The ink cartridge may dry out due to the printer being idle for a long time or as a result of untimely refilling. Manufacturers of inkjet printers are categorically against any manipulation of cartridges (except for their complete replacement), but in most cases this expensive procedure can be avoided.

Recovery methods

If this procedure does not help the first time, you can repeat it or try another recovery method.

The recovery process for black and color cartridges with built-in print heads is the same, but it is easier to restore a black cartridge than a color one, because If it contains one color, then the chances of getting a positive result are greater.

Method 1. Soaking

If the cartridge with a sponge inside dries out, you should try to soak the sponge. To do this, place the cartridge in a vessel filled with distilled water or washing liquid with the nozzles down (in the same position as it is installed in the printer). Soaking can take quite a long time (from several hours to several days.) It is important to pour little water so that only the nozzles are immersed in it (to a height of about 1 cm). Then the cartridge is filled with ink. It doesn't hurt to pump the ink through the suction cup with a syringe, but don't use too much force. Pull the syringe slowly, without sudden jerks, and when the ink begins to come out evenly and in large quantities (no more than 10 ml), it is better to stop the procedure. Before inserting the cartridge into the printer, wipe it clean of any remaining ink, and pay special attention to the electronics contacts. Do 2-3 head cleanings and print a test page.

Or : pour the composition generously onto a napkin and place the cartridge with nozzles on the napkin and let it sit for 1-3 days if it is very dry. Then blow out with a syringe with a rubber adapter in both directions; blow directly into the nozzles (the main thing is not to overdo it with blowing). HP, Lexmark, Canon and the like are quite successfully restored using this method.

Manual ink pressing

In order for the ink from the cartridge to get onto the paper, a set of certain mechanisms is used inside. The design is such that it is possible to manually push out a certain amount of ink, which will allow you to clean the nozzles. There are 2 ways in total.

Method 1 (difficult)

For this method you will need a regular syringe.

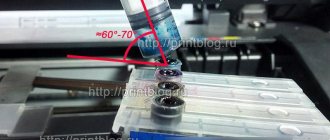

- You need to find a small hole on the back of the cartridge. It acts as an air intake. It is necessary to insert a needle placed on an empty syringe. You need to insert so much that it rests. The part of the needle that remains outside needs to be measured.

- From the end of the needle, cut off the amount that does not fit. Next, you need to take a small piece of rubber material and put it on the base of the needle. It will serve as a gasket and will prevent unnecessary physical impact on the plastic, which can lead to breakage.

- Place the cartridge with the nozzles down on the paper. It will absorb any paint that should run during cleaning. We reinsert the syringe, but this time with air, and slowly squeeze it out until drops appear on the nozzles.

Now all that remains is to remove the released ink, and you can start printing.

Method 2 (easy)

To clean the cartridge using this method, you will need a rubber pad, which may be supplied with it (not available on all models). If it is provided by the manufacturer, then the sequence of actions is as follows.

- There is a hole in the cover. You need to insert a syringe into it without a needle.

- Now it is placed on the cartridge with the syringe installed.

- Holding the paint hopper on the table and pressing the pad (it creates a kind of vacuum), you need to pull the syringe plunger towards you, pulling the ink through the hole.

This completes the cleaning process. All that remains is to make sure that the ink does not leak. If there are any residues on the nozzles, they are simply removed.

Method 2. Boiling or 'the principle of boiling pasta'

- small iron bowl or ladle

- pliers and pliers

- napkin or toilet paper

Instructions

- With the printer turned on, open the lid and wait. and the cartridges themselves move to the replacement position. It is enough to lightly press its box down and it will come out easily. We take out the cartridge

- Now you need to heat a small amount of water on the stove in an iron bowl or ladle so that the water boils and steam comes out. We take the cartridge and hold the print heads over the fumes, you can rinse for 2-3 minutes by lowering the print cartridge into boiling water. Be careful because... The cartridge will heat up, so it is better to hold it with pliers. Just do not squeeze it under any circumstances to avoid damage.

- The dried paint in the head should become wet and begin to drip; wipe off all excess with napkins until all the colors come through. This can take quite a long period of time, depending on the degree of neglect of the printing nozzles.

- If the inkjet cartridge has not been used for a long time, you will have to wash it from the inside. Be careful when opening the lid. Older models have a special metal device for this. Don't be afraid of a little crunch, you can't do without it. On new printers, the cover is sealed with adhesive tape; first you need to get rid of it, and then carefully open it with a screwdriver. The main thing is to prevent cracking of the walls, this can render the container unusable. We take out the absorbent inserts and rinse them with warm water, be sure to remember where each of them was located.

Installation and configuration process

Before assembling the printer, the head is dried and placed back. The latch is lowered and the cartridges are installed in their original place. After installing the head and cartridges, print a test page. At first, extraneous lines may appear on the piece of paper. The text may be faded and unclear, and the pictures may be too, but don't worry. Once installed, the head often becomes misaligned and requires additional calibration. Calibration is carried out as follows:

- place a small stack of paper sheets in the tray;

- connect the printer to the PC;

- in “Control Panel” find the “Devices and Printers” item;

- open the menu;

- select the “Properties” item and the “Advanced” tab;

- in the tab there is an option “Align manually”, check it and save it;

- after saving, go to the “Maintenance” item;

- find the inscription: “Alignment of heads”;

- After this, questions are answered and the calibration comes to an end.

Advice! A test print must be done once every seven days. This is relevant if the printer is not used for a long time.

Method 3. Steaming

You take a dead, dead cartridge from an inkjet printer, which has been lying around no matter how long and has dried up tightly and all sorts of soaking, blowing, and ultrasonic baths do not help and everyone says throw it away and buy a new one - try this method and everything will work. This method applies to HP, Canon, Lexmark cartridges with a built-in print element. Take a kettle, boil water, when it boils and pour it into some bowl, the water depth is about 1 cm in and immediately lower the dried cartridge into this boiling water with the nozzles downwards, just before that remove the top sticker covering the holes as the paint will expand greatly and can flow out through top filling holes, hold in boiling water for 30 seconds and do this three times (carry out all operations with a refilled cartridge). Then you wipe the cartridge nozzles with a napkin and put some photo into the printer to print at the best quality, it will immediately turn out to be anything, then you make 4 main color sheets completely of the same color and print to run each color, the quality will still not be very good for In order to eliminate this, print any photo and in the printer settings set the quality to normal (not fast, not draft, but REGULAR). I would be most grateful if you leave a review here; I would also be grateful if you recommend this site to your friends.

Method 4. Under running hot water

Sometimes it happens that the cartridge head becomes clogged or dries out. In an attempt to clean the head, you have tried many methods for cleaning cartridges, but none of them helped you. I found another way to clean (restore) the ill-fated cartridge. To do this, you do not need to buy anything additional, such as “Liquid for cleaning cartridges”, “Special devices”, etc. To do this, take the cartridge and place it upside down in the bath, head up. Next, turn on the hot water, with a small stream of water. This stream should accurately fall on the head with nozzles. Thus, the cartridge should stand for a couple of minutes. The cartridge needs to be moved a little so that the falling stream of water hits all the nozzles. The meaning of this method of cleaning printing elements is as follows. Water falling from a height of about a meter picks up speed and passes with force through the nozzles (holes through which ink splashes onto the paper during printing) and cleans them. The jet also breaks through dried channels that you had previously resisted. After this procedure, close the tap, take the cartridge and place it head down on a cloth and let it dry. Wipe it down and put it in the printer. Print a test page. If you are not lucky the first time, repeat the procedure several times.

If these methods do not help you, see more material on cartridge recovery below

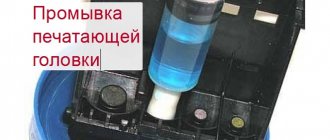

Soaking

Take a lid from a jar and pour a cleaning liquid into it (suitable for windows) a few millimeters high.

Place the cartridge with nozzles in the liquid and leave for 1 or 2 hours (see photo on the right). We take it out, wipe it and check the ink print. If the print is not clear, change the cleaning liquid in the lid and leave it for 1 day. To prevent the liquid from evaporating, you can cover it with some kind of plastic container or change the liquid every 6 hours.

Checking the nozzle print. If the latter does not suit us, then we refill the cartridge with a cleaning agent. For internal use, I would buy a special one. Place the nozzles in the lid with cleaning liquid and leave for 1 day.

We take out the cartridge, wipe it and use a syringe to pump out the liquid inside. Refill with ink and check the print. If the latter leaves much to be desired, then move on to the next method.

Method 5. Cleaning the cartridge in an ultrasonic bath

'Fari' and water are used. Color water-based ink cartridges recover after 10 years in the cabinet.

We also recommend reading:

Published: September 17, 2007 Last modified: August 18, 2013

The ink cartridge may dry out due to the printer being idle for a long time or as a result of untimely refilling. Manufacturers of inkjet printers are categorically against any manipulation of cartridges (except for their complete replacement), but in most cases this expensive procedure can be avoided.

Recovery methods

If this procedure does not help the first time, you can repeat it or try another recovery method.

The recovery process for black and color cartridges with built-in print heads is the same, but it is easier to restore a black cartridge than a color one, because If it contains one color, then the chances of getting a positive result are greater.

The cartridge has dried out: what should the user do?

The fastest and most reliable way to solve the problem is to purchase a new cartridge. If your device is dry, you can contact a service center where you will receive professional help. You can try to restore the printer using the forced cleaning mode.

You can try to solve the problem of resuscitating a cartridge yourself using several effective methods. But it will take time and, of course, you will have to put in some effort. In addition, you need to take into account that this is quite dirty work - then you will have to wash your hands and work area.

To implement one of the methods of cleaning the cartridge, you need to purchase washing liquid and a syringe with a needle, prepare paper towels and a small container with a lid.

It is necessary to determine the degree of drying of the ink: turn the unusable cartridges with the print heads up and drop washing liquid from the syringe onto them. If the composition is absorbed through the nozzles, this means that the restoration process will be short-lived.

Method 1. Soaking

If the cartridge with a sponge inside dries out, you should try to soak the sponge. To do this, place the cartridge in a vessel filled with distilled water or washing liquid with the nozzles down (in the same position as it is installed in the printer). Soaking can take quite a long time (from several hours to several days.) It is important to pour little water so that only the nozzles are immersed in it (to a height of about 1 cm). Then the cartridge is filled with ink. It doesn't hurt to pump the ink through the suction cup with a syringe, but don't use too much force. Pull the syringe slowly, without sudden jerks, and when the ink begins to come out evenly and in large quantities (no more than 10 ml), it is better to stop the procedure. Before inserting the cartridge into the printer, wipe it clean of any remaining ink, and pay special attention to the electronics contacts. Do 2-3 head cleanings and print a test page.

Or : pour the composition generously onto a napkin and place the cartridge with nozzles on the napkin and let it sit for 1-3 days if it is very dry. Then blow out with a syringe with a rubber adapter in both directions; blow directly into the nozzles (the main thing is not to overdo it with blowing). HP, Lexmark, Canon and the like are quite successfully restored using this method.

Shaking off

For light stains, the shaking method works well.

To do this, take the cartridge, move to the bathroom, and, holding the cartridge over the bathtub, with a sharp movement, “shake off” it with the nozzles down. The movements should be exactly the same as if you were shaking off a mercury thermometer.

I highly recommend not doing this in the room, because parents may not appreciate the multi-colored ink blots on the wallpaper.

The point is that the ink, due to centrifugal force, pushes the blockage in the nozzles and makes its way out.

You will see the result immediately - the flying ink drops are hard to miss.

Method 2. Boiling or 'the principle of boiling pasta'

- small iron bowl or ladle

- pliers and pliers

- napkin or toilet paper

Instructions

- With the printer turned on, open the lid and wait. and the cartridges themselves move to the replacement position. It is enough to lightly press its box down and it will come out easily. We take out the cartridge

- Now you need to heat a small amount of water on the stove in an iron bowl or ladle so that the water boils and steam comes out. We take the cartridge and hold the print heads over the fumes, you can rinse for 2-3 minutes by lowering the print cartridge into boiling water. Be careful because... The cartridge will heat up, so it is better to hold it with pliers. Just do not squeeze it under any circumstances to avoid damage.

- The dried paint in the head should become wet and begin to drip; wipe off all excess with napkins until all the colors come through. This can take quite a long period of time, depending on the degree of neglect of the printing nozzles.

- If the inkjet cartridge has not been used for a long time, you will have to wash it from the inside. Be careful when opening the lid. Older models have a special metal device for this. Don't be afraid of a little crunch, you can't do without it. On new printers, the cover is sealed with adhesive tape; first you need to get rid of it, and then carefully open it with a screwdriver. The main thing is to prevent cracking of the walls, this can render the container unusable. We take out the absorbent inserts and rinse them with warm water, be sure to remember where each of them was located.

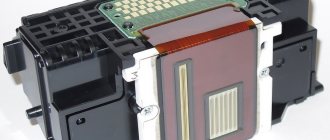

How to remove the print head

To remove the print head, you need to lift the top cover and turn on the printer. Next, observe the movement of the cartridges. When they are in the middle, they are carefully removed one after another. It is important to remember their original location in the device.

The print head is located under the locking lever. Sometimes they don’t lift him, but pull him towards himself. The head is removed and cleaning begins.

Method 3. Steaming

You take a dead, dead cartridge from an inkjet printer, which has been lying around no matter how long and has dried up tightly and all sorts of soaking, blowing, and ultrasonic baths do not help and everyone says throw it away and buy a new one - try this method and everything will work. This method applies to HP, Canon, Lexmark cartridges with a built-in print element. Take a kettle, boil water, when it boils and pour it into some bowl, the water depth is about 1 cm in and immediately lower the dried cartridge into this boiling water with the nozzles downwards, just before that remove the top sticker covering the holes as the paint will expand greatly and can flow out through top filling holes, hold in boiling water for 30 seconds and do this three times (carry out all operations with a refilled cartridge). Then you wipe the cartridge nozzles with a napkin and put some photo into the printer to print at the best quality, it will immediately turn out to be anything, then you make 4 main color sheets completely of the same color and print to run each color, the quality will still not be very good for In order to eliminate this, print any photo and in the printer settings set the quality to normal (not fast, not draft, but REGULAR). I would be most grateful if you leave a review here; I would also be grateful if you recommend this site to your friends.

Method 4. Under running hot water

Sometimes it happens that the cartridge head becomes clogged or dries out. In an attempt to clean the head, you have tried many methods for cleaning cartridges, but none of them helped you. I found another way to clean (restore) the ill-fated cartridge. To do this, you do not need to buy anything additional, such as “Liquid for cleaning cartridges”, “Special devices”, etc. To do this, take the cartridge and place it upside down in the bath, head up. Next, turn on the hot water, with a small stream of water. This stream should accurately fall on the head with nozzles. Thus, the cartridge should stand for a couple of minutes. The cartridge needs to be moved a little so that the falling stream of water hits all the nozzles. The meaning of this method of cleaning printing elements is as follows. Water falling from a height of about a meter picks up speed and passes with force through the nozzles (holes through which ink splashes onto the paper during printing) and cleans them. The jet also breaks through dried channels that you had previously resisted. After this procedure, close the tap, take the cartridge and place it head down on a cloth and let it dry. Wipe it down and put it in the printer. Print a test page. If you are not lucky the first time, repeat the procedure several times.

If these methods do not help you, see more material on cartridge recovery below

Printing with cleaning fluid

The method helps restore the non-removable head, which is built into the cartridge. Instead of dye, cleaning agent is poured in and cleaning starts. If, when printing with a color printer, defects of only one color appear in the image, then you only need to fill the cleaner into the problem compartment. After cleaning, the device cannot be used for two hours. During this time, the cleaning liquid will have time to dissolve the dye that has dried in the nozzles.

After 2 hours, open any graphics editor and fill the page with the color that you had problems with before cleaning. It is optimal to use Photoshop, since it allows you to use the CMYK color scheme when filling the sheet. The resulting fill is printed on a standard sheet, and you must first set the highest print density. The remains of the cleaner, mixing with the paint, will leave marks on the paper. If white horizontal stripes appear when printing, the head has not been cleaned sufficiently. When the filling is homogeneous, the blockage in the head is eliminated.

After washing, the cartridge is refilled with ink, the nozzles are programmed to be cleaned, and the color sheet is printed again.

Method 5. Cleaning the cartridge in an ultrasonic bath

'Fari' and water are used. Color water-based ink cartridges recover after 10 years in the cabinet.

We also recommend reading:

Published: September 17, 2007 Last modified: August 18, 2013

If you are using an inkjet or laser printer, you may need to clean the cartridge. At home, devices are often used irregularly, but despite this, they require proper care. Timely cleaning helps to obtain high-quality printouts and extends the life of the equipment. Do-it-yourself cleaning can be done using hot and cold methods. In order to carry it out on time, you should know the first signs of problems associated with cartridges.

Prevention

Sooner or later, especially if refills are frequent, you will have to clean the inside of the cartridge. But during normal operation, when there are no large volumes of printing, it is necessary to adhere to some rules. Then the ink will not dry out completely and there will be no severe contamination.

- Be sure to test print a color sheet at least once a week to prevent the nozzles from drying out.

- Regularly do wet cleaning of the workplace and the entire room. It wouldn't hurt to clean the printer with a damp cloth and remove dust from accessible areas with a vacuum cleaner.

- Periodic software maintenance will be a good way of prevention.

- When refilling a laser printer, be sure to clean all elements of old toner. Empty the waste hopper, clean the dosing blade, magnetic shaft and others.

5 / 5 ( 3 voices)

Signs that cleaning is needed

The fact that there is a need to inspect inkjet printer cartridges is evidenced by a number of printing defects, the main ones of which are the following:

- the templates on the test printouts contain uneven or unclear lines;

- During operation of the device, ink blots appear on the sheets;

- one or more colors are missing when printing the test pattern;

- When photographs and other color images are taken, horizontal streaks appear on the paper.

Poor print quality

The defects discussed are typical for different device models, for example, Epson, HP, Samsung, Canon. When rebooting does not help get rid of the unpleasant phenomenon, then you will need to clean the device cartridges. There are several reasons why you need to do this regularly:

- during downtime, it may happen that the paint in the nozzles has dried and will need to be removed to remove blockages;

- dust from the air settles inside the printer, especially on ink-coated components - the print head, cartridges.

For laser devices, cleaning is carried out when replacing the toner. At the same time, old ink and other contaminants are removed from the cartridge. The work is carried out using napkins, cloth or a lint-free brush. It is important that the electrical contacts remain clean. The work is carried out according to certain algorithms and does not require special skills.

Pressure

There are situations when a user is in a hurry to print a document, turns on the printer and discovers that the HP cartridge is dry. What to do if you don’t have cleaning products on hand? You can wash the nozzles with ink. To do this, it is necessary to create pressure inside the cartridge. The user needs to use pliers to break off part of the needle so that 2 centimeters of metal remains on the syringe.

Next, you should cut a small piece from the elastic band or eraser. Place the homemade seal on a shortened needle and draw air into the syringe. Place the cartridge on a napkin with the nozzles facing up, insert the needle into the refill hole and squeeze the air out of the syringe. In this case, the piece of eraser should completely cover the filling hole. Ink will come out through the nozzles.

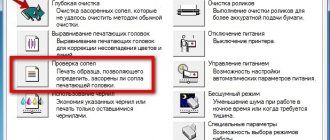

Cleaning algorithm

Many inkjet machines are equipped with built-in automatic cleaning programs. To carry it out, proceed as follows:

- open the control panel;

- go to the printing equipment settings;

- there select the required section - “Remedies and cartridge cleaning”;

- make a test print of a blank sheet.

The operation can be repeated several times. Built-in tools allow you to get rid of minor dirt.

If the function is missing, you can download the program from disk or the Internet and install it. Then in the print settings, select the “Printer Maintenance” section, then you will need to open the print settings and start cleaning. In this case, you must follow the instructions of the program. Most often, the procedure must be performed repeatedly.

When the software method does not help, then you can get rid of the problem in several other ways. For different models of inkjet technology, the algorithms are the same, only the method of accessing the cartridges differs . To do this, you may need a set of screwdrivers with different bits.

The operation scheme, regardless of the chosen cleaning method, is as follows:

- removing the cartridge;

- soaking;

- washing;

- drying;

- gas station;

- installation in the printer;

- control printout.

You must work carefully so as not to smear surrounding objects or clothes with ink.

Cold way

To implement the cold method, you will need to stock up on the following available tools and materials:

- rubber gloves (medical);

- syringe;

- napkins (cloth) made of paper or cotton;

- clean water;

- pipette;

- a special glass cleaner containing isopropyl alcohol or ethylene glycol.

Examples of suitable detergents are “Mr. Muscle”, “Mr. Glitter”.

The whole process takes place in the following sequence:

- remove the cartridge from the printer;

- place it with the nozzles up (on a specially laid fabric);

- a few drops of cleaning liquid are applied to them using a pipette;

- wait approximately 10 minutes;

- then blot the nozzles with a napkin and wipe them dry with a cotton cloth.

A screwdriver may be required to remove it, depending on the model of device you are using.

The manipulations discussed above are not always sufficient. If the nozzles remain clogged, then continue the operation:

- take a small container;

- fill it with cleaning liquid, pouring approximately a layer of 3 mm;

- immersed in the nozzle composition;

- keep them in liquid for 3 hours;

- take it out and wipe it dry.

After wiping the cartridge nozzles, located in the working position, with a cloth, there should be an ink mark on it, which is a characteristic result of complete cleaning. An ordinary plastic jar lid is suitable as a container for the cleaning composition.

If the above steps do not lead to the desired result, then proceed as follows:

- prepare a silicone or rubber plug designed to close the air intake hole located on the top cover of the cartridge;

- by pulling back the piston, fill the syringe with the contents of the atmosphere;

- put a cut-out plug on the needle;

- insert it into the air intake;

- By pressing on the syringe plunger, air is squeezed out.

The dried dye is squeezed out of the nozzles by the increased pressure generated. Afterwards, the cartridge to be cleaned is wiped, refilled and inserted into place inside the device. The quality of cleaning is checked by printing the template.

Recovery

What to do if a Canon or HP cartridge is dry? In this case, it is necessary to dissolve the remaining ink and clean the nozzles. In order to pour the purchased washing liquid into the cartridge, you need to carefully peel off the label with the number. Under it you can see special holes. Then fill the foam adsorber with washing liquid from a syringe.

For a color cartridge you will need 5 milliliters of the composition, for a black cartridge - 10 ml. The remaining special cleaning fluid must be poured into an empty container. The cartridge should be installed in it with the nozzles facing down. Close the container with a lid and leave the cartridge to soak for 24 hours.

After a day, pump out the solution with remaining ink using a syringe. Then you can begin refilling the cartridge and then installing it into the printer. Enable forced cleaning mode and print a test page. If the user is not satisfied with the print quality, he can repeat soaking the cartridge in any container with washing liquid.