Date: 05/07/2015

We think that we will not be lying if we say that almost every person on the planet knows what a washing machine is, of course, if this person lives in society and not in the deep taiga. And in the taiga, they probably already know about washing machines. We all use them, but few of us have thought about the operating principle of an automatic washing machine. Today we want to tell you how an automatic washing machine works, what washing processes the laundry goes through and we think that you will like it.

We will tell you in the order in which this process occurs, i.e. for you it will be as if you are taking part in the process of washing your laundry and watching it from the outside.

Start of washing

It all starts with the fact that we load laundry and powder into the washing machine, open the water supply tap, and then select a washing program. As soon as you have selected the washing program and pressed the start button. The software module received a signal from you that it needs to start washing. The washing process is already built into it and will be performed according to a specific pattern that you have chosen (washing program).

First of all, the laundry loading hatch is blocked to prevent its accidental opening during the washing process. Next, a signal is sent to the water supply valve, which opens. At this time, water begins to flow into the powder receiver and wash the powder from the tray into the tank. As a result, the tank fills with water.

The washing machine is equipped with a water level sensor, which determines how much water is in the tank and as soon as the sensor is triggered, the water supply valve closes. That's it, now it turns out that in the tank there is water with powder, and in the drum there is dirty laundry in this water. The machine is ready for washing.

Water supply

Water is supplied to the washing machine through special hoses connected to the water supply in the apartment. How long it takes to fill the tank depends on the equipment parameters. The system can be set to a certain level for washing.

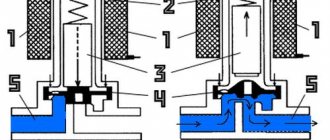

The design also includes pressure monitors, which are small sealed containers with membranes at the inlet. As soon as the desired water level is reached, the pressure inside the container increases. The contact system allows you to close the valve, thereby stopping the flow.

Some machines use pressure sensors in the form of special electronic controllers created using semiconductor technology. In this case, increasing water level with increasing pressure changes the electrical conductive characteristics of the device. The received signal is sent to the control board.

The regulators protect the system from flooding, prevent the heating element from running dry, and also act as foam detectors.

How the washing machine drum works

To make it clearer, we’ll tell you how the tank and drum work. A tank is a kind of reservoir, like a barrel, inside of which there is a drum. Water is filled into the tank, and it enters the drum through small holes with which it is completely permeated. The tank always remains stationary and the drum is driven by a motor through a belt. To remove the drum of a washing machine, you always have to disassemble the tank, and nothing else.

If this LG is with direct drive, then this whole thing can be done without a belt.

Features of units with vertical loading

Top-loading washing machines have most of the parts the same as front-loading models: tank, drum, motor, shock absorbers, etc.

Top-loading washing machines have some design features

The body of such units is equipped with a hinged lid through which laundry is loaded. The drum is mounted on two bearing units and has flaps (many units are equipped with a self-positioning sensor, which ensures that the flaps stop exactly opposite the top cover). The control panel is usually located on the far side at the top of the case.

Many units of this type do not have a rubber sealing collar, since the design features of the tank and drum (with a hole at the top) practically eliminate water leakage through the lid. For the same reason, forgotten laundry can usually be added to such a washing machine throughout the entire wash cycle.

We hope that our article will help you learn more about a home assistant.

Washing machine washing process

We have laundry in the tank, water and powder too. And the programmer gives a signal to the engine to start rotating. The motor begins to rotate the washing machine drum. What is happening inside at this moment? The drum begins not only to splash water, but also to turn the laundry over with the help of special metal protrusions inside the machine, you can see them below in the photo.

There is a mechanical effect on the laundry, similar to what we do when we wash clothes by hand. Only compared to hand washing, everything happens much faster and more efficiently. Since washing in many programs occurs with warm and hot water, the electric heater is turned on, which heats the water until it receives a signal from the temperature sensor that the water has heated up to the required temperature.

A heating element is a tubular electric heater located at the bottom of the tank and is intended only to heat water. The washing machine makes a certain number of revolutions in a certain direction, at a given speed, depending on the program you set.

Main components of the car

Despite the huge number of models and brands, upon closer examination it turns out that all passenger vehicles are designed the same.

The main parts of any car:

- Engine (motor). The device transforms thermal energy into mechanical energy, which is necessary to transmit torque to the wheels. In other words, it makes the car run;

- Transmission (power train). Responsible for the same torque that is stimulated by the energy source from the motor. This unit includes the following units: gearbox, clutch, cardan transmission, drive axle;

- Chassis (in common parlance – “chassis”). Mechanical basis of car movement. The design includes front and rear suspensions, wheels, drive axles;

- Control systems. Strictly speaking, this is the steering system (to drive) and the braking system (to stop);

- Electrical equipment. This includes the battery, wiring, generator. In a word - sources and consumers of current.

All of the above elements are attached to the supporting structure - the car body. The latter consists of the bottom, front and rear side members (power frame parts that make it strong and stable), engine compartment, roof and attachments (doors, hood, trunk lid, bumper, fenders).

This list is just the tip of the iceberg, but it is quite enough to begin to understand the basic principle of the car.

If you are looking for a textbook or manual that describes the structure of a car in an easy and accessible way, “for dummies,” we recommend that you pay attention to the book by Beskaravayny M.I. “The design of the car is simple and understandable for everyone.” The manual can be easily downloaded online from any online library.

Draining water and rinsing clothes

After the washing program pattern is completed, the programmer sends a signal to the drain pump so that the latter begins to pump out water and drain it into the sewer through the drain hose. Dirty water is drained. The pump operates until a signal is received from the water level sensor indicating that there is no more water in the tank.

The rinse cycle then starts. Similar to the start of washing, water is supplied to the tank, only this time without powder; instead, the machine washes out the container with rinse aid. Water enters the tank again, and the machine begins to rotate again according to the given program. The process can be repeated, the machine can fill and drain water more than once, depending on the rinsing mode. After the machine has finished rinsing, the water is drained into the drain again and the spinning process begins.

Main details

The story about how an automatic washing machine works must begin with a description of its parts. In the diagram below you can see the main internal elements and their location. In addition to them, the car may also have additional parts, for example, various sensors, relays, etc.

Here is a schematic representation of the structure of a washing machine

The main components of the washing machine include:

- body (panels, top cover and hatch door);

- control panel and electronic module;

- tank and drum;

- engine;

- tubular electric heater (TEH);

- water intake system (valve, water level sensor, etc.);

- water drainage system (drain pump, filter, etc.);

- balancing system (springs, shock absorbers).

Additional components can be entire systems, for example a leakage protection system, or individual sensors, for example a laundry moisture level sensor in units with a drying function.

Let's talk about the main components in more detail.

Housing and its elements

The body of the washing machine consists of a front, rear and two side panels, as well as a top cover. A hatch door, a lock mechanism and a rubber cuff are mounted in the front part. The door sometimes has a small window (opening separately), through which you can add items to the washing machine drum during washing.

In some models of washing machines, you can add items during the washing process through a small window in the hatch door

The rubber cuff serves to ensure a tight fit of the door and protect against water leakage. The lock mechanism is connected to the control module, which blocks the hatch when the washing program is turned on. At the bottom of the front panel there is a door behind which the drain filter is located.

The back panel, as a rule, is solid, but there are models of washing machines in which part of the back wall can be removed separately.

On some models, part of the back wall can be removed

Control panel and electronic module

The control panel is the “face” of the washing machine, and the electronic module is its “brain”. The panel contains levers and buttons that allow you to select the required washing mode, start the operation of the unit and monitor its progress. Most modern models are equipped with a liquid crystal display, which displays all the necessary information (how many minutes are left until the end of the cycle, whether the hatch is locked, etc.), and in case of problems, information codes are displayed, by which you can recognize the nature of the malfunction.

Using the dashboard, you can select the washing mode, start the washing machine and monitor its progress

The electronic module is located directly under the panel; it transmits commands to all units of the unit and controls their operation. The module's memory contains washing programs and functions that the equipment can perform. For proper operation, the board needs information from different parts of the machine, which it receives thanks to signals from sensors (tachometer, thermostat, etc.).

Pictured is a washing machine control module

The control module and other electronic parts of the unit are especially sensitive to voltage fluctuations.

Tank and drum

A tank is a plastic container with a drum inside. Together they occupy most of the internal space of the case. The structure of the washing machine drum is quite simple - it is made of metal, and there are holes in the surface of the part through which water passes during washing.

In the photo you see a washing machine tank with a drum inside

A bearing unit is installed in the drum - a connecting link between the shaft, pulley and motor, which transmits torque to the drum. The unit consists of two bearings and a rubber seal; the smooth rotation of the part during washing depends on its performance. To extend the service life of the unit, do not overload the washing machine drum with laundry.

The arrow in the photo indicates the location of the bearing assembly.

Engine

The electric motor rotates the washing machine drum. The belt-driven motor is located under the tank, and its shaft is connected by a belt to a pulley - a wheel attached to the drum shaft. With this design, torque is transmitted from the engine to the drum using several parts.

In the photo you can see the structure of the motor with a belt drive

In units equipped with direct drive, the motor is located directly on the tank; there are practically no connecting links between it and the drum - the torque is transmitted directly.

The photo shows an inverter motor with direct drive

heating element

A tubular electric heater is responsible for heating the water to the temperature required for washing. Essentially, it is a curved metal tube that, when heated, transfers thermal energy to water. The part is usually installed in the lower part of the tank under the drum. The water temperature is controlled by a special sensor – a thermostat.

The heating element is installed in the washing machine tank under the drum

Over time, due to constant contact with hard water, the heating element becomes covered with limescale, so in order for it not to fail, it must be cleaned periodically.

Water supply system

The water intake system consists of an inlet valve, an inlet filter and pipes connecting the detergent compartment with the water supply hose and tank. The inlet filter traps large debris that can get from the water supply into the unit, and is installed at the point where the water supply hose is attached to the washing machine. Usually this is a small round mesh made of plastic or metal.

The inlet valve is responsible for the water supply

The inlet valve ensures the supply of water to the tank and detergent tray, and also shuts off its supply when the pressure switch (water level sensor) sends a signal to the control module to fill the tank to the required level.

Water drain system

The main element in the water drainage system is a pump or pump. On one side, the part consists of a volute containing a filter, and on the other, an electric motor with a cross impeller. When the control module transmits a signal to the pump, the motor begins to pump water out of the tank and discharge it through the drain hose into the sewer.

Here is a schematic representation of the structure of a washing machine

The filter protects pump parts from debris. It needs to be cleaned from time to time by removing it through the door on the front panel of the case.

Balancing system

The tank and drum have a fairly large volume and weight, and when washing they vibrate quite strongly. To balance the resulting vibration, a system of counterweights is installed in the body of the machine - concrete blocks that are attached to the top and bottom of the tank.

Counterweights help dampen vibrations that occur during operation of the washing machine.

In addition, the tank is installed on shock absorbers, and suspended from above on special springs, which also helps dampen vibrations that occur during the washing process.

Next, let's look at the general operating principle of a washing machine.

Spinning clothes

As soon as the washing and rinsing program is completed, the laundry spin program is turned on (provided that it is not turned off). The operating principle of spinning clothes is based on the laws of physics: the drum spins up to high speeds (usually 800-1600 rpm on different washing machines). The centrifugal force begins to push the laundry outward, pressing it against the drum, and at the same time all the water in the laundry is pushed out. If the laundry itself has nowhere to go beyond the aisles of the drum, then the water through the holes in the drum goes beyond its aisles into the tank, where it flows to the bottom of the tank and is pumped out by a pump into the sewer. Accordingly, the higher the spin speed, the more water will come out of the laundry and the drier the laundry will be.

As you understand, the laundry unwinding in the drum creates an imbalance, forming the eccentric principle. To prevent the machine from vibrating too much, heavy counterweights are installed on the tank to compensate for this load.

The spin speed of laundry in different programs may be different; for delicate fabrics, the spin will be at lower speeds or completely turned off; for fabrics that do not require special care, the spin will be maximum. You set all these parameters by selecting the washing program at the beginning.

End of wash

After all washing, rinsing and spinning programs have been completed, the machine ends the program. But before that, he makes several rotations with the drum so that the laundry is evenly distributed throughout the drum. The car stops, but you cannot open the door. The lock has a lock, which is released 1-2 minutes after the end of the program. After this time, the hatch lock will unlock and we can take things out of the machine and go hang them up.

If the door of your washing machine does not open after finishing washing, then read how to unlock the washing machine door at this link.

We have described the operating principle of an automatic washing machine quite simply, from the point of view of the common man, without going into technical details. After reading this article, you will understand the general principles and know how a washing machine works. If you want to delve into this topic in more detail, then read about the structure of a washing machine on our website.

Material and manufacturing technology

The body of a modern passenger car is made of high-strength steel, which goes through several stages of processing. The small thickness of the metal used makes it possible to significantly reduce the overall weight of the machine, which has a positive effect on its dynamics and efficiency. Despite the small thickness of the steel, the body structure is designed in such a way that it is both light and strong.

On most modern cars, body parts are joined together by spot welding. This makes it possible to ensure reliable connections between elements and reduce the number of edges and sharp corners that are most vulnerable to corrosion. In the future, the automotive industry will use laser welding of parts. This approach minimizes the presence of bulges and depressions at the seams, and the body structure will become simpler and more reliable.

Post Views: 20,124