits, and this negatively affects the operation of the engine and causes its breakdown. Timely cleaning of the EGR valve will help you avoid negative consequences.

EGR functionality revision

During the inspection, tubes, wires, and other components are subject to inspection. When equipped with a pneumatic valve, a vacuum pump is used for starting. For a comprehensive check, special equipment is suitable that allows you to identify the error code. To carry out diagnostics, you need to know the technical parameters of the device in order to find discrepancies in the declared and final information.

Inspection steps:

- Disconnecting vacuum hoses.

- Blowing through the apparatus until no air passes through it.

- Disconnecting the connector from the solenoid valve.

- Supplying power from the battery to the device via wires.

If the inspection reveals such a breakdown that the device cannot be used, then you need to purchase and install a new one. Often a plug from an existing unit is enough.

Why is cleaning necessary?

The toxicity of emitted exhaust gases depends on cleaning the valve.

The EGR valve performs the following functions:

- reduces the amount of nitrogen oxide emitted into the atmosphere;

- provides additional control over the level of toxicity of fuel combustion products;

- provides low engine detonation;

- increases the completeness of fuel combustion;

- reduces the time required to warm up the input path.

If the system is unstable, the car moves jerkily and stalls. When the situation worsens, the overheated exhaust gases come into contact with the oil, which provokes other breakdowns. Therefore, it is important to carry out cleaning in a timely manner so that the following does not happen:

- contamination of the manifold from the inside, as well as the intake valves;

- malfunction of fuel nozzles;

- accumulation of soot on spark plugs;

- destabilization of the motor.

Selecting diesel egr cleaning products

Car owners complain that cleaning is of no use. But high-quality cleaning of components and assemblies is possible provided that the vehicle owner uses products specially produced for these purposes to perform operations. Do not forget: when cleaning the EGR system, do not use devices that scratch the surface of the parts. You don't even need to use a soft toothbrush. Only aerosol liquids are applied to the treated surfaces of the device.

The most effective:

- foam-forming carburetor cleaners;

- foaming agent in the form of a spray;

- USR, turbine, intake tract cleaner;

- carburetor flushing.

Carbon deposits are removed from the walls with a foam cleaner. The procedure is repeated up to 6 times. The number of repetitions depends on the thickness of the carbon layer. It is possible to keep the system operating stably by waiting for the moment when the dirt is removed from the action of the chemicals.

Carburetor flush is used as a means of soaking valve parts if they are significantly dirty. After soaking and pre-cleaning, you can use a spray. The product will help remove any remaining dirt.

What it is?

The EGR valve is a device that is responsible for returning exhaust gases back to the intake manifold for reuse together with fresh portions of fuel. The main task is to reduce toxicity when the engine is running in warm-up mode or if the driver fully depresses the gas pedal and also begins to accelerate sharply. Signs that the USR needs to be cleaned are:

- frequently stalling engine;

- instability of engine operation at idle speed with floating speed;

- car jerking when starting;

- flame leaks from the exhaust pipe.

How to clean the egr valve

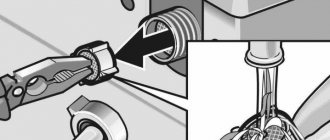

First it is removed from the car. Before dismantling, you need to purchase new valve gaskets. The old ones are pressed in and air is leaking through them. The EGR valve is located in front of the intake manifold. Sometimes it is between the intake and exhaust manifolds, the connection goes through the tubes.

Cleaning the USR does not require the use of special means. Regular WD40 will do. Carburetor cleaner is also suitable. This cleaning option will bring more noticeable results. You need to pour the cleaning agent onto the contaminated parts and leave for a few minutes to soak the dirt. Then clean it using available means, let the valve dry, and put it back in place. We must not forget that new gaskets will need to be installed.

If you experience symptoms of a clogged USR valve, we recommend that you contact a specialist as soon as possible, which will allow you to quickly eliminate problems with uneven engine operation. The staff will be happy to help you. To do this, simply fill out the form below.

How do you know when the EGR valve needs to be cleaned?

Car manufacturers recommend cleaning the exhaust gas recirculation valve every 80,000 km. However, it is worth reducing this period if you notice any of the following symptoms:

— Unusual noise or engine knocking;

— The engine suddenly stalls;

— Rough idle;

— The Check Engine indicator lights up;

— There was a smell of fuel when the engine was running;

— Increased fuel consumption.

How to remove the adsorber valve

This procedure is not particularly difficult on the Chevrolet Cobalt and Ravon R4. Yes, on some cars this valve is located outside and, in principle, no dismantling is required, but still, 15 minutes is not that much time that is worth saving and continuing to drive with the wrong mixture.

Tools you will need:

- Torx bit T‑25;

- Head 10;

- A screwdriver with a straight slot (flat, minus - in common parlance).

To access the valve, you will have to dismantle the air filter along with the box, the corrugated air duct of the intake system and the throttle valve.

We unscrew two screws with a Torx head (star) of the air filter box cover:

For convenience, you can use a slotted screwdriver to loosen the clamp on the air duct and put the cover aside. Next, remove the air filter and simply pull the lower part of the box housing towards you and to the right towards the engine:

Removed air filter box. As you can see, the dirt remains at the bottom and the filter successfully performs its function.

Taking this opportunity, we clean it of sand and other debris and put it aside. Next we are interested in the throttle valve. Loosen the clamp on the intake air duct on the throttle side and remove it. In order not to check the strength of the latches of the wiring chips on the sensors and the “crocodiles” for attaching the pipes, we simply put it aside and gain access to the damper:

Throttle body with intake duct removed.

We find a fairly dirty damper and proceed to dismantle it. This is done simply, you need to unscrew four bolts with a ten-point head:

Throttle valve mounting bolts

It’s easier to disconnect the chip afterwards, because the first time it’s not immediately clear how to do it correctly without breaking it. Although those who have already changed spark plugs have encountered this type of latch and know perfectly well how to deal with it