The main functions of the intake manifold, signs of contamination, methods for repairing and cleaning the device. Video about the intake and exhaust manifold.

If the engine suddenly begins to run intermittently, loses its former power, or thick smoke comes out of the exhaust pipe when you press the gas, this does not mean that the car’s power plant needs to be “overhauled” immediately. The cause of such phenomena may be contamination of the intake tract, leading to the engine not receiving enough fuel or air. The way out of this situation is quite simple and does not require large financial costs.

Intake manifold functions

A car's intake manifold does not collect debts, but rather substances necessary for the engine to operate. Which ones exactly depend on the type of power plant itself.

Thus, air masses pass through the intake tracts of diesel engines without adding fuel. With gasoline engines the situation is a little more complicated. The main functions of the collectors that supply “power” to power plants of this type are determined by the type of internal combustion engine itself:

- carburetor: transfer of a ready-made air-fuel mixture to the engine;

- injection: mixing fuel and air;

- direct injection systems: directing air to the engine.

It is worth noting that if the engine has a functioning exhaust gas recirculation (EGR) system, they also partially enter the intake manifold.

Structurally, the intake units of carburetor and diesel engines, as well as direct injection systems, are a complex of pipes with low aerodynamic resistance and a barrel called a receiver. In devices that supply fuel to injection engines, there are nozzles that spray the air flow with liquid.

Signs of collector contamination

During vehicle operation, it is almost impossible to avoid dust settling on the outer surface of the intake manifold. Sometimes its layer reaches a thickness of several millimeters. Meanwhile, the inside of the device gradually becomes clogged with carbon deposits, which can be indicated by:

- significant increase in fuel consumption;

- reduction of engine power and slower acceleration of the vehicle;

- at low speeds there is vibration and shaking caused by insufficient throughput of the collector;

- into loud knocks and other noises made by dirty engine valves.

Driving a car with a clogged intake manifold and clogged valves can lead to failure of the hydraulic compensator. And this is already serious.

The situation can be aggravated by excess oil entering the engine due to a malfunction of the cylinder-piston group and adding carbon deposits to the intake system. Here the performance of the power plant itself is in question.

But it will probably be easier to get rid of contaminants that lead to similar consequences in a timely manner. In general, experts advise cleaning the intake manifold every two to three years.

How does he work

Replacement of exhaust manifold gasket VAZ-2114 8 valves

Upon arrival, they are distributed into streams depending on the number of cylinders in the engine. Moving pistons create a vacuum that reaches a maximum at its lowest point. This creates a virtual vacuum, which neutralizes the crater gases.

The intake system has changed greatly during the evolution of the automotive industry.

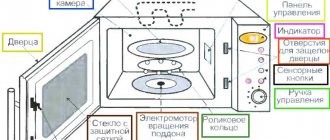

So, its structure has come to us in its current form:

- frame,

- air intake,

- pipe branch,

- throttle valve,

- muffler,

- intake manifold,

- pad.

It turns out that the collector itself is part of an important system that ensures the proper functioning of the engine. Its place is on the left side of the cylinder head

To monitor the pressure and temperature inside, sensors are installed on it. The calculations are carried out by the control unit, which also generates commands.

One of the functions of the intake manifold is the redistribution of the fuel-air mixture between the cylinders in the engine.

The main problem for all car enthusiasts was overheating of the intake manifold; for this reason, heated air expands, and its input volumes are significantly reduced. Thus, fuel consumption increased, and the quality characteristics of the engine decreased. Then the technicians decided to make most of the structure from plastic, which alleviated the problem. But still, in order to avoid breakdowns and other troubles, this compartment must be cleaned in a timely manner.

Cleaning the intake manifold

Since auto science does not offer effective methods for combating the formation of soot and deposits in the intake manifold, these contaminants can simply be removed from there periodically. This is usually done as follows:

- the machine is placed on a lift, overpass or pit if available;

- the screw holding the intake manifold to the frame is carefully unscrewed;

- the throttle valve is removed from the car;

- Tubes, sensors, and wires are carefully disconnected from the collector;

- unscrew the bolts that secure the manifold to the engine;

- the intake manifold is removed from the car and disassembled;

- white spirit or another cleaner is poured into the container that is supposed to be used for processing the collector parts;

- elements of the disassembled collector are placed in a cleaner for 30-60 minutes to get rid of contaminants;

- parts are additionally processed with a cleaning device;

- the components of the collector are dried and, to increase the reliability of the connections, they are coated with sealant at the contact points.

Returning the intake manifold to its place is done in the reverse order. The throttle valve, sensors and tubes are checked and cleaned before installation on the machine. But seals and other consumables are easier to replace altogether.

Thus, it is quite possible to clean the intake manifold in “garage” conditions. Although the design of this unit is not that complicated, it is advisable to be punctual when disassembling and assembling it, so as not to confuse or break anything.

Advice from experienced drivers

- Effective removal of contaminants with a flow of granules.

- A special abrasive ensures stable cleaning quality.

- The specific, non-sharp geometry of the granules, as well as their internal structure, makes it possible to remove contaminants with high quality, while maintaining the surface of the parts.

- The neutralizer allows you to effectively remove slag residues after cleaning.

- The nozzles in the set are selected for various channel shapes.

Experts recommend combining this cleaning procedure with an oil change. This allows you to fill not only the cylinder head cavity with cleaning foam, but also the entire combustion chamber. Thanks to this, it is cleaned and the piston rings are decarbonized.

Folk remedies Recipes for masks At home Hair loss in women How to stimulate growth Causes of hair loss Hair loss in men Review of vitamins Helpful tips

Intake system malfunctions

However, the intake manifold itself can break. The most common problems with this device are:

- restriction of the flow of substances due to accumulated contaminants;

- air entry through the resulting openings;

- oil or coolant leak;

- failure of the control valves.

Corrosion of the intake manifold or the appearance of cracks on it can cause depressurization of this device, as well as leakage of coolant from it. If a leaky unit cannot be reliably patched, it is replaced with a new one.

Gaskets

They tend to lose their tightness if the engine overheats. This also happens when the fastening nuts are loosened.

You can easily check the gaskets for leaks. To do this, you need to cover 10 percent of the air filter duct when the engine is idling. If the engine speed has not decreased, then there is an air leak. If the speed, on the contrary, has increased, then we can say that one or more gaskets have completely failed and need to be replaced.

Drafts in the intake manifold

One of the signs of loss of vacuum in the intake tract is unstable engine idle or even shutdown of the power plant. While at high speeds the engine can operate quite normally.

Depressurization of the intake manifold also sometimes leads to the appearance of the Check Engine icon on the dashboard, or during diagnostics - OBD-II error codes P0171 and P0174. Finally, a hissing sound coming from under the hood can signal the driver about the same problem.

If the manifold sucks in air through worn gaskets, the latter must be replaced. Repair in this case will consist of the following stages:

- dismantling the intake manifold from the car;

- checking and cleaning installation areas;

- replacing worn gaskets with new ones;

- installing the collector in place.

The cause of depressurization of the intake manifold may also be holes in the adjacent pipe or vacuum hose. In this case, the leaky parts are also replaced with new ones.

And deformation of the intake unit can lead to the inability of its gaskets to perform sealing functions. Then you will have to change the collector itself.

Carrying out repair work

Replacing the collector of a VAZ 2114 photo instructions on how to replace the collector on a VAZ 2114

Do not operate a vehicle with a damaged manifold. This is due to the fact that the pressure may drop and unfiltered air may enter the system. Repairs are carried out by completely dismantling the intake system or without removing parts: it all depends on the characteristics of the malfunction.

Repair work in most cases consists of sealing the resulting crack or hole. For this, a special sealant or two-component welding can be used. When choosing the most suitable material, it should be taken into account that the structure is exposed to pressure and high temperature during engine operation.

At the time of repairing the manifold, it is recommended to pay attention to other parts of the fuel mixture supply system. If the sensors and pipes are damaged, they also need to be replaced.

https://youtube.com/watch?v=7w0CVrE1nqY

Coolant leak

The intake manifold, equipped with channels for coolant, may well lose it through leaks. A similar problem often accompanies old V-shaped six-cylinder engines from General Motors.

To eliminate this kind of leakage, it is usually enough to replace the sealing elements on the manifold, but this is provided that it itself is in good condition. If the unit is deformed, then it is replaced with a new one.

Are the dampers “flying”?

The flow of substances inside the intake manifold is controlled by various flaps driven by vacuum actuators. Which, in turn, receive commands from the engine control unit.

An intake manifold with a faulty control flap mechanism not only suffers from a disruption in the circulation of the air-fuel mixture. In fact, it puts the entire engine at risk. And that's why:

- if the drive lever is broken, the dampers gain more freedom of movement and begin to hit the mounting sockets or frame;

- fragments from the flaps, picked up by the air-fuel mixture, enter the cylinder head intake channels and are directed to the engine cylinders;

- large fragments of the flaps get stuck in the intake valves, preventing them from closing;

- the pistons collide with the valves, as a result of which both are deformed.

Indeed, intake flaps can cause a lot of trouble. So if problems are detected in their operation, it is better to immediately replace these parts with new ones. Indeed, if they break, it may also be necessary to replace the intake valves or even the pistons.

How does he work

Upon arrival, they are distributed into streams depending on the number of cylinders in the engine. Moving pistons create a vacuum that reaches a maximum at its lowest point. This creates a virtual vacuum, which neutralizes the crater gases.

The intake system has changed greatly during the evolution of the automotive industry.

So, its structure has come to us in its current form:

- frame;

- air intake;

- pipe branch;

- throttle valve;

- muffler;

- intake manifold;

- pad.

It turns out that the collector itself is part of an important system that ensures the proper functioning of the engine. Its place is on the left side of the cylinder head

To monitor the pressure and temperature inside, sensors are installed on it. The calculations are carried out by the control unit, which also generates commands.

One of the functions of the intake manifold is the redistribution of the fuel-air mixture between the cylinders in the engine.

The main problem for all car enthusiasts was overheating of the intake manifold; for this reason, heated air expands, and its input volumes are significantly reduced. Thus, fuel consumption increased, and the quality characteristics of the engine decreased. Then the technicians decided to make most of the structure from plastic, which alleviated the problem. But still, in order to avoid breakdowns and other troubles, this compartment must be cleaned in a timely manner.

Replacing the intake manifold

There are situations when the intake manifold cannot be cleaned or repaired. And then, instead of the failed unit, a working one is installed. This measure is used, for example, if it is not possible to replace a broken control valve separately.

Along with the collector, its gaskets are also changed, and the areas on which it is attached are thoroughly cleaned. The fixing bolts are tightened in the order specified in the specifications for this unit.

As a last resort, if there is no time to find, purchase and install a new intake manifold, you can try to repair the existing one. At the same time, to seal holes in a metal unit, you can contact a skilled argon welding specialist. If the broken device is plastic, the car enthusiast will need glue or sealant.

How to clean the egr valve

First it is removed from the car. Before dismantling, you need to purchase new valve gaskets. The old ones are pressed in and air is leaking through them. The EGR valve is located in front of the intake manifold. Sometimes it is between the intake and exhaust manifolds, the connection goes through the tubes.

Cleaning the USR does not require the use of special means. Regular WD40 will do. Carburetor cleaner is also suitable. This cleaning option will bring more noticeable results. You need to pour the cleaning agent onto the contaminated parts and leave for a few minutes to soak the dirt. Then clean it using available means, let the valve dry, and put it back in place. We must not forget that new gaskets will need to be installed.

If you experience symptoms of a clogged USR valve, we recommend that you contact a specialist as soon as possible, which will allow you to quickly eliminate problems with uneven engine operation. The staff will be happy to help you. To do this, simply fill out the form below.

Cost of cleaning and repair

You can clean the intake manifold or carry out simple repairs yourself. However, for a car enthusiast who is not familiar with the design of such a unit or if there are serious faults in it, it is still better to use the services of a service. Approximately they will cost:

- disassembly and assembly of the intake manifold: from 800 rubles;

- general cleaning of the intake manifold: from RUB 1,200;

- cleaning of dampers: from RUB 1,200;

- gasket replacement: from 800 rubles;

- replacement of dampers: from 1600 rubles;

- valve replacement: from 400 rubles;

- replacement of the intake manifold assembly: from 800 rubles.

EGR functionality revision

During the inspection, tubes, wires, and other components are subject to inspection. When equipped with a pneumatic valve, a vacuum pump is used for starting. For a comprehensive check, special equipment is suitable that allows you to identify the error code. To carry out diagnostics, you need to know the technical parameters of the device in order to find discrepancies in the declared and final information.

Inspection steps:

- Disconnecting vacuum hoses.

- Blowing through the apparatus until no air passes through it.

- Disconnecting the connector from the solenoid valve.

- Supplying power from the battery to the device via wires.

If the inspection reveals such a breakdown that the device cannot be used, then you need to purchase and install a new one. Often a plug from an existing unit is enough.