- restores damaged wiring or completely changes the cable loop;

- if the contacts are damaged, solder them or replace them with a new contact group.

*Please note that prices are for repair work only. Spare parts required for repairs are paid additionally.

If your Kandy washing machine has stopped washing and shows error code E08, do not hesitate to repair it. Call:

RemBytTech technicians have many years of experience in diagnosing and repairing Candy washing machines. They will accurately determine the cause of the emergency code and carry out all repair work right at home. Quality is confirmed by a guarantee of up to 2 years . Contact us!

What does the code that the Kandy washing machine produces mean?

This coding on the Candy display is due to the lack of rotation of the drum. This may be a malfunction of the tachometer, wear of the motor brushes or its braid, as well as malfunctions in the control module. The problem manifests itself by issuing an error code and stopping work when the drum does not spin.

Before this, one of the following situations could have occurred:

- The rotational movement of the drum does not occur at all.

- The drum was spinning in one direction, and it did not change.

- For a short time the drum rotated in one direction at high speed.

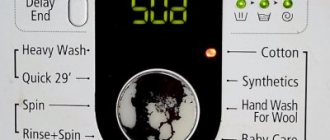

Depending on the device model, the code on the display may look different. It could be:

Depending on the Kandy model, different indicators may flash. The user simply needs to count how many intermittent signals are generated between pauses.

If the error is one-time and was caused by a random combination of circumstances, the issue can be resolved by rebooting the device. To do this you need to do the following:

- Turn off the washing machine.

- Remove the plug from the socket.

- Leave the device turned off for 15 minutes.

- Turn it on again.

- Restart.

If a reboot does not help resolve the issue, more thorough diagnostics and repairs will be needed.

Description of repairs taking into account the main reasons

Breakdowns that occur during the operation of a washing machine may cost nothing to the family budget - for example, forgetfulness when setting up and starting a program, or result in large expenses when the electronics burn out. Self-clarification of the cause of error E02 and knowledge of how to eliminate breakdowns of the fill valve, pressure switch, and control module help you decide to call a technician. To take into account the economic component of the choice, you need to have information about the cost of customer service and spare parts for Kandy washing machines.

Fill valve problems

The first thing you need to do when E02 appears is to restart the machine: unplug it, and after 10-15 minutes, plug the cord back into the outlet. If the code does not disappear, the device is disconnected from the power supply again, the search for the cause continues: is the filling valve open, is water flowing from other taps and with what pressure, is there a blockage in the hose. Check the strainer installed at the water inlet to the fill valve.

The listed actions do not require special knowledge and are performed by the SMA user independently. Inviting a technician to carry out diagnostics is declared as a free service, but if the client refuses subsequent repairs, he will have to pay for the call in the amount of ≥1 thousand rubles. A more complex procedure is to examine the fill solenoid valve.

The distribution device has 1, 2 and 3 coils - according to the number of directions of water supply. Product prices range from 400 to 3.8 thousand rubles. To check the condition of the part, you will need to perform the following steps:

- Disconnect the SMA from the power supply and water supply.

- Provide access to the valve: for a front-loading machine, remove the top cover; for a vertically loaded machine, remove the side panel.

- Inspect the hoses and wires with terminals, check the serviceability of the coil with a multimeter.

You can replace the fill valve completely or repair it by installing a new inductor. When deciding to repair a washing machine when water does not flow into it, you need to take into account that service departments will charge ≥1.2 thousand rubles for correcting a broken valve. + cost of spare parts.

Pressostat inspection and module replacement

Inspection of the pressure switch

A level sensor called a pressure switch is responsible for maintaining the water level in the machine tank. It consists of a pressure tube and a housing with electrical wires, through which a signal is transmitted to the control unit when the contacts are closed or opened. The cost of a new level sensor is 0.8-2.8 thousand rubles. The device is simple, you can check its performance yourself.

Repair procedure with the top cover of the MCA removed:

- The pressure switch is detected by a tube with wires connecting to it. The sensor is inspected for structural integrity.

- Contacts are cleaned to a shine if they are oxidized. The tube connecting the tank to the pressure switch is checked for leaks. If leaks or breaks are detected, replace it.

- Wires and contacts are tested with a multimeter. If the indicators are normal, the reason lies in the sensor itself, it needs to be changed.

Contacting the repair service will cost ≥900 rubles, not counting the cost of the pressure switch. It makes sense to avoid unnecessary expenses and buy and install a pressure sensor yourself. When purchasing a spare part, you must indicate the Kandy modification.

It’s another matter when the problem is in the control module: the electronic board is a complex and expensive part. If there is a voltage drop in the network, the electronic filling of the unit may burn out. Depending on the functionality of the SMA, the price of the product in Moscow is from 3 to 39 thousand rubles. + repair cost 1.1–3.5 thousand rubles. It is better to entrust the replacement of the control board to a professional; a mistake when troubleshooting the problem yourself can be too costly.

Other Possible Causes

The appearance of error E02 can be caused not only by the reasons indicated in the SMA operating manual. Users on the forums report cases related to the options of the machines and their saturation with electronics. For example:

- the error appeared due to weak contacts on tubular electric heaters - heating elements;

- When the “delayed start” function is turned on, E02 lights up.

Disturbances in the circuit of electrical wires connecting the control module with numerous sensors also cause a warning code on the Kandy display. Repairs related to electronics, according to the service price tags, cost 3.5 thousand rubles. The cost of heating elements is 700–1600 rubles and more. But such breakdowns with error E02 are rarely diagnosed.

Reasons for the failure and ways to eliminate it

Code E08 requires, in most cases, serious analysis and further repair. If the cause is not an accidental failure of the module, then partial disassembly of the washing machine will be necessary for diagnosis and repair.

Failure of the tachometer

A tachometer is a device that is responsible for the rotation speed of the drum . If this unit is inoperative, the Candy washer cannot determine at what speed it is spinning. In this case, the washing process stops after drawing water - the drum does not rotate, and the corresponding error code “E08” appears on the display screen.

The solution to the problem is to remove the failed sensor and replace it with a new one. Failure of the tachogenerator is the most common cause of E08.

Brush wear

In commutator-type motors, brushes take part in creating an electromagnetic field, due to which the motor rotates. Physical wear of the brushes causes them to lose functionality , and the engine cannot gain the required power.

If the brushes protrude less than 10mm, they lose contact with the rotor. In this case, they are replaced, and both must be replaced at once, even if the second is less worn.

When the brushes are worn out, the first manifestation may be a lack of required spin speed. Over time, as wear increases, the problem extends to the rotation of the drum during normal washing. The solution to the problem is to replace the motor brushes .

How to get to the motor brushes in a Kandy washing machine, and how to change them - in the video below:

Control unit malfunction

The Candy control module coordinates all processes that take place in the washing machine. If it fails, the necessary commands do not pass and work stops. If the elements of the electronic board (resistor, semistor, etc.) that are associated with the rotation of the drum burn out, code E08 can also be generated.

Failure manifests itself in different ways . This can be either a complete absence of rotational movement of the drum, or movement strictly in one direction, without reverse. There may also be a situation with a rapid increase in speed and a sharp stop. In all cases, Candy displays E08 on the display.

Burnt out elements are replaced, tracks are soldered. In situations where the board is seriously damaged and cannot be repaired, it is replaced.

Motor malfunction

When washing, the Candy motor ensures the rotation of the washing machine drum. If the unit fails, the washing machine fills with water, but the drum does not rotate. The program is interrupted with E08 displayed.

An engine can fail for various reasons:

Engine repair is not advisable. If a part breaks, it must be replaced. If a washing machine with a failed motor is very old, then it may make sense to purchase a new machine rather than carry out very expensive repairs to the old one.

Wiring irregularities

If there is damage in the electrical circuit of the Candy tachometer, motor and control module, code E08 may be generated. If the signal does not pass through due to broken contacts and broken wires, it is necessary to disassemble the washing machine.

The reason may be not only broken wires, but also oxidation , destruction or weakening of the contact terminals. This situation can manifest itself in the complete absence of even attempts to start the engine. The drum does not rotate.

The identified break needs to be repaired. If necessary, change the entire cable, clean the terminals, solder them and perform other work.

Control block

Electronic control module

Kandy washing machine module

Since all the peripherals were working properly, the main problem came down to the control unit. And it became clear that the problem was in the engine control circuit.

In addition, the main cause of the breakdown was previously identified - a voltage surge at the motor level. As a result, the wiring burned out and the module was damaged. Presumably this jump occurred due to moisture getting into the engine.

Expert opinion

You need to understand that the control module of a washing machine never just burns out!

When repairing the module in the workshop, the burnt elements were restored and the memory was re-flashed.

The horror was that the engine still wouldn’t start! The board was taken away again for diagnostics, and all logical circuits began to be “ringed”. As a result, two broken tracks were found in the heating element control circuit. They were restored.

Connected module

The engine started working. The Candy Smart washing machine was tested in different modes, including spin with load. The conclusion from this whole story is that you should not trust the errors that washing machines show. This applies not only to this particular model - Candy smart ctdf 1006, but also to cars of other brands. There are many subtleties in the repair of washing machines, and therefore it is not always possible for an ordinary person, even with a higher technical education, to repair them.

Our patient is Candy smart ctdf 1006.

All errors of Kandy washing machines are written here.

And on this page there is a table of correspondence of spare parts by model.

Call the master

With error E08, in most cases, the help of a specialist is required. You can find a specialist via the Internet by searching for a Candy washing equipment repair company in your city. To avoid falling for scammers, it is advisable to give preference to those companies that have been operating for more than one year and have good reviews.

The average cost of work in Moscow is:

- repair of electrical wiring – from 1,500 rubles;

- repair of the control unit – from 2,400 rubles;

- replacement of motor brushes – from 1,700 rubles;

- replacement of tachometer – from 2,00 rubles, etc.

After the repair is completed, a test run is performed. If everything is in order, the master issues a guarantee.

Prevention measures

In order not to encounter (or encounter as little as possible) error E08, you must follow preventive measures:

- You should not operate the Candy washing machine non-stop, without giving it a break, and running several cycles in a row. Such intensive work can lead to failure of important components, including the motor.

- The washing machine should not be constantly kept in a damp room, as this provokes corrosive processes. Even if the device is not used for some time, it should be stored in a dry place.

- The washing machine must be connected to a separate outlet with an outlet for the machine.

In private buildings, household appliances should be protected from rodents that can damage the wiring, including inside the washing machine.

You need to check the temperature sensor

To check the temperature sensor, you will have to remove it from the car. Disconnect all power wires from it, loosen the fastenings and remove the sensor from the car. After removing the sensor, you need to measure the resistance using a multimeter. Let's look at how to do this.

- Prepare the multimeter for resistance measurement mode.

- Connect the probes to the contacts of the temperature sensor. At a temperature of 20 degrees, the resistance should not exceed 6000 Ohms.

- Pour warm water into a small container and immerse the sensor in it. After placing a working sensor in water, its resistance will be understood. At a water temperature of about 35 degrees it should reach 1350 Ohms.

Do not continue to use the sensor if it is faulty! If this part breaks down, it must be replaced; it cannot be repaired. Operating a faulty sensor will lead to a large number of new breakdowns.

Recommendations

With E08, the following expert advice can help:

- It is advisable to replace broken components in a washing machine with original parts that correspond to the specific model of the device.

- They do not disassemble a washing machine that is under warranty on their own.

- Repair of complex components should be entrusted to professional craftsmen.

- All work that requires opening the Candy case is carried out with the water supply to the washing machine shut off and the electricity turned off.

- If dismantling of elements is required, the supply wires must be pre-marked. You can also take a few photos so you don't make any mistakes with the connections during the assembly process.

Kandy washing machine error E08 what does it mean?

You put things in the drum and started the program, but after a while you discovered that the Kandy washing machine stopped washing, did not spin the drum and displayed code E08 on the display. Before stopping, you may have observed one of the following signs:

- the drum of the machine rotated for a short time at high speeds (right with water immediately after turning it on);

- the drum rotated only in one direction - clockwise or counterclockwise;

- The SMA did not rotate the drum at all - error 8 came on almost immediately.

Note! The writing of the error code on the screen may differ slightly depending on the model of the washing machine. In various Kandies, error E08 may also be referred to as "E8", "Err 8" or "Error 8".

Pump cleaning process

Before you begin the pump cleaning process, prepare the following tools:

- crosshead screwdriver;

- multimeter

In order to clean the pump, unscrew the cap and check the impeller. Hair and woolen threads from things could have settled on it. Carefully clean everything of debris and wipe it dry. Using a multimeter, we check the pump for functionality. To do this, apply the probes to the pump and monitor the resistance on the device screen. The working device should produce a result in the region of 200 Ohms; if this value does not correspond, we replace the pump with a similar new unit.

After replacing the pump, we start the washing machine in test mode and monitor its operation. If after replacing the pump the error has not gone away, we check the functionality of the pressure switch and the wiring that connects the water level sensor to the pump and the electrical board. In most cases, the error is due to damage to the wires, and not to the pressure switch itself. Pressostat error codes are displayed on the display as: E11 and E32.

If checking the pressure switch and wires did not give any results, and the error still appears on the display, check the electronic module. This is a rather expensive and painstaking pleasure; not all masters are ready to take on this problem. However, do not be upset, this error is displayed quite rarely.

Error E08 in SMA Candy without screen

Error 08 in models without a screen can be identified by the blinking indicator lights. The SMA will produce a series of eight flashes in a row, followed by a pause lasting from 5 to 13 seconds and again eight flashes.

Various indicators may light up, depending on the line. For example:

- Models of the Candy Grand series indicate an error with the LED of the “Intensive Wash” button (an icon of a shirt with stains) in combination with the first paw on the left in the indication of the countdown system (usually the “90” indicator);

- In the Candy Smart series - an indicator of the “Intensive wash” button (an icon in the form of a shirt) and an upper LED in the light indication of the reverse time countdown system (this can be “90” or “Start”).

- In the Holiday and Aquamatic lines, the “Wash with cold water” function indicator, which is shaped like a snowflake, blinks.

How to determine the error code on Candy without a display

If your Kandy does not have a display, then it will indicate an error by interrupting the program and flashing the lights. The indicators blink in series. You need to count the number of flashes in a series: it will correspond to the error code. Which LEDs flash depends on the machine model.

Example! If you see 5 flashes of lights in a row, then a long pause, and again 5 blinks of lights, this means that your Candy is signaling error E05.

Detailed information on determining the error is in the article How to find out the error code in Candy without a display by the blinking lights.

[custom_ads_shortcode1]

How to properly reboot the machine

Before restarting the product, carefully study the instructions for your particular washing machine model, since each brand of machine has its own design features and certain methods for urgent stopping. We will look at general recommendations for properly rebooting the machine.

How to stop the program: options

Most washing machines have two unified options for urgently resetting the installed program.

First option

If the “Start” button in the unit also serves as the “Pause” button, then you need to press it once to stop the wash and wait a couple of seconds. After this, the door lock should unlock. Now you can load additional laundry into the drum or take out an item that accidentally got into it, forgotten in your pocket. Before opening the door, make sure there is no water inside, otherwise it will spill out.

Healthy! If water has already accumulated in the washing machine, drain it manually using the drain filter (a small hatch at the bottom of the machine).

Second option

By pressing the "Start/Pause" button, the program is completely reset. In this case, turning off is not done by pressing it once, but by holding the button for a long time (5-6 seconds). Further events will develop depending on the modification of your device:

- in more modern models, after holding the “Start/Pause” button for a long time, the machine will drain the water on its own and the door will unlock;

- In older models, automatic drainage of water is not provided; it must also be drained manually through a drain filter.

Why do you need to reset the program correctly?

Many users believe that the problem of urgent work stoppage can be solved by simply disconnecting the device from the electrical network. Yes, this will allow you to turn off the washing machine, but the previously selected mode may not be reset, since often automatic machines “remember” the last settings and will start them again after turning them on. In addition, due to a sudden disconnection from the network, an important part of the unit - the control board - is at high risk of breakdown.

If the power is out

In the event of a sudden power outage, first of all, disconnect the device from the network. To do this, you need to remove the cord from the outlet so that the washing machine is not subject to a sudden voltage drop.

Errors in the system that you can fix yourself

If a breakdown occurs during operation, the Kandy washing machine will inform the owner in one of two possible ways:

- If there is a display, Activa series appliances will display an error in the form of a digital code.

- In Aquamatic models there is no display; the machine will provide information about the problem using a flashing light on the front panel. By the number of times the light flashes, you can judge the malfunction that has befallen your washing machine.

Error code E01

Before starting the wash, the unit fails to lock the door in the closed position. The appearance of error E01 on the equipment display may be a consequence of the hatch not being tightly closed. The first step is to check if clothes are stuck in the gap. If this is not the problem, the door lock has probably failed. It is also necessary to inspect the wiring for integrity. It is also possible that the electronic controller is not working.

Code E02

Water intake error. By the appearance of such a code on the display, the machine notifies that either its level after a set time is below or above the nominal mark.

If the problem could not be detected, then most likely the filling valve, which is responsible for drawing water in the required quantities, has failed. The code may have been displayed due to a faulty operation or electronic controller.

Error E03

Indicates that the water drains from the drum very slowly, which does not comply with the technical requirements (more than 3 minutes), or does not drain at all.

It is necessary to inspect the hose and make sure that it is not pinched or clogged anywhere, and that the drain filter and siphon are not clogged with scale. It is likely that the problem is caused by a faulty drain pump or pressure switch.

Be careful, as some errors that appear on the display are due to the carelessness of the equipment owners.

- If so, check to see if there is a complete power outage in the entire house, or you have not inserted the plug into the socket.

- Water does not fill into the drum because the delayed start mode is set by mistake.

- much stronger than usual. Probably, the vibration is caused by an imbalance of the unit relative to the floor surface, or the laundry is unevenly distributed throughout the tank during the rinsing process.

- The appearance of abundant foam may be due to the use of washing powder for hand washing.

- At the end of the working cycle, the equipment does not drain the water and does not spin - perhaps due to inattention, the mode “without draining water”, “light ironing”, “without spin” was set.

- All indicators are on or flashing - this may be due to a malfunction of the equipment. Restart your machine by turning it off for a couple of minutes and then turning it on again.

Possible faults requiring repair

Over 10,000 Kandy washing machines were repaired by RemBytTech specialists. We have summarized our experience and identified the most common breakdowns in which error E 8 occurs.

In this case, code E08 is displayed.

- does not spin the drum at all;

- rotates in one direction only;

- breaks at high speeds after switching on

after which error 08 is displayed.

- restores damaged wiring or completely changes the cable loop;

- if the contacts are damaged, solder them or replace them with a new contact group.

*Please note that prices are for repair work only. Spare parts required for repairs are paid additionally.

If your Kandy washing machine has stopped washing and shows error code E08, do not hesitate to repair it. Call:

Or submit an online application.

RemBytTech technicians have many years of experience in diagnosing and repairing Candy washing machines. They will accurately determine the cause of the emergency code and carry out all repair work right at home. Quality is confirmed by a guarantee of up to 2 years . Contact us!

Rate this article: 4.3 1 5 21 votes (average 4.3 based on 21 votes)

Diagnostics

To diagnose the machine you need:

Set the switch to OFF, while the drum should be empty.- Find the first additional function button on the left, press and hold to move the switch to the second position, basically this is a temperature indicator of 60 degrees.

- Wait 5 seconds, all indicators should light up, and only then release the additional functions button and press “Start”.

If it doesn't work, repeat these steps with another additional function button.

What happens during diagnosis?

- The machine draws 6 liters of water through the powder and prewash compartment.

- Pauses and starts the heating element.

- Gets water.

- The drum starts up.

- Pause again (4 seconds).

- Simultaneous collection of water and drum operation.

- Checking the pump with the water completely drained.

- Spin starts.

Diagnostics completed. After completion, all indicators should light up.

Kandy washing machine errors

Decipher error codes for washing machines Candy / Kandy

Photo 1. How to put a Kandy washing machine into diagnostic mode

Photo 2. Entering test mode on the Candy washing machine

I’ll probably start with the most basic faults that are inherent not only to the Kandy washing machine, but to all washing machines in general without exception. First of all, we will talk about the drainage system, the fact is that many do not even know where the pump filter is located, and yet this part is associated with the largest number of breakdowns. In my practice, it often happens that they bring a washing machine and say that it does not drain water, while they claim that they have completely cleaned everything that is possible. When I unscrew the drain pump filter and show exactly where to look, people just look at me with wide open eyes, especially when coins, paper clips and other small objects are pulled out from under the pump impeller. Nobody thinks about the main pipe at all, although it gets clogged with dirt and all sorts of rubbish no less than in the pump filter. If you cleaned the filter and the washing machine still does not drain water, then you must first clean the pipe that comes from the tank to the pump housing. Another nuance is related to the drain hose, it needs to be blown out, but before that, be sure to unscrew the drain pump filter, the fact is that there is a plastic ball in the main pipe and if you blow into the drain hose, this ball can jump out into the tank. I specifically talked a little about the drainage system so that I wouldn’t waste time on this when deciphering the codes. Now you can begin to describe the errors in detail.

What do errors mean on the Kandy washing machine display?

In my opinion, I already said somewhere that on a Kandy washing machine, reading and deciphering the error code is very simple, there are no bells and whistles associated with water pressure sensors or any other crap, in general, this procedure is available to any user. Finding a part that has broken in a chain is also not so difficult. Candy is different in that the display practically already indicates the broken part. A little lower you will see a table in which there will be practically a guide to troubleshooting problems associated with a particular breakdown Table → Error codes for the Candy / Kandy washing machine

- Try closing the sunroof again, if the problem persists, proceed to the next step

- Look how the door hook springs; if it is broken, then you need to change the mechanism

- Take a screwdriver → as a last resort, you need to imitate the hatch door hook, while the machine must be turned on and any program selected. In general, the task is to push the lock mechanism in the same way as the hook on the door does; if water starts to flow or any other function starts, look for a mechanical fault in the hatch mechanism or in the lock itself

- Control module → tinkering here, I don’t recommend you, the spare part is complex and repairing it requires experience and knowledge

An important point is that if the hatch is closed and the lock is activated, the lock indicator will light differently, that is, not the same as when the hatch is open. In short, if the lock indicator shows that the hatch is closed, and this error appears on the displays, then the problem is probably in the lock itself

- There is no water supply → it often happens that household members simply turn off the tap and forget about it. It also happens that there is a mesh in the hose; it tends to get clogged. In general, in this case, unscrew the hose from the CM, lower it into a basin and check the water pressure

- The valve filter is clogged → it is located in the valve body. Unscrew the water inlet hose from the washing machine and use pliers to pull the filter out of the valve body, rinse it well and put it back

- The water inlet valve has failed → the easiest way is to apply 220 volts to it, but here you must follow safety precautions

- The pressure switch is out of order → the best way to check it is to find the same machine or the same water level sensor, that is, we check by replacing

- The pressure switch hose is torn or clogged → you can immediately see this; if there is a lot of water in the washing machine, and this error appears on the display, then 100% of the reason for this breakdown lies in this hose

I have probably listed all the reasons, except for the control module, under no circumstances should you get into this part, it can only cause harm

- The pressure switch hose is clogged

- The water fill valve is faulty

- The pressure switch is broken

I won’t talk about the control module defect; the problem is very complicated if that’s the problem

- We loaded a lot of laundry, so the engine cannot make a revolution and the tachometer does not send a signal to the control module that the motor shaft has made a revolution

- The tachometer has failed, it is also called the Hall sensor; this breakdown is rare, but it does happen. This sensor is located on the rear of the engine.

- Be sure to look at the brushes, the length of the brushes should be at least 1 cm from the body

- The windings or armature are burned out; you can only check if the wire in the windings breaks

- The contacts are oxidized or the wiring is broken

In general, we check everything related to the rotation of the engine and its operation.

Kandy washing machine errors without display

To read errors on a washing machine without a display, you just need to count the number of flashes. Here the following must be taken into account: if a code starts to appear, the indicators blink at intervals of 0.5/1 second, and the interval between the end and the beginning of the error lasts about 5 seconds. So that you understand what happens next, for example, let’s take a code with five flashes, that is, the indicators blink 5 times, then a 5 second pause and again they should blink 5 times, then again a 5 second pause, repeating about 10 times. I think I explained it clearly, now you can look at all these codes in order

Photo of Kandy washing machine without display

The error code is determined by the blinking indicator. The number of flashes in a series corresponds to the numerical value of the code in the table. The pause between series lasts 5 seconds

| How many times does the diode blink | What does this error mean? |

| — | If the board is constantly on, then the matter is slag. Most likely the problem is in the control module → call a technician |

| 1 | Corresponds to code E01, that is, the hatch door is not tightly closed. You can read more about this error in the table above. |

| 2 | Corresponds to code E02 → indicates a long intake of water or no water at all |

| 3 | E03 → drain system malfunction. We look at the pump, clean the filter, pipe and drain hose |

| 4 | E04 → too much water in the tank. In the table above, I talked about this problem well, look for this code and read |

| 5 | The temperature sensor is broken or shorted. First of all, you need to check the contacts and wiring. The temperature sensor or, as it is also called → thermistor, fails extremely rarely, but it is advisable to check it. Check the heating element at the same time |

| 6 | Memory failure on the electronic control module. It is clear that without an experienced craftsman, you cannot fix this problem with your own hands. |

| 7 | E07 → problems with engine operation. We check the tachometer, brushes, contacts, wiring and in general everything related to the rotation of the shaft on the motor |

| 8 | E08 → Look at point 7, it’s practically the same thing |

| 9 | Another error related to the engine, but it specifically indicates a seemingly burnt triac. Of course, it’s good that brains point to this detail, but we need to check everything that I wrote in paragraphs 7 and 8 |

| 12 | The connection between the control boards is interrupted → you can’t fix this error yourself, call a technician. Although, for starters or for your own self-satisfaction, you can ring the wiring and check the contacts |

| 13 | See point 12, it’s no different at all |

| 14 | The control module is covered → call a technician |

| 15 | Program failure → the error is associated, to a greater extent, with the control module, one might even say with its memory. From experience I can say that, as a rule, a simple flashing does not give any results, that is, the control unit needs to be repaired |

| 16 | The washing machine did not heat the water, corresponds to the error code → E05 In the table above, I described this malfunction in detail. We check the heating element, temperature sensor, heating element relay and wiring |

| 17 | Malfunction of the hall sensor, that is, the tachogenerator. Although the error points specifically to this part, everything related to the rotation of the motor shaft must be checked. Simply put, the control module does not see that the motor armature is spinning |

| 18 | The manuals say that this error means the control module is faulty. Yes, in most cases, this is exactly the case, but often this code appears when the voltage in the network is higher or lower than the specified parameters, so first of all, you need to measure the current in your outlet, and then draw conclusions |

Control board check required

With your own hands, you can only conduct a superficial inspection of the module for damage and burnouts. Other methods of checking can only be carried out by a specialist who, if any breakdowns are detected, with error E08, will immediately repair them. For a visual inspection, you should disconnect the machine from the network and perform the following sequence of actions:

- removal of the dispenser tray;

- unscrewing the front panel mounting bolts;

- unlocking the plastic latches with a screwdriver and removing the panel from the body;

- behind the panel is the main unit. Take a photo of it to record the location of the wiring;

- Sometimes, in order to reach the board, the block latches must be released.

Afterwards you will need to conduct a thorough inspection of the board. If there are burnt spots on it, this means that you should call a specialist for repairs. Some details can be fixed with your own hands. We prepare a soldering iron and purchase a replacement part.

- Capacitor. It plays the role of a stabilizer, and to replace it you only need to solder the purchased part to the positive electrode. In order to understand where it is located, you will need to use a tester.

- Resistor. Checking the functionality of this part is also used by the tester. For 1st order parts, the optimal indicators are 8 Ohms and an overload of 2 A. But for the second order it is 3-5 A, and the resistance will depend on the frequency of the module. Deviation from the norm is a reason to replace the part using a soldering iron.

- Thyristor block. To check it, negative voltage is measured. The indicator cannot exceed 20 V. Sometimes the filter of the unit burns out, the repair of which consists of cleaning the cathode.

- Trigger. To check functionality, you will need to measure the voltage at the input. The optimal value is 12 V, and for the trigger resistance is 20 Ohms. To replace, you will need to use the same soldering iron.

If you manage to identify the burnt part, unsolder it and take it to a specialized store. The seller will select a similar spare part for you, and you can safely solder it in place of the old one. Just be careful not to damage the tracks leading to the part.

The integrity of the soldering may be compromised due to vibrations during operation of the equipment, which is why it issues fault code E08. Therefore, it is necessary to ensure the stability of the equipment during washing.

Specialists know what to do in the event of a breakdown and how to properly troubleshoot problems. When starting a DIY repair, think about whether you can do it yourself. If you don’t have the skills to work with a soldering iron, turn to the professionals!

Interesting:

- Homemade honey extractor from a washing machine

- Bosch dishwasher errors

- Gorenje washing machine error codes

- Error 3e in a Samsung washing machine

- Spin does not work in Indesit washing machine

- Door error in washing machines

3 reader comments

- 09/01/2018 at 09:13

Noelle:

Pumping out the excess through the filler neck is interesting to watch. In general, this is done through the hole for the probe. Through the neck only for the most perverted.

Answer

- 01/23/2019 at 07:39

Tatiana:

Hello, what if the Kandy machine has a touch screen? How can I replace the sensor?

Answer

- 02/23/2019 at 15:20

Yuri:

It's strange why the description shows an LG electronic module?

Answer

Washing machine motor tachogenerator

A small note. Attempts to restart the car were unsuccessful. Water is poured and drained, but the drum does not spin, because the motor does not start.

To diagnose a tachometer generator, you can, in principle, not remove the engine, but only remove the contacts with the cable. But because...

The reaction of the washing machine was a little confusing, it was decided to conduct a full diagnostic of the engine. And she was worried because if the tachogenerator malfunctioned, the engine should have tried to start, which did not happen.

So, when ringing, it turned out that the resistance of the tachometer is 45 Ohms - this corresponds to the norm. It does not penetrate the housing, and when the motor shaft is cranked, it produces a constant voltage of approximately 0.2-0.

4 volts. What's the matter? Is the machine giving the wrong error code?

The engine was completely checked. The rotor and stator resistance is normal. No leaks were found on the housing. No interturn short circuit was found in the motor windings.

Diagnosed engine

When connected directly, the motor started. It didn’t get hot, the brushes didn’t spark. Just in case, the brushes were examined. To do this, you need to remove them and visually see the degree of wear, and also make sure that they slide freely and effortlessly in the brush holders. Due to the unclear situation, a diagnosis was carried out. Because when the heater breaks down on the body, washing machines begin to behave incomprehensibly, sometimes producing erroneous error codes. In this case, no problems were identified.

Then it was decided to test the electrical wiring, first of all, the cable from the engine to the control unit. This is done using a simple multimeter. As a result, a break was discovered in one of the cable wires.

The situation became clearer, and it seemed that the problem was solved. But after replacing the damaged wire, the engine did not start through the control unit. But there was little progress - error E08 stopped appearing, which confirmed the engine diagnostics, which showed that the tachometer was working.

.

[custom_ads_shortcode1]

[custom_ads_shortcode2]