All modern automatic washing machines are equipped with a self-diagnosis function. This was done to identify all malfunctions that arise during operation of the device. This trend has also captured the Korean washing machine manufacturer Samsung.

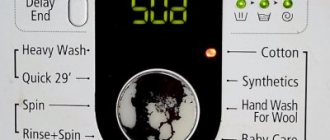

Malfunctions appear for various reasons. May be due to temporary wear and tear of mechanical and electrical parts. Or maybe it depends on the conditions in which they are used. If any malfunction occurs, “intelligent” machines stop the washing processes you have set. On the display they display a combination of letters and numbers.

This is the error code of the malfunction that has occurred. An ordinary housewife can handle many breakdowns of her car. For example, when she cannot open a closed hatch, the filter becomes clogged, the water supply tap is not open, etc.

These code options can be found in decrypted form in the product operating instructions.

Most breakdowns can only be dealt with by a specialist. You shouldn’t start repairs on your own without the skills. Now we will look at some errors of Samsung washing machines, and in more detail we will find out what the h1 error on a Samsung washing machine wants to tell us, as well as ways to troubleshoot problems in which it appears.

Error interpretation

All codes starting with “H” - H1, H2, HE, HE1, HE2 mean that there is a problem with water heating: it is not there or, on the contrary, it is excessive. This is why a Samsung washing machine can function normally in cold water washing modes, but an error appears in heated programs.

Note! Codes E5, E6 typical for older models of Samsung washing machines manufactured before 2007

Heating errors also have their own classification. Error code HI/HEI is issued if:

- dynamics of increase in water temperature after turning on the heating - more than 40°C for 2 minutes;

- the water temperature becomes higher than 95°C for any reason;

and thus signals that the Samsung washing machine is overheating or boiling water.

Error H 2 / HE 2 is issued if:

- When heated, the water temperature increases by less than 2°C in 10 minutes;

and thus reports the absence of heating.

Unfortunately, this code most often indicates a malfunction. Only in rare cases can you correct an error on your own.

Why does it occur

The appearance of codes indicating a breakdown of the heater occurs due to the burnout of the heating element or the activation of protection against its overheating. A fuse or thermal relay can be installed in the power supply circuit to the heating element. Both devices operate when overheated, thereby protecting the heating element from failure.

This situation occurs due to a decrease in the water level in the tank. The cause may be an incorrect connection of the drain hose to the sewer. If it is not secured to the back wall of the unit, and the drainage device is located below the water level in the machine, then it will drain by gravity, because... There is no locking device on the system.

In this case, the heating element periodically remains without cooling and overheats. During the operation of the SMA and poor maintenance, scale forms on the surface of the heater, which will reduce heat removal and contribute to an increase in the surface temperature of the heating element.

Error HE2 in a washing machine may occur due to a faulty control module.

This is often caused by power surges in the network or water (moisture) entering the electronic unit if the SMA is located in a damp room.

An error in Samsung may occur due to a broken temperature sensor or broken connecting lines. Due to the fact that the sensor cannot be repaired, it must be replaced. In some models, the sensor is located on the sealing plate of the heating element, then the replacement should be carried out complete with the heater.

Troubleshooting

The instructions included with the machines contain descriptions of many error codes that you can use to solve the problem of their occurrence on your own.

Some of them:

- Error oe - water overflowing into the tank. Possible problems are a clogged pressure switch tube, a malfunction of the relay, or a malfunction of the water inlet valve (it is stuck in the open position). The only way out is to eliminate foreign formations.

- UE – imbalance. Error code ue occurs when the laundry is laid out incorrectly (the laundry is in a pile, there is no way to spread it out over the entire area of the drum during the spin cycle). What to do? Stop the program, arrange the laundry evenly, and continue washing.

- The meaning of code 5E is that there is no (or difficult) draining of water. The solution is to first pay attention to how dirty the filter is.

Article on the topic: Where to use the motor from a washing machine

There are many fault codes that arise. Save your family budget. And if it doesn’t work out, then contact a specialist.

Probable reasons for failure

When you find a similar signal on the screen, get ready to fix the problem, because the problem is not related to voltage changes in the electrical network. It also cannot be associated with short-term interruptions in electronics.

What should be considered the main problems? There are two of them:

- temperature sensor failure,

- failure of the control board.

The temperature control device sends data about the heating of the heating element. Using such a sensor, the control module regulates the temperature of the heating element in accordance with the specified program. If the sensor is broken, then the management module loses the ability to control the performance of the heating device, and after turning on the CM, it heats up to the maximum level. At the same time, the module responsible for control and not having updated information from the temperature sensor, in emergency mode, turns off the heater and sends the NOT 1 signal, interrupting the wash.

Quite often, the temperature controller is installed directly on the heating element, and finding it is not difficult. True, you will have to get to the heating device by partially disassembling the washing machine.

What to do if the problem is not in the sensor? In such a situation, it is recommended to look for a breakdown directly in the management module. If a track or triac responsible for controlling the heating element burns out, then exactly the same signal will appear on the screen, but repair work will be much more complicated and will require large financial expenses.

Heating system errors

Usually the he2 error appears at the most inopportune moment. A typical situation is that the laundry is loaded, a program is selected and started. The drum is filled with water, but the machine is in no hurry to wash. Instead, after a few minutes, it throws an error like he2. The error code is displayed on the screen, but in cheaper models it is expressed in the form of temperature indicators that glow in a steady red light and flashing operating mode indicators.

Before taking any action, it is worth finding out what such a message means. It is not difficult. Any error whose coding contains the Latin letter “H” indicates a malfunction in the heating system. Actually, there are two possible malfunctions. Heating may not turn on at all, or may not turn off at the required water temperature.

Two error messages indicate that there are problems with the heating:

- he1 indicates excessive heating, the temperature rises at a rate above 40 degrees in two minutes;

- he2, on the contrary, indicates insufficient heating or its complete absence.

As you might guess, this error may not appear when using “cold wash” programs; moreover, the machine can work perfectly in any program, until the moment when heating the water is necessary.

The occurrence of this error most often serves as a reason to begin serious repairs, most likely with the replacement of the heating element. However, before you get upset, you should rule out all other options.

Error as a random failure

Despite the fact that the he2 error on a Samsung washing machine directly indicates a problem with the heating element, it can be caused by completely different reasons, from a lack of water in the system to a malfunction of the firmware. Therefore, before starting repairs, it is worth performing a few simple steps.

- Turn off the machine and unplug the cord from the outlet. Let the device stand for a few minutes, turn it on again and try to run the same program. There is, however, a minimal probability that the machine will work normally again.

- Check the presence of water in the system; it is quite possible that it was turned off at the wrong time. It would also be a good idea to make sure that the supply pipe is not clogged or the inlet valve is clogged.

Washing machine inlet valve

- It would also be a good idea to make sure that the car is not loose. It is likely that due to excessive vibration, the contact of the heating element comes off and as a result it cannot work normally.

If these basic actions do not lead to the desired result, the machine still does not work, he2 signals, repair is impossible.

The process of replacing the heating element

To remove a worn part, you need to perform several steps:

- Using a socket wrench, remove the nut located on the insulating insert;

- slightly loosen the device by holding its contacts with your hands;

- apply a light blow to the stud on which the fastener was installed. You can use a small hammer or socket wrench to do this;

- to displace the worn part from its seat, use a screwdriver, which needs to be used to slightly pry the part;

- remove the device from the inside of the tank.

The seat is vacated, we proceed to install the unused heater:

- check the resistance of the new device using a multimeter;

- we clean the area from accumulated dirt and scale;

- we treat the seal with a special substance WD 40;

- installing a new heating element for a Samsung washing machine;

- insert the temperature sensor;

- We connect the conductors to the heater contacts.

The repair work to replace the electric heater has been completed, and you can begin installing the panels.

Online diagnostics of a washing machine

If your machine stops washing or rinsing clothes normally, then some kind of malfunction or breakdown has occurred. You can try to find the problem yourself.

Let's look at diagnosing and solving problems:

- After gaining access to the heater, be sure to remove the terminals from the contacts and check with a tester. The resistance of a working heating element is 30-35 Ohms. And it should be constant, not “jumping”. That is, do not change the values at the time of measurement. If there are inappropriate parameters, set a new one.

- We check the integrity of the contacts and the absence of oxidation. We use a multimeter to test the wires from the heater to the control module. It happens that they break at a bend. Koreans are very economical with the length of wires - there is no excess.

- The resistance of the NTC sensor for Samsung washing machines at room temperature is 12 kOhm. When heated, it should decrease. If the characteristics do not correspond, then replacement is necessary.

- The temperature in the tank can exceed 100°C if the NTC sensor is faulty or the wires coming from it are damaged. In this case, faulty elements are also changed. If there is no water in the tank during washing, then you need to check the filling system for blockages.

Important point! There are treacherous situations with a tubular heater. It shows normal resistance, but there is a leak to the housing. This can lead to error H1 or strange malfunctions in the operation of different wash cycles.

Troubleshooting

First, we need to remove and diagnose the heating element. We warn you right away that getting to it will not be easy - often you need to remove the front panel to do this, since in many models its contacts are located on the front. If you need to remove the front panel, you need to loosen the control panel and remove the rubber seal, unscrew the screws and carefully remove the front part - not an easy task, especially when you have to put the seal back on.

Next, we proceed to check the heating element, using a multimeter operating in ohmmeter mode. We remove the wires from the contacts of the heating element and temperature sensor, and begin measurements. We have already said that the H2 error in a Samsung washing machine indicates a break - in this case, the multimeter will show infinite resistance. The normal resistance of a working heating element is 25-30 Ohms, depending on its power.

If the resistance is normal, then this may indicate a lack of voltage at the contacts when starting the program - the electronics of the Samsung washing machine should output 220 Volts to the heating element. If there is no voltage, you should suspect the on-board electronics, which for some reason are not supplying power. Also, the appearance of error H2 in Samsung washing machines may be due to a malfunction of the temperature sensor, which incorrectly estimates the water temperature.

To work with a multimeter you do not need any special knowledge or skills. The main thing is to find someone you can borrow it from during the check.

Article on the topic: How to use descaler for washing machines

Error H1 in Samsung washing machines indicates too intense heating. This can happen with a faulty heating element, when it shows a resistance less than normal. The same thing happens when there is an electrical breakdown to the housing. Testing is carried out as follows - we measure the resistance between the contacts, after which we take measurements between the contacts and the body. If the internal insulation is faulty, there will be low resistance between the housing and the contacts, indicating a breakdown.

In total, if the washing machine displays an error (Error) H1, He1, H2 or He2, you should diagnose the heating element and temperature sensor, and also determine the presence of power to the heating element. Based on the measurement results, the following may be faulty:

- Heating element - overheats or does not heat the water at all;

- Thermal sensor – gives incorrect commands to the controller (to carry out the test, control readings of a known-good sensor at a given temperature are needed, so that there is something to compare with);

- The controller does not provide power to the heating element.

It would not hurt to check the connecting wires and clean the contact groups - the latter could oxidize to the point of breaking normal contact.

HE2, H2 - drying problems

Some washing machines are equipped with a built-in drying system. Error codes HE2, H2 can only appear in such machines. The device uses a heating element that heats the air. With its help, the laundry is dried directly in the drum.

This system also uses a blower fan and fuses that trip when overheated. This error occurs mainly when the heating element burns out.

Very often this is caused by a blockage in the air pipes or a malfunction of the fan motor. Therefore, when diagnosing a rupture in the heater, you need to identify the source and check the elements listed above.

When the fuse trips, this code also appears because there is an open circuit. They can be disposable - in this case replacement is necessary, or multiple - here you just need to turn it on.

This code also appears at temperatures exceeding 145°. When it cools down, the machine will resume operation. But if this happens again, then the temperature sensor needs to be replaced.

Call the master

The easiest way to repair a machine reporting a heating system error is to call a technician. This method is suitable for a person who is busy or has no experience in such work. It is up to the owner to decide whether to call a technician to your home or take the car to a workshop. In any case, washing will have to be postponed for the next few days, or even weeks.

A visit to the workshop is also the best solution for those whose car is under warranty. You should not open the device yourself, because in this case the owner will lose the warranty and will have to pay for the repair himself.

HE3 - steam function

This error is generated by Samsung machines equipped with a steam system. The washing principle in them differs from classic models. The water turns into steam, which is then used to process the laundry.

It has its advantages and disadvantages. As a rule, such models are significantly more expensive. The main advantage is delicate washing, comparable to dry cleaning.

HE3 appears when there is a malfunction in this system. The mechanism is quite complex. And if it fails, it is better to contact a specialized service for repairing household appliances.

Errors H2, HE2, H1, HE1, E5, E6 - in which cases you can fix it yourself

- Check the machine's electrical connection. Is the washing machine plug or cord damaged? Make sure that the connection is made directly into a separate outlet and not through an extension cord or adapter.

- If the error appears for the first time, try disconnecting the machine from the power supply for 10 minutes and then turning it on again. There may be a software failure in the “brains” of the washing machine, and a reboot will solve the problem.

- Check the connections of the wire loops from the heating element to the control module, especially if the washing machine was disassembled before the error appeared. Perhaps the contacts have come loose and need to be connected more tightly.

If these recommendations did not help get rid of the error H 1 / H 2 / HE 1 / HE 2 / E 5 / E 6 in the Samsung washing machine, then, unfortunately, you cannot do without professional repairs.

How to prevent the problem from occurring?

Professionals recommend remembering the main rules for operating heating household appliances . Firstly, a separate outlet is allocated for the washing machine. The connection to it must be direct, that is, without the use of adapters and extension cords.

Secondly, the cord and plug of the device should be maintained in working condition. If defects occur, correct them immediately. Thirdly, when replacing heating elements, it is recommended to choose products that are not coated with ceramics. Metal spirals are more resistant to scale and last longer.

How to fix the breakdown?

It is believed that the temperature sensor cannot be repaired - it is simply replaced with a new analogue. But you should first verify that the device is faulty by checking it with a multimeter. If the device proves a complete failure, then you can go to the store.

To perform such work, you should remove the front panel of the machine by unscrewing several screws. Having gained access to the heating element, you must perform certain actions:

- disconnect the wiring from the temperature controller, remove the part from its niche;

- measure the resistance indicator. If the device shows “zero” or “one”, then the sensor can be dismantled and thrown away;

- Having installed the new sensor, we assemble the machine in reverse order and conduct a test run.

In the case when the functionality of the temperature sensor is fully confirmed, and the wiring with the contact group is beyond doubt, we look for the problem in the machine control module. It is not recommended to repair this element yourself, since the work involves certain difficulties, and even a small mistake will only aggravate the failure and create additional financial costs. In this case, you should contact the service center for help.

Replacement of wires and repair of electronic module

In order to find the faulty wire, you need to use a multimeter. With its help, you need to ring all the wires connecting the heating element and the control module, and then replace the faulty one if it is found.

Repairing the control board is a more complex process. To fix it, you need to know how to do this kind of work. Otherwise, you can completely damage the electronic module. In some cases, to repair it, it is enough to solder the burnt out contacts, but to do this you need to detect them. It is very difficult to do this yourself, so it is better to contact a service center and call an experienced specialist. You should also be aware that when repairing the central board, a software update may be required, which is extremely difficult to do on your own.

Article on the topic: How to connect a washing machine to the sewer

If code H2 is displayed on the digital screen of a Samsung washing machine, this indicates a malfunction of the water heating system. Most often, the heating element fails - the weakest and most vulnerable point on devices from the Korean manufacturer, as well as the temperature sensor. Less often, error code H2 indicates a break in the wires connecting the heating element and the electronic module, and very rarely, a breakdown of the control board.

You can replace the heating element, temperature sensor and wires yourself, the main thing is to know how to fix the breakdown and be confident in the successful outcome of the repair work. To repair the control board, you should call a qualified specialist from the service center to prevent the situation from worsening.

The most common cause of heating element failure is scale formed on it as a result of the presence of a large amount of foreign impurities in the water. To avoid such malfunctions, it is recommended to install a special filter on the water entering the house.

DIY repair

Self-repair is possible only if you have complete confidence in its quality, and if not, you should contact the service department. If the error code is displayed for the first time, you need to disconnect the unit from the network for 10-15 minutes, and then turn it on again. If the signal disappeared and the SMA began to execute the program, then there was a malfunction in the operation of the control module. In all other cases, it will be necessary to check the strength of the connections, the integrity of the heating element and the correct operation of the protection. This will require partial disassembly of the unit.

Required Tools

To carry out repair work to replace the heating element in a Samsung washing machine, the following tools are required:

- electrical installation pliers or pliers;

- set of keys;

- a screwdriver with several attachments that differ in geometric shape;

- electrical multimeter;

- lubricant.

Disassembling the machine

In the SMA Samsung heating element can be located both in the front and in the rear of the tank. If the heater is located on the rear side, then to dismantle it it is necessary to unscrew the screws holding the rear wall.

By removing it, the user will have access to the location of the element. For another option, the front panel must be removed. To do this you need:

- Remove the drain filter and drain the remaining water.

- Remove the detergent dispenser and remove the 2 screws holding its housing.

- Unscrew the screw located on the right side of the panel.

- Slide the panel, but do not remove it.

- Dismantle the clamp holding the cuff of the loading hatch and remove it by pushing it into the drum.

- Remove the decorative panel at the bottom of the MCA.

- Unscrew the 4 screws located under the cover.

- Remove 3 screws under the control panel.

- Lift the front cover and remove it from the hooks.

The heating element is located at the bottom of the tank.

Testing the heating element

The heater's functionality is checked in the following order:

- Disconnect the power wires from the heating element.

- Use a multimeter to measure the resistance of the heating filament. Set the device switch to the 200 Ohm range. The readings on the display should be within 15-30 Ohms, depending on the power of the element. If the device shows “1”, then the heating element is faulty.

- Measure the breakdown of the heating element on the body. To do this, install one multimeter probe on the terminal, and the second on the heater body. The readings should be equal to 1. For any other values, the heating element is faulty and must be replaced.

If a residual current device (RCD) is installed in the home power supply system and it trips when the heater is turned on, this means that there is a current leak of more than 5 mA to the heating element body. In this case, there is no direct breakdown, but the element must be replaced.

Heater selection

A new heating element should be selected according to the following parameters:

- Power. The deviation can be no more than 200 W upward. It is not recommended to install heating elements of a lower rating.

- Length. Determined by the dimensions of the complete element. The spread can be 15-20 mm in both directions. To install a longer heating element, it is necessary to determine the possibility of on-site installation.

- Temperature sensor. If the old element had a sensor, then the new one must have a hole for its installation, because the meter rarely fails.

- Type. Straight, curved or stepped.

- Coating. A heating element made of stainless steel will last longer than a steel one.

- Sealing unit. The rubber thickness can be 9 or 14 mm.

All parameters are indicated on the heater flange. The best option would be to purchase a heating element that fully matches the original one.

Replacing the heating element

To dismantle the heater, you need to disconnect the power wires and the temperature meter line. Then unscrew the nut located in the center of the flange and, rocking from side to side, remove the heating element. There is no need to use improvised means for this.

Installation of a working part is carried out in the reverse order. To prevent leaks through the seal, you can apply a thin layer of sealant to the rubber. If the assembly is sealed in this way, it will be much more difficult to dismantle the element during repairs.

Why can a heating element fail?

The reasons for heating element failure are as follows:

- Formation of scale deposited on the pipes. Scale is an obstacle to the transfer of heat generated by an electrical component to cold water. Formed as a result of hard water and the use of detergents, solid deposits have poor thermal conductivity. Due to the slow heating of water in the tank, the heating element overheats, and ultimately the part fails. Scale also causes the formation of a corrosion process, which leads to the destruction of the metal base of the tubes.

- Manufacturing defect. If this fact is established by the examination, the consumer has the right to free repair or replacement of the washing machine.

- Exceeding the established norm of detergent. It is necessary to follow the proportions recommended by the manufacturer.

Important! To extend the service life of the heating element, experts recommend using “Calgon” for washing machines when washing to soften the water, or once every 1-3 months (depending on the frequency of use and water hardness) running it “idle” on the “Cotton 60 C” mode °" with the addition of a special descaling agent or regular citric acid.

The final stage

After completing the full cycle of repair work, we proceed to connecting the machine to all systems:

- installation of the unit in its original place;

- connection to the sewer system;

- setting the water tap to the “open” position;

- connecting the machine to electricity;

- starting the machine in “wash” mode.

If within 10 minutes from the start the code he2 does not appear on the display, then the error has been resolved.

If necessary, spare parts for Samsung washing machines are not difficult to find. But it is better to prevent premature failure of components by following simple rules for operating the device.

To extend the service life, it is not necessary to use Calgon for washing machines every time, as advertising recommends. It is much more economical to install a special water filter on the inlet hose or periodically clean the device using citric acid or special products containing it.

Additional Tips

When the he2 code appears on the display, it is worth considering some diagnostic and repair features. In particular:

if an error appears and then goes away, repairs should not be delayed - temporary disappearance of the image does not indicate the spontaneous disappearance of the defect;- if you lack knowledge and experience, it is not recommended to open the device yourself - contacting a professional will save time, and in some cases, money;

- if the repair is carried out with your own hands, then special attention should be paid to removing the panels - all manipulations must be carried out carefully so as not to damage the contacts;

- after repair, a test wash is started in the same mode in which the error was detected, without the need to add powder or put laundry in the drum.

You can learn more about error codes for Samsung washing machines here.