Error code f13 of the Atlant washing machine

The appearance of error F13 on the display of the Atlant washing machine indicates problems with the module, but is not a 100% guarantee of its failure.

Often, a user may confuse a unit malfunction with a breakdown of another part in SM Atlant, since the symptoms are very similar.

Here are some signs that may indicate a module failure:

As already mentioned, these problems can be caused by a malfunction of either the control board or any part of the Atlant washing machine. How to correct the situation and eliminate the breakdown?

Reasons for failure of the control unit

If the machine shows error F13 on the display, you need to check the unit. But first, let’s find out why it might fail.

Before checking the electronic unit, try resolving error F13 like this:

De-energize the Atlant washing machine by unplugging the plug from the socket for 20 minutes. After reboot, connect to the network. Has the SMA displayed a fault code again? This means that it was not possible to reset error F13, you need to look further.

If your Atlant washing machine model has an autotest, you need to run it to check it. How to do this is written in the operating instructions.

The machine does not heat the water

Problems in the heating circuit are indicated by constant freezing of the device during washing, lack of heating of water, or constant filling and draining. Then the signals f4, f7 or f8 are displayed on the display of the washing machine.

Problems with the heating element or pressure switch, indicated by codes f4, f7

Such errors, indicating a malfunction of the heating element, appear in those modes where washing is carried out with hot water. This happens immediately at start or after filling the water. Those programs where water heating is not needed operate as usual.

In addition to the standard method of solving the problem, there are several more effective methods to cope with this problem. If the problem manifests itself immediately and even water does not fill, then the heater is broken. It burns out or breaks through to the housing due to loose contacts. To troubleshoot the problem, check all connections of the heating element and measure its resistance.

Important!

If the liquid is drained immediately after filling, then the pressure switch has broken down. Then the controller receives information that the heater is not in the water. Because of this, the water does not heat up.

To eliminate the malfunction, check the hose with the pressure switch. It sometimes gets clogged, bends or jumps off. It would be a good idea to inspect the sensor contacts. They may need replacing. If code f4 appears, then the pressure switch itself needs to be changed.

Sometimes problems are more serious. Therefore, to be sure, check all the parts in the area from the controller to the heater and the sensor responsible for the liquid level. If necessary, burnt parts are replaced.

Malfunction of the heating circuit under the designation f8

Fault symbols f8 appear when the heater circuit is not operating correctly. Usually the cause is a broken pressure switch. The failure occurs due to high humidity. Therefore, the board is thoroughly wiped and blown with a hairdryer.

It is also recommended to check the contacts, they may have come loose or need cleaning. This happens especially often when the device is started for the first time after transportation. In other cases, it is not possible to solve the problem on your own.

Faults indicated by f8:

- If the program is interrupted immediately after start or the water does not heat up, you need to replace the heating element.

- If the machine stops after starting or when going to rinse, some chips on the board have failed and need to be replaced. There is also a chance that flashing the board will help.

- The machine “freezing” in different modes indicates a faulty wiring or contacts. The reason may also be a broken pressure switch.

Important!

If, when checking all the elements, the fault could not be identified, then the control module of the machine itself will have to be replaced with a new one.

Checking and repairing the Atlant washing machine

Autotest can show you the corresponding fault code. But if the Atlant washing machine already displays error F13 on the screen, this means that it’s time to start checking.

What needs to be done to reset errors:

Once you have the board in your hands, you can test its elements with a multimeter. A visual inspection will help determine if there are burnt tracks or parts.

You need to decide whether you can repair the electronic module yourself. In this case, this video will help you:

What does it mean

Before eliminating error f13, you must first find out what it means. According to the manufacturer's instructions, this code is deciphered as the occurrence of malfunctions with the wiring system connected to the main module or with it itself. In practice, this results in several problems at the same time, since any semiconductor in the system can cause a problem.

What to do? To correct the current situation, you will have to deal with each element sequentially.

Why does error F13 occur on the Atlant washing machine and how to fix it?

When operating the Atlant washing machine, faulty situations may occur. The device reports problems in operation using the corresponding code, which is displayed on the display.

Possible situations include F13, which almost always signals the need for repairs.

Why error F13 occurs on the Atlant washing machine and how to fix it, we will tell you further.

Recommendations

When faced with the F13 problem on your Atlanta, the following recommendations can help:

Before repairing or disassembling equipment, it must be disconnected from electricity.- It is advisable to entrust complex repairs to a professional technician.

- It is recommended to carry out diagnostics and repair of the control module in a workshop.

- Tools for repair and disassembly must be prepared in advance.

- If the washing machine is under warranty, you should not carry out repairs yourself - you need to contact a service center.

- After the removed control unit and other elements have been repaired, they must not only be correctly connected to the wiring, but also securely fastened.

- If there are residues of accidentally spilled detergent on the removed control unit, it must be cleaned. If it gets wet, dry it.

Finding the fault that led to F13 is not a quick task and is quite painstaking, which can take a lot of time.

Decoding the F13 code

When Atlanta is started, the washing process may not even begin, the device freezes, and after a short time displays error code F13. This situation indicates that an error has occurred in the display or in the control module.

Other signs of a problem situation may include:

In OptimaControl the combination is as follows:

In models that belong to SoftControl, this combination is:

In rare cases, F13 may appear not as a result of a breakdown, but due to a random combination of circumstances and a one-time failure. If this is the problem, then to fix the problem you need to reboot the machine - turn it off from the network for a quarter of an hour, and turn it on again. But in the case when the problem does not go away, you will have to move on to equipment diagnostics and repairs.

How to fix

To troubleshoot F 5 yourself, you should disconnect the refrigerator from the household network and check the voltage with a test device. If the value is normal (in the range of 220-240 V), you need to inspect the plug. Traces of carbon deposits on the surface and overheating of the contacts indicate poor contact; it is recommended to replace the internal mechanism of the socket; the plug is replaced along with the power cable. If the network voltage is high, you must contact your local power supply company. Error F 4 is eliminated in the same way.

To remove error H, you need to inspect the rubber sealing edge mounted around the freezer or refrigerator lid. When an element leaves the guide groove or when foreign objects get under the seal, air flows in from the warm room. A malfunction occurs when the thermostat breaks down, which incorrectly sets the temperature in the chamber, as well as when refrigerant leaks from the compressor and lines (detected by oiling of the tubes or when checked with a test pressure gauge in the service).

On some models, the malfunction disappears after forced defrosting of the equipment for 24-36 hours. It is also recommended to check the operation of the limit switch installed on the door. When using incandescent lamps for illumination, the generated heat warms the air in the chamber, triggering the emergency sensor. The sensor may turn on briefly after loading the chamber with a large amount of high-temperature products.

If errors occur in the operation of the compressors (F6 or F7), you can try to dismantle the control relay and check the resistance of the windings and the absence of short circuits to the housing. A serviceable start winding has a resistance of 20-30 Ohms, a working winding has a resistance of up to 60 Ohms. If the value increases, the electric motor is considered unsuitable for further operation. It is possible to test the operation of the compressor without using a start relay by connecting the power cord directly to the terminals. If the error disappears, then the control relay is faulty or the power circuits are damaged.

The indication of the letter L is an error only when turned on continuously for more than 24 hours; the symbol turns on automatically when the accelerated freezing mode is activated. If the icon does not turn off, then the thermal regulator or power supply is faulty. The technician will determine the cause of the breakdown after diagnosing the components of the refrigeration unit. Error F2, which occurs due to incorrect operation of the sensors in the evaporator, cannot be eliminated on its own. It is necessary to replace the elements and replenish the refrigerant supply.

Codes E 2 and E 1 occur when there is no signal in the power supply circuits of the heating threads of the freezer (for automatic removal of frost). Repairing the parts yourself is not possible; it is recommended to check the condition of the fuses and contacts in the connectors. When water gets on metal surfaces, oxides are formed that do not allow electric current to pass through. Corroded areas are cleaned with sandpaper and coated with a special compound that repels water-based liquids.

Causes of occurrence and solutions

Almost always, the F13 coding in Atlanta indicates that expensive repairs related to electronics are coming. To get to the components whose malfunction can lead to failure, you should partially disassemble the Atlant washing machine.

But you need to start not with a screwdriver and opening the case, but by disconnecting the device from communications . In this case, the machine should not only be turned off with the button, it is important to remove the plug from the socket.

Control unit failure

F13 is almost always a complex failure in the electronics of a washing machine. Dealing with such an issue is most often beyond the power of home craftsmen, and the help of a specialist is required.

For help, it is better to contact companies that provide washing machine repair services more than once. Finding such companies is not difficult on the Internet. If you carefully study the information and read customer reviews, this will reduce the chance of falling for scammers.

Repairing the Atlant washing machine due to the issuance of F13 is an expensive job. Different companies may talk about different amounts. On average in the capital, such work will cost from 2,000 rubles and more; replacing wiring can be cheaper - from 1,600 rubles. If any parts need to be replaced, their cost will be paid separately by the customer.

Prevention measures

To prevent the F13 code from appearing on the device display, experts advise remembering preventive measures to prevent failures, including:

- The washing machine must be connected to the network through a separate socket with output to the machine.

- If there are power surges, it is better to connect Atlant through a voltage stabilizer.

- Do not allow water to enter the control module or other electronic components.

- It is advisable to place Atlant in a room with good ventilation, this will avoid corrosion, moisture condensation and other problems with the equipment.

- The washing machine should be leveled on a level floor to avoid increased vibration, which can lead to malfunctions of the equipment, and even chafing of the wires.

- If shock absorbers wear out, there are problems with the counterweight and other components that lead to disruption of normal operation and vibration, the problem must be solved in a timely manner. Otherwise, one problem can lead to another, related to the control module, and lead to a more global and financially costly repair.

- When operating the device, do not allow excessive foam to form and escape beyond the tank. This state of affairs can provoke short circuits in the circuit and lead to corrosive processes.

- Unclosed containers with liquids, including washing gels, should not be placed on top of the washing machine. If accidentally spilled, moisture can penetrate the electronic components of the washing machine and cause harm.

Washing machine Atlant error F13

This brand of Belarusian origin has earned a good reputation in the former Soviet Union. Numerous household appliances are produced under this brand. The list of this equipment also includes washing machines. Of course, the quality of this unit meets all the requirements imposed by the standards. However, there are certain points that do not have the best effect on the operation of this model of household appliances. For example, very often error F13 in the Atlant washing machine causes housewives a lot of inconvenience.

Therefore, let’s try to understand in more detail what this error is, and how an ordinary user can get out of this situation.

Abbreviation and explanation

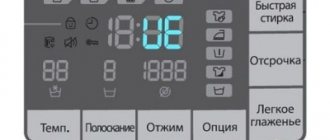

If we consider this device, it should be noted that it has a special display board, which usually provides the necessary amount of information on the operation of the machine. This is an excellent help option in a situation where, for example, the system responsible for self-diagnosis of the device displays an error code on the display. This helps to quickly understand what happened to the unit and how to get out of this situation.

If this concerns a code such as F13, then you just need to see it and open the technical documentation for the washing machine. This will allow you to understand the nature of the error and make it possible to understand what caused it to occur.

In a situation where there is no such screen on it, it becomes very difficult to understand what kind of breakdown is occurring. For this purpose, these models of washing machines were equipped with an indicator panel. The indicators on it light up in a certain order, which signals the user about the presence of the corresponding type of error. If you carefully examine the set of indicators on the device panel, you can see that on the bottom row this type of error is indicated by burning lights of the first, second and fourth order, if you start counting from the left side.

It is interesting to look at the explanation that the unit manufacturer provides when this type of situation occurs. Thus, the documentation notes that we are talking about a faulty state of the control module. This may also indicate a faulty wiring that goes directly to this module.

With this formulation, several dozen breakdowns can be immediately attributed. This explanation is connected with the fact that a semiconductor component can create a problem, and there are a great many of them in the unit. However, don't despair. Upon closer examination of such a situation, one can understand that there is a way out, although not an easy one, from this situation.

How to fix the problem?

The simplest solution to the problem is to reboot the equipment. If it was not possible to deal with error F12 in this way, you will have to disassemble it.

Rebooting the Indesit washing machine if the program fails

If the cause of the error is not related to a breakdown, but is due to a malfunction of the program, you can try to fix it yourself. To do this, reboot the device.

In order not to permanently damage the equipment, the procedure is performed according to the following scheme:

- turn off the device by pressing the “off/on” button on it;

- unplug the cord from the outlet;

- leave the machine turned off for 15-20 minutes;

- After the specified time has passed, the machine is turned on to the network.

If it was not possible to cope with the problem the first time, the procedure can be repeated 2 more times. There is no need to reboot the device more times, as this can lead to serious damage to the module.

Rebooting the control module

If rebooting the device as a whole did not help eliminate the error, you can try to reboot the control module separately.

On an Indesit washing machine, this procedure is carried out as follows - simultaneously press and hold two buttons ON and START/PAUSE.

After resetting the program, the error should disappear (if the reason lies in a malfunction of the control module).

Checking contacts between indicators and module

Sometimes the cause of error F12 is the separation of the contacts connecting the indicators and the control module. Most often this happens during a spin cycle, when the device stands on an uneven surface and moves out of place. Transportation of equipment may also be a reason.

To check the contacts, you will have to remove the top cover to gain access to the control panel. It is attached with bolts that are unscrewed. The wires connecting the module and the panel are checked for integrity, and if necessary, the contacts are cleaned.

Replacing buttons

To access the buttons on the washing machine, you must remove the front panel. Procedure:

- Disconnect the device from the network.

- Tighten the bolts holding the top cover, carefully lift it, without applying much force, so as not to damage the plastic latches.

- Loosen the fasteners of the panel, which are located in the niche of the powder receptacle, and then remove the part.

The latch responsible for securing it is located in the upper left corner of the washing machine body. - When the panel is removed, check the functionality of the buttons. Sometimes to restore them it is enough to simply clean them.

If the button definitely needs to be replaced, then this procedure can be performed without removing the panel. It is enough to pick it up with a thin screwdriver and remove it, then install the new part.

Checking contacts and wiring

In order to check the module that controls the machine, you need to know that it is located in the front part of the unit. At the top right there is a special compartment where it is installed in close proximity to the pressure switch.

Thus, the bulk of the wiring and the chip itself that goes to the board of this module is laid on the right side wall of the case. If you look at the comments of specialists, they often express concern that this particular place in the machine was chosen for the module. In their opinion, such a presence causes frequent breakdowns in the unit.

It should be noted that the listed disadvantages of this module installation location can be compensated by some advantages.

One of the main positive aspects is that it provides quick access to the master. Simply remove the cover and the module is already at hand, as they say. Then all that remains is to take a multimeter and begin the setup procedure. Initially, the wires are checked one by one for a break. If this malfunction is detected, it must be immediately eliminated by replacing the wire along with the contact. Sometimes bad weather happens, so it’s better to replace the entire bundle of wires when several of them fail at the same time.

After this, each contact on the control unit is tested. If there are no breakdowns, you need to move on to the board itself.

Designation and explanation

The display in the washing machine exists to provide the user with more information about the work of the “home assistant”. It is especially helpful when the self-diagnosis system needs to display one or another error code, for example code F13. The user, having seen the code, can immediately look purposefully at the technical documents to find out what error he encountered and what malfunction potentially caused it.

It’s another matter if his washing machine does not have a screen on which some information could be displayed. How does the user know that the machine’s self-diagnosis system wants to tell him something? The answer is simple, a washing machine without a display communicates with the user using control panel indicators, lighting them in a certain order. If you pay attention to the bottom row of lights, you will see that error F13 is indicated by the first, second and fourth lights being lit (counting from the left).

The lights should be on, and not blinking or displaying Morse code.

The error code F13 is explained in some detail. The manufacturer speaks of a malfunction of the control module or the wiring suitable to it. In fact, these are dozens of potential breakdowns, since each semiconductor element is capable of creating a problem. But if you start to understand the problem in detail, it turns out that not everything is as terrible as it might seem at first glance, but it is still quite complicated.

Checking the wiring and contacts

On an Atlant brand washing machine, the control module is located on the top in the right front corner of the case next to the pressure switch. Accordingly, the main bundle of wires and the chip that fits the control board are run along the side wall. Experienced craftsmen complain that such an arrangement of the most important electronic part of the machine (its “brains”) leads to frequent damage.

- The upper part of the body of a front-loading washing machine is more susceptible to the negative effects of vibration. Moreover, the location of “delicate” parts near the side wall is also risky because, vibrating from side to side during the spin cycle, the machine can hit the walls of furniture or some other objects, “shaking off” the electronic module and loosening the chip with wires.

- Users often place bottles of liquid detergent directly on the top cover of the Atlant washing machine and quite often spill them. The liquid gel flows from the cover onto the front panel, flows along the side wall from the outside and gets inside the case, where the control module and numerous wires and contacts are located. As a result, the contacts oxidize, burn, and the module fails.

- For most washing machines, the automatic module is located in the lower right corner near the back wall. In other words, it is quite far from the dispenser with the powder, and if the user pours the wrong powder, the resulting abundant foam is unlikely to reach the plastic block with the control board. The Atlant washing machine, in this sense, has an obvious disadvantage, because if foam gets out in all directions, its puffs will definitely end up on the control module, and then it’s a lottery.

Despite the above disadvantages, this arrangement of wiring, main contacts and module has obvious advantages. The main advantage that concerns us is convenient access - I removed the top cover and here is the module. It’s right at hand and all the wiring that goes to it can also be pulled up and checked without any problems. Well, this is where the useful background can end, let’s start checking the wiring and contacts of the control module.

So, we disconnect the chip with the bundle of wires from the control unit. We take out and set up a multimeter. We check each wiring for breaks. If such a wire is found, it must be immediately replaced along with the contact, but if there are several damaged wires (for example, mice have chewed them), you can change the entire bundle at once - less problems. Next, we need to ring each contact on the control unit, and if everything is in order, proceed to checking the control board.

Checking and repairing the electronic module

At this stage of the test, it becomes clear that the wiring and contacts are not to blame for the F13 error, which means that the control board of the electronic module will have to be removed and subjected to thorough testing. If traces of detergent are visible on the control board, you need to wash it with warm water, then dry it very thoroughly with a hairdryer, and then rinse it with ethyl alcohol.

The general procedure for checking and repairing the control module of the Atlant washing machine is shown using the example of the Invensys 5521CC board.

After these procedures, you can pick up and check the board for functionality. If it was not possible to fix error F13 in this way, do the following:

- check the power supply using a multimeter;

- call 21 pin - VDD0, 32 pin - VDD1, 43 pin - VDD2;

- Next, check pin 39 – RESET, and then pin 32;

- at the next stage we connect to the board and remove the firmware.

Find and install new firmware. If this measure does not help solve the problem, you will have to test the processor in more detail. First we check the SDA and SCL buses. Next, we test legs 5 and 6 of the processor; if there is no voltage on one of them, the processor is faulty and you will have to replace the entire board.

The new control board may also require a firmware update.

In conclusion, we note that the error code for Atlant washing machines F13 may indicate serious problems with the electrical or electronics of the “home assistant”. You should carefully weigh everything before you start checking and repairing these parts of the machine, because without the appropriate skills it is almost impossible to do this. To form an additional motivational attitude, read the article Is it worth doing repairs of electronic modules with your own hands? Perhaps it will motivate you to take specific actions. Happy renovation!

Signs of module failure

If this error occurs, you can independently eliminate a number of possible problems. For example, there are a number of indirect signs by which you can find out that it is the unit module that is faulty.

Thus, error F13 in the Atlant washing machine indicates a faulty unit. The reason for this, in addition to the above points, may be several more situations.

Therefore, it is recommended to start the device in automatic testing mode. This can be done by carefully reading the instructions.

Error codes that you can fix yourself

| Error code | Probable Cause | Elimination method |

| None all indicators light up Excessive foaming | – The composition of the detergent is not suitable for machine washing – The washing mode is selected incorrectly – A lot of detergent has been poured into the powder tank | – You need to select a washing powder for automatic washing machines. For normal operation of the SMA, you need to select a different mode that is most suitable for a certain type of fabric. |

| Sel or All indicators are not active | – There is no voltage in the electrical network – There is no contact between the washing machine power plug and the electrical outlet – The machine power button is not pressed | – It is necessary to check the presence of voltage in the electrical outlet by turning on any other electrical appliance – Make sure that the power cord plug is in contact with the outlet. – Turn on the machine by pressing the machine power button |

| door or lighting of the 1st, 3rd and 4th indicators | The door is not closed | Close the door until the lock clicks. |

| F5 lighting of the 2nd and 4th indicators Water supply error | – The hose is not installed according to the instructions – The bend of the hose is immersed in water – No water flows from the water supply – The water supply is turned off, the tap is closed – The inlet hose is pinched – The filters are clogged: in the inlet hose or in the threaded pipe of the solenoid valve – The protective system is activated when there is a water leak in the inlet hose . To make sure, you can check the color of the window in the inlet hose - if there is a water leak, it is red | – The drain hose must be installed according to the instructions – Install the drain hose so that the free part of the water is not in the water – Check the cold water tap, check for the presence of water in the water supply – Open the water supply tap – Lay the drain hose without kinks, thereby freeing access water – Clean the filters – Replace the inlet hose with a new one |

| F4 2nd indicator glows Drain error | – The drain hose is not installed according to the instructions – The drain hose is pinched – The pump filter is clogged – The drainage system is clogged – When washing, a detergent was used that is not intended for automatic washing machines and produces a lot of foam – Uneven loading of items in the drum | – Install the drain hose according to the instructions – Install the drain hose correctly – without kinks – Clean the pump filter – Clean the drain – Select and turn on the “RINSING” program. Rinse the laundry to remove excess suds – Arrange the items evenly in the drum |